HEY GRUMPY< QUESTION<?

I am trying to install a stock replacement set of new ARP rod bolts on stock BBC thumb rods. These aren't the wave-loc type; they are a high quality stock replacement.

I thought they would tap in place, but I've hit them fairly hard and they won't install.

I miked the diameter and they are .001" bigger than the old bolts where the cross-hatching is on the body of the bolt.

Keep in mind removing old rod bolts or installing new rod bolts tends to distort the rods large end where the rod bearings are, seated.

If you have a 12 ton hydraulic press and the correct fixture you can easily seat new rod bolts with the hydraulic press ,the ARP STOCK REPLACEMENT rod bolts they sell have a knurled surface and are larger because that cross hatch area is designed to deform slightly to hold the bolts firmly in place once installed, If you don,t have a decent hydraulic press, you can Buy 5 lbs of dry ice at your local grocery store, don,t touch with bare skin,place the rod bolts in a cardboard box on DRY ICE , heat the rods with a heat gun or place them in boiling water for 10 minutes, pick the rods up with insulated gloves so you don't get burnt and quickly place them in a vise with wood cushioning the clamp jaws, so you don,t nick the rods,with the hole for inserting the rod bolt at an easily accessed angle, then pick the bolts up quickly with needle nose pliers and insert in rods,then the bolts will drop in part way and a few taps with a plastic mallet seats them.

youll have to reheat the rod and preposition it to do the opposite side rod bolt.

yes you can have the local machine shop use the correct tools and do it for you , they don,t generally charge all that much, but Id also point out that your not simply replacing the rod bolts, you need to verify the rods correctly honed and sized so if your refurbishing rods you have a choice of finding a decent machine shop you trust to do the job correctly OR you can purchase new SCAT forged rods with cap screw 7/16" ARP rod bolts which in most cases are stronger that your used rods with who knows how many hundreds of thousands of stress cycles

RELATED THREADS YOU SHOULD READ

http://www.youtube.com/watch?v=TX-eFEqA ... re=related

viewtopic.php?f=53&t=341

viewtopic.php?f=53&t=1856

viewtopic.php?f=53&t=1168

viewtopic.php?f=53&t=10213

viewtopic.php?f=53&t=5478&p=16429&hilit=micrometer#p16429

http://www.hotrod.com/techarticles/stee ... rods_tech/

http://www.mechanicsupport.com/engine__ ... ilure.html

http://www.carcraft.com/techarticles/cc ... ewall.html

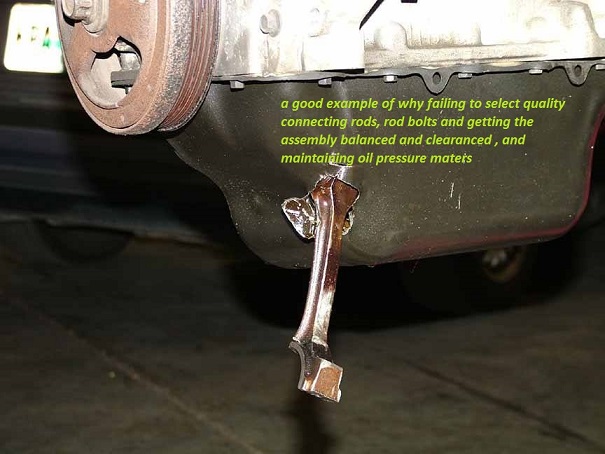

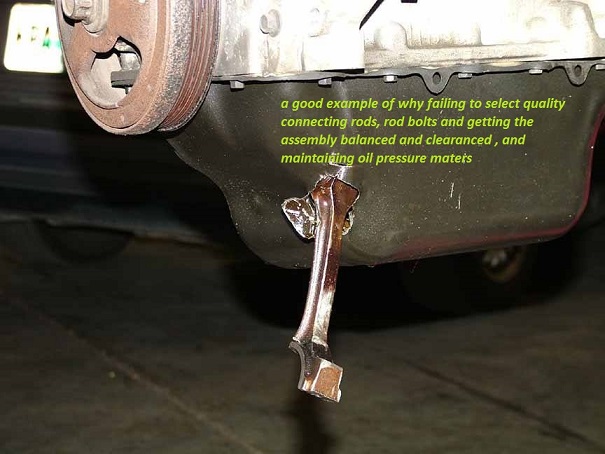

If you ever get the idea that selecting high quality connecting rods with ARP 7/16" rod bolts is a waste of cash and effort, consider the results when a rod bolt snaps due to stress at high rpms. you might be able to save the rockers,valve covers and intake manifold and water pump

I am trying to install a stock replacement set of new ARP rod bolts on stock BBC thumb rods. These aren't the wave-loc type; they are a high quality stock replacement.

I thought they would tap in place, but I've hit them fairly hard and they won't install.

I miked the diameter and they are .001" bigger than the old bolts where the cross-hatching is on the body of the bolt.

Keep in mind removing old rod bolts or installing new rod bolts tends to distort the rods large end where the rod bearings are, seated.

If you have a 12 ton hydraulic press and the correct fixture you can easily seat new rod bolts with the hydraulic press ,the ARP STOCK REPLACEMENT rod bolts they sell have a knurled surface and are larger because that cross hatch area is designed to deform slightly to hold the bolts firmly in place once installed, If you don,t have a decent hydraulic press, you can Buy 5 lbs of dry ice at your local grocery store, don,t touch with bare skin,place the rod bolts in a cardboard box on DRY ICE , heat the rods with a heat gun or place them in boiling water for 10 minutes, pick the rods up with insulated gloves so you don't get burnt and quickly place them in a vise with wood cushioning the clamp jaws, so you don,t nick the rods,with the hole for inserting the rod bolt at an easily accessed angle, then pick the bolts up quickly with needle nose pliers and insert in rods,then the bolts will drop in part way and a few taps with a plastic mallet seats them.

youll have to reheat the rod and preposition it to do the opposite side rod bolt.

yes you can have the local machine shop use the correct tools and do it for you , they don,t generally charge all that much, but Id also point out that your not simply replacing the rod bolts, you need to verify the rods correctly honed and sized so if your refurbishing rods you have a choice of finding a decent machine shop you trust to do the job correctly OR you can purchase new SCAT forged rods with cap screw 7/16" ARP rod bolts which in most cases are stronger that your used rods with who knows how many hundreds of thousands of stress cycles

RELATED THREADS YOU SHOULD READ

http://www.youtube.com/watch?v=TX-eFEqA ... re=related

viewtopic.php?f=53&t=341

viewtopic.php?f=53&t=1856

viewtopic.php?f=53&t=1168

viewtopic.php?f=53&t=10213

viewtopic.php?f=53&t=5478&p=16429&hilit=micrometer#p16429

http://www.hotrod.com/techarticles/stee ... rods_tech/

http://www.mechanicsupport.com/engine__ ... ilure.html

http://www.carcraft.com/techarticles/cc ... ewall.html

If you ever get the idea that selecting high quality connecting rods with ARP 7/16" rod bolts is a waste of cash and effort, consider the results when a rod bolt snaps due to stress at high rpms. you might be able to save the rockers,valve covers and intake manifold and water pump

Last edited by a moderator: