There is a difference in design between solid flat tappet and hydraulic flat tappet cam lobe designs.

you may be able to run NEW hydraulic lifters on a NEW flat tappet solid lifter cam

but NOT solid flat tappet lifters on a hydraulic cam, if you expect any reasonable durability.

roller lifters run on totally different cam lobe designs so any roller lifter cam component cam or lifter can not be used with flat tappet lifters of either type.

most solid lifter cam designs would show slightly less low rpm lift and slightly less effective duration as a result of the hydraulic lifters ability to have the push rods compress the lifter seat before the valve spring starts to compress and the valve starts to lift off its seat but this process takes time and oil in the lifter will not easily compress so you don,t loose as much lift and duration as you might think.

now some ones bound to ask, have you done this?

and the answer is yes Ive done it a couple times and mostly with rhoads lifters as they are very similar to solids in the way they act at low engine speeds , and yes I was totally satisfied with the result and had zero problems.

now that doesn,t guarantee your going to have similar results, but it was a functional combo

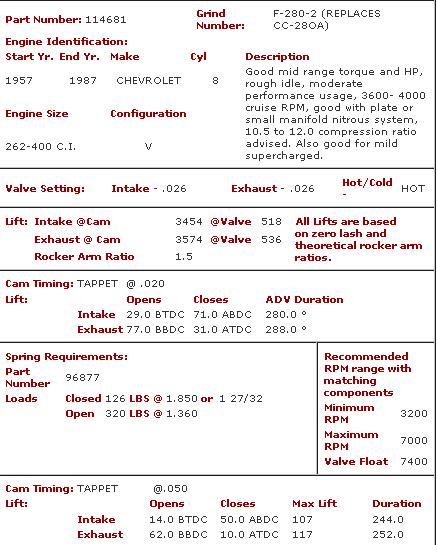

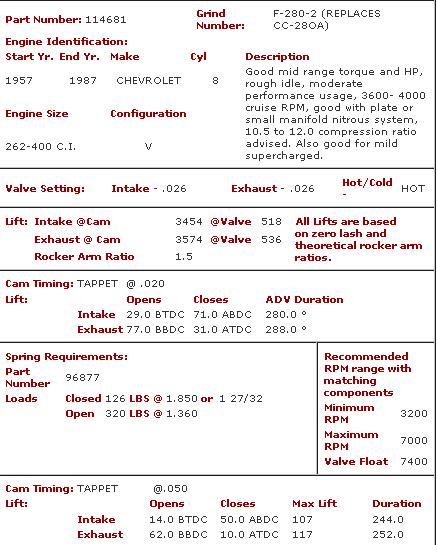

I ran this crane cam each time' usually in a 383 with 10.5:1 compression,I built for friends , but twice on my own personal engines, built with a dual plane intake and headers, a manual transmission in something like a nova or camaro with a decent rear gear like a 3.90:1 or 4.11:1

but I also built a 400 pontiac engine with 11:1 compression, and used rhoads lifters on this cam. just a few years ago, for a friend who has a 1967 firebird

http://www.summitracing.com/parts/cca-sk51-245-4/overview/make/pontiac

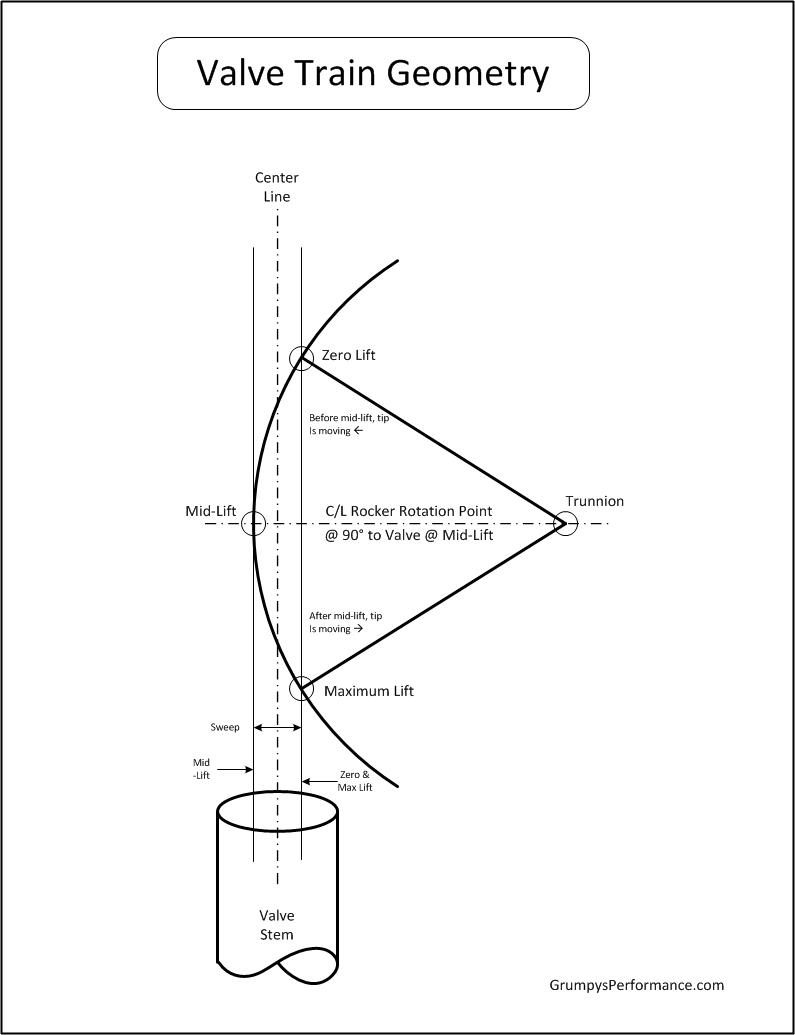

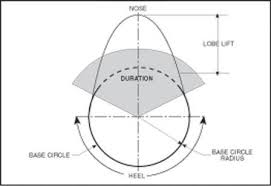

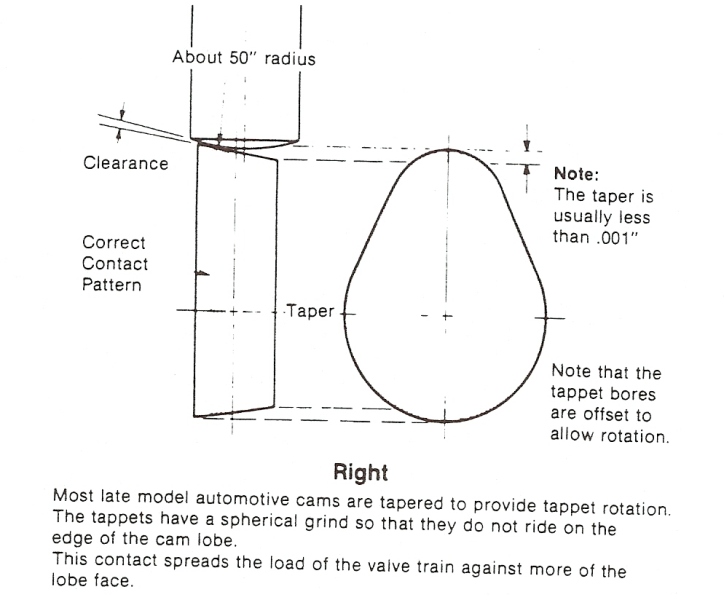

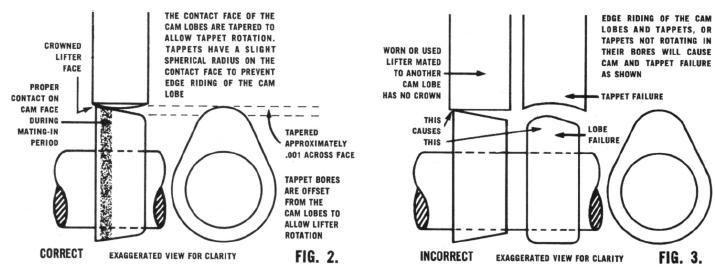

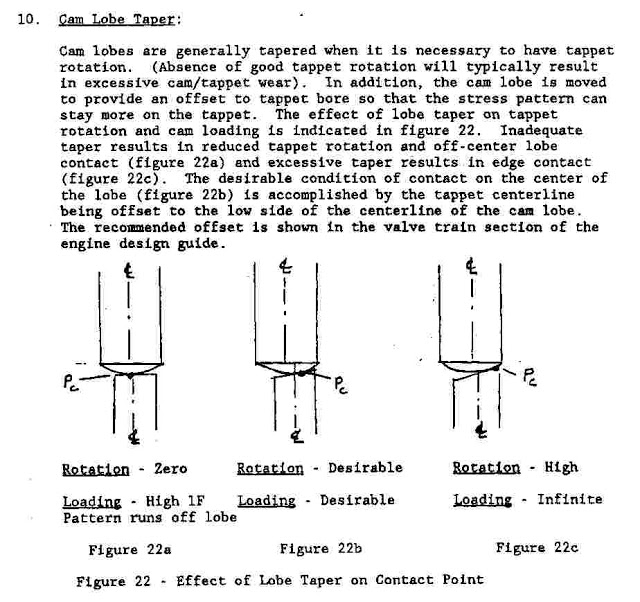

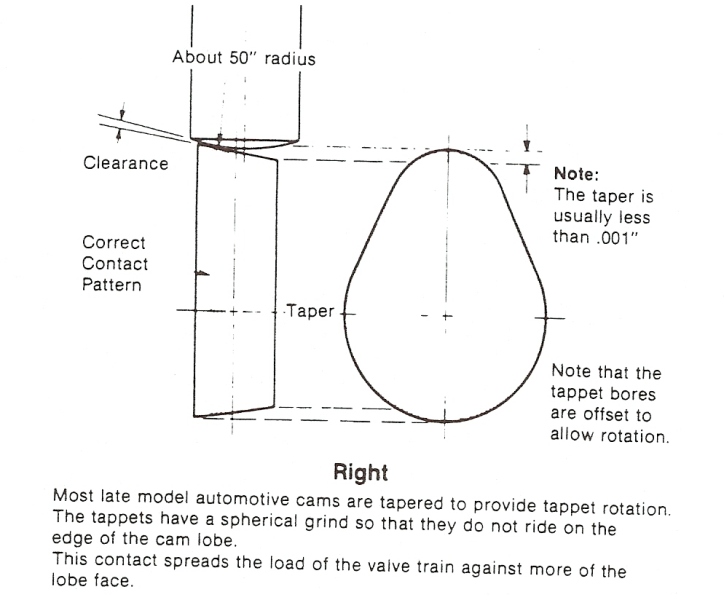

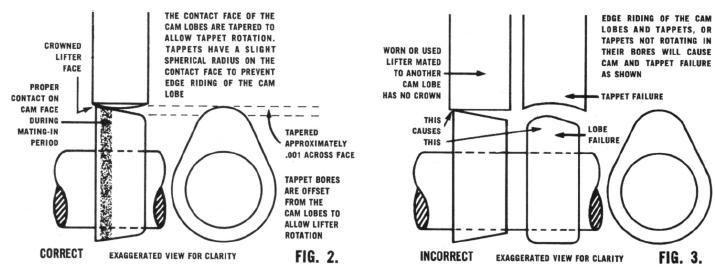

Look at the diagram above, flat tappet cams are ground on a very slight tapper on the cam lobe and the lifter base is very slightly curved to force the lifter to rotate as the cam lobe rotates under the base as this tends to reduce wear and increase oil flow rates between the sliding surfaces.

he following recommendations are from Erson Cams. If you have questions, you can reach their tech department at 800-641-7920.

Hydraulic Flat Tappet Camshaft: 110 lbs Seat pressure/250-280 lbs open pressure

Solid Flat Tappet Camshaft: 130 lbs Seat Pressure/300-325 lbs open pressure

Hydraulic Roller Camshaft: 130-140 lbs Seat Pressure/300- 355 lbs open pressure

Solid Roller Camshaft: (Minimum Safe Pressures DEPEND ON SEVERAL FACTORS)

Up to .600Ë valve lift: 200-235 lbs Seat Pressure/600 lbs open pressure

Over .600Ë valve lift: 250-280 lbs Seat pressure /100 lbs pressure for every .100Ë of valve lift

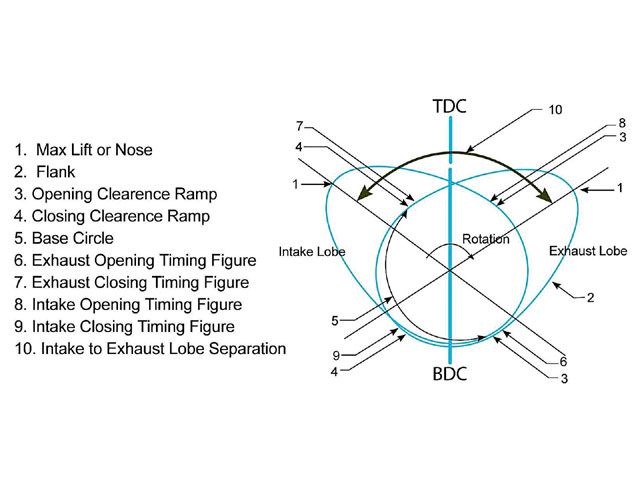

flat tappet solid lifter cam lobes are designed with a slightly lower acceleration rate starting at the base circle and continuing to at least .020 lift to reduce the stress on the cam lobe and lifter base, this is not mandatory on the hydraulic lifter cam lobes, as theres some cushion, in the basic lifter design that reduces the shock loads that would on a solid lifter cam, eventually hammer that area of the cam lobe accelerating potential wear.

you should never install used lifters on a new cam or even use a used cam with used lifters if they don,t get installed back on the original cam lobe the lifter lapped in with as minor changes in the wear pattern can cause failures of components are later mis-matched.

you could in theory install a set of NEW hydraulic flat tappet lifters on a NEW solid lifter flat tappet camshaft, and have it function reasonably well up to about 6300 rpm in most engines,as the solid lifter cam lobe design includes a bit slower ramp acceleration ramp speed at the beginning of the cam lobe acceleration ramp to take up slack with a solid lifter in use that generally won,t hurt the hydraulic cam lifter, you CAN,T install solid flat tappet lifters on a hydraulic lifter cam and expect long term durability as it lacks the slower inertial cam acceleration rates so wear is generally going to be at an unacceptable higher rate.

If you use hydraulic lifters on a cam designed for solid lifters, the power curve will tend to move up a bit in the lower rpm range (maybe 100 rpm )but there will also frequently be an overall loss of power and torque compared to what the cam would normally deliver with solid lifters, simply because a hydraulic lifter will generally not maintain valve train stability to the same peak rpm limitations that the solid lifter valve train usually will.

The best advice is to use the type of lifters (solid or hydraulic) the cam was ground for, and use matched components with the spring pressures and clearances the manufacturer suggested, rather than trying to change one lifter design for the other, or change the valve train dynamics or geometry.

CAST CAM CORES ARE NOT DESIGNED TO HANDLE OVER ABOUT 130lbs SEAT and 400lbs OPEN SPRING LOADS YOU NEED A BILLET CAM CORE FOR DURABILITY IF THOSE LIMITS ARE EXCEEDED

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

In nearly all circumstances, a good roller camshaft design will outperform its flat tappet counterpart. Among the benefits of roller cams are higher tappet velocity, more lift and more area, along with reduced valve train friction (often a 15+ hp increase) and higher engine rpm with little effect on low speed driveability and power.

THERES BILLET AND TOOL STEEL CAM CORES AVAILABLE

http://www.callies.com/wp-content/uploads/2014/06/Cam-Core-Master-Price-Sheet.pdf

Callies Crankshafts Producing 8620 Billet Cam Cores

Recieved notice today, that Callies, is producing billet cam cores for the camshaft industry. This has been in the making for about 1.5 yrs. Since Crane started to have problems, the owner of Callies, took a look at the equipment, but as far as I know only purchased the gear cutting equipment. Crane used to produce the the cams for the aircraft engine mfgs that Callies, makes crankshafts for and when Crane was going down the aircraft engine mfgs notified Callies ,that production of cranks was going to end until a cam mfg was found. So they now mfg and finish cams for aircraft engines and are solving the shortage of cores elsewhere. To me it's good to know that the mfg that makes cranks for aircraft engines also mfg cranks in our market. THEY ARE NOT SUPPLYING CAMS ONLY CORES FOR FINISH TO THE CAM GRINDING COMPANYS

http://garage.grumpysperformance.co...hydraulic-flat-tappet-break-in-springs.10182/

related info

http://www.enginebuildermag.com/2012/01/hydraulic-camshafts-and-lifters-101/

http://garage.grumpysperformance.co...lifter-to-increase-oil-flow.11152/#post-49968

http://www.hotrod.com/how-to/engine/mopp-0312-solid-vs-hydraulic-lifters/

http://garage.grumpysperformance.co...-solid-and-hydraulic-lifter.10431/#post-43419

http://www.hotrod.com/how-to/engine/flat-tappet-cam-tech/

http://www.lunatipower.com/Tech/Valvetrain/ValvetrainUnderstanding.aspx

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://garage.grumpysperformance.co...cost-vs-a-flat-tappet-design.3802/#post-54090

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

you may be able to run NEW hydraulic lifters on a NEW flat tappet solid lifter cam

but NOT solid flat tappet lifters on a hydraulic cam, if you expect any reasonable durability.

roller lifters run on totally different cam lobe designs so any roller lifter cam component cam or lifter can not be used with flat tappet lifters of either type.

most solid lifter cam designs would show slightly less low rpm lift and slightly less effective duration as a result of the hydraulic lifters ability to have the push rods compress the lifter seat before the valve spring starts to compress and the valve starts to lift off its seat but this process takes time and oil in the lifter will not easily compress so you don,t loose as much lift and duration as you might think.

now some ones bound to ask, have you done this?

and the answer is yes Ive done it a couple times and mostly with rhoads lifters as they are very similar to solids in the way they act at low engine speeds , and yes I was totally satisfied with the result and had zero problems.

now that doesn,t guarantee your going to have similar results, but it was a functional combo

I ran this crane cam each time' usually in a 383 with 10.5:1 compression,I built for friends , but twice on my own personal engines, built with a dual plane intake and headers, a manual transmission in something like a nova or camaro with a decent rear gear like a 3.90:1 or 4.11:1

but I also built a 400 pontiac engine with 11:1 compression, and used rhoads lifters on this cam. just a few years ago, for a friend who has a 1967 firebird

http://www.summitracing.com/parts/cca-sk51-245-4/overview/make/pontiac

Look at the diagram above, flat tappet cams are ground on a very slight tapper on the cam lobe and the lifter base is very slightly curved to force the lifter to rotate as the cam lobe rotates under the base as this tends to reduce wear and increase oil flow rates between the sliding surfaces.

he following recommendations are from Erson Cams. If you have questions, you can reach their tech department at 800-641-7920.

Hydraulic Flat Tappet Camshaft: 110 lbs Seat pressure/250-280 lbs open pressure

Solid Flat Tappet Camshaft: 130 lbs Seat Pressure/300-325 lbs open pressure

Hydraulic Roller Camshaft: 130-140 lbs Seat Pressure/300- 355 lbs open pressure

Solid Roller Camshaft: (Minimum Safe Pressures DEPEND ON SEVERAL FACTORS)

Up to .600Ë valve lift: 200-235 lbs Seat Pressure/600 lbs open pressure

Over .600Ë valve lift: 250-280 lbs Seat pressure /100 lbs pressure for every .100Ë of valve lift

flat tappet solid lifter cam lobes are designed with a slightly lower acceleration rate starting at the base circle and continuing to at least .020 lift to reduce the stress on the cam lobe and lifter base, this is not mandatory on the hydraulic lifter cam lobes, as theres some cushion, in the basic lifter design that reduces the shock loads that would on a solid lifter cam, eventually hammer that area of the cam lobe accelerating potential wear.

you should never install used lifters on a new cam or even use a used cam with used lifters if they don,t get installed back on the original cam lobe the lifter lapped in with as minor changes in the wear pattern can cause failures of components are later mis-matched.

you could in theory install a set of NEW hydraulic flat tappet lifters on a NEW solid lifter flat tappet camshaft, and have it function reasonably well up to about 6300 rpm in most engines,as the solid lifter cam lobe design includes a bit slower ramp acceleration ramp speed at the beginning of the cam lobe acceleration ramp to take up slack with a solid lifter in use that generally won,t hurt the hydraulic cam lifter, you CAN,T install solid flat tappet lifters on a hydraulic lifter cam and expect long term durability as it lacks the slower inertial cam acceleration rates so wear is generally going to be at an unacceptable higher rate.

If you use hydraulic lifters on a cam designed for solid lifters, the power curve will tend to move up a bit in the lower rpm range (maybe 100 rpm )but there will also frequently be an overall loss of power and torque compared to what the cam would normally deliver with solid lifters, simply because a hydraulic lifter will generally not maintain valve train stability to the same peak rpm limitations that the solid lifter valve train usually will.

The best advice is to use the type of lifters (solid or hydraulic) the cam was ground for, and use matched components with the spring pressures and clearances the manufacturer suggested, rather than trying to change one lifter design for the other, or change the valve train dynamics or geometry.

CAST CAM CORES ARE NOT DESIGNED TO HANDLE OVER ABOUT 130lbs SEAT and 400lbs OPEN SPRING LOADS YOU NEED A BILLET CAM CORE FOR DURABILITY IF THOSE LIMITS ARE EXCEEDED

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

In nearly all circumstances, a good roller camshaft design will outperform its flat tappet counterpart. Among the benefits of roller cams are higher tappet velocity, more lift and more area, along with reduced valve train friction (often a 15+ hp increase) and higher engine rpm with little effect on low speed driveability and power.

THERES BILLET AND TOOL STEEL CAM CORES AVAILABLE

http://www.callies.com/wp-content/uploads/2014/06/Cam-Core-Master-Price-Sheet.pdf

Callies Crankshafts Producing 8620 Billet Cam Cores

Recieved notice today, that Callies, is producing billet cam cores for the camshaft industry. This has been in the making for about 1.5 yrs. Since Crane started to have problems, the owner of Callies, took a look at the equipment, but as far as I know only purchased the gear cutting equipment. Crane used to produce the the cams for the aircraft engine mfgs that Callies, makes crankshafts for and when Crane was going down the aircraft engine mfgs notified Callies ,that production of cranks was going to end until a cam mfg was found. So they now mfg and finish cams for aircraft engines and are solving the shortage of cores elsewhere. To me it's good to know that the mfg that makes cranks for aircraft engines also mfg cranks in our market. THEY ARE NOT SUPPLYING CAMS ONLY CORES FOR FINISH TO THE CAM GRINDING COMPANYS

http://garage.grumpysperformance.co...hydraulic-flat-tappet-break-in-springs.10182/

related info

http://www.enginebuildermag.com/2012/01/hydraulic-camshafts-and-lifters-101/

http://garage.grumpysperformance.co...lifter-to-increase-oil-flow.11152/#post-49968

http://www.hotrod.com/how-to/engine/mopp-0312-solid-vs-hydraulic-lifters/

http://garage.grumpysperformance.co...-solid-and-hydraulic-lifter.10431/#post-43419

http://www.hotrod.com/how-to/engine/flat-tappet-cam-tech/

http://www.lunatipower.com/Tech/Valvetrain/ValvetrainUnderstanding.aspx

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://garage.grumpysperformance.co...cost-vs-a-flat-tappet-design.3802/#post-54090

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

Last edited: