The

intake system on a four-stroke car engine has one main goal, to get as much air-fuel mixture into the cylinder as possible. One way to help the intake is by

tuningthe lengths of the pipes.

When the

intake valve is open on the engine, air is being sucked into the engine, so the air in the intake runner is moving rapidly toward the cylinder. When the intake valve closes suddenly, this air slams to a stop and stacks up on itself, forming an area of high pressure. This high-pressure wave makes its way up the

intake runner away from the cylinder. When it reaches the end of the intake runner, where the runner connects to the

intake manifold, the pressure wave bounces back down the intake runner.

If the

intake runner is just the right length, that pressure wave will arrive back at the intake valve just as it opens for the next cycle. This extra pressure helps cram more

air-fuel mixinto the cylinder -- effectively acting like a

turbocharger. The problem with this technique is that it only provides a benefit in a fairly narrow speed range. The pressure wave travels at the speed of sound (which depends on the density of the air) down the intake runner. The speed will vary a little bit depending on the temperature of the air and the speed it is moving, but a good guess for the speed of sound would be 1,300 feet per second (fps). Let's try to get an idea how long the intake runner would have to be to take advantage of this effect.

Let's say the engine is running at 5,000 rpm. The intake valve opens once every two revolutions (720 degrees), but let's say they stay open for 250 degrees. That means that there are 470 degrees between when the intake valve closes and when it opens again. At 5,000 rpm it will take the engine 0.012 seconds to turn one revolution, and 470 degrees is about 1.31 revolutions, so it takes 0.0156 seconds between when the valve closes and when it opens again. At 1,300 fps multiplied by 0.0156 seconds, the pressure wave would travel about 20 feet. But, since must go up the intake runner and then come back, the intake runner would only have to be half this length or about 10 feet.

Two things become apparent after doing this calculation:

1. The tuning of the intake runner will only have an effect in a fairly narrow RPM range. If we redo the calculation at 3,000 rpm, the length calculated would be completely different.

2. Ten feet is too long. You can't fit pipes that long under the hood of a car very easily. There is not too much that can be done about the first problem.

A tuned intake has its main benefit in a very narrow speed range. But there is a way to shorten the intake runners and still get some benefit from the pressure wave. If we shorten the intake runner length by a factor of four, making it 2.5 feet, the pressure wave will travel up and down the pipe four times before the intake valve opens again. But it still arrives at the valve at the right time.

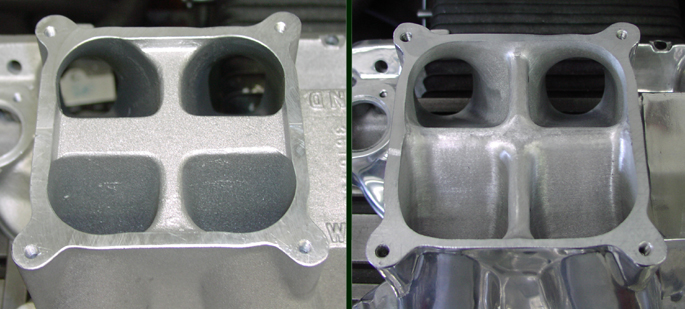

There are a lot of intricacies and tricks to intake systems. For instance, it is beneficial to have the intake air moving as fast as possible into the cylinders. This increases the

turbulenceand mixes the fuel with the air better. One way to increase the air velocity is to use a smaller diameter intake runner. Since roughly the same volume of air enters the cylinder each cycle, if you pump that air through a smaller diameter pipe it will have to go faster.

The downside to using smaller diameter intake runners is that at high engine speeds when lots of air is going through the pipes, the restriction from the smaller diameter may inhibit airflow. So for the large airflows at higher speeds it is better to have large diameter pipes. Some car makers attempt to get the best of both worlds by using dual intake runners for each cylinder -- one with a small diameter and one with a large diameter. They use a butterfly valve to close off the large diameter runner at lower engine speeds where the narrow runner can help performance. Then the valve opens up at higher engine speeds to reduce the intake restriction, increasing the top end power output.