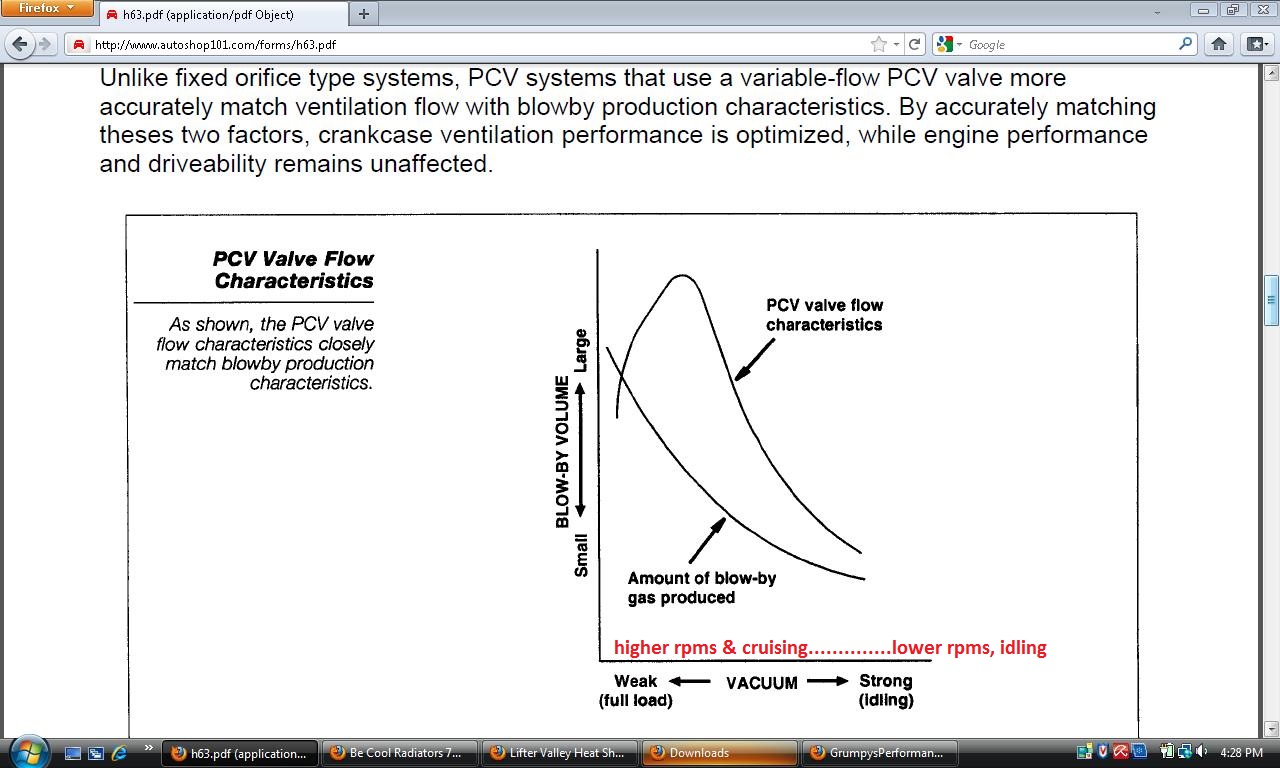

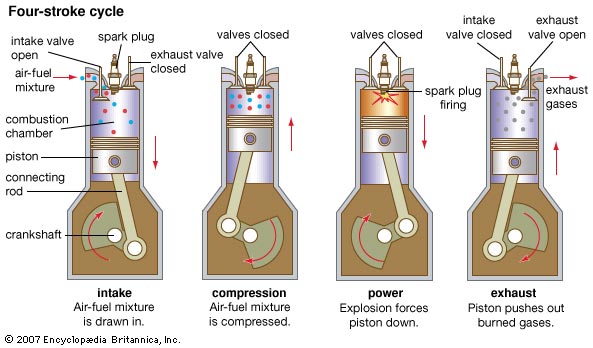

In every engine a small amount of pressurized gases from combustion pressure, during the engines power stroke that's been generated is getting past the rings, as the compression and combustion stroke begins before that cylinder pressure forces the rings out against the cylinder walls.

and it is more than likely the cause of most oil leaks,internal pressure that builds in the in crank case in a slight positive pressure, results in your gaskets even if they were properly installed, being constantly subjected to oil trying too push past or through the seal, and having a good valve cover breather is one way to reduce the pressure build-up ,it the most common quick fix as it prevents pressure build up, but that constant oil flow exiting the breather carries with it, a constant fine oil mist.

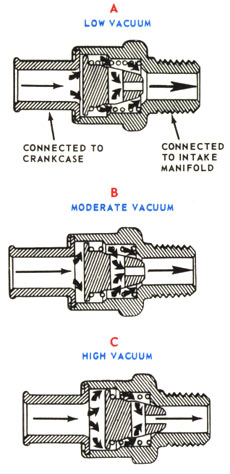

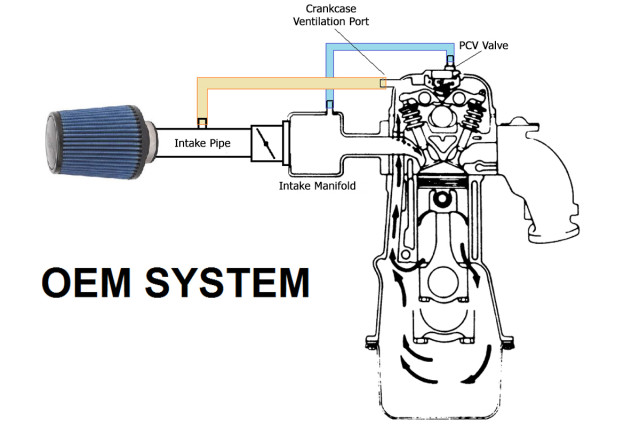

all engines have some pressure get past the rings but most have a breather that allows most of the crank case pressure to remain low, and a PVC valve that constantly allows the crankcase vapors to be sucked into the intake to be burnt, if your system works correctly the breather allows more air flow in than it ever does under normal operational conditions than it does ,crank case pressure out, as the PVC tends to minimize positive crank case pressures.

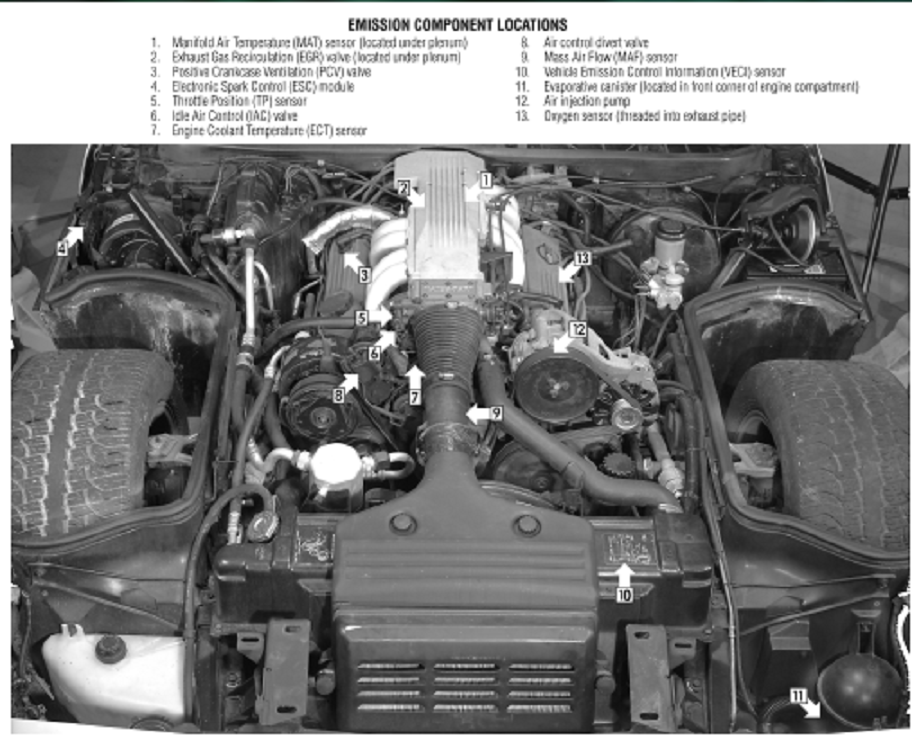

If your carburetor or efi plenum intake doesn,t have a fitting for a PVC valve fitting and you have the hood clearance, its a good deal easier to drill and tap a 2" aluminum carb spacer for a vacuum connection, and that routes less likely to cause mixture distribution issues.

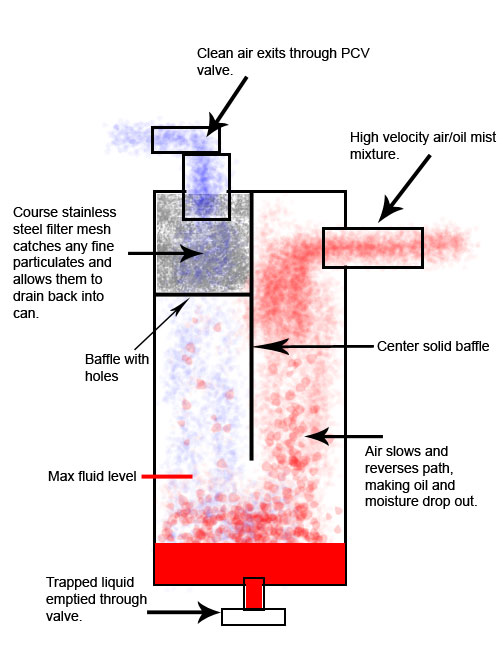

A catch can, is a device that is designed to separate the droplets of oil from the air flow, condense it and route it either back into the engines sump or to be drained occasionally

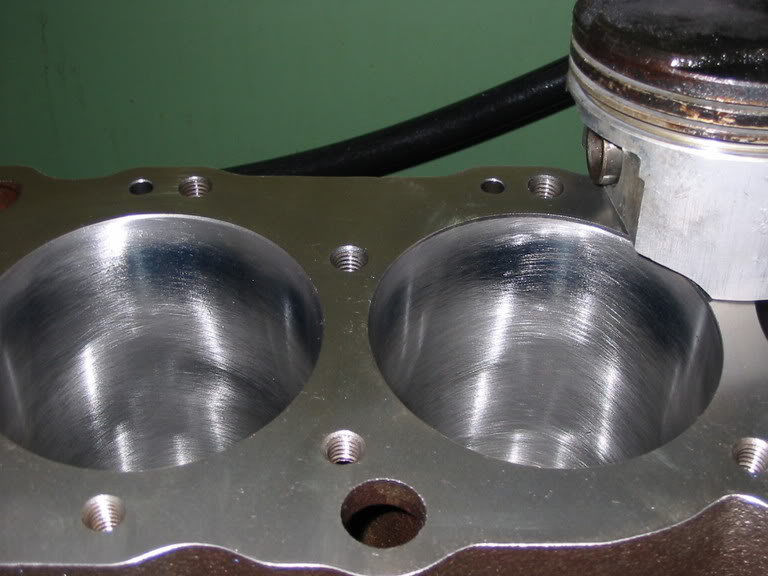

bores must be honed with a deck torque plate to simulate the stress of a installed cylinder head stress , the torqued bolts exert on the bore walls, the torque plate induces and duplicates that stress so that the bore walls will be pulled into the same relationship when you hone the walls concentric, rings won,t seal correctly in a non concentric bore

http://www.harborfreight.com/knockout-p ... 91201.html

http://garage.grumpysperformance.co...breather-hole-in-valve-covers.2005/#post-5328

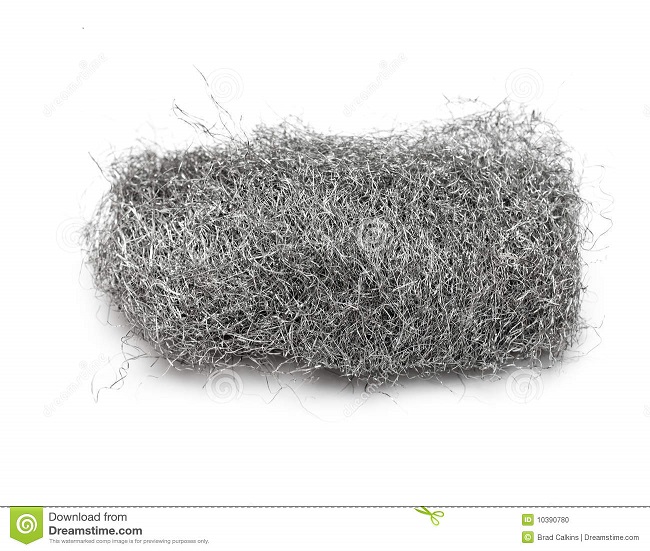

BTW we found we could just insert one or two stainless steel scrub pads in side the valve cover breather tube space, (A and B) as that will absolutely control any air flow turbulence, that tends to drag oil out the breathers and make the engine a oil soaked mess, oil mist collects on the maze of internal metallic surfaces then gravity tends to let the heavier liquid drain back into the valve covers.

I know we did that on road race cars, for oil control on crank case breathers, and it drastically improved the flow back rates and controlled the formation of oil foam, allowing the oil to flow back with a noticeable reduction in air trapped in the oil.

these links may help

/viewtopic.php?f=52&t=2005&p=5328&hilit=+valve+vacuum+PVC#p5328

http://garage.grumpysperformance.co...n-cylinder-head-intake-ports.5081/#post-14463

these electrical box punch tools work great for punching breather holes in some valve covers for rubber grommets, to mount breathers or holes in certain types of oil pan baffles etc.

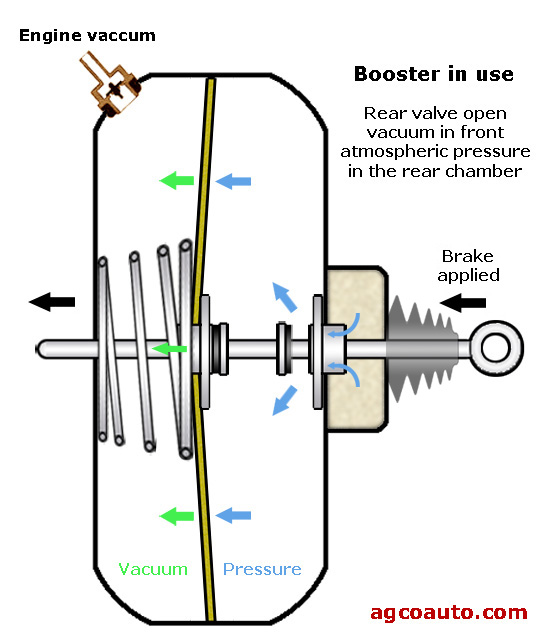

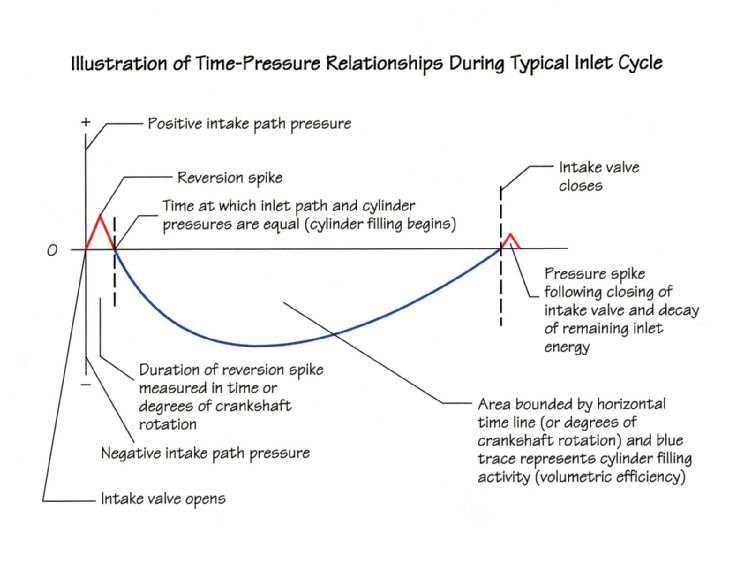

almost any cam will cause intake manifold reversion or pulsed low speed air flow in the engines intake runners , this often results in the PCV valve rapidly oscillating in response to the changes in air vacuum/pressure

viewtopic.php?f=52&t=2005

related threads

/viewtopic.php?f=52&t=2005&p=5328&hilit=+valve+vacuum+PVC#p5328

viewtopic.php?f=87&t=4636&p=12610&hilit=ventilation#p12610

http://garage.grumpysperformance.com/index.php?threads/oil-stained-intake-runners.14209/

/viewtopic.php?f=55&t=2994&p=7857&hilit=+vacuum+venturie#p7857

SHORT VERSION:

Oil Catch Can is designed to effectively separate oil from the crankcase vapors, thereby eliminating all negative effects of excessive intake system oil contamination.

LONG VERSION

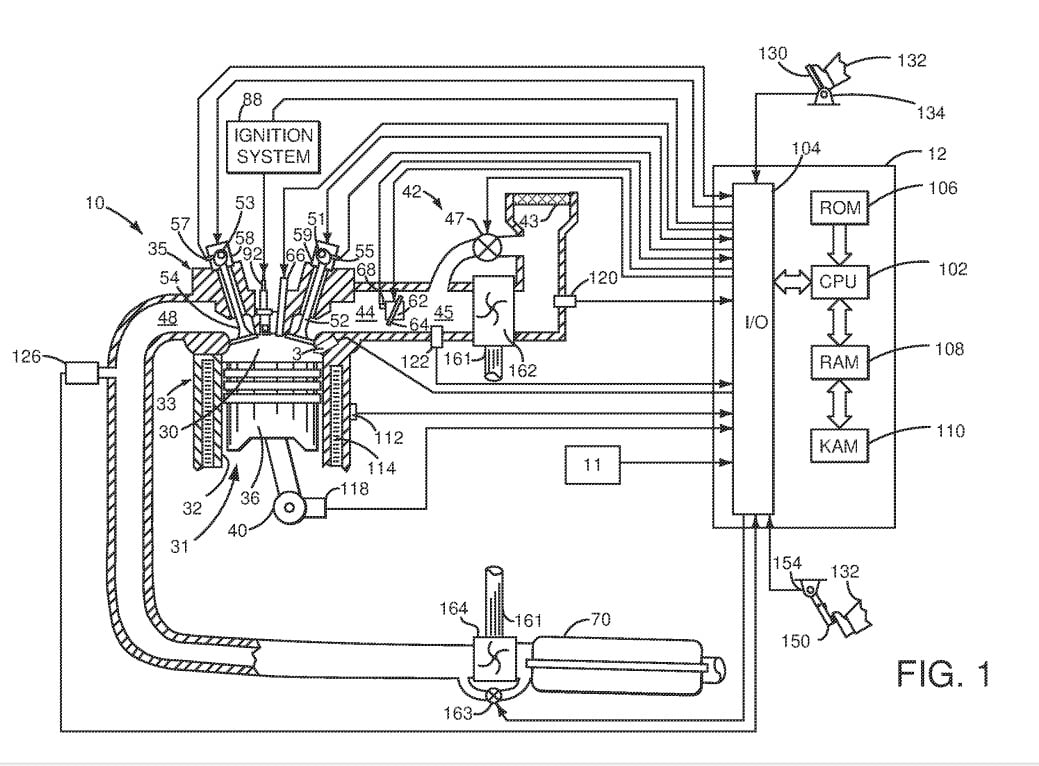

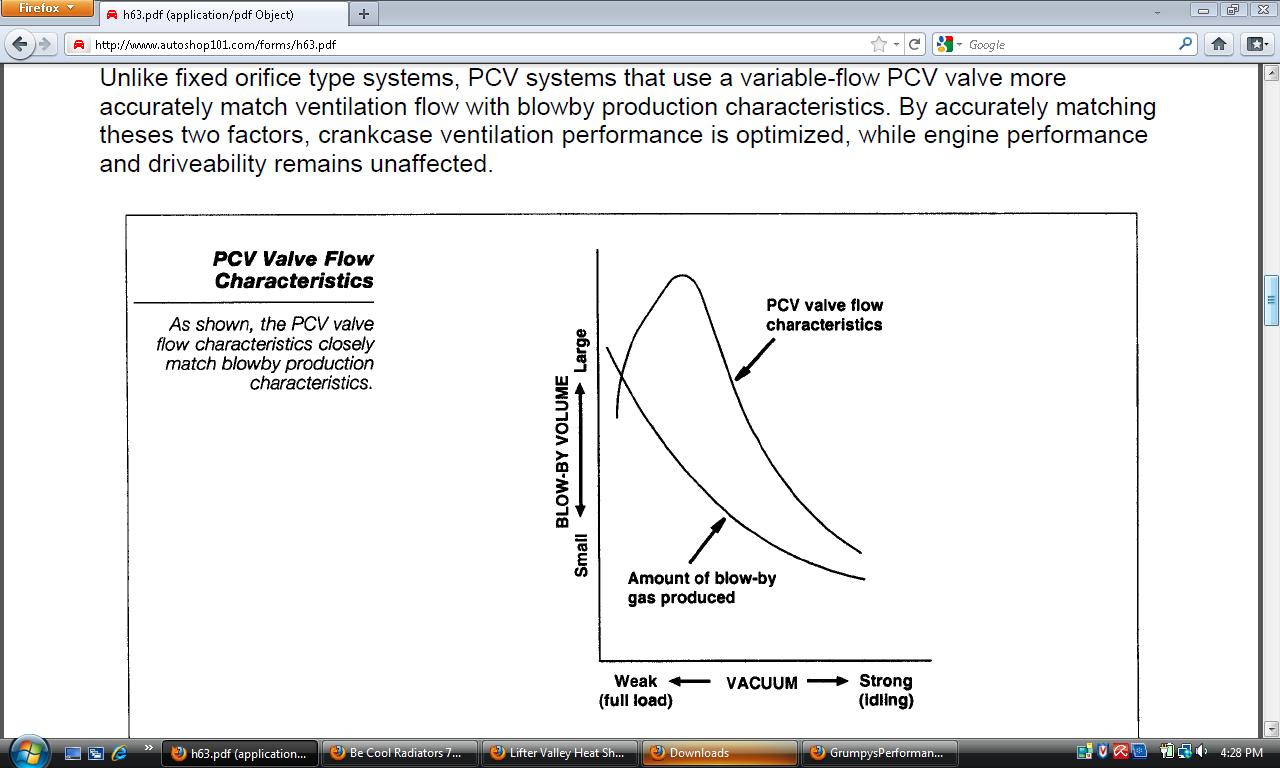

The PCV (Positive Crankcase Ventilation) system is designed to regulate and remove fumes from the engine crankcase, and to alleviate crankcase pressure which

could cause oil leaks or seal damage. The PCV system routes crankcase fumes into the intake manifold where they can be burned to eliminate harmful emissions into the atmosphere. The PCV valve controls the amount of crankcase flow volume depending on the engine's load. With large throttle openings (high engine loads),

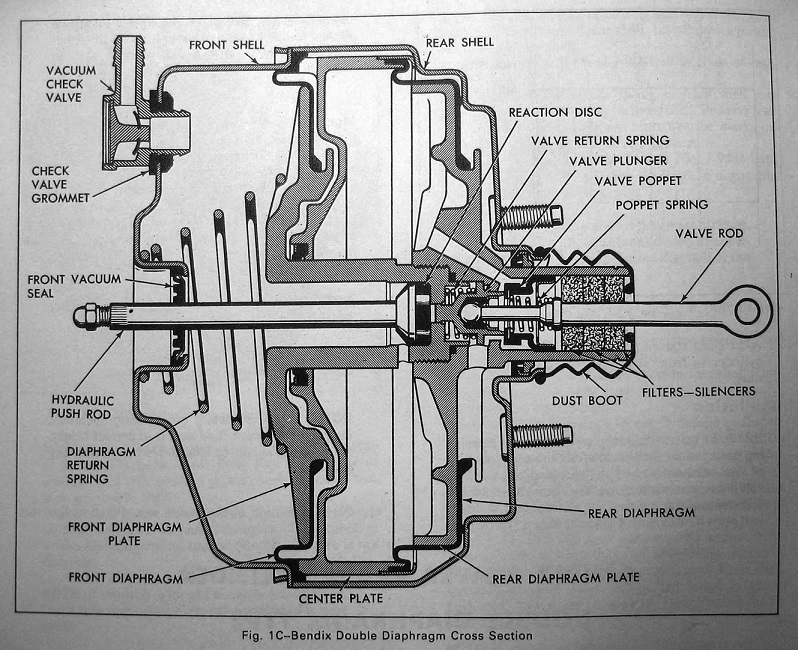

the more blow-by gases are produced, and the more the PCV system flows oil vapor in to the intake manifold. The PCV valve also functions as a check valve to prevent intake manifold flow from reversing back into the crankcase when there is a backfire, or during periods of high manifold pressure (boost) during forced induction by turbocharger or supercharger.

Negative Effects of your Stock PCV System:

Many owners with LSX engines can testify to the amount of oil residue that can accumulate inside the intake manifold,

throttle body, intake track and even the air filter during aggressive driving conditions.

There are various negative effects when excess oil vapor contaminates the intake

system from the stock PCV system - such as:

*Throttle body and/or MAFS (Mass Air Flow Sensor) malfunction or failure.

*Air filter, intercooler (if equipped) and intake ducting contamination if oil pools and run back out the intake system after engine shutdown.

*Reduced octane of the air/fuel mixture, which can cause detonation and the ECM (Engine Control Module) to retard timing, thereby reducing engine power.

*Excessive carbon build-up on valves, piston crowns, combustion chambers and spark plugs. This also increases the chance of detonation and power loss.

*Increased emissions & possible contamination of catalytic converters and oxygen sensors.

NEVER use a STEEL WOOL BRILLO PAD

this is just common steel wool with a detergent coating that will HURT your engine, as both the detergent destroys oils ability to lubricate and fine metallic trash in your engine will destroy bearings

what you want is a stainless steel scrub pad, and place these only where oil vapor will collect and drip back into the engine like inside the breather cross over

BETWEEN A & B

read thru the links

https://www.redline-motorworks.com/kb_results.asp?ID=8

http://www.conceptualpolymer.com/new_page_1.htm

viewtopic.php?f=55&t=5081

viewtopic.php?f=52&t=2005&p=5328&hilit=breather#p5328

http://www.conceptualpolymer.com/PCV%20 ... %20102.pdf

Last edited by a moderator: