Gear drive VS chain cam drives,

http://www.summitracing.com/parts/CLO-9-1100/

http://www.compcams.com/Technical/Instr ... es/117.pdf

viewtopic.php?f=52&t=5734&p=17492#p17492

http://www.jegs.com/InstallationInstruc ... -20325.pdf

http://www.jegs.com/InstallationInstruc ... 0-7892.pdf

read thru these threads and sub linked info also

viewtopic.php?f=32&t=1761&p=5980&hilit=+chain#p5980

viewtopic.php?f=52&t=205&p=241&hilit=+vibrations#p241

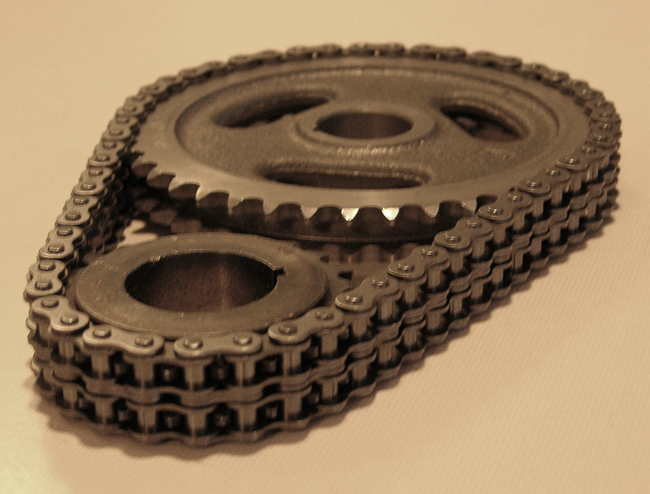

ALL TIMING CHAINS STRETCH OVER TIME, the BETTER/MORE EXPENSIVE ONES TEND TOO LAST FAR LONGER, THAN THE CHEAPER VERSIONS and PROPER LUBRICATION HELPS THEM LAST LONGER

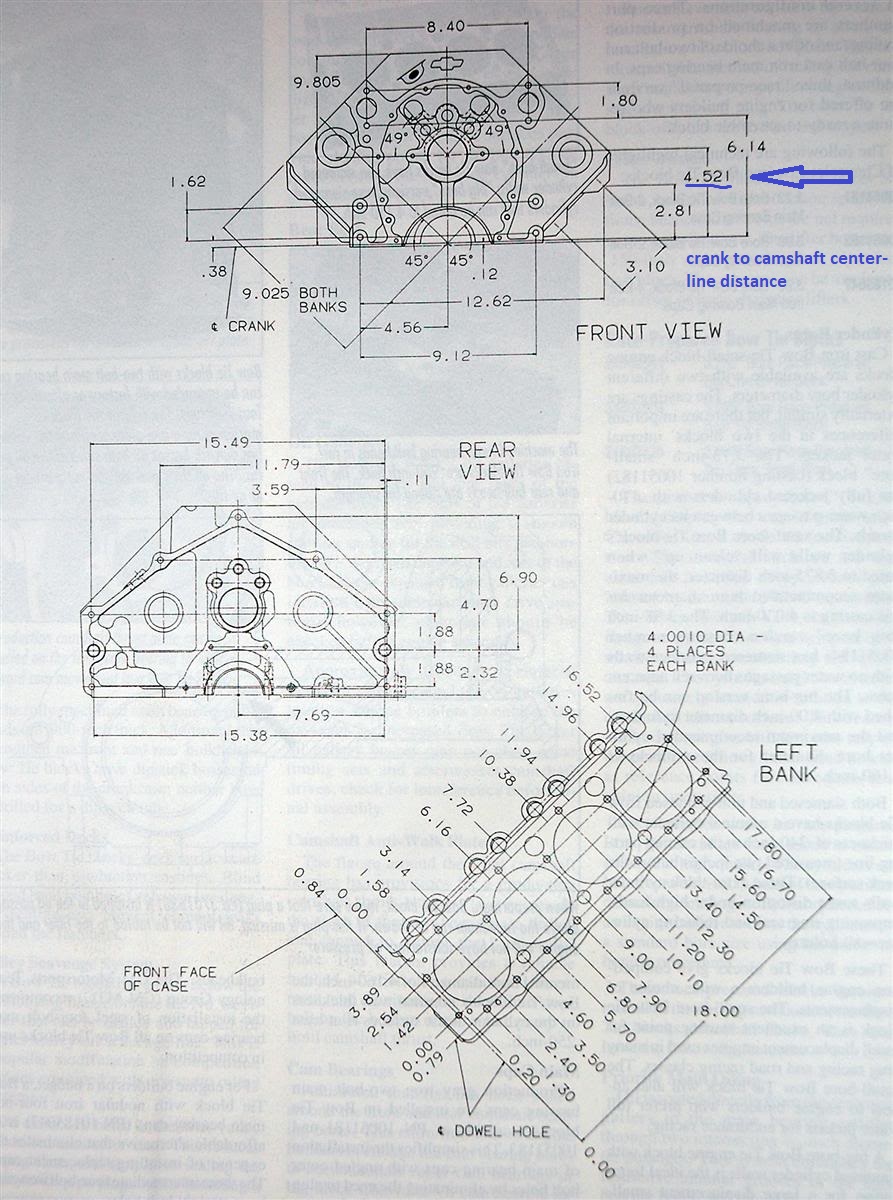

Id first point out that a CLOYES true roller chain cam drive will work just fine in most applications, but you need to check the slack every 20,000 miles or so after 60,000 miles or more if your using the car for serious performance applications and higher rpm operation, replace the old timing chain after about 60,000 miles if you want to maintain precise timing,under the conditions most guys put street engines, but I constantly hear guys repeating the MYTH that all gear drives cause harmful harmonic loads to be transferred to the cam, I,ve tested, and checked extensively and all the gear drives I've looked at very closely, tend to maintain the correct timing longer and have no bad problems and certainly last far longer than the chain drives WHEN CORRECTLY INSTALLED AND INDEXED

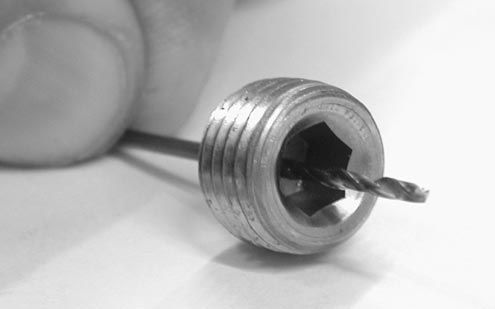

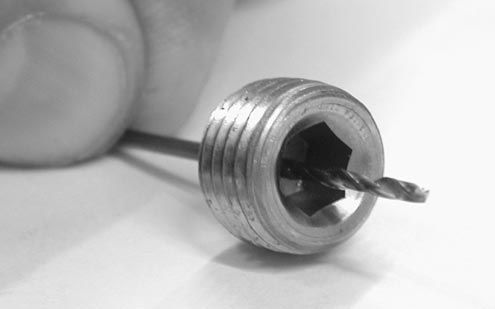

drilling an oil passage plug with a .oo31 hole to provide a constant bath of hot oil spray on the gear or chain drive timing set tends to add too and aid durability.

drilling the pass side oil passage plug with a 1/32" bit so oil constantly sprays on the timing gears helps extend chain and gear life.

btw the multi part timing chain covers that allow a faster cam change are available at a not much increased price for some 1966-1990 BBC applications,

obviously youll want to ask questions and get the correct matched components for your application.

https://www.summitracing.com/parts/cca-312/overview/

and sbc

$265

https://www.summitracing.com/parts/cca-310

BTW if you soak a new timing chain and gears in a pan , covering them in a mix of synthetic oil and moly assembly lube and heat them to about 220 degrees to allow the oil to penetrate into the metals pores it will tend to pre-lubricate the chain and gears more effectively than just installing them dry, and from what Ive seen they last slightly longer, a cheap tin pan can be used, and if you don,t have an IR temp gun(you really should get one) adding a 1/4 teaspoon of water to the oil and watching it boil off as an indicator that the oils up to temp is a good idea, as you don,t want to over heat the oil or smoke up the kitchen

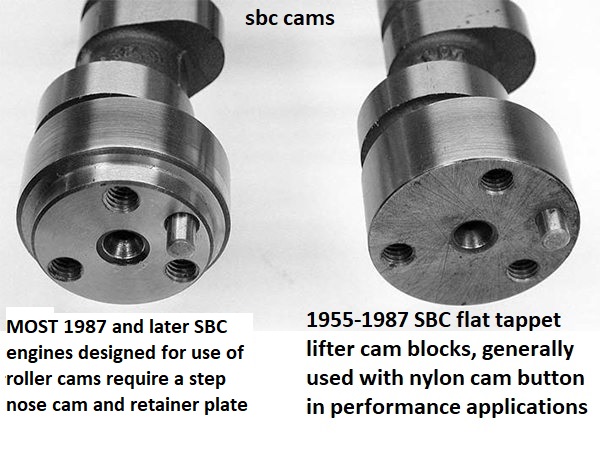

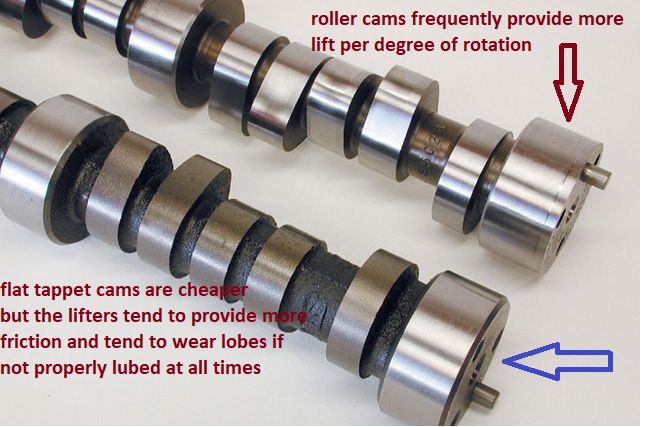

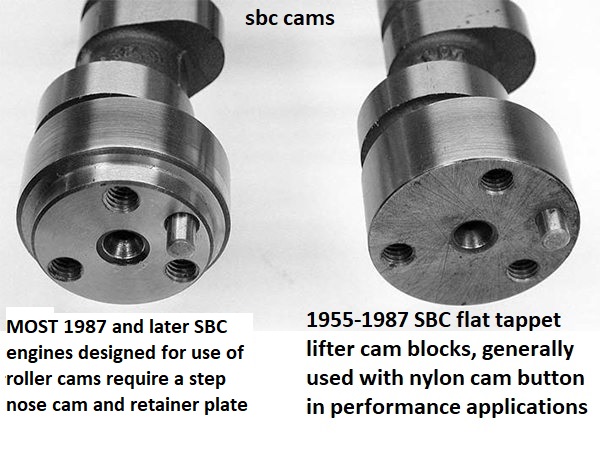

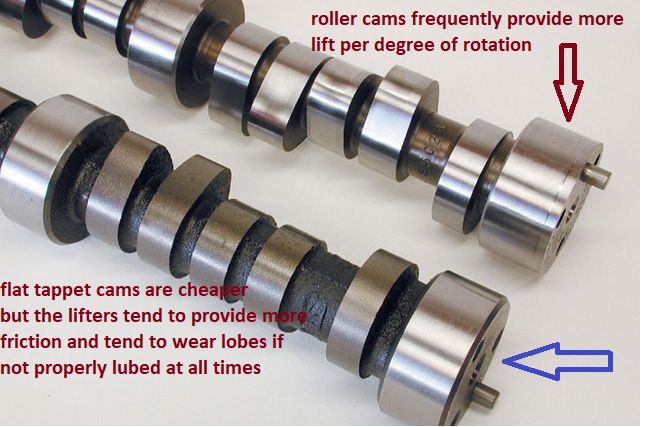

Starting in 1987 GM began using a hydraulic roller cam in their production car engines.

This required a cam thrust plate on the front of the block.

The step in the nose of this cam (left) identifies it as a cam intended for use in a production roller cam block.

If your ever in doubt, about the correct timing chain application,

CALL THE TECH GUYS AT CLOYES

cloyes tech dept 1-479-646-1662 EXT 228

with the older style non-step nose cam, in the newer style "08" block, you will NOT use the retainer plate

you should use a cloyes 9-3100 timing chain, set

https://www.summitracing.com/parts/clo-9-3100

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

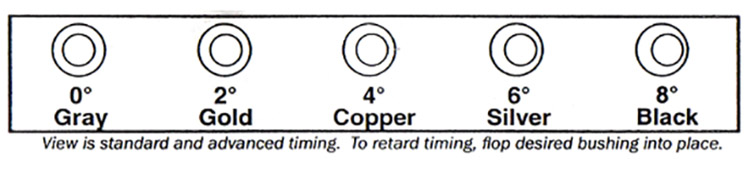

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12050

http://garage.grumpysperformance.com/index.php?threads/cam-drive-details.3809/#post-10226

http://garage.grumpysperformance.com/index.php?threads/wear-plate.3777/#post-10011

I tend to favor QUIET gear cam drives, in some applications

in PERFORMANCE ENGINE BUILDS,over chain drives , because chain drives get slack and tend to allow the cam timing to vary with rapid engine load changes like during shifts

http://www.cloyes.com/HighPerformance/P ... fault.aspx

except in cars with KNOCK sensors, where the slight gear whine might cause the knock sensor to randomly retard the ignition timing.

Ive used several different brands and find nothing wrong with a CORRECTLY INSTALLED Pete Jackson dual idler gear drive, in fact Ive used that (QUIET) Pete Jackson gear drive, in the 383 thats been in my corvette for several years with zero problems

as with most parts, installation must be correct, clearances checked, ETC. or youll HAVE PROBLEMS!, READ/UNDERSTAND THE INSTRUCTIONS, and ASK, QUESTIONS and know the reasons and answers , before installing any part or youll probably run into problems, Id have changed several chain drives bye this time, but the same gear drive I installed over 8 years ago still works fine and maintains the correct clearances

but Ill also point out I run a high volume oil pump, a 10 baffled QT oil pan and have extra oil jets drilled (#60 drill bit)in the oil passage plugs behind the cam gear

READ THE LINKED INFO CAREFULLY

http://garage.grumpysperformance.co...ped-nose-cam-in-early-block.14182/#post-71937

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...-street-roller-cam-selection.5709/#post-46850

http://garage.grumpysperformance.co...a-better-cam-to-a-zz3-350-sbc.182/#post-26013

http://www.engineersedge.com/drill_sizes.htm

the two outside plugs

thats part of the install process place (with the gasket) using a large lump of modeling clay , and dial calipers

http://www1.mscdirect.com/CGI/NNSRIT?PMPXNO=2079569&PMT4NO=9937412

http://www.officedepot.com/ddSKU.do?leve...rue&An=text

Under the timing cover and test bolt it in place, remove the clay an carefully measure the clearances..

(BTW spray the inside cover and the block with WD 40 first it tends to prevent the clay from sticking)the axles on the idler gears should have about a .002-.010 clearance between the cover and the block, this keeps the gears running in the same basic track once the engines assembled, you don,t want the axles to bind/or be in constant contact, under tension with the cover, as that might tip/bind the gear, and a light coat of moly on the gears wont hurt. This frequently requires a light touch of a file to shorten the axles a few thousands, but youll not know without TESTING for the correct clearances with the clay :grin:

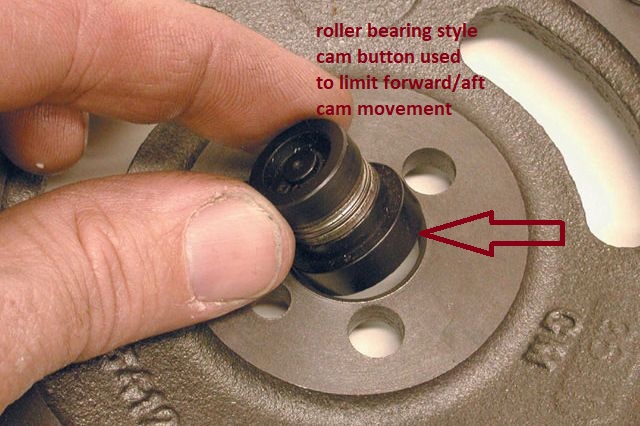

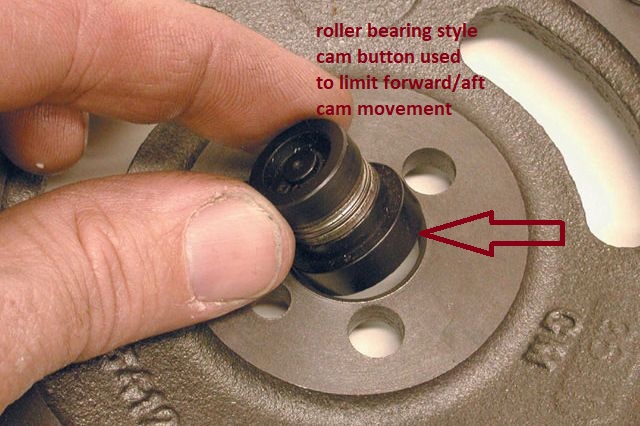

youll also need the retaining plate, cam button and loc-tite

http://store.summitracing.com/partdetail.asp?part=MOR-60460&N=115&autoview=sku

http://www.compcams.com/Technical/Instr ... es/117.pdf

viewtopic.php?f=52&t=5734&p=17492#p17492

http://www.jegs.com/InstallationInstruc ... -20325.pdf

http://www.jegs.com/InstallationInstruc ... 0-7892.pdf

read thru these threads and sub linked info also

viewtopic.php?f=32&t=1761&p=5980&hilit=+chain#p5980

viewtopic.php?f=52&t=205&p=241&hilit=+vibrations#p241

ALL TIMING CHAINS STRETCH OVER TIME, the BETTER/MORE EXPENSIVE ONES TEND TOO LAST FAR LONGER, THAN THE CHEAPER VERSIONS and PROPER LUBRICATION HELPS THEM LAST LONGER

Id first point out that a CLOYES true roller chain cam drive will work just fine in most applications, but you need to check the slack every 20,000 miles or so after 60,000 miles or more if your using the car for serious performance applications and higher rpm operation, replace the old timing chain after about 60,000 miles if you want to maintain precise timing,under the conditions most guys put street engines, but I constantly hear guys repeating the MYTH that all gear drives cause harmful harmonic loads to be transferred to the cam, I,ve tested, and checked extensively and all the gear drives I've looked at very closely, tend to maintain the correct timing longer and have no bad problems and certainly last far longer than the chain drives WHEN CORRECTLY INSTALLED AND INDEXED

drilling an oil passage plug with a .oo31 hole to provide a constant bath of hot oil spray on the gear or chain drive timing set tends to add too and aid durability.

drilling the pass side oil passage plug with a 1/32" bit so oil constantly sprays on the timing gears helps extend chain and gear life.

btw the multi part timing chain covers that allow a faster cam change are available at a not much increased price for some 1966-1990 BBC applications,

obviously youll want to ask questions and get the correct matched components for your application.

https://www.summitracing.com/parts/cca-312/overview/

and sbc

$265

https://www.summitracing.com/parts/cca-310

BTW if you soak a new timing chain and gears in a pan , covering them in a mix of synthetic oil and moly assembly lube and heat them to about 220 degrees to allow the oil to penetrate into the metals pores it will tend to pre-lubricate the chain and gears more effectively than just installing them dry, and from what Ive seen they last slightly longer, a cheap tin pan can be used, and if you don,t have an IR temp gun(you really should get one) adding a 1/4 teaspoon of water to the oil and watching it boil off as an indicator that the oils up to temp is a good idea, as you don,t want to over heat the oil or smoke up the kitchen

Starting in 1987 GM began using a hydraulic roller cam in their production car engines.

This required a cam thrust plate on the front of the block.

The step in the nose of this cam (left) identifies it as a cam intended for use in a production roller cam block.

If your ever in doubt, about the correct timing chain application,

CALL THE TECH GUYS AT CLOYES

cloyes tech dept 1-479-646-1662 EXT 228

with the older style non-step nose cam, in the newer style "08" block, you will NOT use the retainer plate

you should use a cloyes 9-3100 timing chain, set

https://www.summitracing.com/parts/clo-9-3100

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12050

http://garage.grumpysperformance.com/index.php?threads/cam-drive-details.3809/#post-10226

http://garage.grumpysperformance.com/index.php?threads/wear-plate.3777/#post-10011

I tend to favor QUIET gear cam drives, in some applications

in PERFORMANCE ENGINE BUILDS,over chain drives , because chain drives get slack and tend to allow the cam timing to vary with rapid engine load changes like during shifts

http://www.cloyes.com/HighPerformance/P ... fault.aspx

except in cars with KNOCK sensors, where the slight gear whine might cause the knock sensor to randomly retard the ignition timing.

Ive used several different brands and find nothing wrong with a CORRECTLY INSTALLED Pete Jackson dual idler gear drive, in fact Ive used that (QUIET) Pete Jackson gear drive, in the 383 thats been in my corvette for several years with zero problems

as with most parts, installation must be correct, clearances checked, ETC. or youll HAVE PROBLEMS!, READ/UNDERSTAND THE INSTRUCTIONS, and ASK, QUESTIONS and know the reasons and answers , before installing any part or youll probably run into problems, Id have changed several chain drives bye this time, but the same gear drive I installed over 8 years ago still works fine and maintains the correct clearances

but Ill also point out I run a high volume oil pump, a 10 baffled QT oil pan and have extra oil jets drilled (#60 drill bit)in the oil passage plugs behind the cam gear

READ THE LINKED INFO CAREFULLY

http://garage.grumpysperformance.co...ped-nose-cam-in-early-block.14182/#post-71937

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...-street-roller-cam-selection.5709/#post-46850

http://garage.grumpysperformance.co...a-better-cam-to-a-zz3-350-sbc.182/#post-26013

http://www.engineersedge.com/drill_sizes.htm

the two outside plugs

the idlers seem to sort of float front to back. I guess install the balancer without the timing cover and check?

thats part of the install process place (with the gasket) using a large lump of modeling clay , and dial calipers

http://www1.mscdirect.com/CGI/NNSRIT?PMPXNO=2079569&PMT4NO=9937412

http://www.officedepot.com/ddSKU.do?leve...rue&An=text

Under the timing cover and test bolt it in place, remove the clay an carefully measure the clearances..

(BTW spray the inside cover and the block with WD 40 first it tends to prevent the clay from sticking)the axles on the idler gears should have about a .002-.010 clearance between the cover and the block, this keeps the gears running in the same basic track once the engines assembled, you don,t want the axles to bind/or be in constant contact, under tension with the cover, as that might tip/bind the gear, and a light coat of moly on the gears wont hurt. This frequently requires a light touch of a file to shorten the axles a few thousands, but youll not know without TESTING for the correct clearances with the clay :grin:

youll also need the retaining plate, cam button and loc-tite

http://store.summitracing.com/partdetail.asp?part=MOR-60460&N=115&autoview=sku

Last edited by a moderator: