=" 64ausbelair"] Hi all.

I was in need of some tech teaching or advice on springs. I have a hydraulic lifter camshaft that suggests springs that have an installed height of 1.7 giving a seat pressure of 105.

I was also looking at a set of trick flow super 23 heads which come assembled with three options. One option and the closest is a spring with an installed height of 1.78 and seat pressure of 110. Will these still work even though the cam suggested springs suggest 1.7? And what is the consequence of a mismatch like this if any.

Cheers in advance Jason.

yes you need to as stated, many times on this and other websites, check all your valve train clearances carefully, but in this case theres almost certainly no cause to be concerned here as the minor difference in spring load rates and installed heights is probably well within the intended valve train and cams design limitations, keep in mind the max cam lift is .520

those heads (keep in mind that price is for a single (1) cylinder head)

https://www.summitracing.com/parts/tfs-30410001/overview/

OBVIOUSLY YOULL WANT THE CORRECT VALVE SPRINGS

http://www.competitionproducts.com/1500-1585-OD-Valve-Springs/products/2631/1/0

https://www.summitracing.com/search/part-type/valve-springs

https://www.iskycams.com/cart/valve-springs-c-99.html

http://www.cranecams.com/userfiles/file/334-343.pdf

https://www.racingsprings.com/Valve-Spring/Store/13

http://www.lunatipower.com/Category.aspx?id=23

http://www.pspring.com/products/engine-valve-springs/

http://www.competitionproducts.com/Valve-Springs/departments/49/

http://psisprings.com/products/

http://www.compcams.com/Products/CC-'Valve Springs By Usage'-0.aspx

http://www.racingsprings.com/Beehive-Valve-Springs

https://www.supertechperformance.com/valve-springs-p109

http://www.cvproducts.com/index.php/psi-springs/

you might also want to keep in mind theres a great deal more to setting up a valve train than slapping some springs and retainers and keepers on the valves.

read thru the links and sub links as theres a great deal of useful info, that youll want to know.

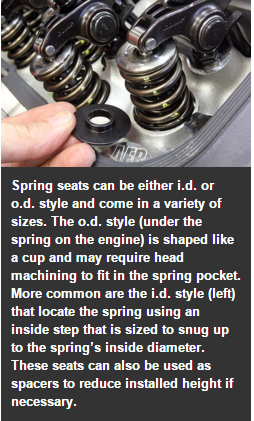

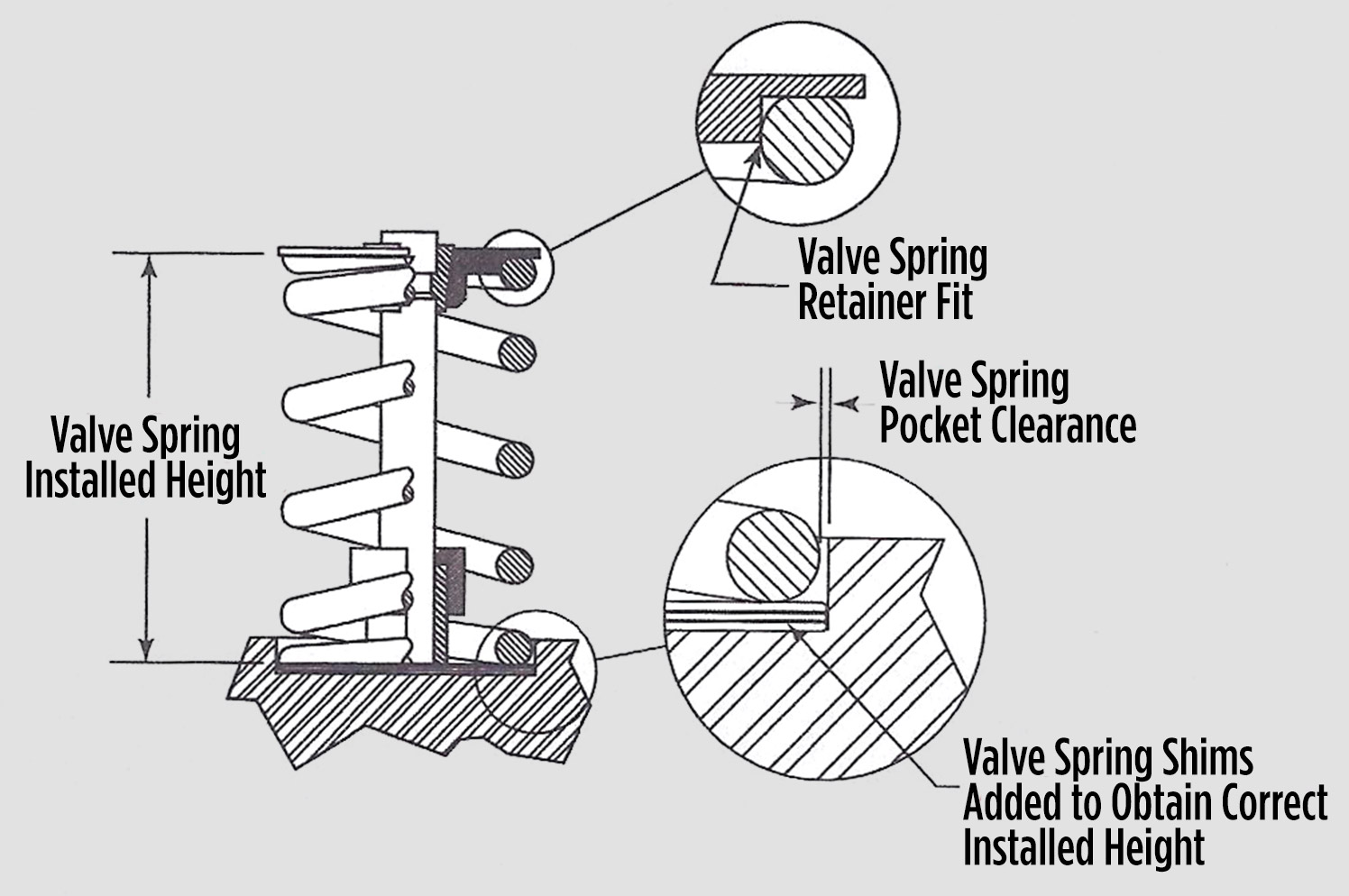

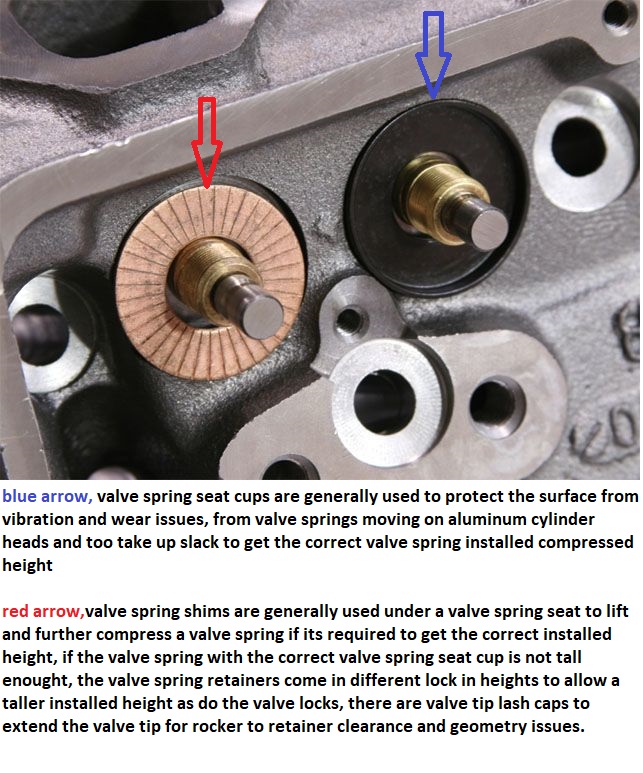

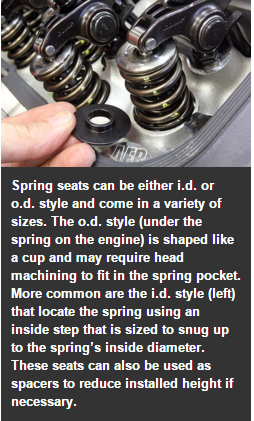

btw just a bit more info, there are valve spring retainers, valve spring seats, shims, valve retainer keepers etc. that can be used that have different sizes or depths that allow you to change the installed height, or relation of the spring to the valve stem , it compressed height, or the valve springs location in relationship to the stems locking groove

keep in mind shims under the valve springs can be used to raise the spring or shorten the valves installed height, valve locks and retainers can be purchased with non-O.E.M dimensions to adjust the valves installed height or spring load rates

you use either or both depending on the application

a .050 PLUS valve lock moves the retainer .050 higher on the valve stem with no other changes, a plus .050 retainer would move the retainer .050 higher with stock valve locks or an additional .050 if matched to .050 plus locks

if you used a plus .o50 retainer with a set of minus .o50 valve locks the retainer would remain at the stock height on the valve stem

http://www.jegs.com/p/Crane/746983/10002/-1

http://www.jegs.com/p/Moroso/764349/10002/-1

http://www.jegs.com/p/Manley/940089/10002/-1

http://www.jegs.com/p/Comp+Cams/757964/10002/-1

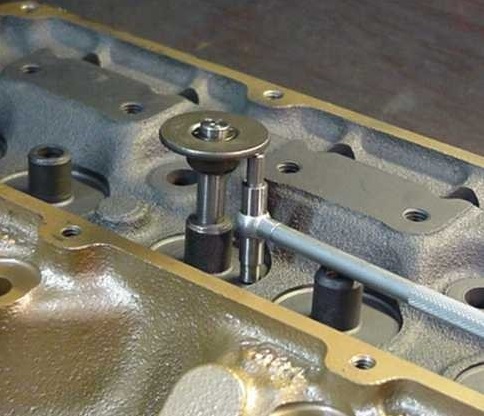

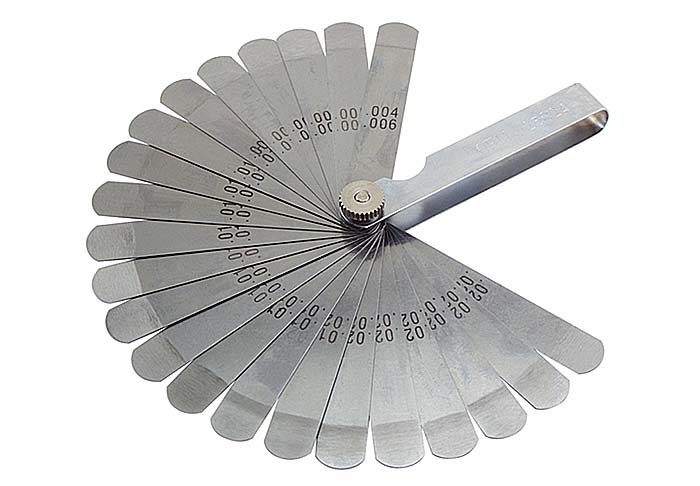

youll have to correctly measure the clearance on your heads with the valve springs and cam specs you selected too use to know if you have the correct valve spring installed height and clearances, failure to accurately check frequently results in very expensive repairs and to what new guys frequently blame on the cam when it was a installers ignorance that was the true cause.

https://www.summitracing.com/parts/pro-66902/overview/

https://www.summitracing.com/parts/sum-900032/overview/

https://www.summitracing.com/parts/rsc-pac-t902/overview/

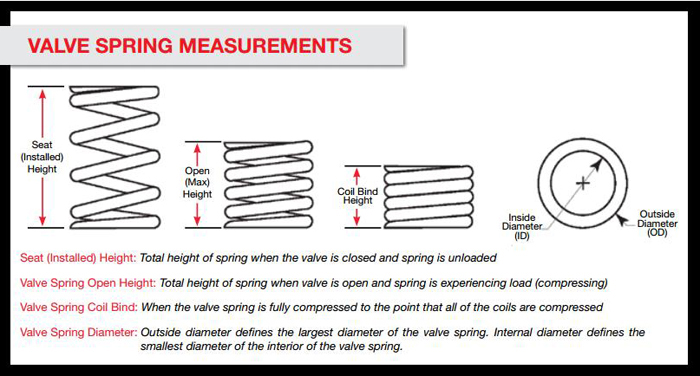

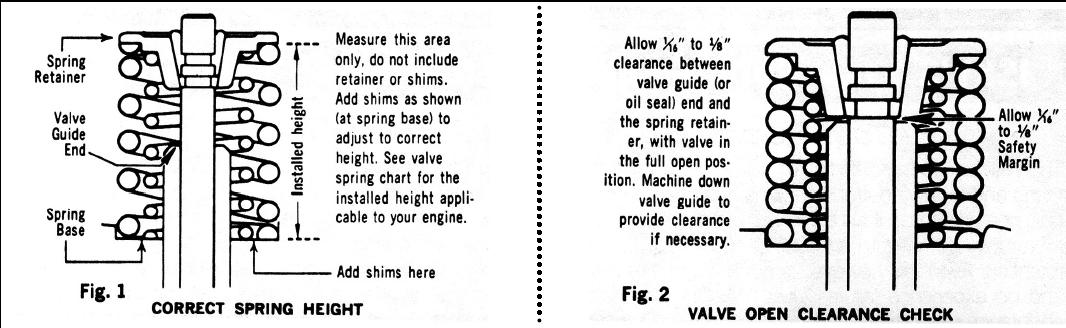

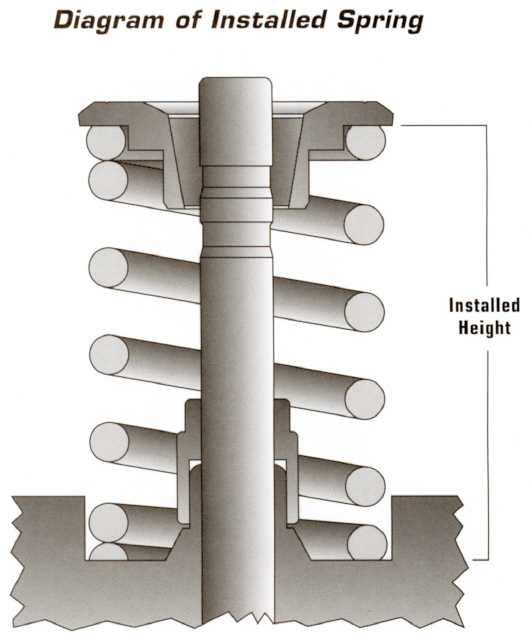

valve springs must be installed at a specific semi compressed and listed installed height,

to provide the listed load rates and clearances,

example

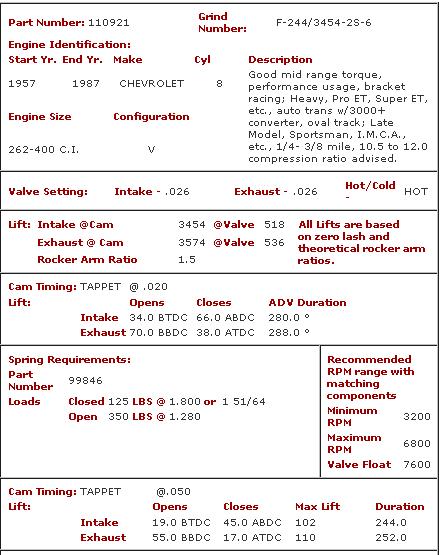

the cam you select will generally come with a suggested listed valve spring load rate and installed height,

(NOTICE THE SUGGESTED INSTALLED HEIGHT WITH THIS CAM IS 1.800"

and the loads are listed)

you must maintain minimum coil bind and retainer to valve seal clearance and proper push-rod and rocker geometry

the distance between the lower edge of the valve spring retainer and the cylinder head is adjustable to achieve the desired valve spring height through the use of valve spring seat cups and shims placed under the valve spring which can be purchased to lock into a stock height, or plus or minus about .050, and valve locks that cam move the retainer (stock or aftermarket) an additional .050 either tighter or longer allowing the valve spring to expand taller, shims can be placed under the valve seat hardened cups that are almost always mandatory on aluminum head but may be optional on iron heads,(O.E.M. cast iron and lower valve spring load rates)

max lift is installed height minus .060 minus coil bind

related info you really need to read

http://garage.grumpysperformance.co...ring-installation-questions.12833/#post-66460

http://garage.grumpysperformance.co...-loads-and-installed-height.10709/#post-46658

http://garage.grumpysperformance.co...ve-spring-iinstalled-height.12791/#post-66038

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.com/index.php?threads/valve-springs.9613/#post-50556

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

push rod to short

WIDE SWEEP ON VALVE TIP FROM ROCKER ADDS ADDITIONAL,

SIDE LOAD WEAR

push rod to long

push rod length correct

AS CLOSE TO CENTER AS POSIABLE BUT BEING CENTERED IS LESS IMPORTANT THAN MINIMAL SWEEP ON THE VALVE TIP< INDICATING MINIMAL SIDE LOADING

http://garage.grumpysperformance.co...-pushrods-and-check-info-you-might-need.5931/

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

a few simple tools will tell you if clearances are ok

READ THESE LINKS CAREFULLY

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/

http://garage.grumpysperformance.com/index.php?threads/checking-piston-to-valve-clearances.399/

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

Last edited: