read thru these links they provide you with a good deal of useful info

viewtopic.php?f=53&t=562

viewtopic.php?f=53&t=83

http://www.professional-products.com/da ... Bchevy.php

http://www.damperdudes.net//index.php?c ... b499dd046c

http://store.summitracing.com/egnsearch ... &y=13&x=43

http://www.flatlanderracing.com/scat-dampers.html

http://www.moparmusclemagazine.com/tech ... index.html

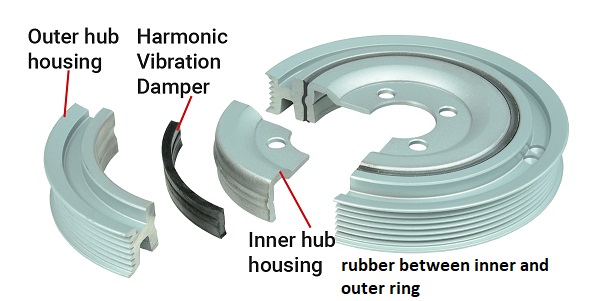

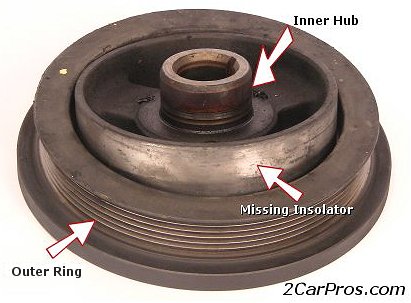

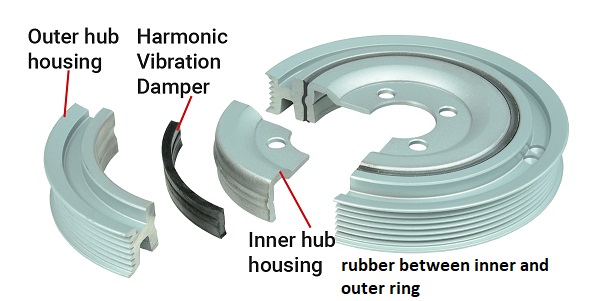

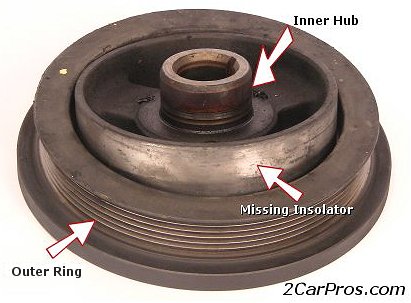

the stock TYPE balancer has a rubber ring glued between the inner hub and outer inertial ring and yes they do deteriorate over time and have been known to slip, especially if subjected to being oil soaked over time

http://www.atiracing.com/products/dampe ... amserp.htm

http://www.bhjdynamics.com/downloads/pd ... r_Info.pdf

ID strongly suggest you buy a decent damper it can prolong your rotating assembly's life expectancy, not look for the least expensive component,

KEEP in mind as the rpms increase the number of power strokes per minute and the speed of the crank moving away from that force on each crank journal increases so the TIME and DURATION of individual power strokes has less individual effect on the rotating assembly, as the crank can,t flex as far or return as much between power pulses.

I almost hate to comment, on Chinese import stuff, but yes its been my experience that for a cheaper damper they work reasonably well, in the lower rpm bands,certainly as well or better than a stock damper, but you need a damper that works over a full rpm range of the engine,they also may not be indexed correctly so verify that before you trust them, as even a cheap replacement part.

you might also keep in mind stock elastomer dampers have a distressing tendency to come apart violently at 6000-9000rpm and large chunks of metal suddenly exiting the engine tend to be counter productive

you might want to read thru these

almost 60% of the articles, Ive read through show the ATI has a minor advantage,

Ive generally built engines using the top tier version fluid dampers and Ive not had any issues.

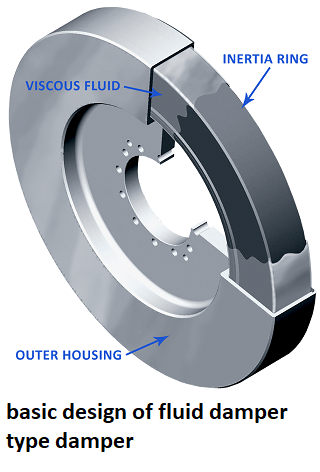

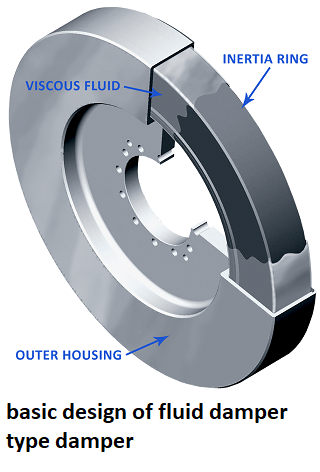

from an engineering stand point I like the fluid damper concept of a heavy ring suspended in a thick viscus, silicone base, grease,

I can easily see it effectively, absorbing shock loads effectively over a wide range of rpms

keep in mind both companys sell a much less expensive damper line,

so you need to ask questions, and not assume all products from a manufacturer are identical or designed for your application.

that would be like saying chevys SUCK, because you bought a chevy VOLT..... if you were looking for the speed and handling of a corvette or or carry capacity of a c2500 pick-up

https://www.dieselarmy.com/engine-tech/engine/how-it-works-viscous-dampers-a-k-a-harmonic-balancers/

https://www.dragzine.com/tech-stori...ers-are-crucial-to-the-health-of-your-engine/

http://www.laskeyracing.com/shop/harmonics.htm

https://fluidampr.com/how-a-fluidampr-works/

http://www.dieseltechmag.com/2009/02/dt-tested-fluidampr-performance-damper

https://motoiq.com/project-golf-r-mkvii-fluidampr-test/3/

http://fluid-damper.com/

http://www.circletrack.com/techarticles ... index.html

http://www.moparmusclemagazine.com/tech ... index.html

http://www.fluidampr.com/HOWITWORKS.htm

http://www.popularhotrodding.com/engine ... index.html

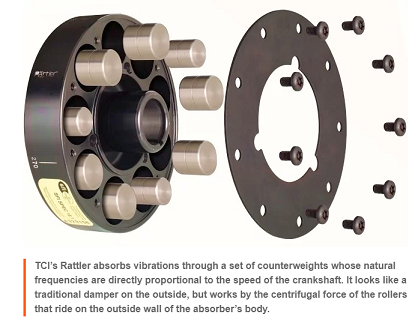

http://www.tciauto.com/Products/TechInf ... r_tech.asp

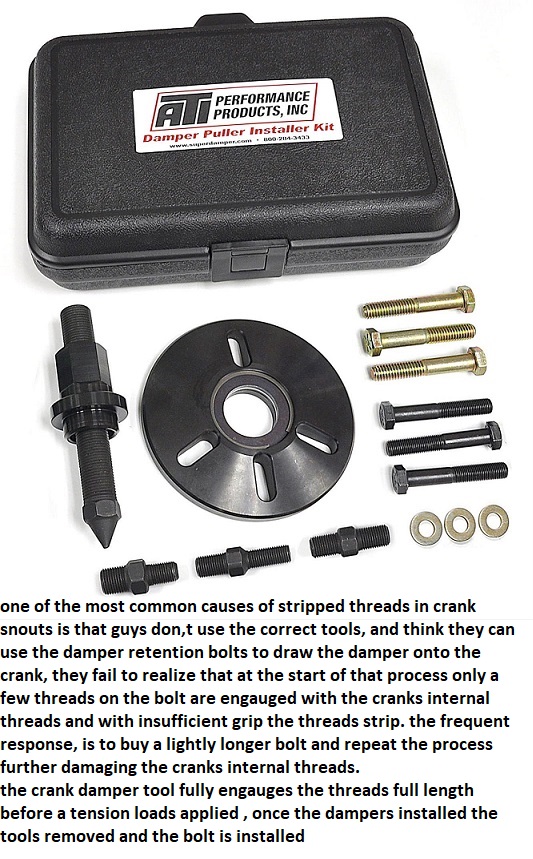

use the correct tool to install the balancer

http://www.summitracing.com/parts/OTC-6505/?rtype=10

watch video

http://www.jegs.com/i/Proform/778/66514/10002/-1

http://www.atiracing.com/products/dampers/charts/damchevy.htm

https://innovatorswest.com/faq.html

life is SOOOO MUCH easier if you buy and use the correct tools

viewtopic.php?f=53&t=562

viewtopic.php?f=53&t=83

http://www.professional-products.com/da ... Bchevy.php

http://www.damperdudes.net//index.php?c ... b499dd046c

http://store.summitracing.com/egnsearch ... &y=13&x=43

http://www.flatlanderracing.com/scat-dampers.html

http://www.moparmusclemagazine.com/tech ... index.html

the stock TYPE balancer has a rubber ring glued between the inner hub and outer inertial ring and yes they do deteriorate over time and have been known to slip, especially if subjected to being oil soaked over time

http://www.atiracing.com/products/dampe ... amserp.htm

http://www.bhjdynamics.com/downloads/pd ... r_Info.pdf

ID strongly suggest you buy a decent damper it can prolong your rotating assembly's life expectancy, not look for the least expensive component,

KEEP in mind as the rpms increase the number of power strokes per minute and the speed of the crank moving away from that force on each crank journal increases so the TIME and DURATION of individual power strokes has less individual effect on the rotating assembly, as the crank can,t flex as far or return as much between power pulses.

I almost hate to comment, on Chinese import stuff, but yes its been my experience that for a cheaper damper they work reasonably well, in the lower rpm bands,certainly as well or better than a stock damper, but you need a damper that works over a full rpm range of the engine,they also may not be indexed correctly so verify that before you trust them, as even a cheap replacement part.

you might also keep in mind stock elastomer dampers have a distressing tendency to come apart violently at 6000-9000rpm and large chunks of metal suddenly exiting the engine tend to be counter productive

you might want to read thru these

almost 60% of the articles, Ive read through show the ATI has a minor advantage,

Ive generally built engines using the top tier version fluid dampers and Ive not had any issues.

from an engineering stand point I like the fluid damper concept of a heavy ring suspended in a thick viscus, silicone base, grease,

I can easily see it effectively, absorbing shock loads effectively over a wide range of rpms

keep in mind both companys sell a much less expensive damper line,

so you need to ask questions, and not assume all products from a manufacturer are identical or designed for your application.

that would be like saying chevys SUCK, because you bought a chevy VOLT..... if you were looking for the speed and handling of a corvette or or carry capacity of a c2500 pick-up

https://www.dieselarmy.com/engine-tech/engine/how-it-works-viscous-dampers-a-k-a-harmonic-balancers/

https://www.dragzine.com/tech-stori...ers-are-crucial-to-the-health-of-your-engine/

http://www.laskeyracing.com/shop/harmonics.htm

https://fluidampr.com/how-a-fluidampr-works/

http://www.dieseltechmag.com/2009/02/dt-tested-fluidampr-performance-damper

https://motoiq.com/project-golf-r-mkvii-fluidampr-test/3/

http://fluid-damper.com/

http://www.circletrack.com/techarticles ... index.html

http://www.moparmusclemagazine.com/tech ... index.html

http://www.fluidampr.com/HOWITWORKS.htm

http://www.popularhotrodding.com/engine ... index.html

http://www.tciauto.com/Products/TechInf ... r_tech.asp

use the correct tool to install the balancer

http://www.summitracing.com/parts/OTC-6505/?rtype=10

watch video

http://www.jegs.com/i/Proform/778/66514/10002/-1

http://www.atiracing.com/products/dampers/charts/damchevy.htm

https://innovatorswest.com/faq.html

life is SOOOO MUCH easier if you buy and use the correct tools

Last edited by a moderator: