http://www.hotrod.com/howto/113_0504_ch ... index.html

http://www.moroso.com/eb/catalog/naviga ... eset=false

http://garage.grumpysperformance.com/index.php?threads/big-block-or-ls-series-motor.6866/#post-22294

http://www.superchevy.com/how-to/project-cars/sucp-0805-ls-engine-power-packages/

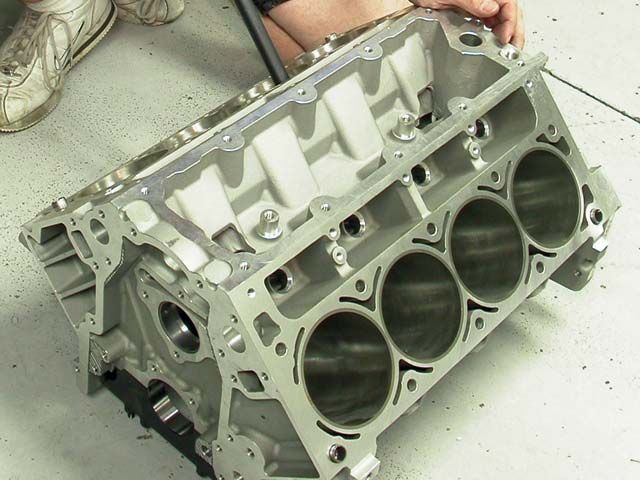

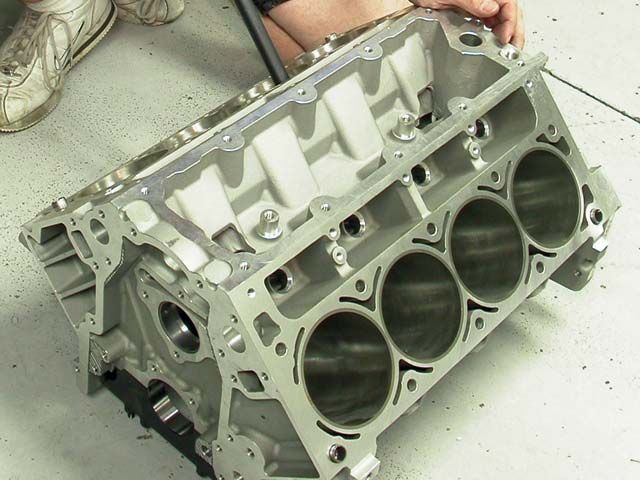

LSNext Blocks have arrived @ SDPC!!!

https://sdparts.com/category/engine-components

GOT AN LS engine swap?

http://www.mastmotorsports.com/view.php?id=160&c=49&s=7

http://www.youtube.com/watch?v=taYsbtDw ... bedded#t=1

http://www.dartheads.com/dart-news/ls-next-sneak-peeks/

https://sdparts.com/category/engine-com ... der-blocks

https://sdparts.com/category/ls-gen-iii ... erformance

http://www.dartheads.com/dart-news/ls-n ... eo-760-hp/

https://www.onallcylinders.com/2017...oductory-overview-gen-iiiiv-ls-engine-family/

https://hqconsumer.com/ls-engine-swap/

https://www.lsxmag.com/tech-stories/the-dos-and-donts-of-buying-a-used-ls-engine-for-a-project/

https://www.onallcylinders.com/2017/09/21/ls-engine-spotters-guide-cars-trucks-ls-engines/

https://www.lsxmag.com/news/everything-you-need-to-know-for-your-ls-swap/

https://www.onallcylinders.com/2017...-advice-for-ls1-mods-to-maximize-performance/

https://www.racingjunk.com/news/drag-race-101-building-an-ls-bracket-motor-from-scratch-part-i/

https://www.dragzine.com/tech-stories/10-basic-tips-to-building-your-first-ls-engine/

https://grassrootsmotorsports.com/articles/addressing-internet-myths-about-ls-swaps/

http://www.superchevy.com/how-to/engine ... -lsxr.html

http://www.carcraft.com/techarticles/cc ... sults.html

http://www.carcraft.com/techarticles/12 ... s_engines/

http://www.carcraft.com/techarticles/12 ... gine_swap/

a few tips on installing a manual trans behind an LS series engine in an older muscle car, and identifying that LS engine

http://www.carcraft.com/techarticles/14 ... r_ls_swap/

http://www.carcraft.com/techarticles/13 ... 8_engines/

http://www.carcraft.com/techarticles/14 ... _a_427_ls/

Front oxygen sensor for 2002 6L applications: 12565397

Brake booster intake manifold fitting (needed if you got your 6L engine from a truck with hydroboost, and you have a vacuum booster): 12555831

3-wire coolant temperature sensor connector: 12102748

If you want to maintain the integrity of the EVAP system:

EVAP vent valve: 15759044

EVAP vent valve connector: 12101858

Fuel tank pressure sensor connector: 88986451

Fuel system stuff:

Fuel pump module (note, will not fit in 88-95 tanks besides 4 door 95 Yukon/Tahoe): ACDelco MU146 (get it off ebay, much cheaper)

Fuel pump connector: 12167154

4L80e conversion parts:

Dipstick: 15183801

Dipstick tube: 15198439

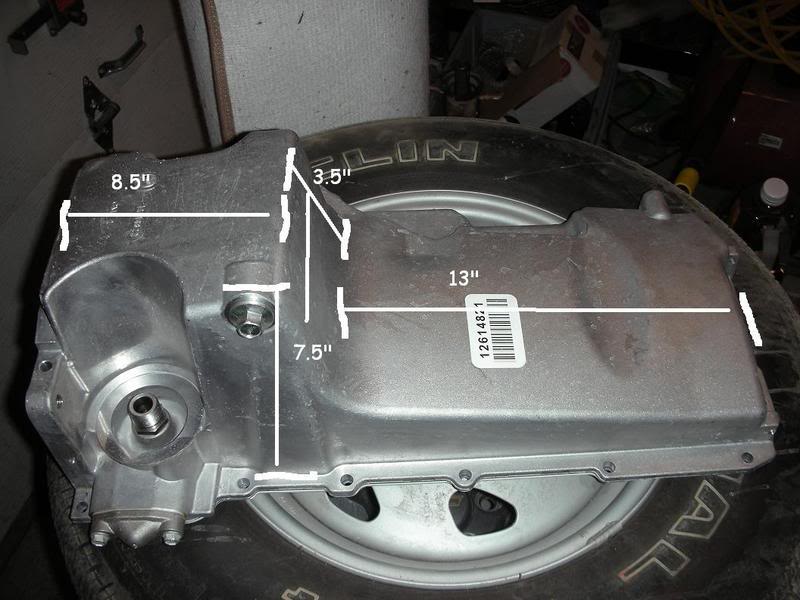

Dust cover to use with 4.8, 5.3, 6.0L engines: 15765623

GMPP spark plug wires for LS1: 12495519

3 piece "Vortec 6000" engine cover, without hole for EGR valve on passenger side: 15006417, 15006418, 15006419

Mobil 1 oil filler cap: 12555685

If you are using a stock wiring harness and want to be able to remove it, you will need the following connectors:

C100 (engine to body harness): Delco PT1401

C152 (engine to chassis harness): GM 15306199

C153 (engine to 4WD harness): Delco PT420

6L engine gaskets/seals:

Front main seal- 12585673

Rear main seal- 12585671

Front cover gasket- 12574294

Rear cover gasket- 12574293

Top cover gasket- 12558178

Oil pan gasket- 12558760

Head gasket- 12589227

Valve cover gasket (2)- 12560696

Water pump gasket (2)- 12559271

Oil pickup tube o-ring- 12557075

6L engine internal parts:

Main bearings- 1,2,4,5: 89017469 each, 3: 89017470 each

Rod bearings-12493712 each

Valve seals- intake: 12482063 (8) , exhaust: 12482062 (8)

Valve keepers- 10166345 each

Some interesting facts about the GEN III engines including the LS1:

ENGINE: Liters: Cubic I: Bore: Stroke: Rod Length: Comp:

LR4 4.8 293 3.780 3.268 6.276 9.5

LM7 5.3 325 3.780 3.622 6.098 9.5

LS1 5.7 346 3.898 3.622 6.098 10.1

LS6 5.7 346 3.898 3.622 6.098 10.5

LQ4 6.0 364 4.00 3.622 6.098 9.4

_____________________

Engine: HP TQ Application

LR4, 4.8L 255@5,200 285@4,000 '99 Silverado

270@5,200 285@4,000

LM7, 5.3L 265@5,000 320@4,000 '99 Silverado

285@5,200 325@4,000

LS1, 5.7L 305@5,200 335@4,000 '98-99' Camaro

335@5,200 335@4,000 '98-99' SS Camaro

345@5,600 350@4,400 '97-99 Corvette

350@5,600 350@4,400 2000 Corvette

350@5,600 375@4,400 '01 Corvette

350@5,600 360@4,000 '01 Corvette Auto

310@5,200 340@4,000 '01 Camaro Auto

325@5,200 350@4,000 '01 Camaro six-speed

LS6, 5.7L 385@6,000 385@4,800 '01 Corvette

LQ4, 6.0L 300@4,800 355@4,000

300@4,400 360@4,000

all ratings are up to 2001 models

______________________________

Significant Gen III

Engineering Points:

1. All Gen III truck engines use iron blocks. Only the Camaro (F-Car) and Corvette (Y-car)LS1/LS6 engines feature aluminum blocks.

2. All Gen III engines have aluminum heads except for the '99 LQ4 engines that were equipped with iron heads. These engines received aluminum heads for the 2000 model year.

3. All Gen III engines share common main,rod,and cam-bearing journal diameters for ease of interchange. All blocks use a cross-bolted six-bolt main cap.

4. All Gen III engines are completely metric.

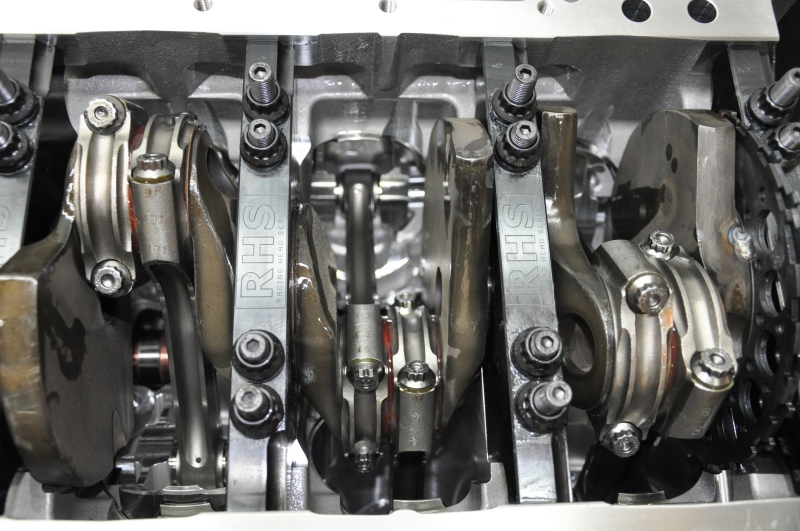

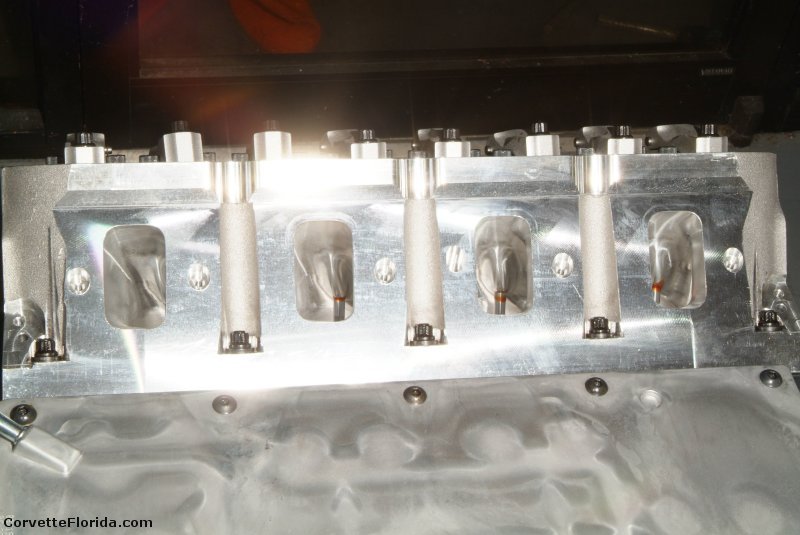

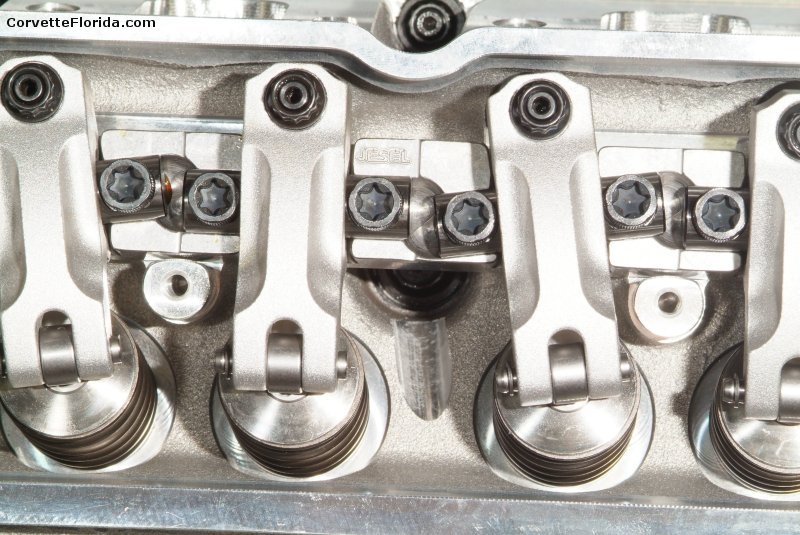

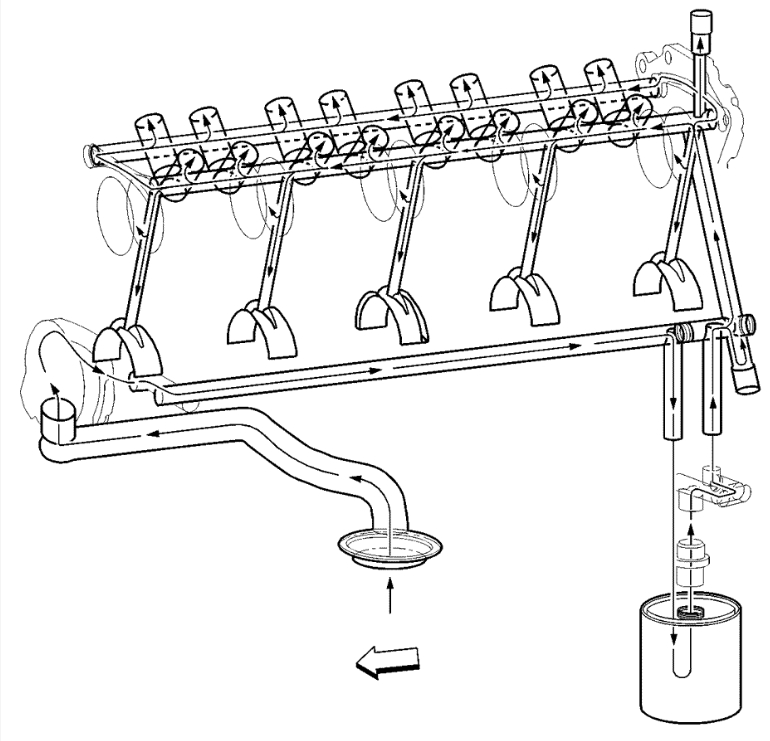

5. All valvetrain pieces are completely interchangable. The standard rocker ratio for all Gen III engines is 1.7:1.

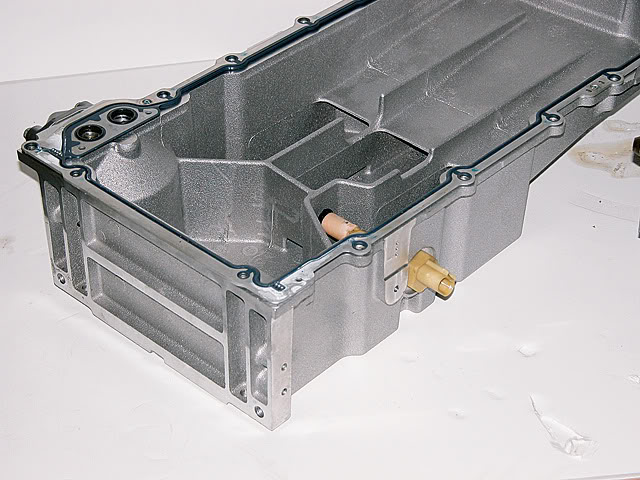

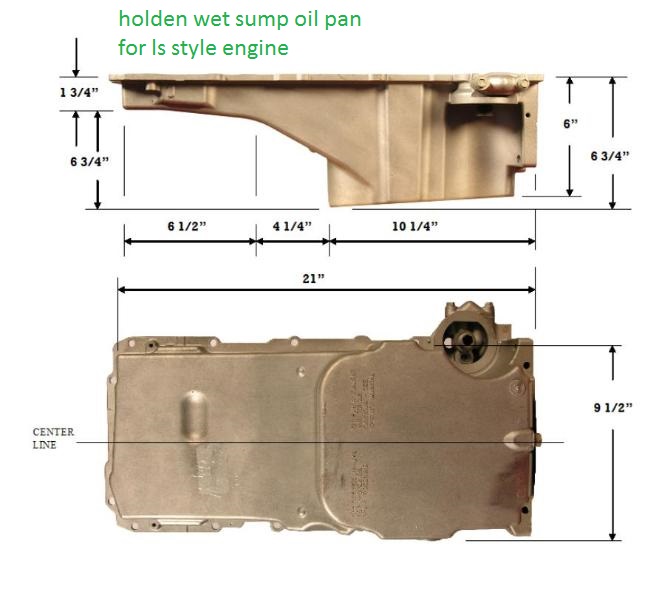

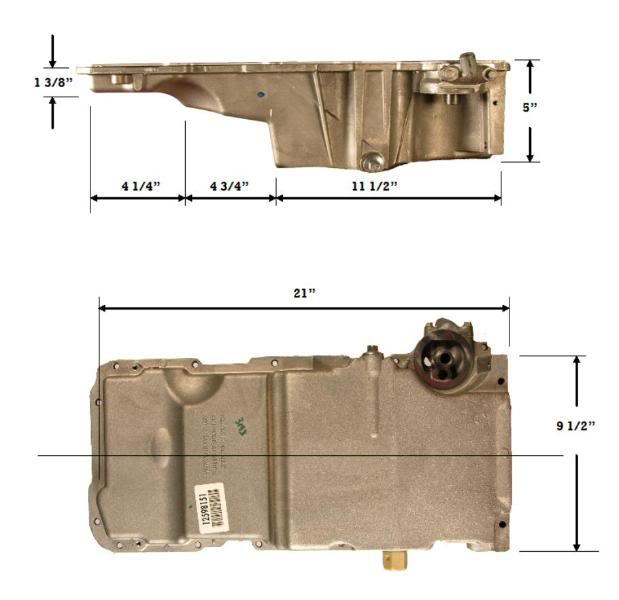

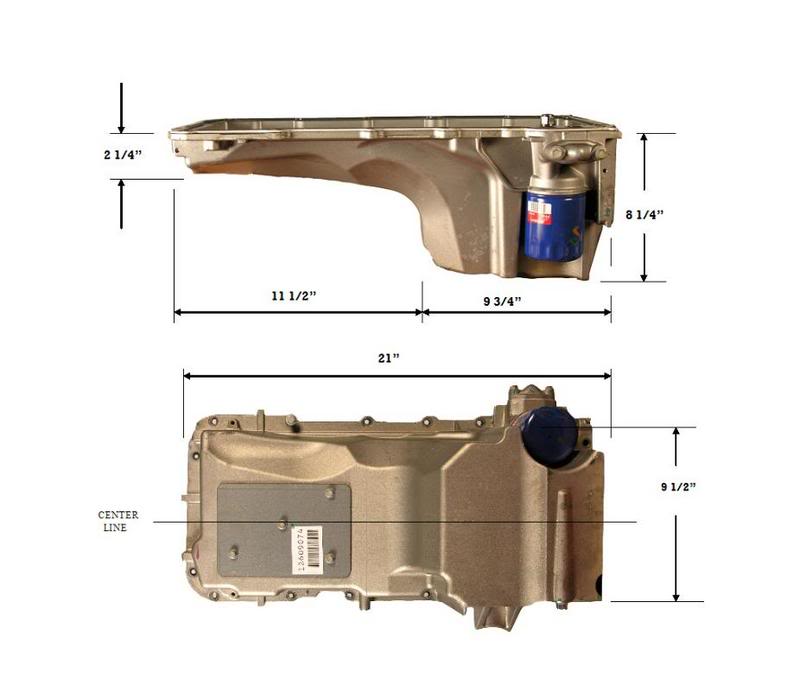

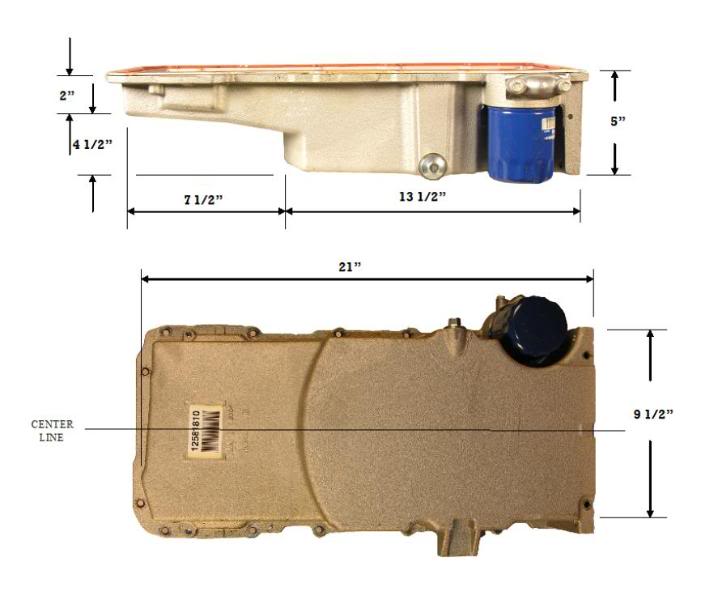

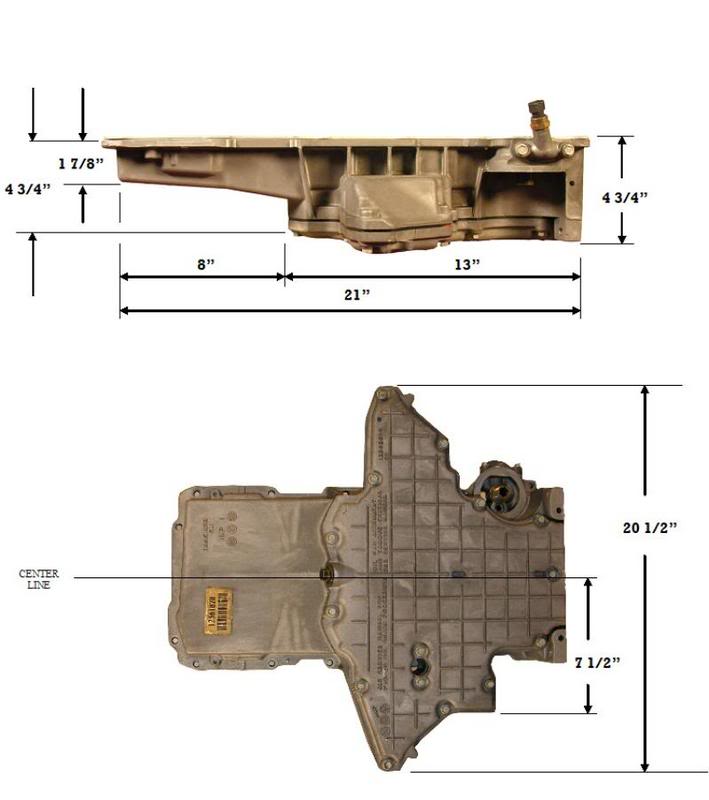

6.All Gen III truck engines use cast aluminum oil pans that are deeper than the camaro or corvette pans.

7. All intake manifolds interchange. The truck intakes are roughly 3-4 inches taller than the passenger-car intakes.

8. All Gen III engines employ reusable gaskets for sealing surfaces except for the head gaskets. This makes it much quicker and easier to service the engine.

9. There are only two intake valve sizes for all the Gen III engines. Exhaust valves are all the same diameter.

10. Truck and camaro engines use cable throttle linkage while the corvettes use an electronic throttle. There are also some SUV engines with traction control that use electronic throttle control.

11. Bellhousing patterns are the same for all Gen III engines. The crank flange is basically the same depth as the bellhousing flange.

12. The Gen III firing order has been revised from 1-8-4-3-6-5-7-2 to 1-8-7-2-6-5-4-3. Note that the pairings 1-8, 4-3, 6-5, 7-2 remain the same, but the pairing order is different for reduced vibration.

13. The valve angle on all Gen III engines is 15 degrees versus 23 degrees for the origional and Gen II small-blocks.

14. The Gen III bore spacing is the same as the origional small-block, but each cylinder is ringed with only four head bolts instead of five.

__________________

Custom Cubes:

If you are fortunate enough to get your hands on an LQ4 6.0L engine block, you can bore it .030-over and purchase a 4.250 Lunati stroker crankshaft to produce a 434ci. GenIII engine.

Add a set of GM Performance Parts ZO6 cyclinder heads (PN 12560801) or have the stock LS1 heads ported and you've got yourself a serious engine.

__________________

All information is taken from Chevy High Performance Magazine May 2002 edition.

resource, and related part info

http://www.coasthigh.com/chevy-ls-serie ... 011001.htm

http://www.edelbrock.com/automotive_new ... _ls1.shtml

http://www.cartechbooks.com/vstore/show ... apter=6065

http://www.amazon.com/How-Build-High-Pe ... 1884089844

http://www.summitracing.com/parts/HPB-HP1407/?rtype=10

http://www.campbellenterprises.com/k1-l ... shafts.php

http://www.moroso.com/eb/catalog/naviga ... eset=false

http://garage.grumpysperformance.com/index.php?threads/big-block-or-ls-series-motor.6866/#post-22294

http://www.superchevy.com/how-to/project-cars/sucp-0805-ls-engine-power-packages/

LSNext Blocks have arrived @ SDPC!!!

https://sdparts.com/category/engine-components

GOT AN LS engine swap?

http://www.mastmotorsports.com/view.php?id=160&c=49&s=7

http://www.youtube.com/watch?v=taYsbtDw ... bedded#t=1

http://www.dartheads.com/dart-news/ls-next-sneak-peeks/

https://sdparts.com/category/engine-com ... der-blocks

https://sdparts.com/category/ls-gen-iii ... erformance

http://www.dartheads.com/dart-news/ls-n ... eo-760-hp/

https://www.onallcylinders.com/2017...oductory-overview-gen-iiiiv-ls-engine-family/

https://hqconsumer.com/ls-engine-swap/

https://www.lsxmag.com/tech-stories/the-dos-and-donts-of-buying-a-used-ls-engine-for-a-project/

https://www.onallcylinders.com/2017/09/21/ls-engine-spotters-guide-cars-trucks-ls-engines/

https://www.lsxmag.com/news/everything-you-need-to-know-for-your-ls-swap/

https://www.onallcylinders.com/2017...-advice-for-ls1-mods-to-maximize-performance/

https://www.racingjunk.com/news/drag-race-101-building-an-ls-bracket-motor-from-scratch-part-i/

https://www.dragzine.com/tech-stories/10-basic-tips-to-building-your-first-ls-engine/

https://grassrootsmotorsports.com/articles/addressing-internet-myths-about-ls-swaps/

http://www.superchevy.com/how-to/engine ... -lsxr.html

http://www.carcraft.com/techarticles/cc ... sults.html

http://www.carcraft.com/techarticles/12 ... s_engines/

http://www.carcraft.com/techarticles/12 ... gine_swap/

a few tips on installing a manual trans behind an LS series engine in an older muscle car, and identifying that LS engine

http://www.carcraft.com/techarticles/14 ... r_ls_swap/

http://www.carcraft.com/techarticles/13 ... 8_engines/

http://www.carcraft.com/techarticles/14 ... _a_427_ls/

Front oxygen sensor for 2002 6L applications: 12565397

Brake booster intake manifold fitting (needed if you got your 6L engine from a truck with hydroboost, and you have a vacuum booster): 12555831

3-wire coolant temperature sensor connector: 12102748

If you want to maintain the integrity of the EVAP system:

EVAP vent valve: 15759044

EVAP vent valve connector: 12101858

Fuel tank pressure sensor connector: 88986451

Fuel system stuff:

Fuel pump module (note, will not fit in 88-95 tanks besides 4 door 95 Yukon/Tahoe): ACDelco MU146 (get it off ebay, much cheaper)

Fuel pump connector: 12167154

4L80e conversion parts:

Dipstick: 15183801

Dipstick tube: 15198439

Dust cover to use with 4.8, 5.3, 6.0L engines: 15765623

GMPP spark plug wires for LS1: 12495519

3 piece "Vortec 6000" engine cover, without hole for EGR valve on passenger side: 15006417, 15006418, 15006419

Mobil 1 oil filler cap: 12555685

If you are using a stock wiring harness and want to be able to remove it, you will need the following connectors:

C100 (engine to body harness): Delco PT1401

C152 (engine to chassis harness): GM 15306199

C153 (engine to 4WD harness): Delco PT420

6L engine gaskets/seals:

Front main seal- 12585673

Rear main seal- 12585671

Front cover gasket- 12574294

Rear cover gasket- 12574293

Top cover gasket- 12558178

Oil pan gasket- 12558760

Head gasket- 12589227

Valve cover gasket (2)- 12560696

Water pump gasket (2)- 12559271

Oil pickup tube o-ring- 12557075

6L engine internal parts:

Main bearings- 1,2,4,5: 89017469 each, 3: 89017470 each

Rod bearings-12493712 each

Valve seals- intake: 12482063 (8) , exhaust: 12482062 (8)

Valve keepers- 10166345 each

Some interesting facts about the GEN III engines including the LS1:

ENGINE: Liters: Cubic I: Bore: Stroke: Rod Length: Comp:

LR4 4.8 293 3.780 3.268 6.276 9.5

LM7 5.3 325 3.780 3.622 6.098 9.5

LS1 5.7 346 3.898 3.622 6.098 10.1

LS6 5.7 346 3.898 3.622 6.098 10.5

LQ4 6.0 364 4.00 3.622 6.098 9.4

_____________________

Engine: HP TQ Application

LR4, 4.8L 255@5,200 285@4,000 '99 Silverado

270@5,200 285@4,000

LM7, 5.3L 265@5,000 320@4,000 '99 Silverado

285@5,200 325@4,000

LS1, 5.7L 305@5,200 335@4,000 '98-99' Camaro

335@5,200 335@4,000 '98-99' SS Camaro

345@5,600 350@4,400 '97-99 Corvette

350@5,600 350@4,400 2000 Corvette

350@5,600 375@4,400 '01 Corvette

350@5,600 360@4,000 '01 Corvette Auto

310@5,200 340@4,000 '01 Camaro Auto

325@5,200 350@4,000 '01 Camaro six-speed

LS6, 5.7L 385@6,000 385@4,800 '01 Corvette

LQ4, 6.0L 300@4,800 355@4,000

300@4,400 360@4,000

all ratings are up to 2001 models

______________________________

Significant Gen III

Engineering Points:

1. All Gen III truck engines use iron blocks. Only the Camaro (F-Car) and Corvette (Y-car)LS1/LS6 engines feature aluminum blocks.

2. All Gen III engines have aluminum heads except for the '99 LQ4 engines that were equipped with iron heads. These engines received aluminum heads for the 2000 model year.

3. All Gen III engines share common main,rod,and cam-bearing journal diameters for ease of interchange. All blocks use a cross-bolted six-bolt main cap.

4. All Gen III engines are completely metric.

5. All valvetrain pieces are completely interchangable. The standard rocker ratio for all Gen III engines is 1.7:1.

6.All Gen III truck engines use cast aluminum oil pans that are deeper than the camaro or corvette pans.

7. All intake manifolds interchange. The truck intakes are roughly 3-4 inches taller than the passenger-car intakes.

8. All Gen III engines employ reusable gaskets for sealing surfaces except for the head gaskets. This makes it much quicker and easier to service the engine.

9. There are only two intake valve sizes for all the Gen III engines. Exhaust valves are all the same diameter.

10. Truck and camaro engines use cable throttle linkage while the corvettes use an electronic throttle. There are also some SUV engines with traction control that use electronic throttle control.

11. Bellhousing patterns are the same for all Gen III engines. The crank flange is basically the same depth as the bellhousing flange.

12. The Gen III firing order has been revised from 1-8-4-3-6-5-7-2 to 1-8-7-2-6-5-4-3. Note that the pairings 1-8, 4-3, 6-5, 7-2 remain the same, but the pairing order is different for reduced vibration.

13. The valve angle on all Gen III engines is 15 degrees versus 23 degrees for the origional and Gen II small-blocks.

14. The Gen III bore spacing is the same as the origional small-block, but each cylinder is ringed with only four head bolts instead of five.

__________________

Custom Cubes:

If you are fortunate enough to get your hands on an LQ4 6.0L engine block, you can bore it .030-over and purchase a 4.250 Lunati stroker crankshaft to produce a 434ci. GenIII engine.

Add a set of GM Performance Parts ZO6 cyclinder heads (PN 12560801) or have the stock LS1 heads ported and you've got yourself a serious engine.

__________________

All information is taken from Chevy High Performance Magazine May 2002 edition.

resource, and related part info

http://www.coasthigh.com/chevy-ls-serie ... 011001.htm

http://www.edelbrock.com/automotive_new ... _ls1.shtml

http://www.cartechbooks.com/vstore/show ... apter=6065

http://www.amazon.com/How-Build-High-Pe ... 1884089844

http://www.summitracing.com/parts/HPB-HP1407/?rtype=10

http://www.campbellenterprises.com/k1-l ... shafts.php

Last edited by a moderator: