Hello Grumpyvette,

I enjoy reading you posts and articles, and would like to ask your opinion on what to do. I bought a real XCH LS7 454 from a fellow. He had masking taped-close the exhaust ports and intake ports and lifter valley ( no intake manifold on it) when he stored it. We removed part of the tape on the intake/lifter valley so I could see the heads and valley. We taped it back up and loaded it into the back of my pickup truck. On the 3-hour ride home, the tape over the lifter valley came loose, and I think some debris or grit might have blown into the valley, but I cannot see it. The engine is basically ready to run minus the intake manifold and carb, and a shame that I made more work for myself by not covering it up better for the ride home. Should I try to clean it, or take it apart and make sure it is really clean before putting back together? I thought about removing the oil pan and trying to flush it out with oil or solvent. I can't see debris, but suspect something might have gotten into the crankcase. Best regards. John.

BTW This LS7 will be going into my '86 Regal TType.

posting clear detailed pictures would be very helpful but I suspect you could be reasonably safe, putting the engine on an engine stand,then pulling the oil pan plug, and pouring a gallon of mixed 50% diesel fuel and 50% cheap oil into the lifter gallery , and allowing it to drain through a cheap paint filter

if theres very little crud in the filter you should be able to replace the oil pan plug, fill the engine with quality oil,and filter, prime the oil system while slowly manually turning in several full revolutions until oil flows from all rockers,, and replace the intake, then get it ready to fire it up if everything looks good.

that said, I prefer to deal in verified fact vs guessing and assuming.

now if it was my engine I'd have pulled the oil pan, and heads and replaced the rotating assembly bearings, rings, timing chain, and flat tappet solid lifters simply because I really don,t trust anyone that a 40 plus year old engines in great shape until I verify it personally, a gasket set, rings and bearings and a quick rebuild is cheap insurance and Id sleep better. etc and checked the clearances, looked over the old components

http://garage.grumpysperformance.com/index.php?threads/oil-filters.11189/#post-54673

almost all of us are operating on a strictly limited budget, yes I'm aware,moneys tight,

but if you simply re-ring and re-bearing a low compression truck, 427 bbc,

slap those stock non-reworked 781 heads on the rebuilt short block

and swap in a mild performance cam, you'll have a myriad of problems you may not be aware of,

first the valve train geometry and clearances and valve spring load rates and rocker geometry,

and piston to valve clearance , is very unlikely to be correct.

next the heads if not reworked are not going to flow nearly as much air/fuel as they potentially might,

and the truck tall deck engines rotating assembly was designed for operation in the 1000 rpm-4000 rpm range.

the original pistons were heavy and were designed to be used in an engine with an operational rpm range similar to how a diesel engine.

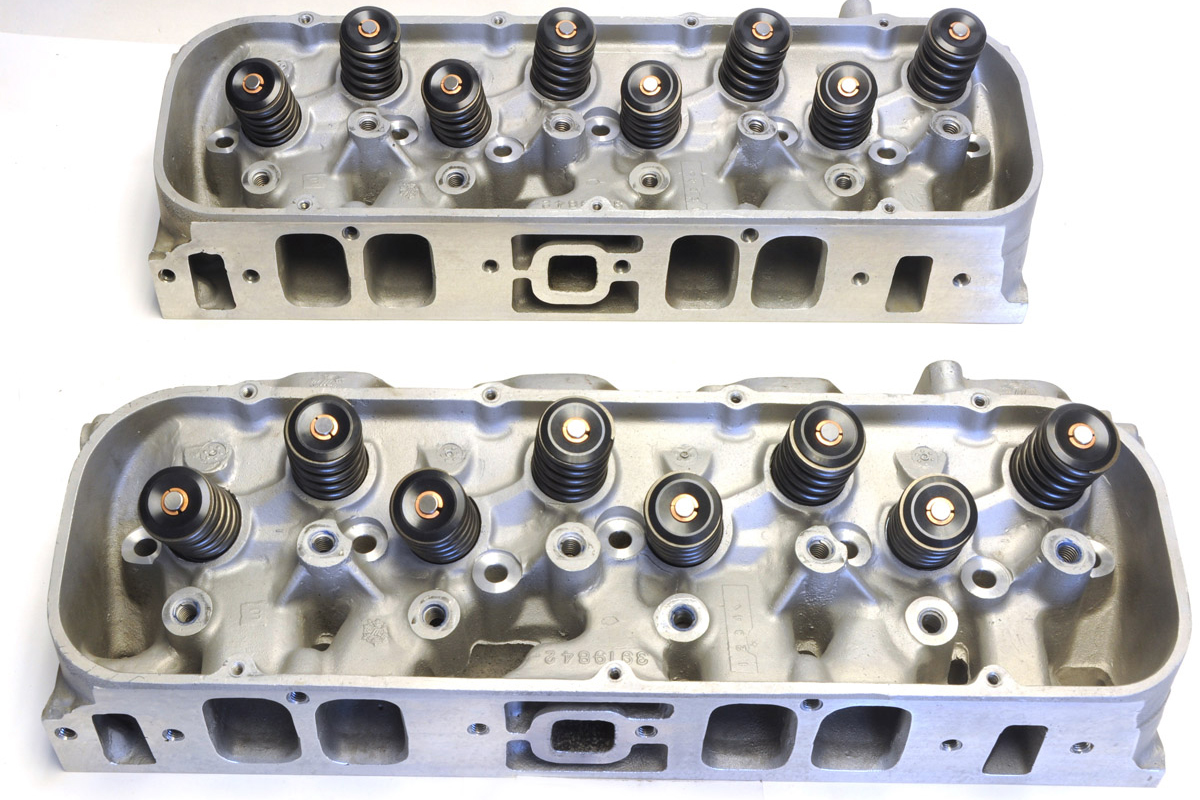

In the GM part number change book, the 3899643, 67 L88 engine assembly part number was changed to 3819831 in January of 1968.

That part number fits nicely with the new 3819838 aluminum cyl heads that were released at about the same time.

Last edited: