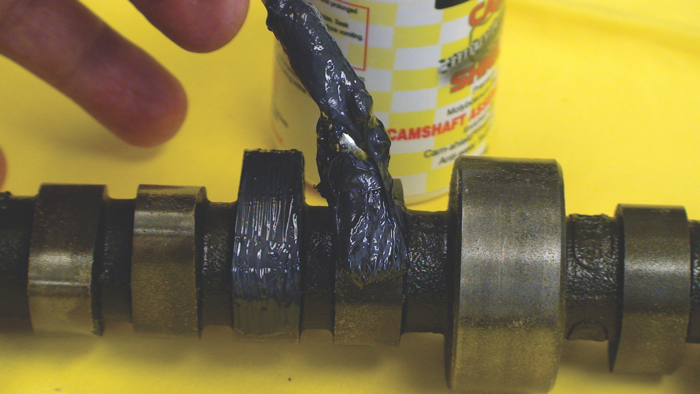

Grumpy I was reading the install directions on my new Crane cam and they suggest cleaning the cam off with mineral spirits before coating it with the supplied moly lube and installing the cam ,

any idea why?

the reason you clean the cam before covering it with the moly lube is the waxy shipping protective coating must be removed prior to the moly application so the moly can soak into the metal micro surface to protect the cams wear surface, and to remove any micro trash that might be stuck to that protective waxy shipping protective coating that was used to prevent rust in storage.(that protective waxy anti rust coating is not an ideal lubricant')

http://garage.grumpysperformance.com/index.php?threads/assembly-lube-summary.6352/#post-68508

http://garage.grumpysperformance.com/index.php?threads/moly-lube.16044/#post-96767

http://garage.grumpysperformance.com/index.php?threads/function-of-lubricants.2102/#post-5639

http://garage.grumpysperformance.com/index.php?threads/breaking-in-a-cam.798/#post-1160

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving surfaces in contact, rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on the rifle bore surface, This protective armor coating has a number of properties that are very beneficial for your rifles bore surface

moly is a bit like graphite, in that it appears to be a super fine powder suspended in a solvent carrier, that evaporates over time, put some between finger tips and rub, youll get the idea.. it spreads. like anti seize paste, and yeah it can be cleaned off hands with soapy hot water, but it gets into metal surfaces and its very dificult to remove (thats the idea)

The Moly platelets that make up the protective layers on your bore wall surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the bore to projectile surface contact

This coating effectively fills in the microscopic pores that cover the surface of all micro bore imperfections making them smoother. By filling in the craters and pores Moly improves this seal

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. The high pressures that occur between these moving surfaces that tend to squeeze normal lubricants out.