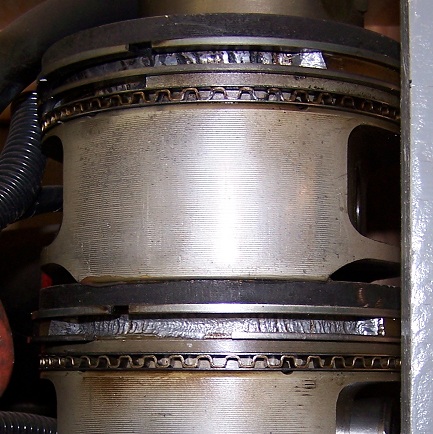

now if there's any job that's frequently ignored or avoided during an engine rebuild , its more than likely ,cleaning pistons and cleaning the grooves its high on the list!

RELATED INFO

(take advantage of millions of hours of previous engine builds, by skilled and experienced people, and the knowledge gained)

A couple days of

reading the linked and sub-linked info

could save you a great deal of wasted time and money

and money spent on wrong or un-necessary parts

read the links and sub links below

a day or so spent doing reading and research,

(reading links and threads)

will frequently save you thousands of dollars and weeks of wasted work.

if you want a fast dependable car you will need to either do the research required to know exactly how and why things should work, or pay someone else to do the work that has taken that time and effort.

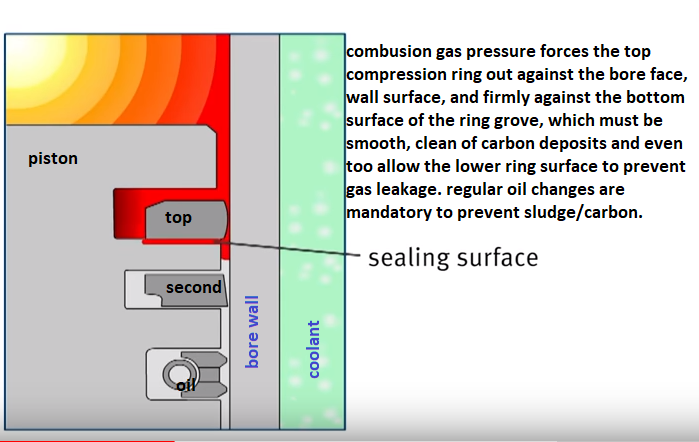

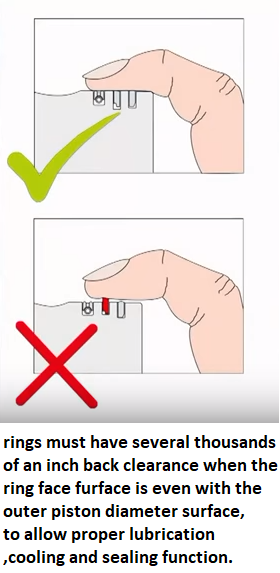

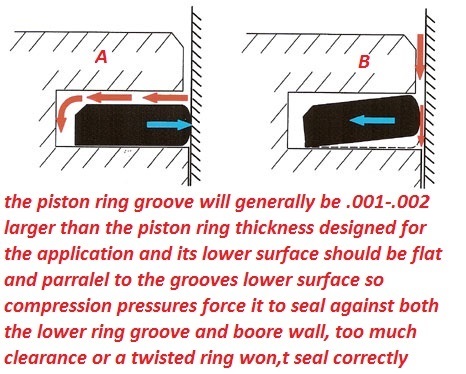

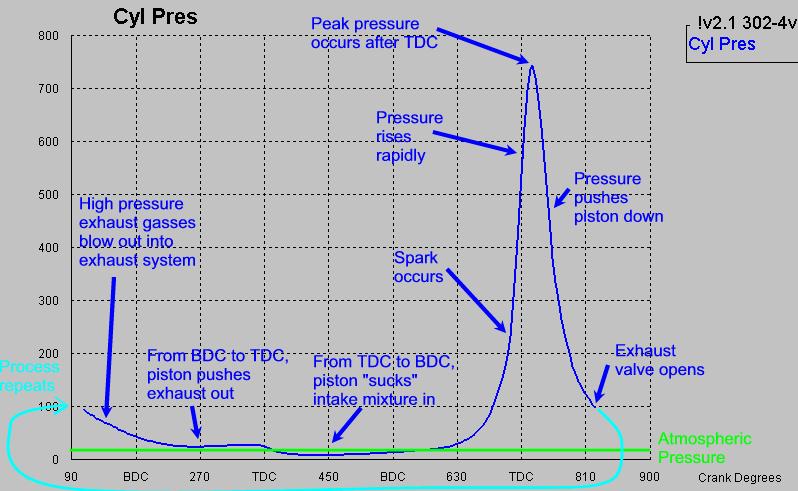

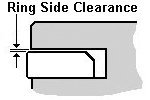

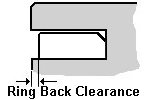

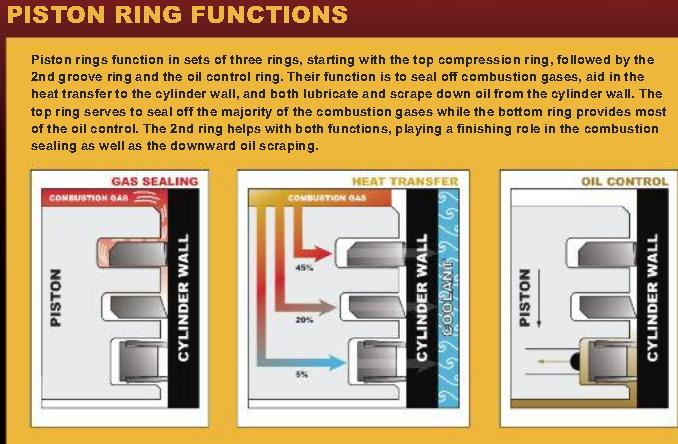

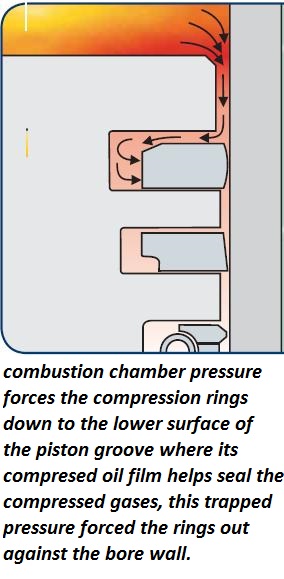

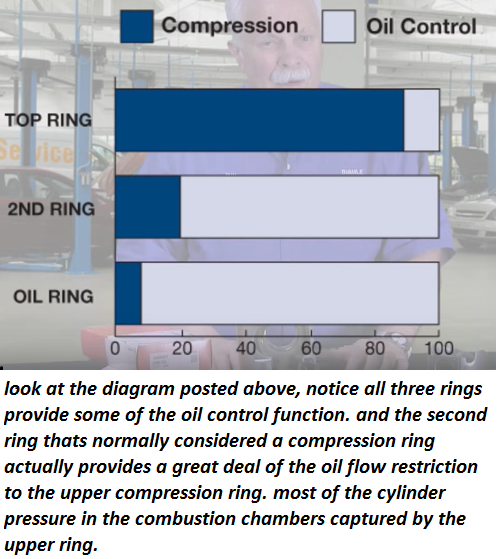

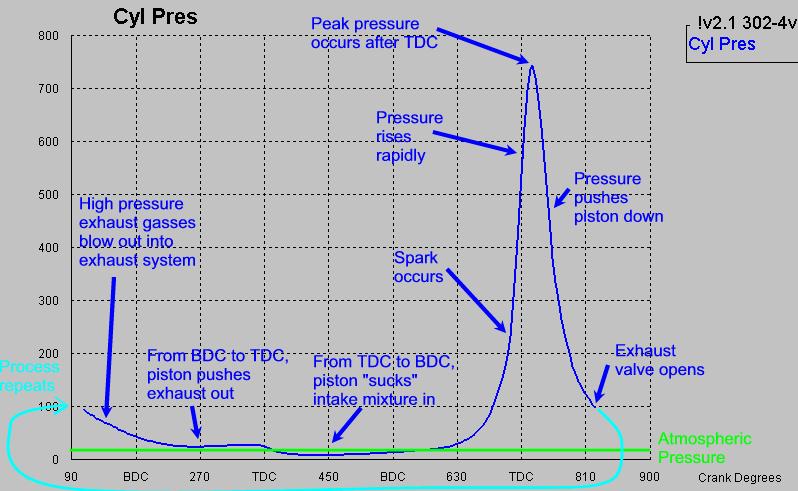

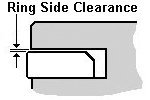

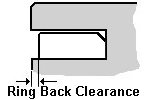

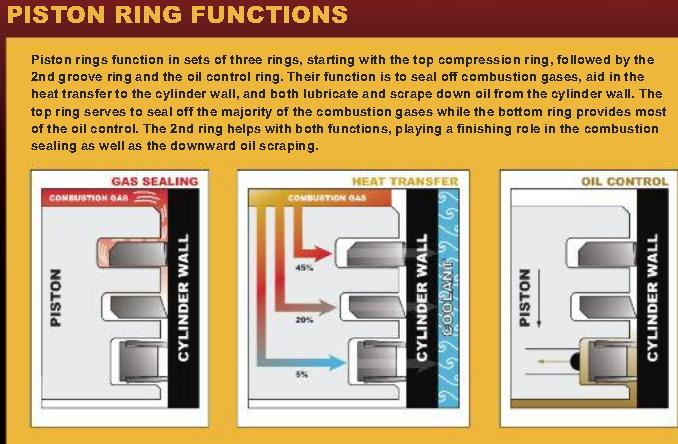

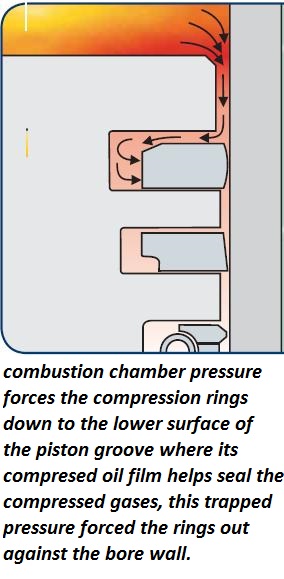

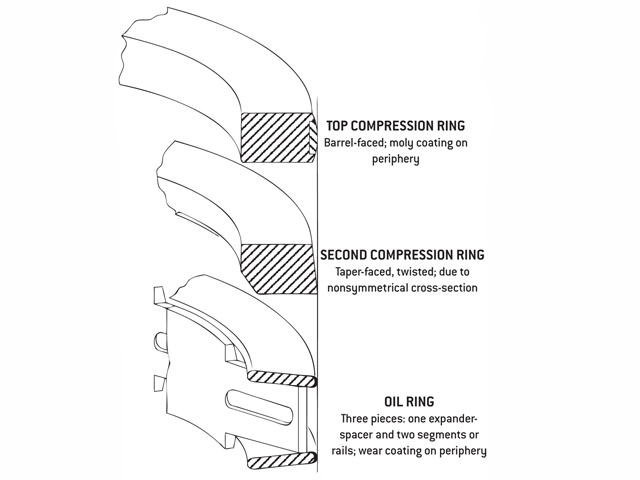

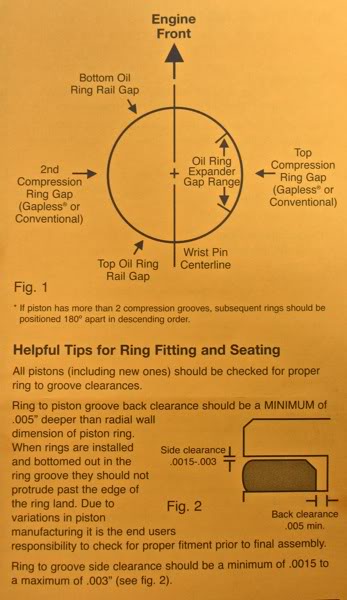

one factor I find amazing is how few guys realize that the rings MUST have space both above the ring and behind the ring in the piston grooves simply because its the hundreds of PSI of cylinder pressure that first forces the ring into the bottom of its groove then the pressure gets behind the ring and tends to expand it and hold it into the bore that is a huge factor in how effective the ring seals combustion pressure in the combustion chamber, if the clearances are filled with carbon build up the rings loose a great deal of there ability to seal.

ideally the pressure above the piston gets behind the top compression ring and increases the force holding the ring face to the bore surface, noticeably;y more than the ring tension alone can do.

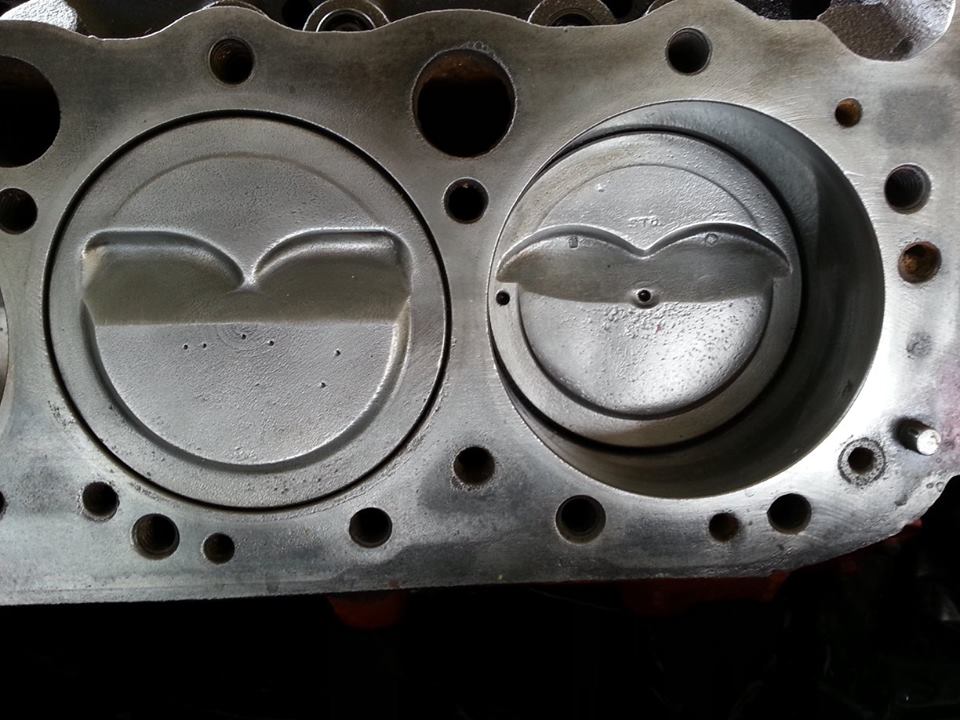

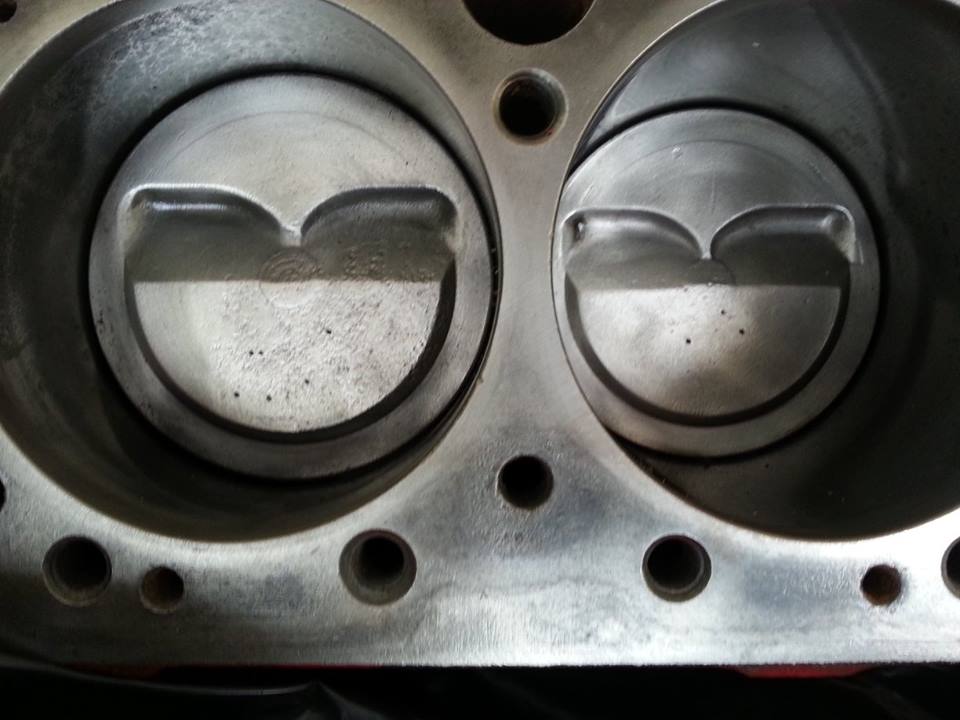

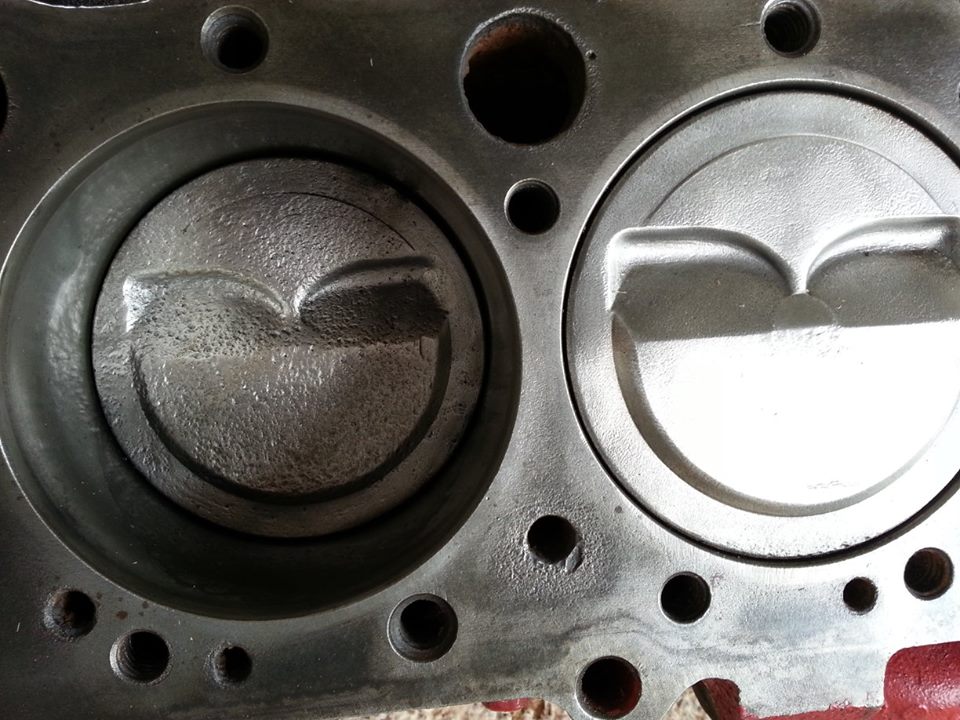

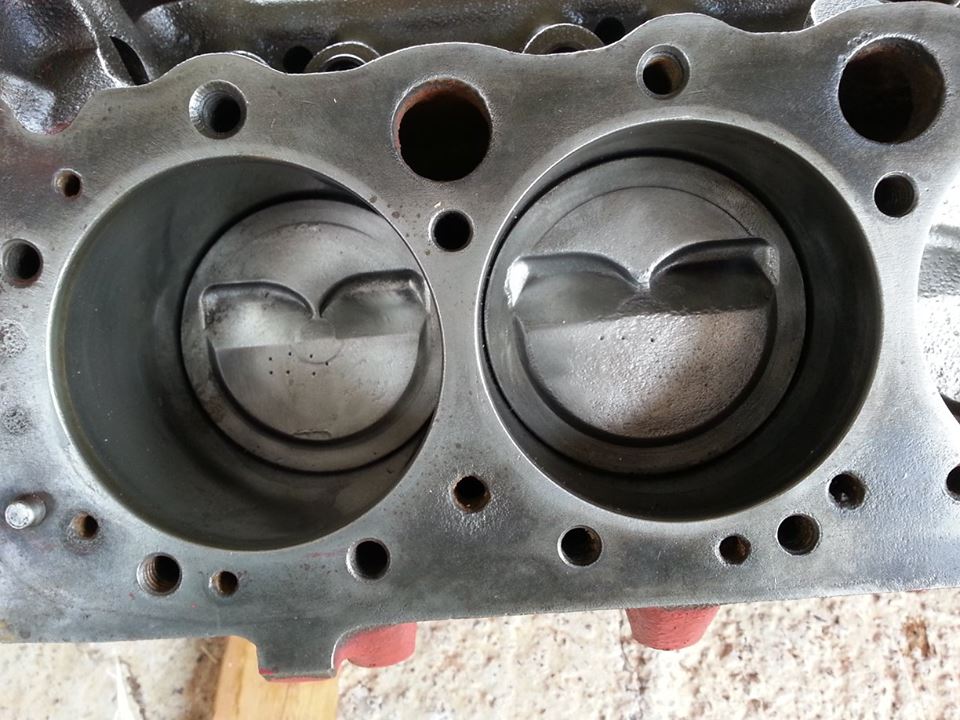

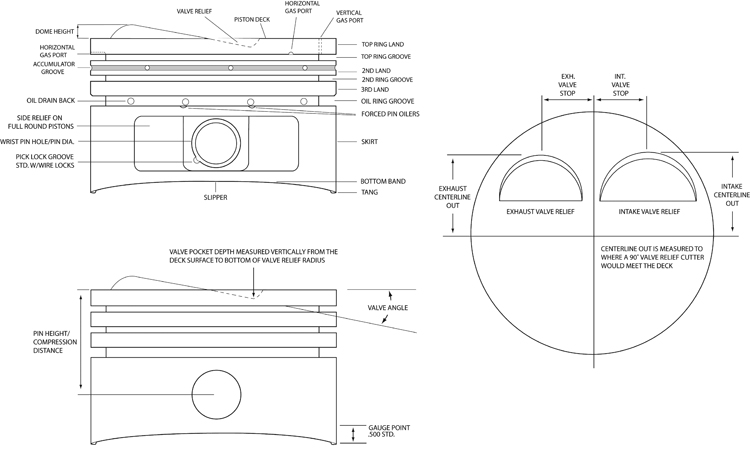

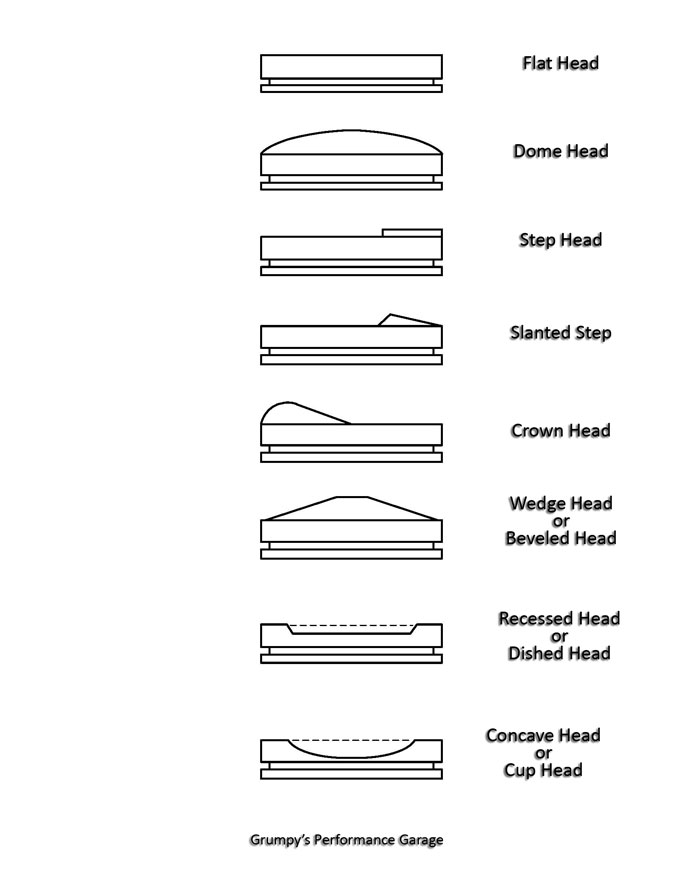

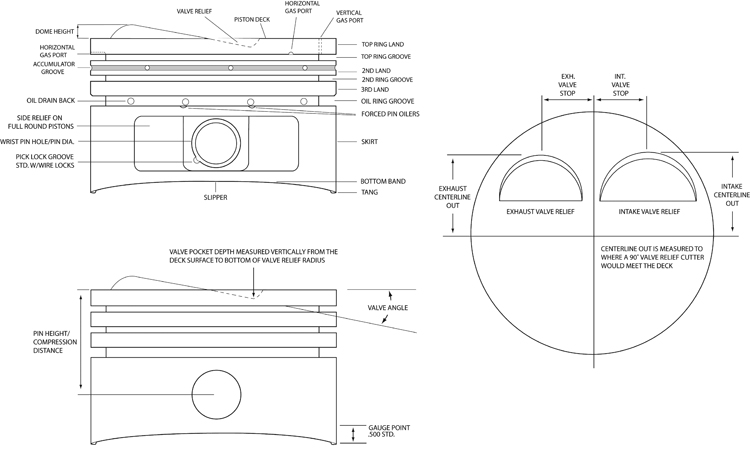

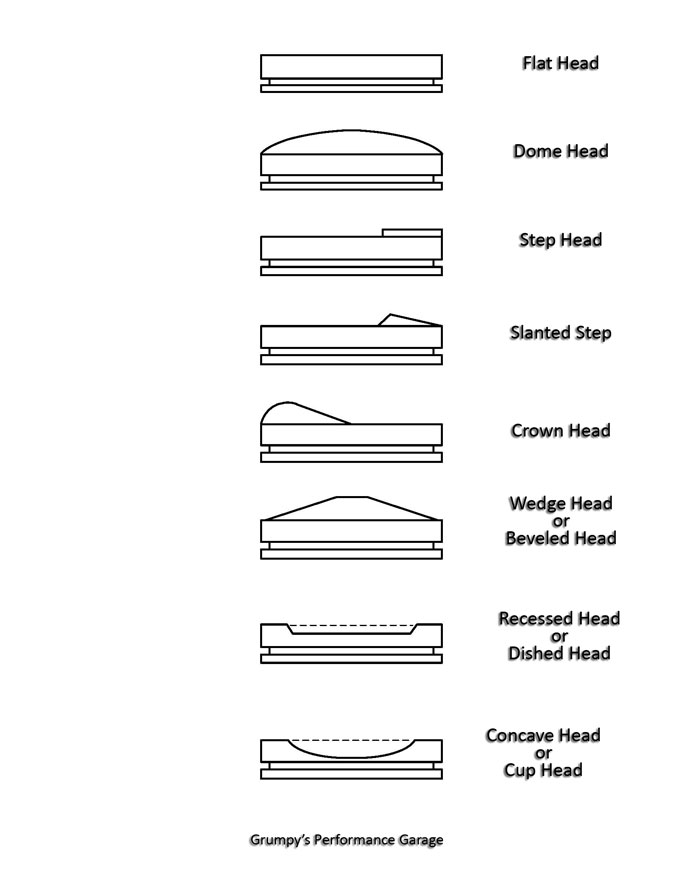

types of piston dome configurations

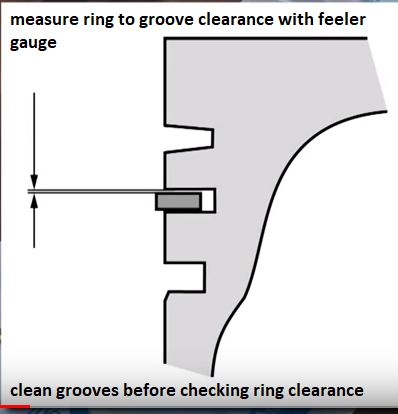

most used pistons need to be carefully inspected and cleaned, soaking them over night in a carbon solvent like a mix of carb cleaner and diesel fuel and using a stiff plastic brush will do a good job on mildly dirty pistons with some "elbow grease" considerable rubbing but you need to use the proper size groove cutting tool to remove the built up carbon from the rear area of the piston grooves at times and you don,t want to enlarge or damage the grooves surfaces because that potentially has a huge effect of ring seal.

rings must be able to retract fully flush with the pistons outer diam. without the ring ends butting or there being no room for high pressure gasses to get in behind the ring to help them seal on the bore.

having access to a decent parts washer HELPS

viewtopic.php?f=27&t=2886&p=7599&hilit=+parts+washer#p7599

step one

READ AND UNDERSTAND THE MANUFACTURERS INSTRUCTIONS

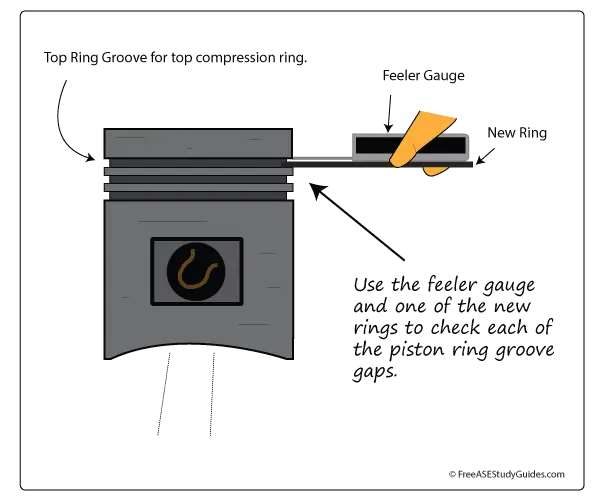

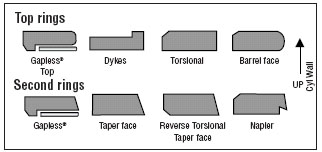

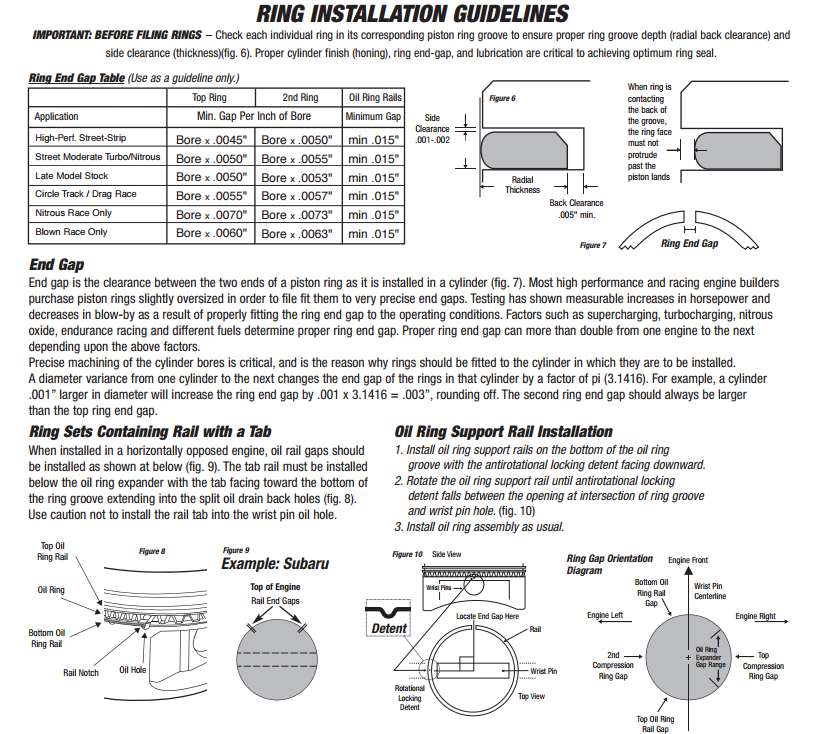

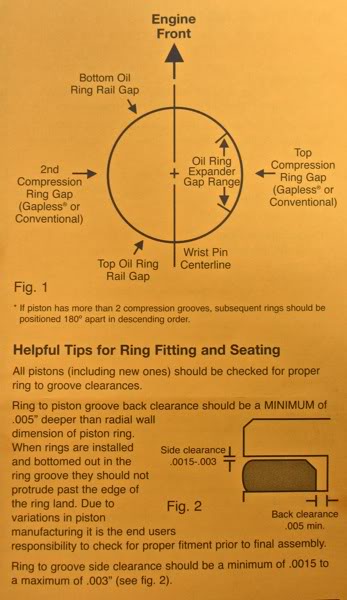

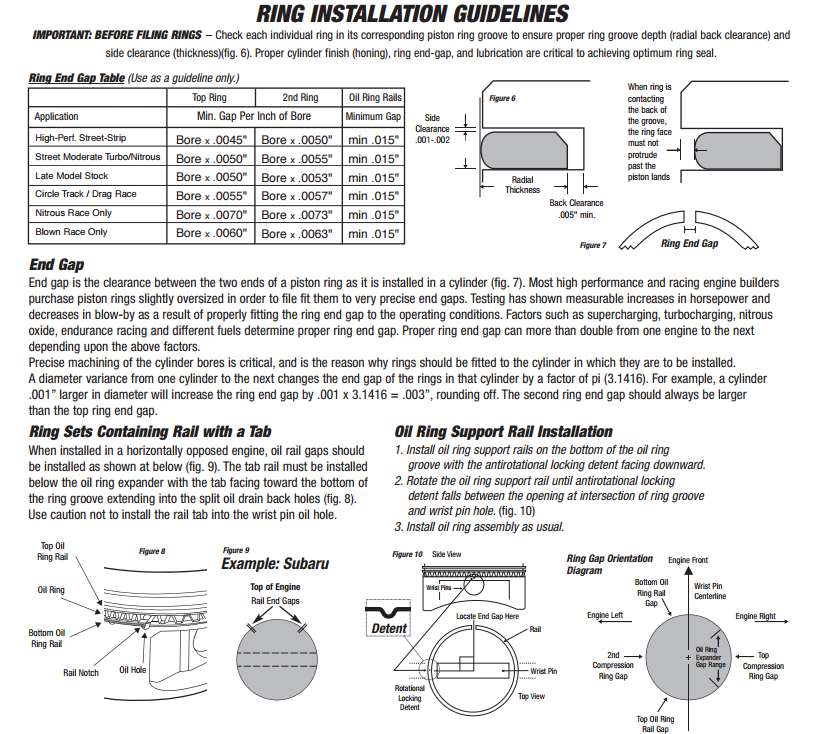

make damn sure the rings you buy are designed for and correctly fit the piston groove design your working with, and you understand the clearance issues, those change with the intended heat range and engine combo, example hyper eutectic pistons require a good deal larger end gap than forged pistons, and use of nitrous will require a larger clearance still.

step two

make sure the rings are properly installed with the correct side facing up and the correct end gap has been measured and checked carefully,

step three

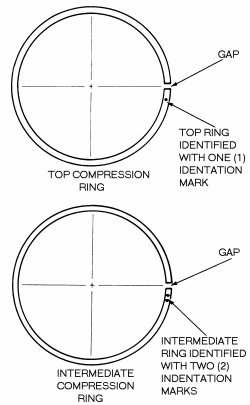

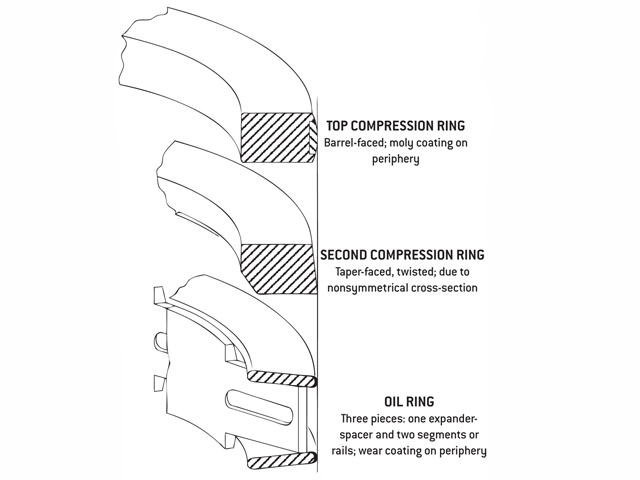

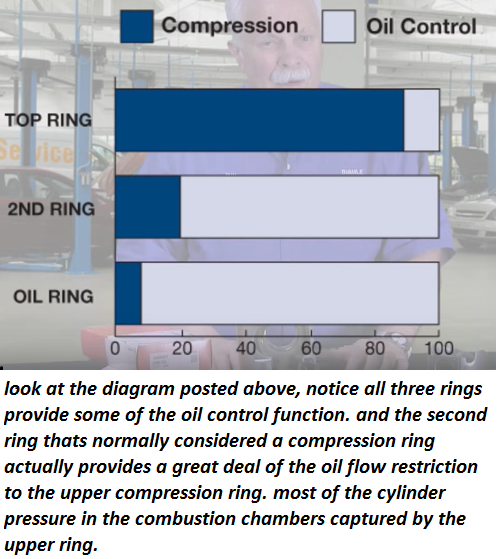

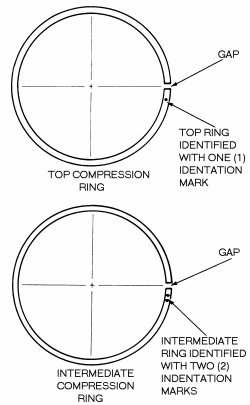

make sure the top ring gets placed in the top groove and the second ring gets placed in the second groove because in many cases THEY ARE NOT INTERCHANGEABLE

its just not that important in most guys list of things to do, but you might be very surprised at the difference in performance clean and properly installed rings in properly prepared ring grooves have on performance results.

now Im sure most guys say ,"why bother a broken piston ring can be used to scrape out the carbon build up where the old rings were after they are removed and soaking in diesel fuel for a few hours tends to loosen the baked on carbon fouling.

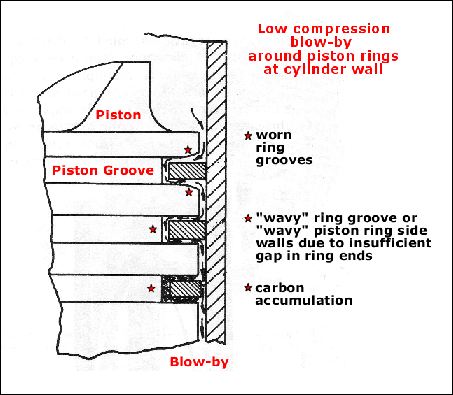

what many guys don,t understand is its not just the tension the piston rings exert on the bore walls that seats and seals the rings to the bore wall, but high pressure gases that force the ring to the floor of its groove and get behind the ring and press it out against the bore that do much of the sealing on the top piston ring, a job that can,t function if the correct clearances don,t exist or if those clearances are filled with carbon or oil sludge, or varnish from burnt oil residue,

so use of a cleaning tool , the correct back clearance, room for the high pressure gasses to get behind the top ring and proper oils with high detergents that burn with little ash residue are critical for proper long term function.

naturally the ring selected and its design will effect the proper ring seal, the cylinder wall hone and the bore condition will also need to be considered.

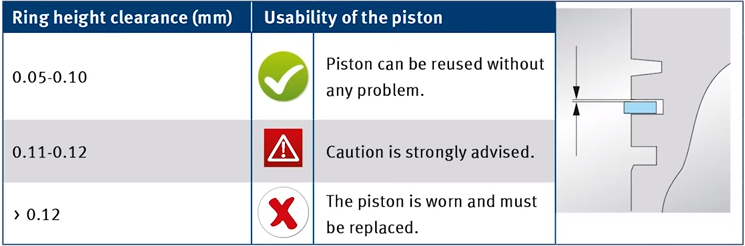

get the ring groove to large and inconsistent and the ring flutter/ or movement will hammer the ring groove, get it to small and there's a good chance the ring will bind in the groove, if there's not enough clearance behind the ring it tends to seal poorly, if the rings not end gaped correctly it may bind in the bore and yank the top of the piston off or at least crack the ring lands

soaking a piston you've removed from an engine in a 5 gallon bucket of 50%/50% mix of diesel fuel and carb cleaner for a few minutes to a 1/2 hour , before you start cleaning the crud off it usually helps a great deal to soften the crud built up on it

BTW rings generally have a mark or (DOT) on the side that faces up or a bevel that faces up on the inner upper rim

remember that when you go to re-install the compressed piston rings, and piston in the engine block,bores that dunking the piston in MARVEL MYSTERY OIL , just before, its slid into the ring compressor will coat the rings and bore contact areas enough to prevent many small problems that insufficient lube might case

http://kb-silvolite.com/calc.php

http://kb-silvolite.com/article.php?action=read&A_id=56

http://kb-silvolite.com/article.php?action=read&A_id=32

viewtopic.php?f=53&t=5454&p=16301&hilit=clean+piston+groove#p16301

http://kb-silvolite.com/article.php?action=read&A_id=7

viewtopic.php?f=53&t=247

http://kb-silvolite.com/article.php?action=read&A_id=6

http://kb-silvolite.com/article.php?action=read&A_id=5

http://www.carcraft.com/techarticles/pi ... index.html

http://www.jepistons.com/dept/tech/dl/p ... rc4032.pdf

http://www.jepistons.com/dept/tech/dl/p ... rc2618.pdf

http://www.ask.com/bar?q=correctly+clea ... mance.aspx

http://buy1.snapon.com/catalog/item.asp ... up_ID=1596

http://www.tpub.com/engine2/en2-58.htm

cheap but functional

http://www.sjdiscounttools.com/lis24000.html

http://toolsandmore.us/index.asp?PageAc ... ProdID=237

viewtopic.php?f=53&t=2795

http://www.tpub.com/content/airconditio ... 140194.htm

http://www.totalseal.com/TechPage.aspx# ... sPistRings

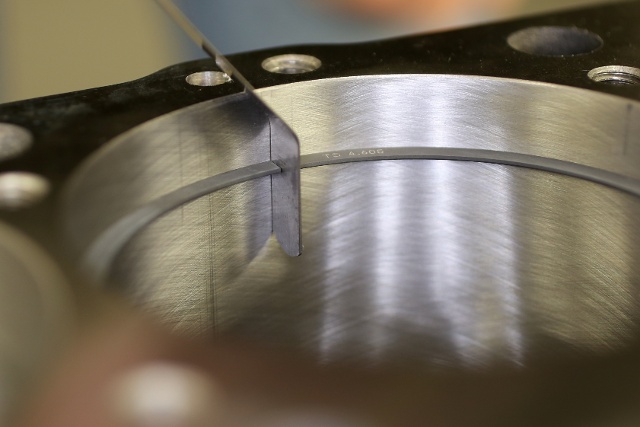

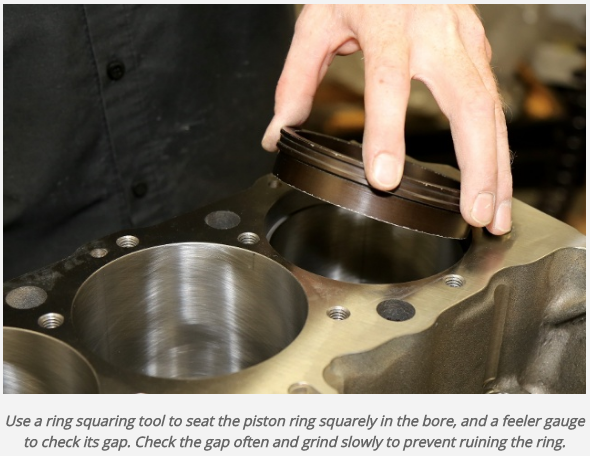

MEASURING RING END GAP

ball hones are fast and easy, to use but have the problem that they easily follow non-round cylinder surfaces, rather than tend to keep the cylinders surface flat and concentric like the bar hone design

RELATED INFO

(take advantage of millions of hours of previous engine builds, by skilled and experienced people, and the knowledge gained)

A couple days of

reading the linked and sub-linked info

could save you a great deal of wasted time and money

and money spent on wrong or un-necessary parts

read the links and sub links below

a day or so spent doing reading and research,

(reading links and threads)

will frequently save you thousands of dollars and weeks of wasted work.

if you want a fast dependable car you will need to either do the research required to know exactly how and why things should work, or pay someone else to do the work that has taken that time and effort.

one factor I find amazing is how few guys realize that the rings MUST have space both above the ring and behind the ring in the piston grooves simply because its the hundreds of PSI of cylinder pressure that first forces the ring into the bottom of its groove then the pressure gets behind the ring and tends to expand it and hold it into the bore that is a huge factor in how effective the ring seals combustion pressure in the combustion chamber, if the clearances are filled with carbon build up the rings loose a great deal of there ability to seal.

ideally the pressure above the piston gets behind the top compression ring and increases the force holding the ring face to the bore surface, noticeably;y more than the ring tension alone can do.

types of piston dome configurations

most used pistons need to be carefully inspected and cleaned, soaking them over night in a carbon solvent like a mix of carb cleaner and diesel fuel and using a stiff plastic brush will do a good job on mildly dirty pistons with some "elbow grease" considerable rubbing but you need to use the proper size groove cutting tool to remove the built up carbon from the rear area of the piston grooves at times and you don,t want to enlarge or damage the grooves surfaces because that potentially has a huge effect of ring seal.

rings must be able to retract fully flush with the pistons outer diam. without the ring ends butting or there being no room for high pressure gasses to get in behind the ring to help them seal on the bore.

having access to a decent parts washer HELPS

viewtopic.php?f=27&t=2886&p=7599&hilit=+parts+washer#p7599

step one

READ AND UNDERSTAND THE MANUFACTURERS INSTRUCTIONS

make damn sure the rings you buy are designed for and correctly fit the piston groove design your working with, and you understand the clearance issues, those change with the intended heat range and engine combo, example hyper eutectic pistons require a good deal larger end gap than forged pistons, and use of nitrous will require a larger clearance still.

step two

make sure the rings are properly installed with the correct side facing up and the correct end gap has been measured and checked carefully,

step three

make sure the top ring gets placed in the top groove and the second ring gets placed in the second groove because in many cases THEY ARE NOT INTERCHANGEABLE

its just not that important in most guys list of things to do, but you might be very surprised at the difference in performance clean and properly installed rings in properly prepared ring grooves have on performance results.

now Im sure most guys say ,"why bother a broken piston ring can be used to scrape out the carbon build up where the old rings were after they are removed and soaking in diesel fuel for a few hours tends to loosen the baked on carbon fouling.

what many guys don,t understand is its not just the tension the piston rings exert on the bore walls that seats and seals the rings to the bore wall, but high pressure gases that force the ring to the floor of its groove and get behind the ring and press it out against the bore that do much of the sealing on the top piston ring, a job that can,t function if the correct clearances don,t exist or if those clearances are filled with carbon or oil sludge, or varnish from burnt oil residue,

so use of a cleaning tool , the correct back clearance, room for the high pressure gasses to get behind the top ring and proper oils with high detergents that burn with little ash residue are critical for proper long term function.

naturally the ring selected and its design will effect the proper ring seal, the cylinder wall hone and the bore condition will also need to be considered.

get the ring groove to large and inconsistent and the ring flutter/ or movement will hammer the ring groove, get it to small and there's a good chance the ring will bind in the groove, if there's not enough clearance behind the ring it tends to seal poorly, if the rings not end gaped correctly it may bind in the bore and yank the top of the piston off or at least crack the ring lands

soaking a piston you've removed from an engine in a 5 gallon bucket of 50%/50% mix of diesel fuel and carb cleaner for a few minutes to a 1/2 hour , before you start cleaning the crud off it usually helps a great deal to soften the crud built up on it

BTW rings generally have a mark or (DOT) on the side that faces up or a bevel that faces up on the inner upper rim

remember that when you go to re-install the compressed piston rings, and piston in the engine block,bores that dunking the piston in MARVEL MYSTERY OIL , just before, its slid into the ring compressor will coat the rings and bore contact areas enough to prevent many small problems that insufficient lube might case

http://kb-silvolite.com/calc.php

http://kb-silvolite.com/article.php?action=read&A_id=56

http://kb-silvolite.com/article.php?action=read&A_id=32

viewtopic.php?f=53&t=5454&p=16301&hilit=clean+piston+groove#p16301

http://kb-silvolite.com/article.php?action=read&A_id=7

viewtopic.php?f=53&t=247

http://kb-silvolite.com/article.php?action=read&A_id=6

http://kb-silvolite.com/article.php?action=read&A_id=5

http://www.carcraft.com/techarticles/pi ... index.html

http://www.jepistons.com/dept/tech/dl/p ... rc4032.pdf

http://www.jepistons.com/dept/tech/dl/p ... rc2618.pdf

http://www.ask.com/bar?q=correctly+clea ... mance.aspx

http://buy1.snapon.com/catalog/item.asp ... up_ID=1596

http://www.tpub.com/engine2/en2-58.htm

cheap but functional

http://www.sjdiscounttools.com/lis24000.html

http://toolsandmore.us/index.asp?PageAc ... ProdID=237

viewtopic.php?f=53&t=2795

http://www.tpub.com/content/airconditio ... 140194.htm

http://www.totalseal.com/TechPage.aspx# ... sPistRings

MEASURING RING END GAP

ball hones are fast and easy, to use but have the problem that they easily follow non-round cylinder surfaces, rather than tend to keep the cylinders surface flat and concentric like the bar hone design

Last edited by a moderator: