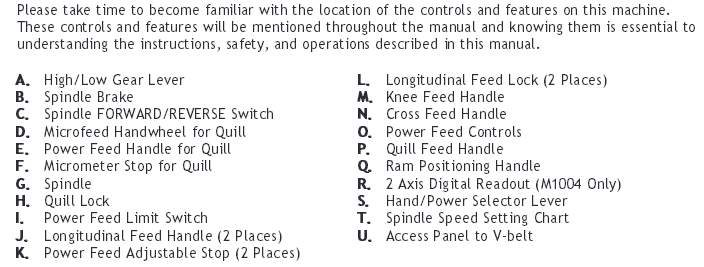

http://www.grizzly.com/products/g6760

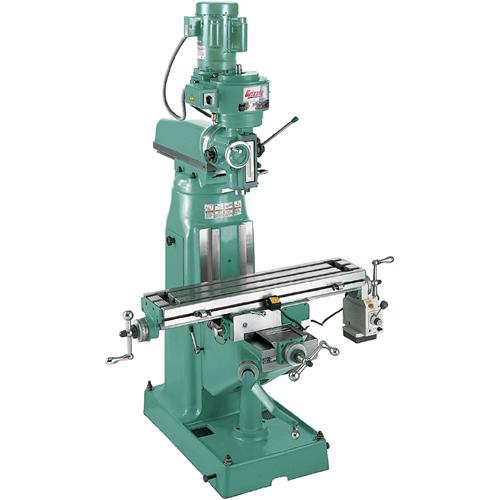

http://www.grizzly.com/products/g3617

http://www.grizzly.com/products/g3616

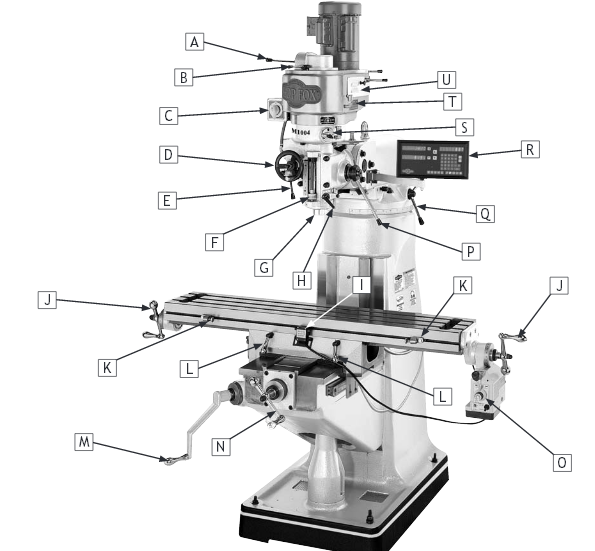

LOOKING AT THESE FOR THE SHOP......COMMENTS , COMPARING THEM OR OPTIONS WELCOME

the problem in my case has always been that I know how to do the work, how to use the tools and get half insane when I see the pathetic quality of work and the absurdly high cost a few machine shops charge you.

yes I could have spent the money I spent on tools and had several nice cars completed and been far ahead cost wise, but ordering parts and bolting them together or paying 5 times what the works worth, to get shoddy work quality back after waiting for far longer that it should take,makes me insane.

I saved for years to get a MILL and got one 5 years ago.

Ive constantly upgraded welders and Ive had several good drill presses for decades, I looked for a used mill for years but never found one at a decent price that looked like it had much life left, most were worn out or seldom used but well rusted, and keep in mind the end mills or bits, chucks, clamps, and drill bits , vises etc. can cost THOUSANDS more than the mill alone costs

viewtopic.php?f=50&t=9191&p=43136#p43136

http://www.grizzly.com/products/g3617

http://www.grizzly.com/products/g3616

LOOKING AT THESE FOR THE SHOP......COMMENTS , COMPARING THEM OR OPTIONS WELCOME

the problem in my case has always been that I know how to do the work, how to use the tools and get half insane when I see the pathetic quality of work and the absurdly high cost a few machine shops charge you.

yes I could have spent the money I spent on tools and had several nice cars completed and been far ahead cost wise, but ordering parts and bolting them together or paying 5 times what the works worth, to get shoddy work quality back after waiting for far longer that it should take,makes me insane.

I saved for years to get a MILL and got one 5 years ago.

Ive constantly upgraded welders and Ive had several good drill presses for decades, I looked for a used mill for years but never found one at a decent price that looked like it had much life left, most were worn out or seldom used but well rusted, and keep in mind the end mills or bits, chucks, clamps, and drill bits , vises etc. can cost THOUSANDS more than the mill alone costs

viewtopic.php?f=50&t=9191&p=43136#p43136