Its a fact of life that if you start pushing the engine performance to its limits that youll eventually have components fail, and that can get expensive rapidly.

But parts rarely just "FAIL" theres usually a REASON that parts fail,that can be traced to the CAUSE, thru a careful inspection.

the cause is frequently, use of the wrong component for the application, miss matched components ,improper installation, improper clearances , or lack of proper lubrication , or cooling ,are high on the list, but there's an opportunity to learn what went wrong and what process or clearance issue, lack of cooling or lubrication,or improper tuning caused the part to fail!

post very clear pictures of all damaged components, and theres a good chance the CAUSE will be indicated, by the type of failure or damage

if you don,t understand why a part failed and just blindly replace it, your certainly going to have similar failures operation under similar conditions with similar parts.

cams, lifters,rockers, valve springs, pistons, bearings and rings are the parts that generally take the most abuse so these components are the ones that tend to fail.

Having a constant flow of fairly cool, pressurized oil bathe over the surfaces of the moving components, keeping the coolant level below 210F most of the time and keeping the stress levels within reasonable limits reduces failures.

a great many people concentrate on installing things like radical cam profiles without taking the time to verify clearances, spring pressures, etc. thats a bit like building a car to go 150mph with out a seconds thought to having decent brakes and suspension, and its eventually going to result in problems in both cases.

If you are careful and inspect damaged parts you will frequently find the cause of the failure is obvious, some times its simply a lack of understanding of how to measure clearances

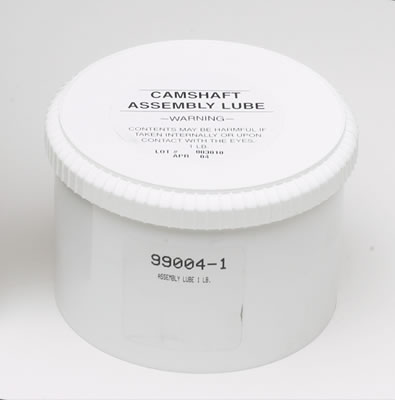

BTW Ive seen guys advise the use of lithium axle grease as bearing assembly lube on cams, lifters rockers and bearings occasionally, at times , this is VERY BAD ADVICE , ITS SIMPLY the wrong lubricant to be used, when guys substitute white lithium bearing grease for moly assembly lube, (white lithium bearing grease) is generally not automotive oil soluble,its a soap base grease, that clumps up like old peanut butter in the oil pan, and it quickly plugs oil passages, in lifters and, clogs filter mediums in oil filters, and can and does completely clog shrapnel screens causing oil to, fail to drain back into the oil pan sump, and it can and will clog oil pump pick-up screens

EXAMPLE

ASSEMBLY LUBE USED ON CAMS AND LIFTERS ROCKERS< BEARINGS ETC. like CRANE CAM LUBE, has molybdenium disulfide in assembly lube, that helps maintain a strong heat resistant high pressure lubricating support film on sliding surfaces,

BUT assembly lube is NOT INTERCHANGEABLE WITH MOLY AXLE GREASE

which has other ADDITIVES, in some cases its mixed with non-compatible lithium grease base,

you must use a moly based assembly lube thats designed to mix with automotive oil to provide a strong surface film on sliding surfaces

obviously buying an oil filter can opener tool, and doing some close personal inspection of what your dealing with won,t hurt.

http://www.summitracing.com/parts/sum-900510/overview/

http://www.homedepot.com/s/paint+filter?NCNI-5

almost any auto paint store and most hardware stores sell these disposable throw away paint strainer filters , that cost about 20-35 cents each, or a bit less in bulk packs, honestly I don,t see why most guys don,t invest the dollar it takes for a magnet and a couple filters

heres a helpful diagnostic tool,(the oil filter cutter pictured below) and yes I still cut open the oil filters and inspect the filter element on my cars oil filter [/color]

http://www.summitracing.com/parts/pro-66490/overview/

http://en.wikipedia.org/wiki/Lithium-based_grease

http://www.summitracing.com/parts/sum-900013/overview/

http://www.summitracing.com/parts/sum-900012/overview/

viewtopic.php?f=53&t=2726

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=2727

viewtopic.php?f=53&t=9490

viewtopic.php?f=51&t=2919

viewtopic.php?f=52&t=7716&p=38047&hilit=busted+valve#p38047

viewtopic.php?f=50&t=5893&p=35134&hilit=busted+valve#p35134

viewtopic.php?f=52&t=6237&p=31799&hilit=busted+valve#p31799

viewtopic.php?f=44&t=4712&p=12798&hilit=busted+valve#p12798

viewtopic.php?f=52&t=181&p=9294&hilit=busted+valve#p9294

viewtopic.php?f=53&t=341

viewtopic.php?f=54&t=1479&p=35245&hilit=groove+bore#p35245

viewtopic.php?f=50&t=2883&p=31941&hilit=groove+bore#p31941

viewtopic.php?f=54&t=1479&p=23822&hilit=groove+bore#p23822

viewtopic.php?f=53&t=4690