You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

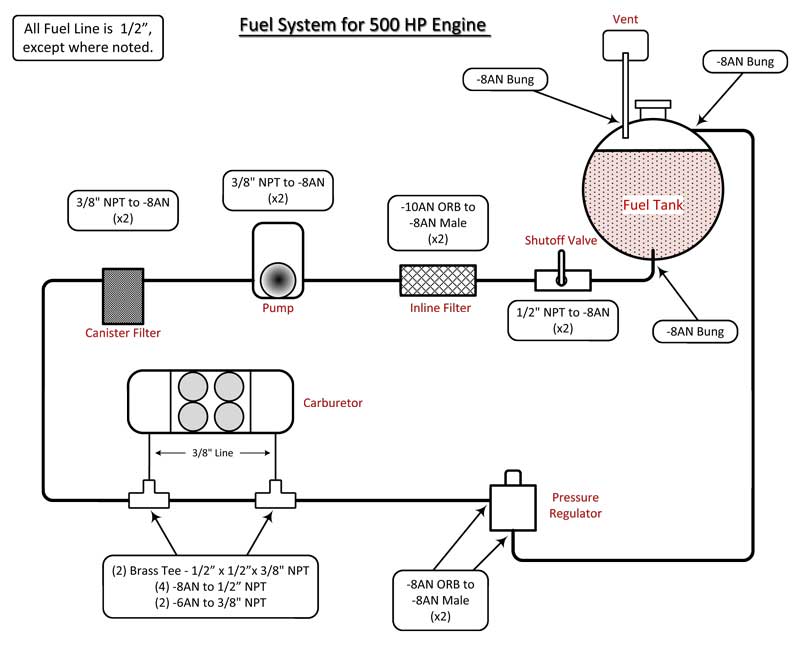

Component Selection & Design for 500 HP Fuel System

- Thread starter Indycars

- Start date

its been my experience in every test, that Ive tried it on with cars, that the regulator mounted after the fuel rail produces better results

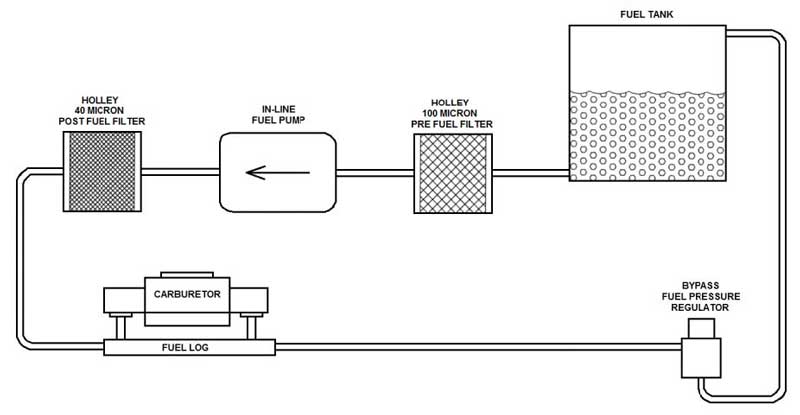

Below is the components I have decided to use in my fuel system. Now I'm working

out ALL the AN fittings that will be needed to connect it together. When I get all

the final details worked out I will post that also.

I'm going to pull the 3/8" line out of the frame and put in 1/2", the more I think

about it, it shouldn't be much more work really.

I'm also going to purchase 37° flaring tool.

Last edited:

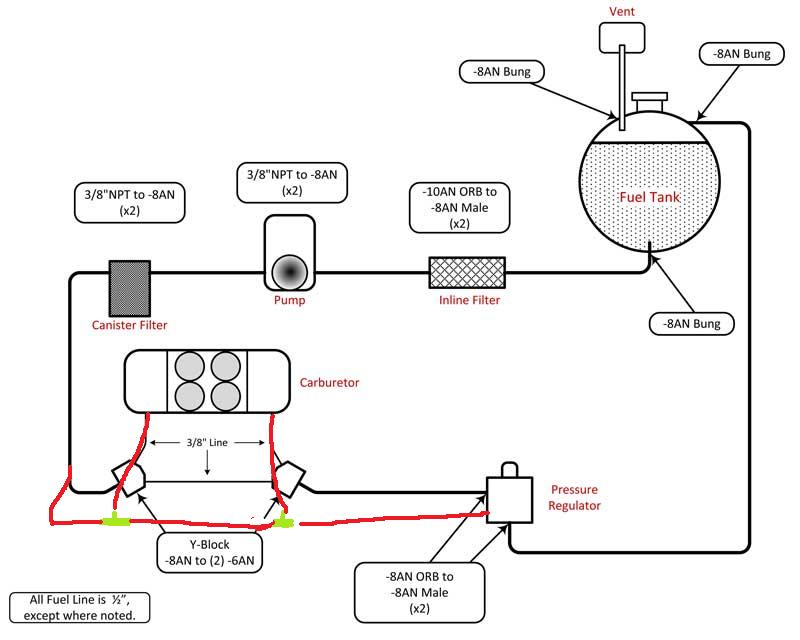

I'm working out the connections for the carburetor. It seem to me one these would

be a lot more restrictive than using a Y-Block and bending my own 3/8" lines to

each float bowls.

Anyone have any experience with using these components.

MORE RESTRICTIVE:

$31.13

http://www.summitracing.com/parts/dem-140057

$69.99

http://www.summitracing.com/parts/aaf-all26158

LESS RESTRICTIVE:

Both Y-Blocks are both 1/2" inlet and 3/8" outlets to each float bowl.

$25.95

https://www.summitracing.com/parts/mrg-2961bl

$26.95

http://www.summitracing.com/parts/sum-220108b

Last edited:

youll find you can use (Y) or (TEE) block fittings or AN (Y) or (TEE) fitting that are usually much cheaper at your local hydraulic hose supply fabricator.

what Ive always done is take careful measurements, on the car Im having the fuel lines built to fit, using a section of old garden hose,to duplicate the route and location,of the AN #8 fuel line a model, , and then write down all the lengths and types of fittings on a piece of paper so I could show the diagram to the guys at the hydraulic supply and they usually have it fabricated to match my specs in under 30 minutes

if theses some threads that are not all that common I bring the fitting Im trying to duplicate, in most cases they have the required adapters or can make them dirt cheaply in minutes.

once you carefully explain exactly what your doing and that your building a high flow fuel system, they build you exactly whats required.

I almost always have easy access to short sections of garden hose because I occasionally run over longer sections with my tractor.

what Ive always done is take careful measurements, on the car Im having the fuel lines built to fit, using a section of old garden hose,to duplicate the route and location,of the AN #8 fuel line a model, , and then write down all the lengths and types of fittings on a piece of paper so I could show the diagram to the guys at the hydraulic supply and they usually have it fabricated to match my specs in under 30 minutes

if theses some threads that are not all that common I bring the fitting Im trying to duplicate, in most cases they have the required adapters or can make them dirt cheaply in minutes.

once you carefully explain exactly what your doing and that your building a high flow fuel system, they build you exactly whats required.

I almost always have easy access to short sections of garden hose because I occasionally run over longer sections with my tractor.

viewtopic.php?f=80&t=8505&p=29830&hilit=clear+vinyl#p29830

THANK YOU! FOR THE UPDATED PICTURE

Its been my experience that, careful measurement and a trip to the local hydraulic supply fabrication guys with a detailed diagram will usually result in exactly what you need being custom fabricated to your needs at a very reasonable cost

Ive generally used two reducer brass female fittings with two AN#8 and one AN#6 fitting and flex hose between all connections with swivel connectors, (please clean up my ugly diagram, but it should give you the idea

Last edited:

bytor

Well-Known Member

Hey Indy, decided on a carb yet? This one may be a bit much but I haven't seen it before.

http://www.prosystemsracing.com/svseries.html

http://www.competitionplus.com/drag-rac ... tor-design

Interesting design concept.

http://www.prosystemsracing.com/svseries.html

http://www.competitionplus.com/drag-rac ... tor-design

Interesting design concept.

the carburetor itself looks good but you need a 4500 Holley compatible intake and at $1220 PLUS per carburetor its sure not cheap.

personally if I was going to spend $1200 plus on a carburetor....

http://store.summitracing.com/parts/edl-2025

but if it was my car Id be more likely to go this route

http://store.summitracing.com/parts/hly ... dia/images

http://store.summitracing.com/parts/edl-8713

personally if I was going to spend $1200 plus on a carburetor....

http://store.summitracing.com/parts/edl-2025

but if it was my car Id be more likely to go this route

http://store.summitracing.com/parts/hly ... dia/images

http://store.summitracing.com/parts/edl-8713

I purchased most of the fuel system today while the shipping was free on Summit, ends tonight

at mid-night. I still need the 2 Tee's at the carburetor, fuel shut off valve and some 3/8" fuel

line. So maybe another $25.......Ok, Ok, you don't have to shout at me!!! .....so take

the estimate and triple it to $75.

The only item that changed from the original list was the vent filter (row 12), since it was

going to be a special order. Turned out to be a good thing, because I found a better fit for

the 1/2" line that I'm using.

I estimated a $100 for the AN fittings, but it ended up costing $157.64. I used the diagram

below for reference while searching for the fitting, but it does NOT tell me everything, I

needed a fitting to pass thru the frame(line 20). Most likely I've got something wrong or

will have to buy more, but this is my best guess at my needs. Never run any AN lines/fittings

before so it will be a learning experience for me. Also in the total purchase price are

fittings(lines 22,23 & 24) that will be welded to my aluminum gas tank (Beer Keg),

although they weren't part of my original plan.

Below is a picture of what I bought, but just above that is the actual Excel spreadsheet

with links to every item. Plus there are links to the manufacture's manual for the fuel

pump and pressure regulator. Again I was glad I checked the manufactures website,

because I found out that the Mallory Pressure Regulator comes with the "AN O-Ring"

fittings, which saved me about $24.

For your reference again, same diagram as before:

Download Excel file below.

Attachments

Last edited:

it looks like your doing everything too specs that easily allow your engine to run at, or even above 500plus hp with zero restrictions

you should have zero problems.

just a bit of info

people rarely weld AN style fuel line fittings directly to a fuel tank.

they weld female bungs designed for that, the reason is that the fuel fittings themselves, are less easily damaged and easily replaced.

Russell 640100 Fitting Bung Weld-In Female 8 AN Aluminum

http://store.summitracing.com/search?ke ... 0100&dds=1

you should have zero problems.

just a bit of info

people rarely weld AN style fuel line fittings directly to a fuel tank.

they weld female bungs designed for that, the reason is that the fuel fittings themselves, are less easily damaged and easily replaced.

Russell 640100 Fitting Bung Weld-In Female 8 AN Aluminum

http://store.summitracing.com/search?ke ... 0100&dds=1

Thanks, that's a good idea for the fuel outlet. The other two connections

(Vent & Return Line) are in a tight spot between the tank and body. So I

will probably go with the direct weld AN connection there.

I did a search on Summit and the prices range from $4.95 to $21.96, quite

a wide range on the prices. Looks like the one with a flange would provide

a better weld, so I might go with this one from Summit for $6.95.

https://www.summitracing.com/parts/sum-220073/overview/

ALL Summit 1/2" Aluminum Bungs

https://www.summitracing.com/search/part-type/weld-in-bungs-and-fittings/thread-size/1-2-in-npt?N=4294948829+4294908579&SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=1/2" bung

Last edited:

There is zero doubt, that ,your going to have a damn impressive car when your done!

viewtopic.php?f=55&t=211&p=23798&hilit=tube+bending#p23798

viewtopic.php?f=55&t=4381&p=16285&hilit=flex+fuel+line#p16285

viewtopic.php?f=55&t=211&p=23798&hilit=tube+bending#p23798

viewtopic.php?f=55&t=4381&p=16285&hilit=flex+fuel+line#p16285

grumpyvette said:There is zero doubt, that ,your going to have a damn impressive car when your done!

And NO money for gas after I get done spending !!!

Thanks you Sir!

It was necessary to order another tool so I can make the fuel lines with AN fittings

that require a 37° flare. The Ridgid 377 got some excellent reviews so I ordered one

from Amazon, but it ships from Toolup.

Notice how it clamps on the tube you are working on, not out at the very end.

Ridgid 41162 Model 377 37 degree SAE Ratcheting Flaring Tool will flare

Steelhard, Copper, Stainless Steel and Brass thru wall thickness of 0.35". The

ratcheting feed screw Handle turns easily and requires less motion and effort

than a standard Handle. Hardened Steel flaring concentrically mounted in

needle bearings produces rolling Action for even metal flow.

http://www.amazon.com/gp/product/B001B1 ... 00_s00_i00

While on Amazon I can across the 1/2" ball valve that I needed for my fuel shutoff.

Last edited: