Dear Forum Members,

I found a lot of helpfull information about static and dynamic compression and the influencing factors here. But Im not absolutely clear what are the maximum but secure values to strive for. The conclusion out of my reading is represented by the values listed as examples. My questions to you are:

1. Do you think this configuration will work?

2. May I ask you to share your data for reason of information exchange?

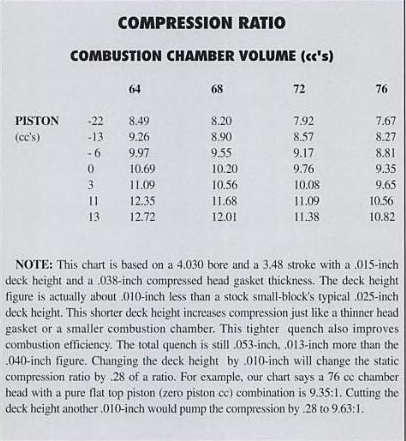

- static compression: e.g. 11.52:1

- dynamic compression: e.g. 9.25:1

- engine stability: good reliable daily street driver (vs. race)

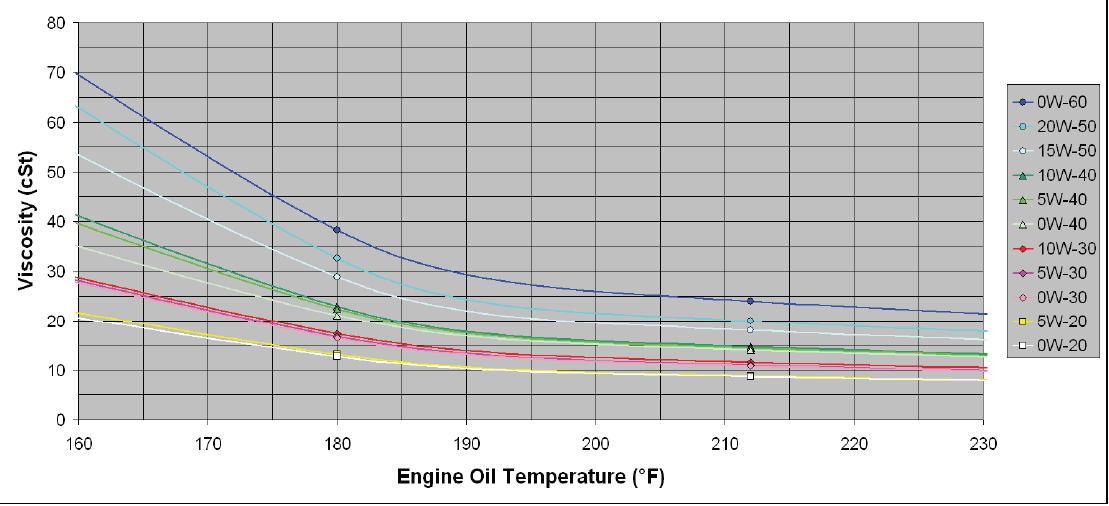

- Max. engine oil temperatur: 225 F

- Max. cooling water temperatur: 185 F

- heat exchange capability of engine: iron (vs. alu)

- heat exchange capability of the heads: alu (vs iron)

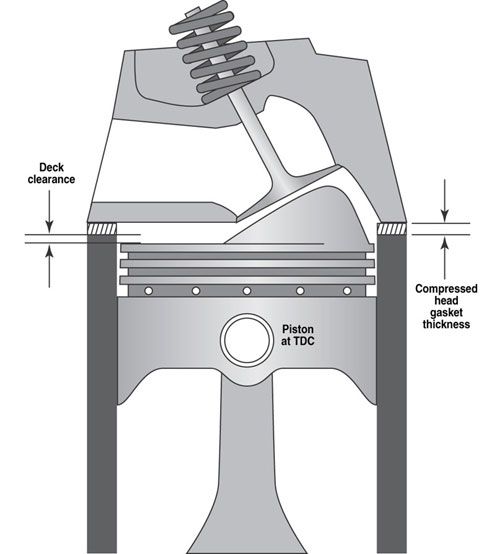

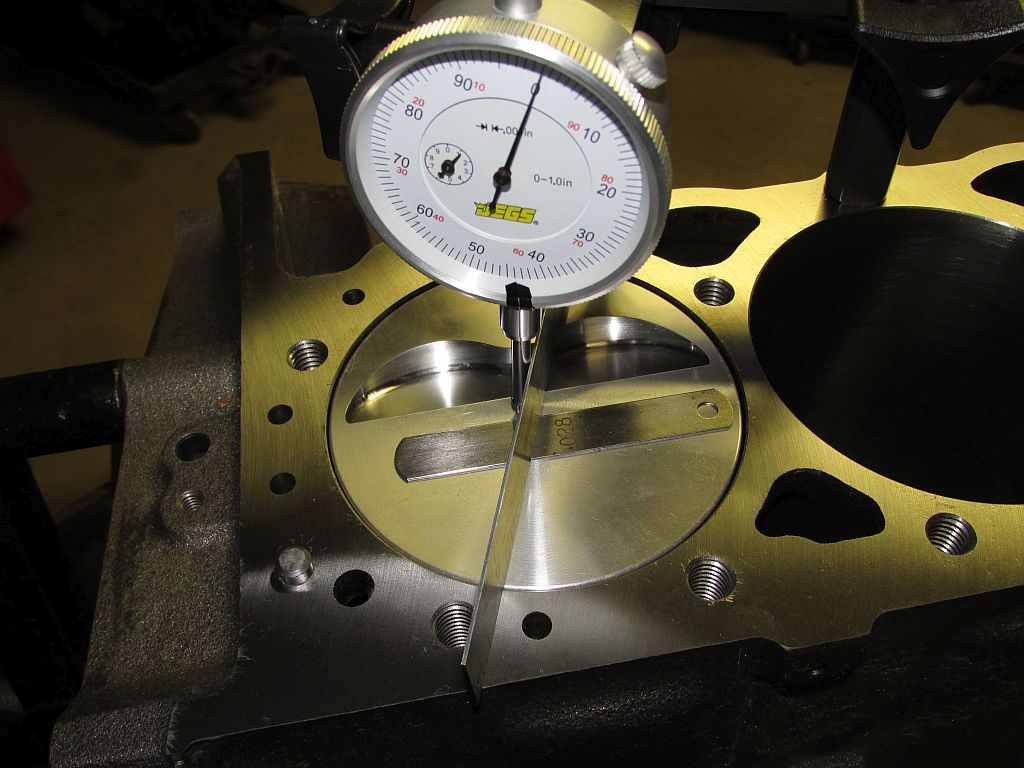

- piston to deck clearence: 0.017 inch

- piston to head clearens: 0.044 inch

- Max. summer environmental temperature: 104 F

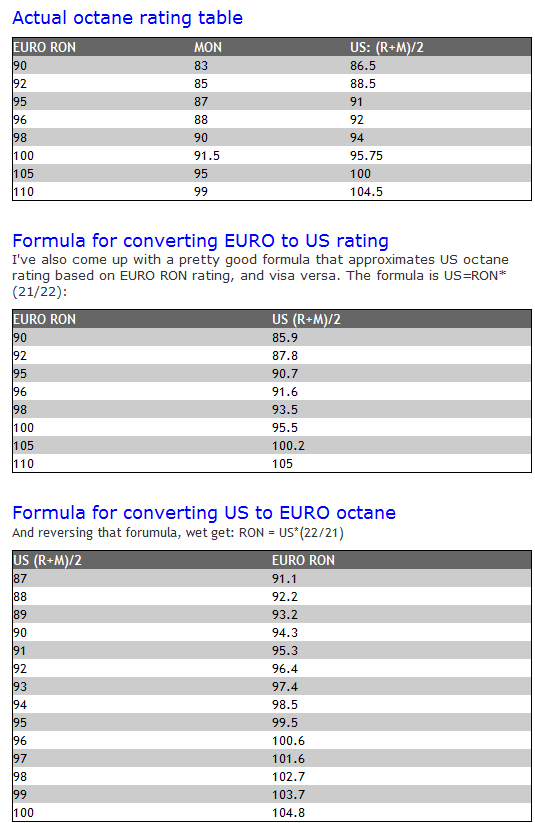

- min. octane rating required: e.g. premium 100 octane eurpean gas

- max. ignition retard and rpm: 34 at 3000 rpm

Thanks for your assessment and data.

sincerely

Sascha Bihler

I found a lot of helpfull information about static and dynamic compression and the influencing factors here. But Im not absolutely clear what are the maximum but secure values to strive for. The conclusion out of my reading is represented by the values listed as examples. My questions to you are:

1. Do you think this configuration will work?

2. May I ask you to share your data for reason of information exchange?

- static compression: e.g. 11.52:1

- dynamic compression: e.g. 9.25:1

- engine stability: good reliable daily street driver (vs. race)

- Max. engine oil temperatur: 225 F

- Max. cooling water temperatur: 185 F

- heat exchange capability of engine: iron (vs. alu)

- heat exchange capability of the heads: alu (vs iron)

- piston to deck clearence: 0.017 inch

- piston to head clearens: 0.044 inch

- Max. summer environmental temperature: 104 F

- min. octane rating required: e.g. premium 100 octane eurpean gas

- max. ignition retard and rpm: 34 at 3000 rpm

Thanks for your assessment and data.

sincerely

Sascha Bihler