Piston movement was computed by simulating the crankshaft/connecting rod/piston assembly in several precise engineering drawings (DesignCad) and then determining the exact amount of piston movement for each of 256 divisions of one rotation.

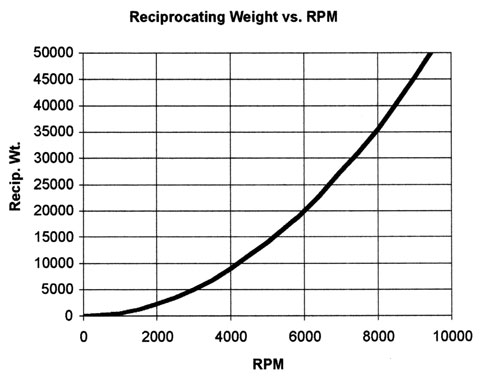

The piston movement data was then used as an input vector in a MathCad program to calculate velocity, acceleration, and dynamic forces.

The simulation of an infinitely long connecting rod, which imparts true harmonic motion to the piston, is the starting point.

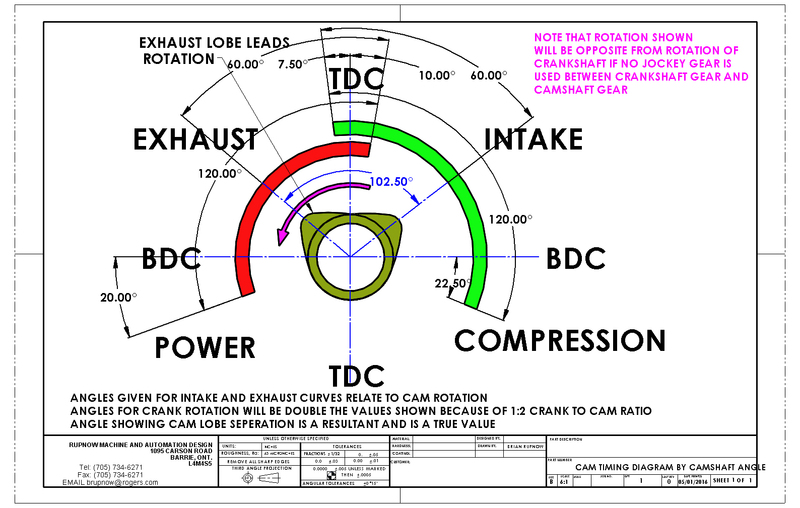

The motion generated by a finite length connecting rod is quite distorted by comparison. It has much more velocity and acceleration at the top of the stroke compared to the bottom. A graph of the movement is peaked at the top of each cycle and rounded and flattened at the bottom. This is caused by the rod angle increasing and pulling the piston down and adding to the motion caused by the crankshaft rotating down from top dead center. At the bottom as the rod journal slows the angle decreases. This retards the movement of the piston by subtracting the rod angle component that was added at the top of the stroke from the crankshaft movement component at the bottom of the stroke.

Compression and combustion pressures are in opposition to the inertial forces so the top of exhaust and intake strokes generate the largest forces on the rod.

1) Maximum Piston Acceleration

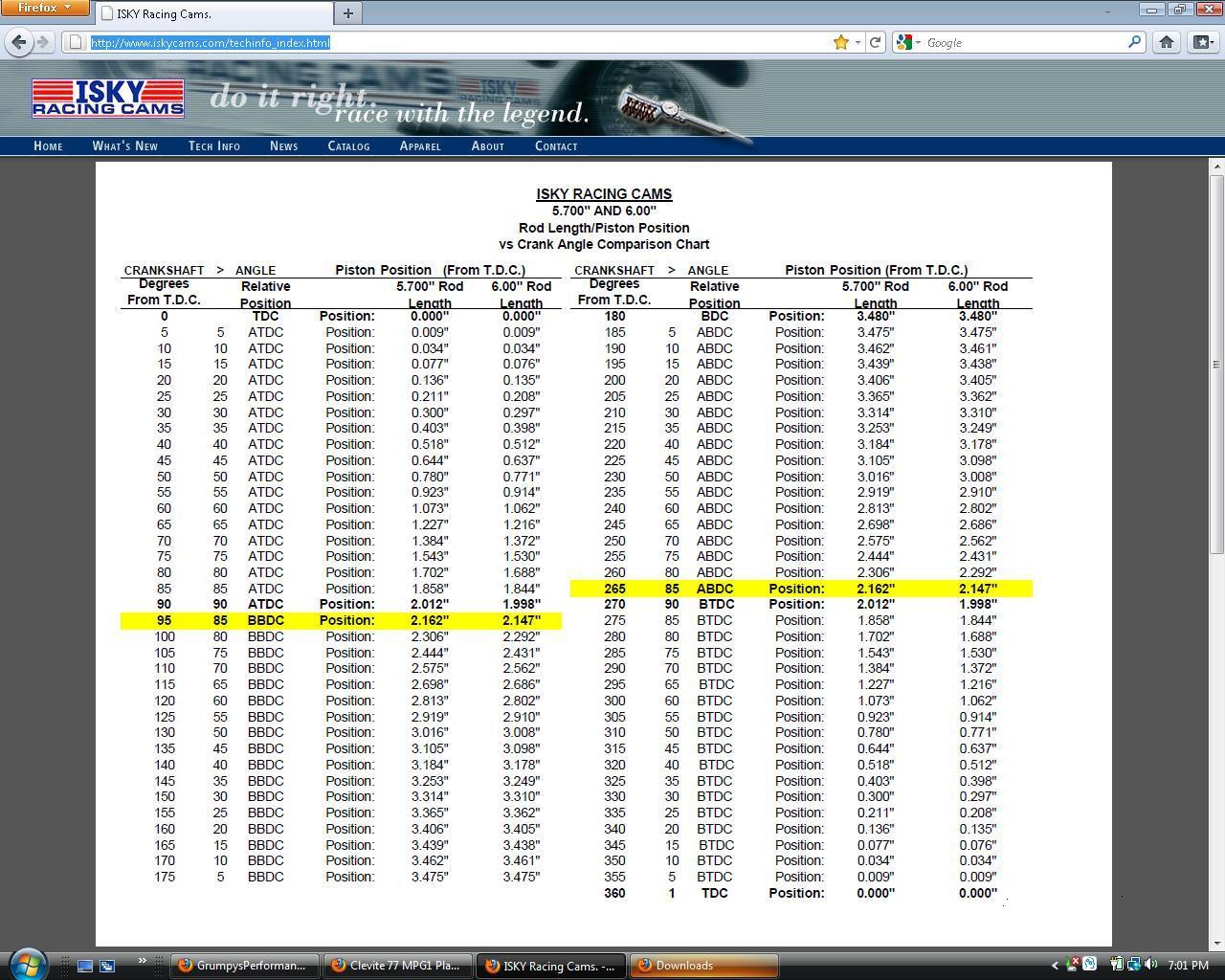

This table is for a 3.75" stroke used in a 400 0r 383 small block Chevy engine.

------infinite rod--------6.0" rod---5.7" rod---5.565" rod

5000rpm 1332G 1749G 1776G 1790G

6000rpm 1933G 2525G 2558G 2578G

7000rpm 2631G 3437G 3482G 3509G

Percent difference due to rod length in above table.

Difference between 6" rod and 5.565" rod 2.34%

Difference between 6" rod and 5.7" rod 1.54%

Difference between 5.7" rod and 5.565" rod 0.79%

This table is for a 3.48" stroke used in a 350 or 305 small block Chevy engine.

------infinite rod---------6.0" rod---5.7" rod

5000rpm 1240G 1600G 1623G

6000rpm 1786G 2305G 2338G

7000rpm 2432G 3138G 3182G

2) Maximum Connecting Rod Dynamic Load (Tension)

This table is for a 3.75" stroke used in a 400 or 383 small block Chevy engine. The forces are based on the weight of the piston and pin assembly and do not include the percentage of force generated by the acceleration of the end of the connecting rod. The reference piston is the stock replacement Silv-O-Lite piston for a 400 engine.

------infinite rod-----------6.0" rod-----5.7" rod----5.565" rod

5000rpm 2249LBS 2938LBS 2976LBS 3000LBS

6000rpm 3239LBS 4232LBS 4287LBS 4320LBS

7000rpm 4409LBS 5769LBS 5834LBS 5849LBS

Percent difference due to rod length in above table.

Difference between 6" rod and 5.565" rod 2.34%

Difference between 6" rod and 5.7" rod 1.54%

Difference between 5.7" rod and 5.565" rod 0.79%

3) Maximum Rod Angularity

This is the angle the connecting rod makes with the axis of the cylinder bore at 90 degrees after top dead center (maximum excursion from bore axis. This measurement is for the 3.75" stroke of the 400 and 383 only.

6.0" rod-----18.21 degrees

5.7" rod-----19.20 degrees

5.565" rod-19.69 degrees

4) Cylinder Wall Load

Percentage of compression and combustion force against the top of piston transmitted to the major thrust face of the piston and then to the cylinder wall.

This table is for the 3.75" stroke.

6.0" rod----32.89%

5.7" rod----34.83%

5.565" rod-35.64%

This table is for the 3.48" stroke.

6.0" rod---30.31%

5.7" rod---32.05%

5) Piston Speed

Maximum piston speed for the 3.75" stroke at 5000 rpm.

Infinite rod---81.68 feet per second, 55.69 MPH

6.0" rod------85.64 feet per second, 58.4 MPH

5.7" rod------86.01 feet per second, 58.6 MPH

5.565" rod---86.20 feet per second, 58.8 MPH

6) Effective Stroke

Because of the mechanical advantage provide by the toggling effect of the rod the shorter rods act as if they were in a longer stroke engine at the top of the stroke. This effect would make the short rod engine rev faster from 2000 to 4000 rpm and the circle track people claim that acceleration out of the turns is significantly improved with the shorter rod. In all other factors the longer rod comes out superior...

Effective stroke as compared to the infinite rod model for the 3.75" stroke.

infinite rod-=- 3.75"

6.0" rod------- 4.20"

5.7" rod------- 4.23"

5.565" rod---- 4.25"

Note that the differences are subtle...

7) Dwell Time

This measurement is of the number of crankshaft degrees the piston is within 0.250 inches of top dead center. It is the subject of much conjecture and controversy in the automotive literature.

This table is for a 3.75" stroke used in a 400 0r 383 small block Chevy engine.

Infinite rod---59.853 degrees

6.0" rod------52.397 degrees

5.7" rod------52.071 degrees

5.565" rod---51.915 degrees

Percentage difference in dwell time between the 6.0" rod and the 5.7" rod is 0.626%.

Percentage difference in dwell time between the 5.7" rod and the 5.565" rod is 0.3%.

Percentage difference in dwell time between the 6.0" rod and the 5.565" rod is 0.928%. (Still less than 1 percent)

This table is for a 3.48" stroke used in a 350 or 305 small block Chevy engine.

Infinite rod---62.188 degrees

6.0" rod------54.929 degrees

5.7" rod------54.605 degrees

Percentage difference in dwell time between the 6.0" rod and the 5.7" rod is 0.593% at the 3.48" stroke.