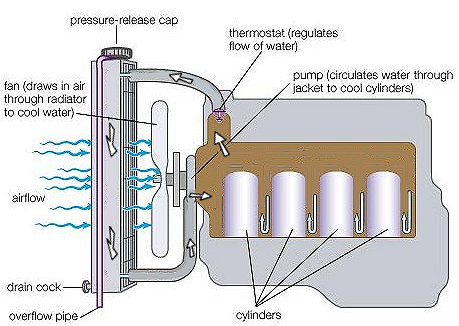

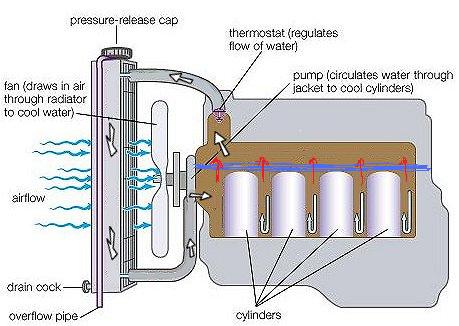

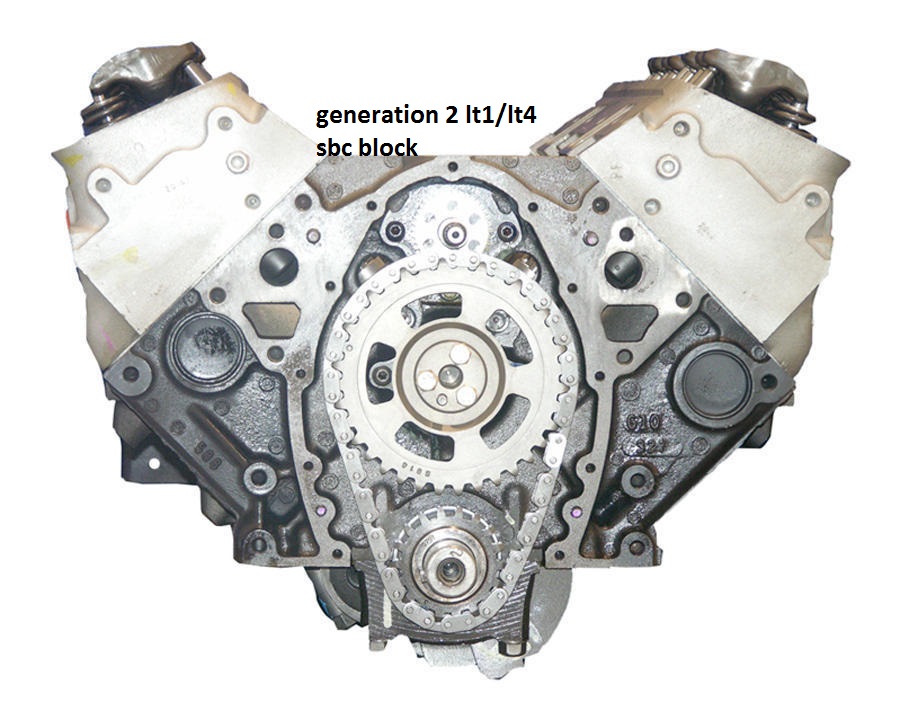

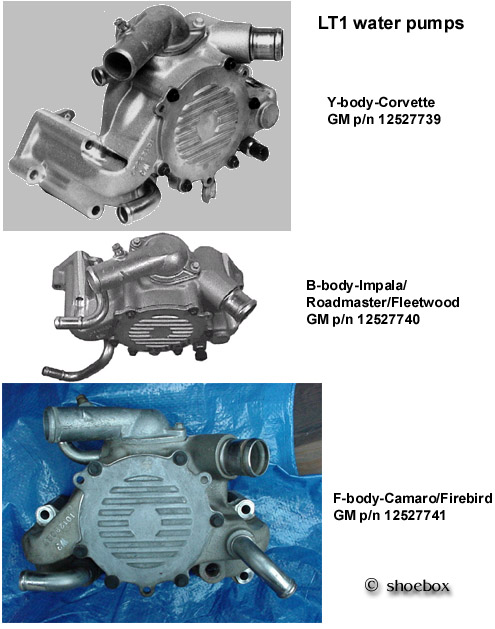

Chevy reversed the flow direction in the LT1-LT4 engines to direct the cooler coolant from the radiator into the heads first, before in flowed into the block in an effort to reduce cylinder head temps because high cylinder head temps tend to increase the potential for detonation with lower octane fuels, and most modern cars run at higher average temps and have restricted air flow rates thru the radiators,

keep in mind an LT1 or LT4 production engine made well under 400hp in factory form, needed to pass emission testing and was designed to operate for years mostly spinning well below 5000rpm

the vortec head design took the basic LT1 intake port and used it in a standard flow head design, reverse flow was a band-aid cure for a problem that better heads and a larger cooling system can easily over come. the direction of coolant flow is not nearly as important as keeping a rather consistent and controlled low coolant temp, in the cylinder heads coolant passages, if you have an aftermarket high capacity multi core aluminum radiator, and a high flow water pump and several other mods that maintain consistent coolant temps the direction of coolant flow is not critical, what is critical is moving the coolant under pressure at a fairly fast rate of flow thru the heads so the coolant can absorb and transport heat out of the heads to be dispersed in the radiator to air flow.

if coolant is not moving rapidly thru the heads steam pockets can form reducing the coolants ability to extract heat.

Ive tested dozens of engine combos, and for awhile that deal of running extra coolant ports at the rear of the intake and several more between the center exhaust ports, and the result is that, If you have aluminum heads and you use thermal barrier coating on the combustion chamber and pistons,and if you have a fully functional high volume water pump and a radiator capable of dissipating much more engine heat from the coolant than the engine produces, rather rapidly and your using a surface tension destroying additive in the coolant like

purple ice or

water wetter and a fully functioning oil and transmission fluid cooler with auxiliary fans and with a t-stat that keeps the trans fluid at 180F and the oil at 215F-220F the potential gains of reversing the coolant flow are minimal at best.

the effort required simply is wasted in my opinion ,time and money best spent else-ware, if you've maximized the cooling capacity and maximized the heat transfer rates.

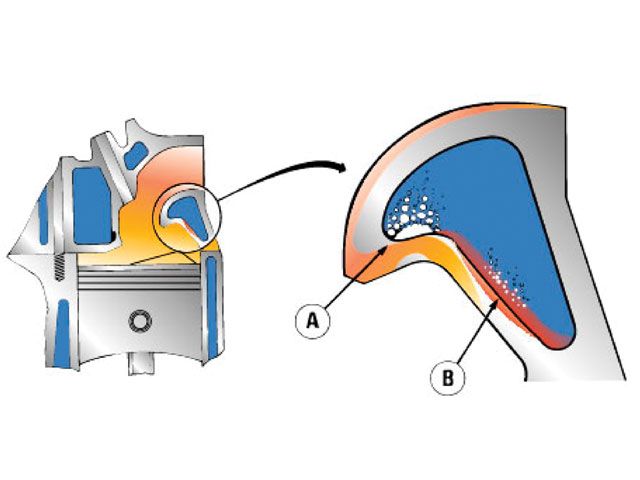

the object is to remove heat from the heads to reduce the potential for detonation, and to increase cylinder pressure, a correctly designed cooling system can do both.

some chevy race intakes have rear coolant ports to allow rapid coolant extraction from both ends of the cylinder heads

using a surface tension destroying additive in the coolant like

purple ice or

water wetter can significantly reduce or prevent this, which is one of the reasons the 400 chevy has extra steam holes in the heads and gaskets.

pumping cooler coolant that has a higher capacity to absorb heat also reduces cylinder head temps as does increased oil flow thru the valve train if your using an oil cooler that maintains consistently lower 215F oil temps

RELATED THREADS

http://www.carcraft.com/techarticles/cc ... to_03.html

viewtopic.php?f=57&t=2140

viewtopic.php?f=57&t=176

viewtopic.php?f=57&t=4701

viewtopic.php?f=57&t=2140&p=5768#p5768

viewtopic.php?f=57&t=1540

viewtopic.php?f=57&t=2991&p=7851&hilit=steam+holes#p7851

viewtopic.php?f=53&t=2610&p=12861&hilit=thermal+coating#p12861