any decent machine shop can bore the small ends of most connecting rods a few thousands required to allow the thin pressed in bronze sleeves that are normally used to reduce friction and any chance of a free floating piston pin from seizing in the small end of a connecting rod too install bronze sleeves converting the rods to full float design.

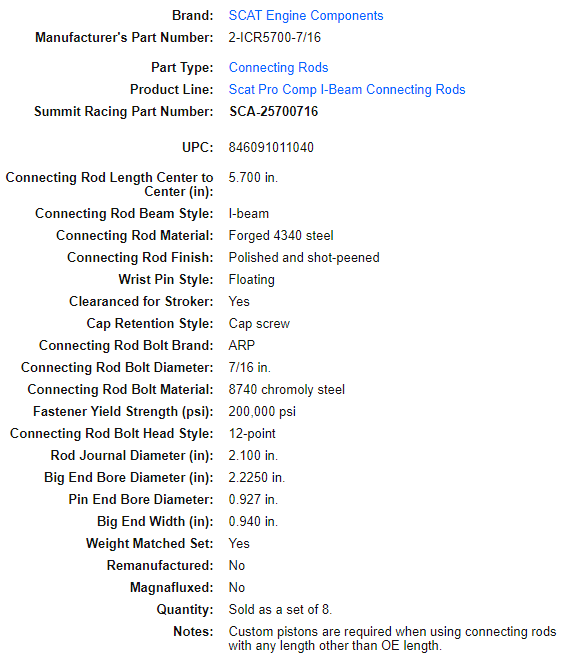

keep in mind aftermarket performance connecting rods with 7/16" ARP bolts that are easily 200% stronger than stock connecting rods cost $280-$600 for most chevy ,pontiac and mopar engines , while converting stock rods to full float design can easily cost that much if they need to be brass bushed and new ARP rod bolts, and re sizing, making the process vs cost a rather bad deal, why pay the same total cash outlay for rods that are significantly weaker when your done when good aftermarket rods are cheaper and stronger.

bushings are cheap at about $7-$8 each but the required machine work plus decent rod bolts can easily cost over $100 a set , making the reworked stock rods cost more than new connecting rods

if you wonder why anyone would want to swap from pressed to floating pins its because of the ease of self assembly and the FACT that pressed pins do get loose occasionally , especially if not properly assembled and inspected for the proper interference fit, the ability to check clearances and if required swap rods to best equalize the differences between cylinders, critical dimensions is a big advantage if your building more than an engine to be used for minimal power and basic transportation

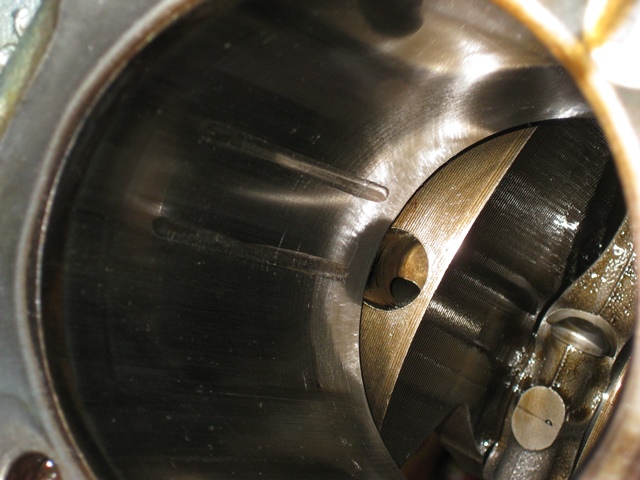

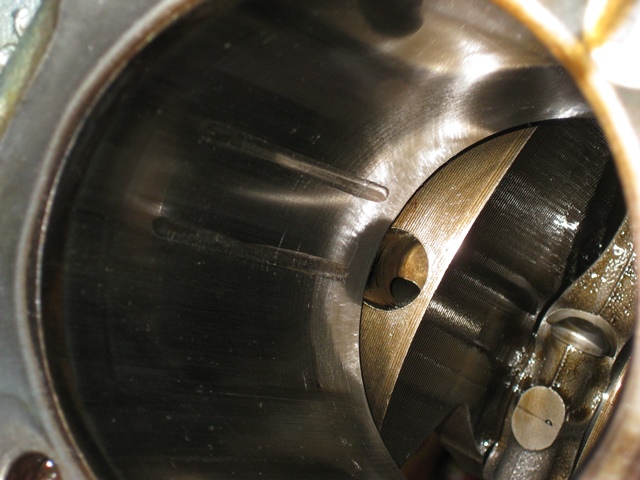

EXAMPLE' heres the result of a pin working loose, luckily caught before the bore wall was cut into the water jacket, this bore will need to be sleeved

http://www.hotrod.com/techarticles/hrdp ... ting_rods/

http://www.jegs.com/i/ARP/070/200-6203/10002/-1

Keep in mind when selecting components that full float pins in connecting rods and pistons make rapid assembly far easier,and while you generally can use pressed pin connecting rods and pressed in pins in full float design pistons if you wanted too, because all your effectively doing is eliminating the need to use the piston pin retention rings, spiro locks or buttons to keep the wrist pin centered in the pin bore, the best idea is to use the pins the pistons and rods are designed to be used with,.

and yes Ill point out that you generally can not use full floating pin connecting rods and piston pins in pressed pin design pistons because theres nothing to prevent the pin working its way laterally until its rubbing the cylinder bore and allowing the piston to run cocked in the bore as its not fully supported equally side to side.

its a really good idea to talk to and have a long detailed discussion with, your engine builder or machine shop before selecting components and if you have any questions on part compatibility issues

http://www.chevydiy.com/crankshafts-connecting-rods-pistons-guide-chevy-big-blocks/

ALMOST ALL stock production 454 bbc rods were pressed fit pin designs

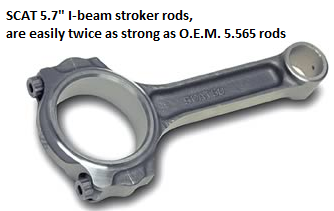

SCAT sells very reasonably priced bushed connecting rods that will work with full floating pins PROVIDED the correct matching piston is used of course.

and yes a decent machine shop can machine the current rods and insert brass pin sleeves but by the time they recondition the rods and insert new ARM rod bolts, resize and balance the rods the price usually exceeds new stronger SCAT RODS

If your thinking of re-using stock connecting rods in a performance engine build-up, you may have gotten an erroneous idea,

full float pistons and pins provide you with a great deal more flexibility,

and most stock connecting rods, are at best marginal in strength,

compared to many of the cheaper aftermarket options.

reading the linked and sub linked info here will take time,

but its sure too save you a great deal of money and wasted effort,

and generally be useful.

btw I would NEVER reuse the 400 sbc 5.565 rods, they are at least 40 years old,

have been through unknown millions of stress cycles,

and are well known to be a rather weak design,

that was originally designed for a lower to mid rpm torque engine,

intended mostly for pick-up trucks and luxury cars with automatic transmissions.

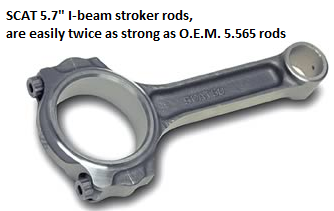

you can purchase 5.7" connecting rods that are

easily over twice as strong as the O.E.M. connecting rods used in a stock 400 sbc

for LESS,

than it would cost to rebuild ,resize and add ARP rod bolts to the original rods

below is only one of several dozen options if your building a performance SBC

https://www.summitracing.com/parts/sca-25700716

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.co...ng-rods-from-pressed-to-full-float-pins.6909/

http://garage.grumpysperformance.co...s-one-really-over-looked-part.978/#post-79095

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://garage.grumpysperformance.co...ds-vs-aftermarket-4340-connecting-rods.13321/

http://garage.grumpysperformance.co...ng-piston-pin-height-compression-height.5064/

http://garage.grumpysperformance.co...roove-depth-clearance-effects-ring-seal.5454/

http://garage.grumpysperformance.co...ighter-wristpin-balance-a-heavy-piston.16513/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

http://garage.grumpysperformance.com/index.php?threads/maximizing-piston-to-bore-ring-seal.3897/

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/

http://garage.grumpysperformance.com/index.php?threads/rods-that-don-t-destroy-your-budget.10958/

http://garage.grumpysperformance.co...guess-on-clearances-and-journal-surface.9955/

http://garage.grumpysperformance.com/index.php?threads/piston-related-info.110/

http://garage.grumpysperformance.com/index.php?threads/chamfering-oil-feed-holes-in-cranks.4419/

http://garage.grumpysperformance.com/index.php?threads/pink-rods-why-bother.1110/

http://garage.grumpysperformance.co...ct-compression-or-pin-height-in-pistons.1017/

http://garage.grumpysperformance.com/index.php?threads/should-you-re-use-stock-connecting-rods.140/

http://garage.grumpysperformance.com/index.php?threads/piston-rings-related-info.2795/

http://pitstopusa.com/c-134461-engine-c ... hings.html

http://www.summitracing.com/search/bran ... toview=SKU

http://www.summitracing.com/search/Depa ... CHEVROLET/

http://www.enginebuildermag.com/Item/38 ... rings.aspx

keep in mind aftermarket performance connecting rods with 7/16" ARP bolts that are easily 200% stronger than stock connecting rods cost $280-$600 for most chevy ,pontiac and mopar engines , while converting stock rods to full float design can easily cost that much if they need to be brass bushed and new ARP rod bolts, and re sizing, making the process vs cost a rather bad deal, why pay the same total cash outlay for rods that are significantly weaker when your done when good aftermarket rods are cheaper and stronger.

bushings are cheap at about $7-$8 each but the required machine work plus decent rod bolts can easily cost over $100 a set , making the reworked stock rods cost more than new connecting rods

if you wonder why anyone would want to swap from pressed to floating pins its because of the ease of self assembly and the FACT that pressed pins do get loose occasionally , especially if not properly assembled and inspected for the proper interference fit, the ability to check clearances and if required swap rods to best equalize the differences between cylinders, critical dimensions is a big advantage if your building more than an engine to be used for minimal power and basic transportation

EXAMPLE' heres the result of a pin working loose, luckily caught before the bore wall was cut into the water jacket, this bore will need to be sleeved

http://www.hotrod.com/techarticles/hrdp ... ting_rods/

http://www.jegs.com/i/ARP/070/200-6203/10002/-1

Keep in mind when selecting components that full float pins in connecting rods and pistons make rapid assembly far easier,and while you generally can use pressed pin connecting rods and pressed in pins in full float design pistons if you wanted too, because all your effectively doing is eliminating the need to use the piston pin retention rings, spiro locks or buttons to keep the wrist pin centered in the pin bore, the best idea is to use the pins the pistons and rods are designed to be used with,.

and yes Ill point out that you generally can not use full floating pin connecting rods and piston pins in pressed pin design pistons because theres nothing to prevent the pin working its way laterally until its rubbing the cylinder bore and allowing the piston to run cocked in the bore as its not fully supported equally side to side.

its a really good idea to talk to and have a long detailed discussion with, your engine builder or machine shop before selecting components and if you have any questions on part compatibility issues

http://www.chevydiy.com/crankshafts-connecting-rods-pistons-guide-chevy-big-blocks/

ALMOST ALL stock production 454 bbc rods were pressed fit pin designs

SCAT sells very reasonably priced bushed connecting rods that will work with full floating pins PROVIDED the correct matching piston is used of course.

and yes a decent machine shop can machine the current rods and insert brass pin sleeves but by the time they recondition the rods and insert new ARM rod bolts, resize and balance the rods the price usually exceeds new stronger SCAT RODS

If your thinking of re-using stock connecting rods in a performance engine build-up, you may have gotten an erroneous idea,

full float pistons and pins provide you with a great deal more flexibility,

and most stock connecting rods, are at best marginal in strength,

compared to many of the cheaper aftermarket options.

reading the linked and sub linked info here will take time,

but its sure too save you a great deal of money and wasted effort,

and generally be useful.

btw I would NEVER reuse the 400 sbc 5.565 rods, they are at least 40 years old,

have been through unknown millions of stress cycles,

and are well known to be a rather weak design,

that was originally designed for a lower to mid rpm torque engine,

intended mostly for pick-up trucks and luxury cars with automatic transmissions.

you can purchase 5.7" connecting rods that are

easily over twice as strong as the O.E.M. connecting rods used in a stock 400 sbc

for LESS,

than it would cost to rebuild ,resize and add ARP rod bolts to the original rods

below is only one of several dozen options if your building a performance SBC

https://www.summitracing.com/parts/sca-25700716

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.co...ng-rods-from-pressed-to-full-float-pins.6909/

http://garage.grumpysperformance.co...s-one-really-over-looked-part.978/#post-79095

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://garage.grumpysperformance.co...ds-vs-aftermarket-4340-connecting-rods.13321/

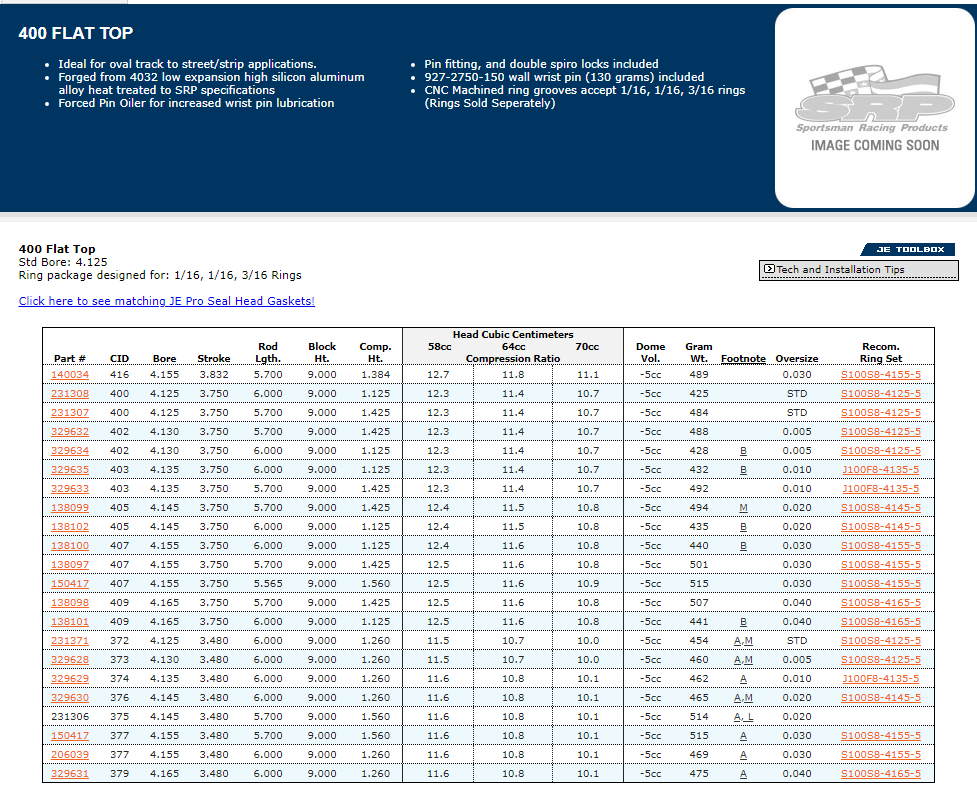

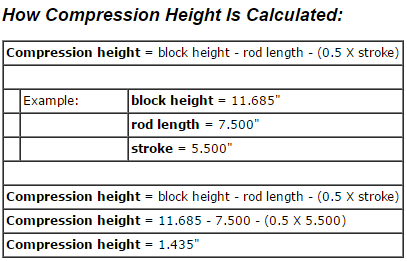

http://garage.grumpysperformance.co...ng-piston-pin-height-compression-height.5064/

http://garage.grumpysperformance.co...roove-depth-clearance-effects-ring-seal.5454/

http://garage.grumpysperformance.co...ighter-wristpin-balance-a-heavy-piston.16513/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

http://garage.grumpysperformance.com/index.php?threads/maximizing-piston-to-bore-ring-seal.3897/

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/

http://garage.grumpysperformance.com/index.php?threads/rods-that-don-t-destroy-your-budget.10958/

http://garage.grumpysperformance.co...guess-on-clearances-and-journal-surface.9955/

http://garage.grumpysperformance.com/index.php?threads/piston-related-info.110/

http://garage.grumpysperformance.com/index.php?threads/chamfering-oil-feed-holes-in-cranks.4419/

http://garage.grumpysperformance.com/index.php?threads/pink-rods-why-bother.1110/

http://garage.grumpysperformance.co...ct-compression-or-pin-height-in-pistons.1017/

http://garage.grumpysperformance.com/index.php?threads/should-you-re-use-stock-connecting-rods.140/

http://garage.grumpysperformance.com/index.php?threads/piston-rings-related-info.2795/

http://pitstopusa.com/c-134461-engine-c ... hings.html

http://www.summitracing.com/search/bran ... toview=SKU

http://www.summitracing.com/search/Depa ... CHEVROLET/

http://www.enginebuildermag.com/Item/38 ... rings.aspx

Last edited by a moderator: