cooling fans come in a large variety of types, but the idea is too increase the flow of heat absorbing air flow over the fins of the radiator while maintaining high cooling system efficiency and engine durability and low loads on the engine. an engine driven fan is fine, the main factor in moving air is in promoting high air flow rates thru the radiator to induce efficient coolant heat transfer from the radiator fins to the air, moving thru that radiator and it sure helps having the correct design on the fan blades , the max number of fan blades you can easily fit in side the shroud and an ideal set-up the tips of the fan blades are within about 1/2" of the inside diam, of the fan shroud and the blades are located so they are centered on or at least near the rear edge of the radiator fan shroud

If your having cooling issues while the cars stationary but not when the cars moving theres an excellent chance that the problem is lack of low speed air flow rates, a larger more effective fan or a more efficient fans or adding a pusher fan or more efficient fan shroud would help. clear pictures of the car,s engine compartment, radiator fans, fan shroud etc would help here a great deal.

keep in mind oil does a good deal of the heat transfer, in an engine, so an oil pan with a larger than stock capacity and an oil cooler with a built in electrical fan can do a good deal to lower engine temps.

keep in mind automatic transmissions tend to add a significant amount of heat to radiators that use the lower section to cool the transmission, adding a large efficient trans fluid cooler to the car can also significantly reduce the heat loads on the radiator

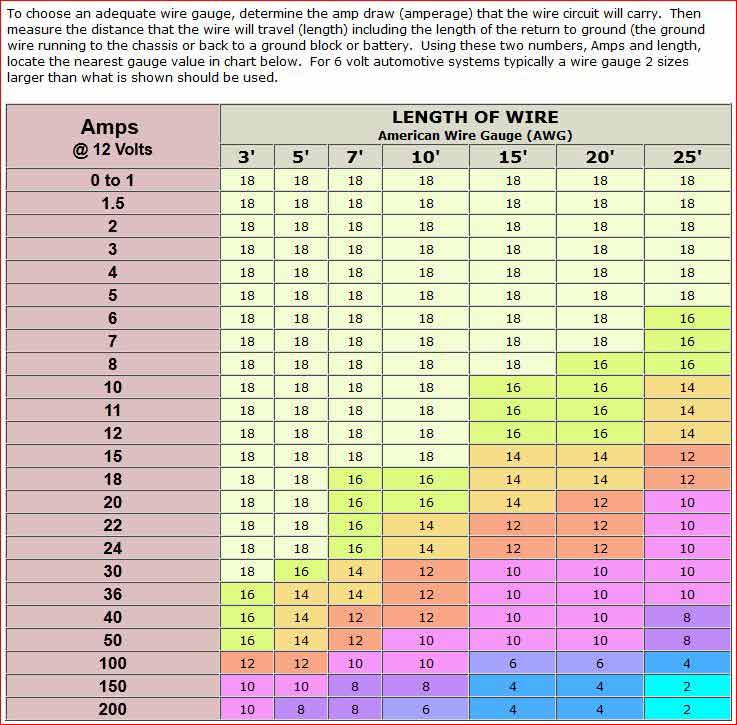

BTW one frequently overlooked factor, in cooling your engine or adding an additional oil cooler, is your alternator size,in amps and wiring the alternator correctly, if your running a 70amp-100 amp stock alternator and using electric fans to cool the engine,its not going to provide the power required to spin the fans nearly fast enough to cool the engine like a better 200 amp alternator can, Ive seen several corvettes cure cooling issues by swapping to 200 amp alternators, that simply allowed the electrical cooling fans to spin significantly faster

READ THESE

if you need to use a fan spacer kit to get the fan positioned forward into the fan shroud for increased efficiency

viewtopic.php?f=57&t=853

viewtopic.php?f=57&t=348

http://www.mrgasket.com/Portals/0/downl ... t_1992.pdf

http://www.corvettefever.com/techarticl ... index.html

http://www.ecklers.com/catalogsearch/re ... n&x=42&y=6

http://www.parts123.com/parts123/yb.dll ... 1~cadeikba

don,t forget you NEED a matching FAN SHROUD duct work to maximize air flow thru the radiator, a properly fitted fan ducting shroud can increase air flow and cooling efficiency by over 35%

below about 55-70mph (depends on the ducting and radiator surface areas, and engine heat loads the system must deal with ETC.)

the natural air flow rates of air being forced thru the radiator coils and fins flows thru the openings, due to the cars moving thru the surrounding air and the pressure differential that results, at too low a rate to efficiently absorb heat from the coolant in the radiator to effectively cool the engine, so fans and duct work are used to increase the air flow and heat transfer rates.

correctly designed and installed fan shrouds allow you to significantly increase the a fans efficiency at pulling air thru a radiator, pusher fans tend to help but generally are far less effective than puller fans.

the larger the diameter of the fan,the more blades it has and the faster it spins, the more air flow it generally provides but obviously the design of the impellers and ducting will effect the results, and loads or resistance the impeller or fan blades must deal with.

until fairly recently most radiator cooling fans were directly driven from the engine mechanically or with accessory bet drives. those fans turn at engine speed and at high rpms put a significant load on the engine

mechanical fans come in clockwise and counterclockwise rotation designs that must match the application

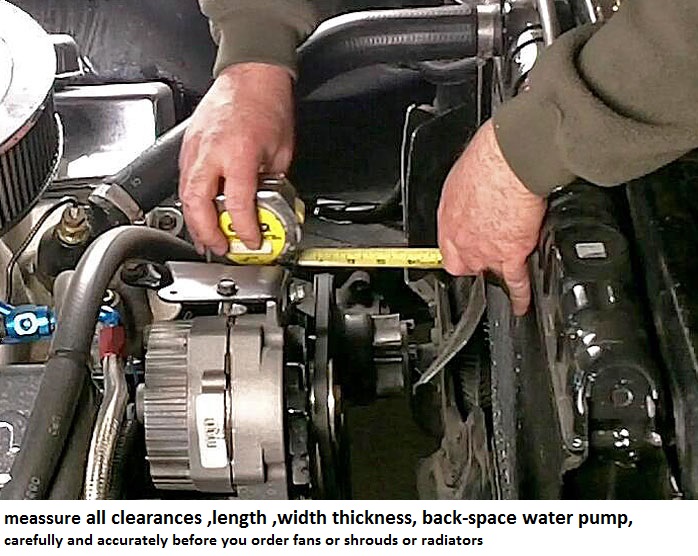

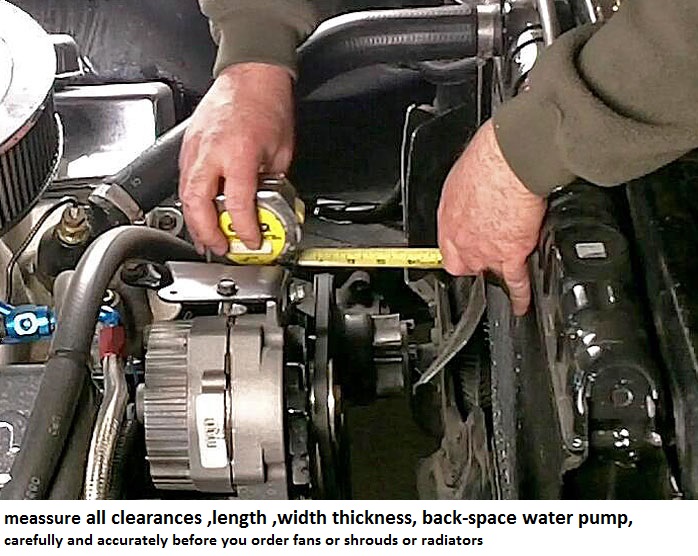

(NO YOU CAN,T JUST INSTALL THE OTHER SIDE FACING THE RADIATOR) and must be used with a matching water pump design. generally a fan works best if its mounted within 1" of the rear radiator surface with a MATCHED shroud or duct work that are within about 3/8" from the outer arc of the impellers, they tend to be noisy and in some cases dangerous at at high rpms its not unheard of for blades to fling off and do considerable damage.

keep in mind that the coolant must constantly flow thru the radiator to allow it to transfer heat from the engine to the outside air, the fan is a single component in a system that requires a constant inflow of hot coolant into the radiator so that the heat can be transferred continuously out to air flow and the resulting cooled ,coolant needs to flow under slight pressure back thru the block in an endless cycle

clutch fans have a viscus clutch that spins the fan based against the resistance its working against

the fans generally spin the fastest at about 2000-3000 rpm

,so from idle to about 2500 rpm fan speeds increase along with but not directly related too engine rpm,

much above that rpm the resistance won,t allow the fan speeds to increase nearly as fast as rpms increase

so the clutch fans do soak up some engine power , but not nearly as much as a solidly mounted fan would have.

generally the more blades on a quality clutch fan, the better it cools

I generally used to look for the clutch fans of caddys and buicks as many will mount to chevy water pumps with minimal or no mods

most were available from salvage yards dirt cheap in years past you ideally want something similar to this

https://www.ss396.com/chevelle/FANK...MIqpLemIjB6QIVDtbACh1uzwYdEAQYBSABEgKWbvD_BwE

http://www.network54.com/Forum/215655/message/1066184641/Car+Craft+Cooling+Fan+Dyno+Test

don,t forget a matching fan shroud that matched the radiator and fan diameter,greatly increases cooling efficiency

http://www.summitracing.com/parts/DER-17618/

better quality metal flex fans, when properly matched to a close fitting radiator shroud, can and usually do, move a huge increase in air flow rates over what can be expected from most electric radiator fans. this will generally reduce engine temps significantly and reduce loads on the alternator as you don,t need to run an electric radiator fan (s).

the problem's are that as the engine rpms increases much past 3500 rpm-4000 rpm they become a huge horse power wasting drag on the engine, and the blades by design tend to change angles to reduce the parasitic losses, some flex fan designs can require well over 35 extra horsepower to spin,once the rpm levels increase over 4500rpm,

at over 4000 rpm,and above, they all use significantly more torque to turn than at lower engine speeds and thats a big problem, the flexing also eventually causes stress fractures in the blades and if used long enough over time the blades do occasionally come off and that can be a big problem as the blades fracturing instantly unbalance the fan, and shortly after the water pump bearings fail due to vibration related stress.

there are several sources for flex fans and quality and size , and designs obviously vary so shop carefully and avoid the cheap fiberglass versions,

READ

http://www.haydenauto.com/Featured Products-Fan Clutches and Fan Blades/Content.aspx

http://www.licorvette.com/Corvette Fan Clutch.htm

http://www.popularmechanics.com/cars/how-to/a302/1772922/

and REMEMBER CHEVY

WATER PUMPS,

FAN CLUTCHES

AND

FANS,

ROTATIONAL DIRECTION

VARIES BETWEEN CARS

SO YOU MUST MATCH THE INTENDED APPLICATION FOR THE COMPONENTS BEING USED FOR ALL THREE COMPONENTS

https://m.summitracing.com/parts/der-19118

https://m.summitracing.com/parts/flx-1318

https://m.summitracing.com/parts/prm-83182

http://www.v8s10.org/forum/viewtopic.php?f=46&t=20834

but there is a well proven and fairly inexpensive solution

installing a viscus fan clutch

if you install a viscus fan clutch at lower rpms the fan spins at almost engine rpms, the internal hydraulic friction clutch keeps the fan blades , spinning but as rpms increase and resistance to the fans blades increase, the internal clutch allows some of the engines energy to push the fan, but slippage increases, so your fan may only spin at 3700rpm-4500rpm ( this mostly depends on the fan clutch design, fan loads and clutch age and condition) the fan clutches do eventually wear out, but its been my experience they are generally good for 6-7 years before youll find any significant wear.

use of a fan clutch can easily reduce the parasitic drag loses , by over 50% from those the engine would see without the fan clutch.

theres little doubt they move a good deal of airflow and help cool the engine effectively, yes thats an impressive looking and probably much more effective fan, , and while its a personal choice, if it was my car, Id have a clutch fan not a spacer installed, and a surrounding fan shroud around the fan blades, to further increase the air flow rate efficiency through the radiator fins. remember the object to effectively transfer heat from the engine coolant to outside airflow,

The use of the fan without a clutch hub, wastes some power,simply because it robs, your car of some potential peak power , through added drag, in its current config. compared to using a clutch fan hub. yet the cars cooling capacity, is not really benefiting from the lack of a clutch fan hub. adding a shroud forces the air to flow even from areas the fans not directly behind.

http://www.summitracing.com/parts/DER-17018/

clutch fans, mount a viscus clutch between the fan and the water pump belt drive that slips a a preset load rate, this limits the rpms the fan will turn, lowering the max load rates on the engine and making the blade flinging off at high rpms a far lower risk

http://www.popularmechanics.com/how_to_ ... tml?page=3

http://www.popularmechanics.com/how_to_ ... 72922.html

http://www.summitracing.com/parts/FLX-5555/

For the record: Clutch fans & blades never see RPM wise much over 3-4 grand.

This is one of the reasons in the 60-70s ALL the BIG THREE Mfg. with big Cube engines had CLUTCH FANS.

I have a page out of a 60s hot rod Magazine. It tells the story of Chrysler, The 440s Hemis and so on.

Chrysler used the clutch fans for TWO REASONS.

#1--Clutch fan blade Assmb. only spin around 3-4 thousand RPMs.

#2--Chrysler stated through dyno testing the clutch fan Assmb. would save 16.2 H.P. over a Mech. Fan. Also the Mech. Direct driven fan blade would fracture if it sustained many high RPM. cycles.

This could be the reason the big three with big horse engines used clutch fan Assmb. on the street driven big blocks in the " So Called 60s & 70s era ".

There are two basic types of fan clutches: thermal and non-thermal (also called "torque limiting"). Thermal fan clutches have a temperature-sensitive bimetal coil spring on the front that reacts to temperature changes. When the air coming through the radiator is hot, the spring expands and opens an internal valve that reduces clutch slippage. This causes the fan to spin faster for increased cooling. As the air cools, the spring contracts and closes the valve. This increases the amount of clutch slippage, allowing the fan to slow down and decrease cooling.

The clutch consists of a fluid coupling filled with a silicone based oil. In the cutaway view at the left, the area between the teeth on the clutch plates is filled with silicone fluid. An internal valve opens and closes a passage between the main fluid cavity and a fluid reservoir. When the passage is open, fluid enters the clutch and makes the fan to turn faster. When the valve is shut, fluid flows back to the reservoir but doesn't return, causing the clutch to slip and the fan to turn more slowly.

Here's step-by-step from a Haynes manual

Warning:The engine must be completely cool when this procedure is performed .

Note: A special fan clutch wrench is required (GM#46406 or Equivalent)

1.Remove the bolts and push pins that attach the intake air baffle to the radiator support,then remove the baffle. (On 2002s only)

2.Disconnect the transmission cooler lines at the engine bracket and fan shroud.

3.Disconnect the electro-viscous clutch electrical connector from the shroud.

4.Remove the upper radiator hose from the radiator;be prepared for coolant spillage.

5.Remove the fan clutch hub from the water pump by turning it counterclockwise.

6.Unclip the shroud from the radiator side panels then tilt the condenser and radiator forward.This will be easier if someone assists you.

7.Remove the fan and shroud as one unit by lifting straight up as the condenser and radiator are being held in the forward position.

8.The fan can now be unbolted from the clutch, if necessary.Be sure to tighten the fan-to-clutch bolts to the torque listed in this chapter's specifications(20 Ft.-Lbs.)!

9.Installation is reverse removal,Tighten the fan hub nut to the torque listed in this chapter's specifications(41 FT.-Lbs)!

10. Check the coolant,adding as necessary to bring it to the appropiate level.

You can replace all 4, front and back, stabilizer links with Moogs for about $100 yourself. If the rears are worn the fronts probably are too.

The blower resistor I think runs about $25. You can do that yourself. Behind the glove box door and blower motor.

Dealers still charging $700 for that clutch job based on old labor rates and parts price, when part has gone down in price about half what it was and it takes them less than an hour to actually do the job. The $70 diagnostic fee seems about normal these days.

http://www.aa1car.com/library/cooling_fan_clutch.htm

http://www.harborfreight.com/5-in-1-dig ... 98674.html

having a wide assortment of different multi meter test leads available is a huge benefit while testing

the clip test leads that test thru a wires insulation without much damage are a big help

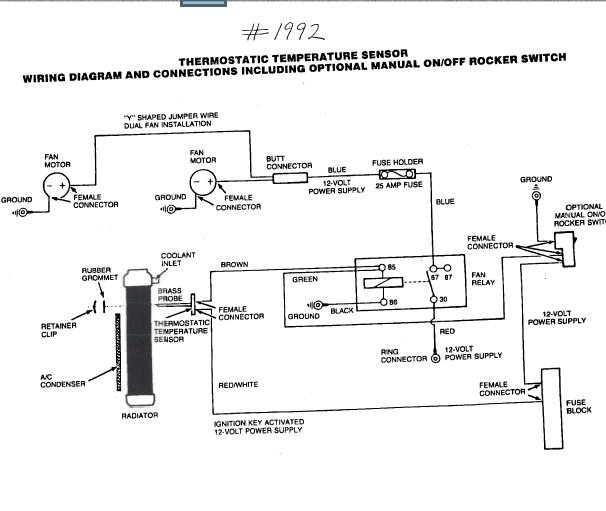

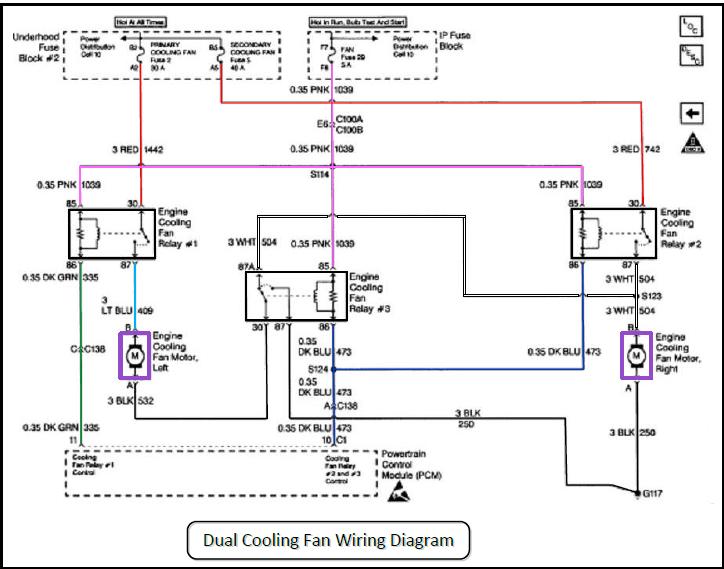

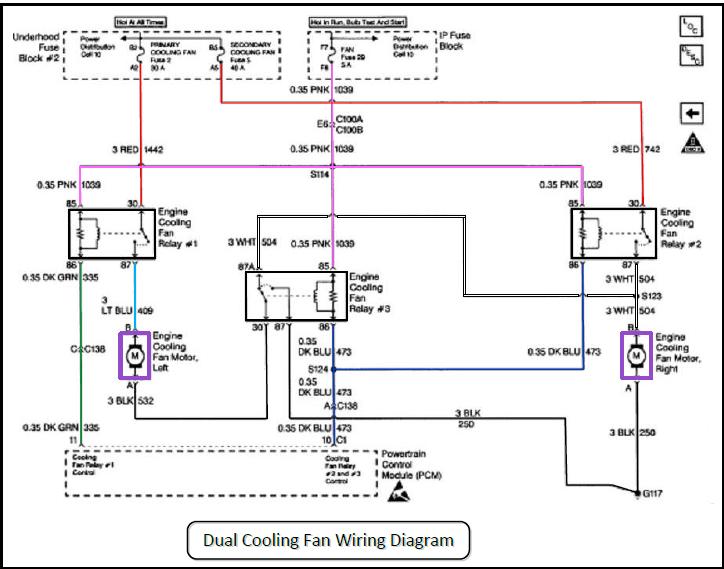

more recently electric fans that are thermostatically controlled have become popular,most but not all electric fans have variable speeds, and if wired incorrectly will spin in the wrong direction from that desired, and many people are not aware of the high amp loads these fans can put on the alternator and fail to realize that the larger fans REQUIRE a high out put alternator or the fan blade speeds suffer noticeably if the current required is not up to the fans designed needs, at max rpms with electric fans one of the most common problems is not the fans or motors but the relays or sensors that control when and how fast the fan starts and spins, having a shop manual is mandatory in many case to track down the cause of problems as more than one relay or sensor is common

http://www.summitracing.com/parts/SUM-G4852/

http://www.summitracing.com/parts/FLX-180/

http://www.summitracing.com/search/bran ... toview=SKU

http://garage.grumpysperformance.co...electric-fan-in-4-easy-steps.7774/#post-45162

http://www.stl-vettes.com/65Vette/corvette_Misc/Images/Fan_Clutch_Adjust.pdf

http://www.summitracing.com/parts/FLX-365/?rtype=10

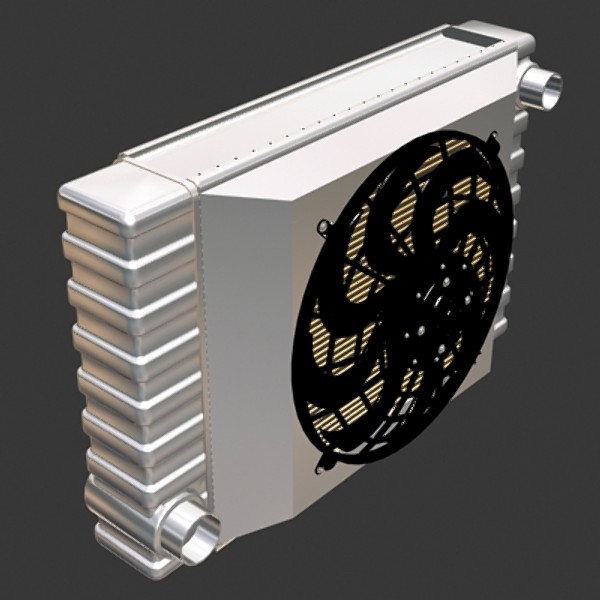

duct work can significantly increase the fans efficiency, so its a great idea to have duct work that forces air to flow over the full surface of the radiator fins

theres several ways you can do this,and pull fans with a shroud mounted behind the radiator are far more efficient than pusher fans mounted in front of the radiator.

theres a huge difference in quality in electric fans that are available and unless you have an upgraded alternator putting out serious amps you generally don,t get the best potential results

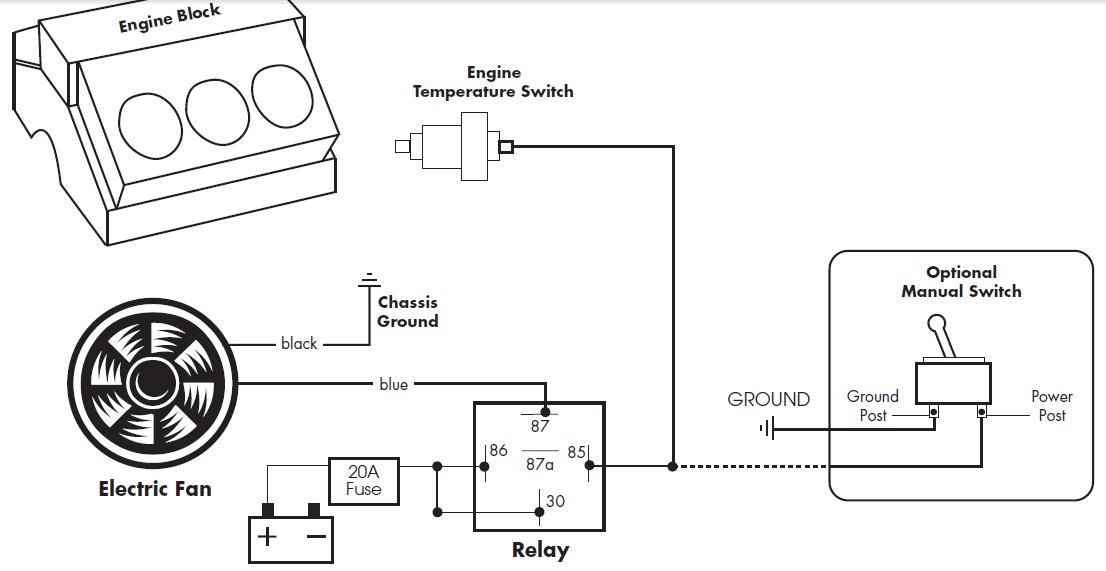

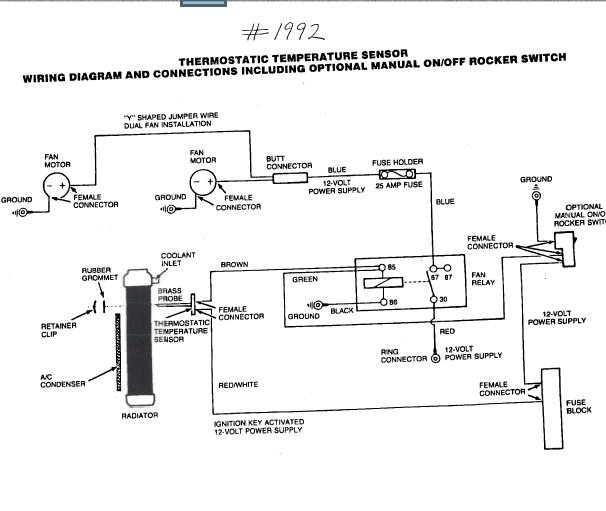

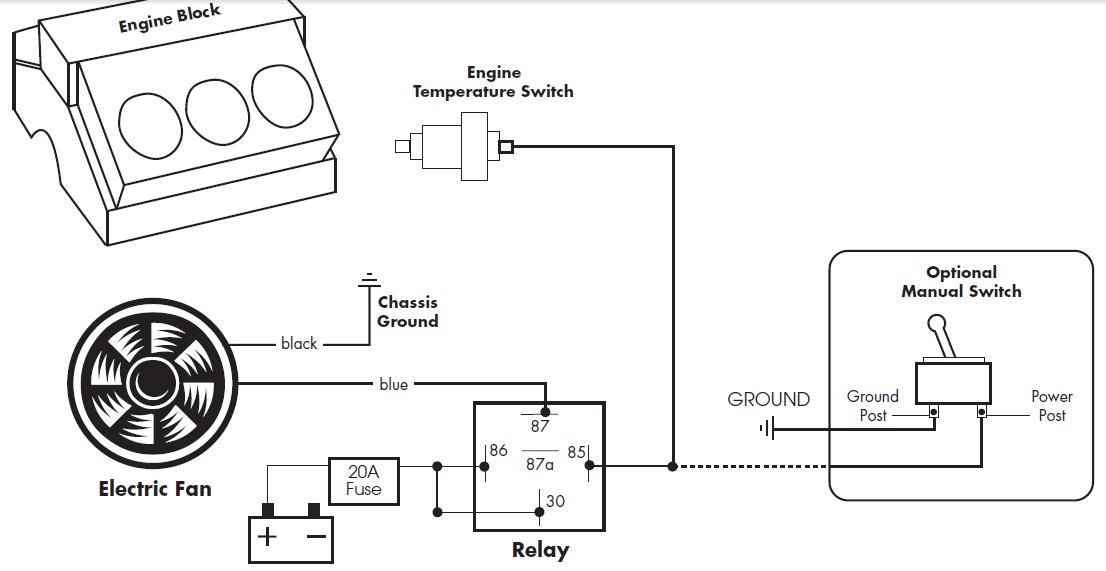

generally you hook up the fan to a positive battery lead thats only hot when the ignition switch is in the ON position, and the ground lead to a sensor that provides a ground connection at a set temp, generally in the 160F-180F range

http://www.summitracing.com/parts/HFM-ZFSWF/?rtype=10

http://www.summitracing.com/parts/FLX-298/

READ THRU THESE THREADS

http://garage.grumpysperformance.co...lf-the-time-starts-and-dies.11187/#post-50245

viewtopic.php?f=70&t=3504

viewtopic.php?f=70&t=355

viewtopic.php?f=32&t=3954&p=18559&hilit=corvette+alternator#p18559

viewtopic.php?f=80&t=2465&p=6444&hilit=taurus#p6444

viewtopic.php?f=57&t=1540&p=4791&hilit=taurus#p4791

one friend of mine had a 1988 corvette that he installed a 200 amp alternator on, and he did the required wiring to install it correctly, the car runs much smoother and cools far better since the electric current flow to the radiator fans and ignition now stays consistent

IT was REALLY noticeable and his old stock alternator checked out good it just had no where close to the same out-put

http://www.db-starter-alternator.com/c- ... 0-amp.aspx

buy a quality fan, heres what can happen if the blades on your fan get loose at high rpms, what do you think would happen if your face and neck were hit with a flying blade while you looked for a noise or vibration under the hood, when the hood was up?

obviously the quality of parts, and the rpm and stress levels will effect the results , the cheap versions of flex fans have a rather well deserved reputation for turning to shrapnel after years of stress or if they get loose or hit anything that might cause an imbalance.

I've used them, in the past, but generally found the clutch fans that slip as the rpms exceed a designed rpm and resistance, or induced drag level , or installing electric fans vs mechanically spun fans has advantages in durability

If your having cooling issues while the cars stationary but not when the cars moving theres an excellent chance that the problem is lack of low speed air flow rates, a larger more effective fan or a more efficient fans or adding a pusher fan or more efficient fan shroud would help. clear pictures of the car,s engine compartment, radiator fans, fan shroud etc would help here a great deal.

keep in mind oil does a good deal of the heat transfer, in an engine, so an oil pan with a larger than stock capacity and an oil cooler with a built in electrical fan can do a good deal to lower engine temps.

keep in mind automatic transmissions tend to add a significant amount of heat to radiators that use the lower section to cool the transmission, adding a large efficient trans fluid cooler to the car can also significantly reduce the heat loads on the radiator

BTW one frequently overlooked factor, in cooling your engine or adding an additional oil cooler, is your alternator size,in amps and wiring the alternator correctly, if your running a 70amp-100 amp stock alternator and using electric fans to cool the engine,its not going to provide the power required to spin the fans nearly fast enough to cool the engine like a better 200 amp alternator can, Ive seen several corvettes cure cooling issues by swapping to 200 amp alternators, that simply allowed the electrical cooling fans to spin significantly faster

READ THESE

if you need to use a fan spacer kit to get the fan positioned forward into the fan shroud for increased efficiency

viewtopic.php?f=57&t=853

viewtopic.php?f=57&t=348

http://www.mrgasket.com/Portals/0/downl ... t_1992.pdf

http://www.corvettefever.com/techarticl ... index.html

http://www.ecklers.com/catalogsearch/re ... n&x=42&y=6

http://www.parts123.com/parts123/yb.dll ... 1~cadeikba

don,t forget you NEED a matching FAN SHROUD duct work to maximize air flow thru the radiator, a properly fitted fan ducting shroud can increase air flow and cooling efficiency by over 35%

below about 55-70mph (depends on the ducting and radiator surface areas, and engine heat loads the system must deal with ETC.)

the natural air flow rates of air being forced thru the radiator coils and fins flows thru the openings, due to the cars moving thru the surrounding air and the pressure differential that results, at too low a rate to efficiently absorb heat from the coolant in the radiator to effectively cool the engine, so fans and duct work are used to increase the air flow and heat transfer rates.

correctly designed and installed fan shrouds allow you to significantly increase the a fans efficiency at pulling air thru a radiator, pusher fans tend to help but generally are far less effective than puller fans.

the larger the diameter of the fan,the more blades it has and the faster it spins, the more air flow it generally provides but obviously the design of the impellers and ducting will effect the results, and loads or resistance the impeller or fan blades must deal with.

until fairly recently most radiator cooling fans were directly driven from the engine mechanically or with accessory bet drives. those fans turn at engine speed and at high rpms put a significant load on the engine

mechanical fans come in clockwise and counterclockwise rotation designs that must match the application

(NO YOU CAN,T JUST INSTALL THE OTHER SIDE FACING THE RADIATOR) and must be used with a matching water pump design. generally a fan works best if its mounted within 1" of the rear radiator surface with a MATCHED shroud or duct work that are within about 3/8" from the outer arc of the impellers, they tend to be noisy and in some cases dangerous at at high rpms its not unheard of for blades to fling off and do considerable damage.

keep in mind that the coolant must constantly flow thru the radiator to allow it to transfer heat from the engine to the outside air, the fan is a single component in a system that requires a constant inflow of hot coolant into the radiator so that the heat can be transferred continuously out to air flow and the resulting cooled ,coolant needs to flow under slight pressure back thru the block in an endless cycle

clutch fans have a viscus clutch that spins the fan based against the resistance its working against

the fans generally spin the fastest at about 2000-3000 rpm

,so from idle to about 2500 rpm fan speeds increase along with but not directly related too engine rpm,

much above that rpm the resistance won,t allow the fan speeds to increase nearly as fast as rpms increase

so the clutch fans do soak up some engine power , but not nearly as much as a solidly mounted fan would have.

generally the more blades on a quality clutch fan, the better it cools

I generally used to look for the clutch fans of caddys and buicks as many will mount to chevy water pumps with minimal or no mods

most were available from salvage yards dirt cheap in years past you ideally want something similar to this

https://www.ss396.com/chevelle/FANK...MIqpLemIjB6QIVDtbACh1uzwYdEAQYBSABEgKWbvD_BwE

http://www.network54.com/Forum/215655/message/1066184641/Car+Craft+Cooling+Fan+Dyno+Test

don,t forget a matching fan shroud that matched the radiator and fan diameter,greatly increases cooling efficiency

http://www.summitracing.com/parts/DER-17618/

better quality metal flex fans, when properly matched to a close fitting radiator shroud, can and usually do, move a huge increase in air flow rates over what can be expected from most electric radiator fans. this will generally reduce engine temps significantly and reduce loads on the alternator as you don,t need to run an electric radiator fan (s).

the problem's are that as the engine rpms increases much past 3500 rpm-4000 rpm they become a huge horse power wasting drag on the engine, and the blades by design tend to change angles to reduce the parasitic losses, some flex fan designs can require well over 35 extra horsepower to spin,once the rpm levels increase over 4500rpm,

at over 4000 rpm,and above, they all use significantly more torque to turn than at lower engine speeds and thats a big problem, the flexing also eventually causes stress fractures in the blades and if used long enough over time the blades do occasionally come off and that can be a big problem as the blades fracturing instantly unbalance the fan, and shortly after the water pump bearings fail due to vibration related stress.

there are several sources for flex fans and quality and size , and designs obviously vary so shop carefully and avoid the cheap fiberglass versions,

READ

http://www.haydenauto.com/Featured Products-Fan Clutches and Fan Blades/Content.aspx

http://www.licorvette.com/Corvette Fan Clutch.htm

http://www.popularmechanics.com/cars/how-to/a302/1772922/

and REMEMBER CHEVY

WATER PUMPS,

FAN CLUTCHES

AND

FANS,

ROTATIONAL DIRECTION

VARIES BETWEEN CARS

SO YOU MUST MATCH THE INTENDED APPLICATION FOR THE COMPONENTS BEING USED FOR ALL THREE COMPONENTS

https://m.summitracing.com/parts/der-19118

https://m.summitracing.com/parts/flx-1318

https://m.summitracing.com/parts/prm-83182

http://www.v8s10.org/forum/viewtopic.php?f=46&t=20834

but there is a well proven and fairly inexpensive solution

installing a viscus fan clutch

if you install a viscus fan clutch at lower rpms the fan spins at almost engine rpms, the internal hydraulic friction clutch keeps the fan blades , spinning but as rpms increase and resistance to the fans blades increase, the internal clutch allows some of the engines energy to push the fan, but slippage increases, so your fan may only spin at 3700rpm-4500rpm ( this mostly depends on the fan clutch design, fan loads and clutch age and condition) the fan clutches do eventually wear out, but its been my experience they are generally good for 6-7 years before youll find any significant wear.

use of a fan clutch can easily reduce the parasitic drag loses , by over 50% from those the engine would see without the fan clutch.

The use of the fan without a clutch hub, wastes some power,simply because it robs, your car of some potential peak power , through added drag, in its current config. compared to using a clutch fan hub. yet the cars cooling capacity, is not really benefiting from the lack of a clutch fan hub. adding a shroud forces the air to flow even from areas the fans not directly behind.

http://www.summitracing.com/parts/DER-17018/

clutch fans, mount a viscus clutch between the fan and the water pump belt drive that slips a a preset load rate, this limits the rpms the fan will turn, lowering the max load rates on the engine and making the blade flinging off at high rpms a far lower risk

http://www.popularmechanics.com/how_to_ ... tml?page=3

http://www.popularmechanics.com/how_to_ ... 72922.html

http://www.summitracing.com/parts/FLX-5555/

For the record: Clutch fans & blades never see RPM wise much over 3-4 grand.

This is one of the reasons in the 60-70s ALL the BIG THREE Mfg. with big Cube engines had CLUTCH FANS.

I have a page out of a 60s hot rod Magazine. It tells the story of Chrysler, The 440s Hemis and so on.

Chrysler used the clutch fans for TWO REASONS.

#1--Clutch fan blade Assmb. only spin around 3-4 thousand RPMs.

#2--Chrysler stated through dyno testing the clutch fan Assmb. would save 16.2 H.P. over a Mech. Fan. Also the Mech. Direct driven fan blade would fracture if it sustained many high RPM. cycles.

This could be the reason the big three with big horse engines used clutch fan Assmb. on the street driven big blocks in the " So Called 60s & 70s era ".

There are two basic types of fan clutches: thermal and non-thermal (also called "torque limiting"). Thermal fan clutches have a temperature-sensitive bimetal coil spring on the front that reacts to temperature changes. When the air coming through the radiator is hot, the spring expands and opens an internal valve that reduces clutch slippage. This causes the fan to spin faster for increased cooling. As the air cools, the spring contracts and closes the valve. This increases the amount of clutch slippage, allowing the fan to slow down and decrease cooling.

The clutch consists of a fluid coupling filled with a silicone based oil. In the cutaway view at the left, the area between the teeth on the clutch plates is filled with silicone fluid. An internal valve opens and closes a passage between the main fluid cavity and a fluid reservoir. When the passage is open, fluid enters the clutch and makes the fan to turn faster. When the valve is shut, fluid flows back to the reservoir but doesn't return, causing the clutch to slip and the fan to turn more slowly.

Here's step-by-step from a Haynes manual

Warning:The engine must be completely cool when this procedure is performed .

Note: A special fan clutch wrench is required (GM#46406 or Equivalent)

1.Remove the bolts and push pins that attach the intake air baffle to the radiator support,then remove the baffle. (On 2002s only)

2.Disconnect the transmission cooler lines at the engine bracket and fan shroud.

3.Disconnect the electro-viscous clutch electrical connector from the shroud.

4.Remove the upper radiator hose from the radiator;be prepared for coolant spillage.

5.Remove the fan clutch hub from the water pump by turning it counterclockwise.

6.Unclip the shroud from the radiator side panels then tilt the condenser and radiator forward.This will be easier if someone assists you.

7.Remove the fan and shroud as one unit by lifting straight up as the condenser and radiator are being held in the forward position.

8.The fan can now be unbolted from the clutch, if necessary.Be sure to tighten the fan-to-clutch bolts to the torque listed in this chapter's specifications(20 Ft.-Lbs.)!

9.Installation is reverse removal,Tighten the fan hub nut to the torque listed in this chapter's specifications(41 FT.-Lbs)!

10. Check the coolant,adding as necessary to bring it to the appropiate level.

You can replace all 4, front and back, stabilizer links with Moogs for about $100 yourself. If the rears are worn the fronts probably are too.

The blower resistor I think runs about $25. You can do that yourself. Behind the glove box door and blower motor.

Dealers still charging $700 for that clutch job based on old labor rates and parts price, when part has gone down in price about half what it was and it takes them less than an hour to actually do the job. The $70 diagnostic fee seems about normal these days.

http://www.aa1car.com/library/cooling_fan_clutch.htm

http://www.harborfreight.com/5-in-1-dig ... 98674.html

having a wide assortment of different multi meter test leads available is a huge benefit while testing

the clip test leads that test thru a wires insulation without much damage are a big help

more recently electric fans that are thermostatically controlled have become popular,most but not all electric fans have variable speeds, and if wired incorrectly will spin in the wrong direction from that desired, and many people are not aware of the high amp loads these fans can put on the alternator and fail to realize that the larger fans REQUIRE a high out put alternator or the fan blade speeds suffer noticeably if the current required is not up to the fans designed needs, at max rpms with electric fans one of the most common problems is not the fans or motors but the relays or sensors that control when and how fast the fan starts and spins, having a shop manual is mandatory in many case to track down the cause of problems as more than one relay or sensor is common

http://www.summitracing.com/parts/SUM-G4852/

http://www.summitracing.com/parts/FLX-180/

http://www.summitracing.com/search/bran ... toview=SKU

cooling system / pressure/cooling issue?

BBC with mechanical water pump will hold a lot of pressure for a week or more. When I remove the cap 6 or 7 days after the last drive to check fluid level, the water blows out with pressure. It doesn't seem to loose any fluid while driving but does seem to run hotter than I would like. Have been...

garage.grumpysperformance.com

http://garage.grumpysperformance.co...electric-fan-in-4-easy-steps.7774/#post-45162

http://www.stl-vettes.com/65Vette/corvette_Misc/Images/Fan_Clutch_Adjust.pdf

http://www.summitracing.com/parts/FLX-365/?rtype=10

duct work can significantly increase the fans efficiency, so its a great idea to have duct work that forces air to flow over the full surface of the radiator fins

theres several ways you can do this,and pull fans with a shroud mounted behind the radiator are far more efficient than pusher fans mounted in front of the radiator.

theres a huge difference in quality in electric fans that are available and unless you have an upgraded alternator putting out serious amps you generally don,t get the best potential results

generally you hook up the fan to a positive battery lead thats only hot when the ignition switch is in the ON position, and the ground lead to a sensor that provides a ground connection at a set temp, generally in the 160F-180F range

http://www.summitracing.com/parts/HFM-ZFSWF/?rtype=10

http://www.summitracing.com/parts/FLX-298/

READ THRU THESE THREADS

http://garage.grumpysperformance.co...lf-the-time-starts-and-dies.11187/#post-50245

viewtopic.php?f=70&t=3504

viewtopic.php?f=70&t=355

viewtopic.php?f=32&t=3954&p=18559&hilit=corvette+alternator#p18559

viewtopic.php?f=80&t=2465&p=6444&hilit=taurus#p6444

viewtopic.php?f=57&t=1540&p=4791&hilit=taurus#p4791

one friend of mine had a 1988 corvette that he installed a 200 amp alternator on, and he did the required wiring to install it correctly, the car runs much smoother and cools far better since the electric current flow to the radiator fans and ignition now stays consistent

IT was REALLY noticeable and his old stock alternator checked out good it just had no where close to the same out-put

http://www.db-starter-alternator.com/c- ... 0-amp.aspx

buy a quality fan, heres what can happen if the blades on your fan get loose at high rpms, what do you think would happen if your face and neck were hit with a flying blade while you looked for a noise or vibration under the hood, when the hood was up?

obviously the quality of parts, and the rpm and stress levels will effect the results , the cheap versions of flex fans have a rather well deserved reputation for turning to shrapnel after years of stress or if they get loose or hit anything that might cause an imbalance.

I've used them, in the past, but generally found the clutch fans that slip as the rpms exceed a designed rpm and resistance, or induced drag level , or installing electric fans vs mechanically spun fans has advantages in durability

Last edited by a moderator: