64 Impala with small block 327 (bored/stroked to 383), mild cam, otherwise pretty stock. The goal is to reduce engine temperatures in hot weather with the A/C on in slow speed or stopped conditions. While maintaining a stock appearance.

Low or no speed is when I have the over heating issue. It can keep reasonably cool when on the freeway (assuming you could ever find an free flowing freeway in California). The design of the grill and shroud is not that good on the 64 Impala. But all that has been optimized as best as it can be and retain stock appearance.

The oil cooler would be tucked away with an electric fan to make it effective.

In nice weather with no AC, it runs about 190-200 (thermostat temp is 190). Engine is happy at that range.

With 90 degree weather and AC on and not moving, it goes into run away over heating. I shut it down at 230-240 as I don't want to let things get any hotter. I have heard some say that it is "ok" to run that hot, but I do not agree. Popping the hood, the engine is HOT! It also causes issues with fuel boiling in the carb, that is a separate issue. I have used a IR temp reader on the thermostat housing, a radiator cap with a temp gauge in it and a electrical temp gauge inside under the dash(sender in the place of the idiot light temperature sender (on the intake manifold next to the oil fill tube). So I feel the readings are correct, not gauge error.

I am considering an oil cooler, as it is a stealthy way to remove more heat from the engine when it is getting hot. From Grumpy's info, a proper thermostat on the cooler can allow the oil to get hot enough to purge moisture, yet start cooling things down when things start getting too hot. My biggest concern was causing an oil pressure drop with the longer lines. It sounds like that is not an issue if proper lines are used and the inside diameter is sufficient on the hose, fittings and cooler, so as not to impede the flow of oil.

it is an issue with getting enough air through the radiator when the car is moving slowly or stopped. I have a higher pitched fan from a corvette installed, and also bumped it up from 17" fan to an 18" fan, so it fits tighter in the 19" shroud. One other factor to consider, I have a 700r4 transmission running through the stock cooler in the bottom of the radiator. I would not think it generates more heat than the original Powerglide, especially when stopped.

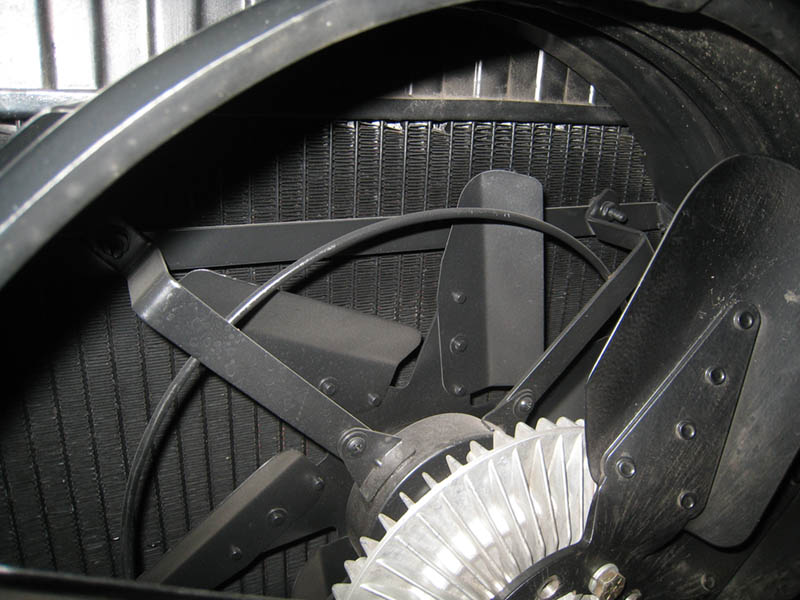

Currently I have an electric fan helping out. Carefully hidden in the far front of the shroud and painted black, you would probably never notice it till it comes on. It slows the over heating down some, but does not stop it.

Radiator is stock for a 327/300 or 409. Has 3 rows. I had it cleaned/rodded out before installation, so it is in good condition.

You can see the gap between the shroud and radiator, this is the way it they built them and would be hard to come up with a way of sealing that without looking modified. It might be possible to disassemble the shroud by cutting out the spot welds and reassembling it with a smaller gap.

Fan positioned 'half in / half out' of the shroud.

Stock style 5 blade clutch fan. 18" fan in a 19" shroud opening. This one is from a Corvette and has a bit higher pitched than the original.

I have even tried a Heavy Duty fan clutch, which involved modifying a fan blade (mounting hole locations are different). But the fan just roared VERY LOUD under normal (normal temperatures too) driving and I could even feel it taking power away when I tried to accelerate fast.

(stock on left, HD on right)

Thank you grumpy. A ton of good info always seems to be at your finger tips

yes your correct, anything much over 220f is higher than ideal, and if you think about it the clue here is that it maintains temps while moving but over heats while stationary, this strongly indicates the lack of significant air flow rates when the car/truck is not forcing additional air flow through the radiator through its movement, you obviously need a larger radiator or a fan and shroud combo that sucks more air through the existing radiator when stationary,

adding an aux engine oil cooler with its own electrical fan will also reduce the heat load on the existing radiator.

obviously a new larger radiator is rather expensive, can you post pictures of the fan and shroud?

in many cases adding a matched clutch fan and fan shroud can make a big improvement in cooling and adding an aux oil cooler always results in a lower heat load on the radiator

Id be looking at the fan and shroud , and checking for trash in the radiator fins as a first step in solving the heat issue,

yes tuning issues could be an issue, as could a marginally defective water pump, slipping fan belt, low oil level in the engine, isolate and test!

I know my neighbors 1995 corvette had a cooling issue that turned out to be a bad sensor on the water pump, and a plastic bag it sucked up covering part of the radiator

http://garage.grumpysperformance.com/index.php?thr...

if it was my car id take very careful measurements and visit a local salvage yard looking for a compatible

or easily modified fan shroud, off a luxury car,

no one sees the fan shroud with the hood closed and 90% of the people won,t have a clue its not original,

if the hood open

hell I had a 496 BBC with a three deuce corvette intake in my 1965 lemans painted pontiac light blue,

and had 389 stickers on the valve covers,

and you would be amazed at the number of people that thought,

it was the original tri power 389 pontiac GTO engine

that looked similar to this picture

many full size pontiac, buick and caddys of the 1970s-1980s even 1990s had great fan shrouds,

Id bet it solve the issue and probably costs you less than $30 .

and a couple hours time,

keep the original parts if you ever sell the car,

but why deal with 50 year old technology when its an easily solved issue

btw some mopar big blocks came with 7 blade 20" clutch fans that can be modified to fit a chevy water pump and do a great deal better at providing air flow

most salvage yards will sell you those reasonably (under $60)

a shop manual, code reader and multi meter could be helpful

read the linked info,

yeah reading links takes time ,

but youll be amazed at the details and

info contained in the links and sub links

http://garage.grumpysperformance.com/index.php?thr...

http://garage.grumpysperformance.com/index.php?thr...

http://garage.grumpysperformance.com/index.php?thr...

http://garage.grumpysperformance.com/index.php?thr...

http://garage.grumpysperformance.com/index.php?thr...

http://garage.grumpysperformance.com/index.php?thr...

http://garage.grumpysperformance.com/index.php?thr...

http://garage.grumpysperformance.com/index.php?thr...

http://garage.grumpysperformance.co...i-miss-the-older-muscle-cars.4211/#post-11077

http://garage.grumpysperformance.co...oosing-an-engine-oil-cooler.15375/#post-90261

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.com/index.php?threads/remote-oil-filters.14755/#post-80757