Re: Crankshaft Crankpin Index Checking at home for True 90 d

you do realize its been 42 years since I needed to figure crank angles and piston acceleration rates and when I was in college we actually used slide rules

your average lap top computer has 1000 times more computing power today, than the computer that took up the entire second floor or our tech center in 1967... yeah I have several degrees but its been a LONG TIME and I generally just measure and check things and remember not only do crank journal indexes vary, so do block decks, connecting rod lengths, piston pin compression heights and pin offsets, and crank journal concentricy

" QUOTE, Crank angle refers to the position of an engine's crankshaft in relation to the piston as it travels inside of the cylinder wall. Measured in degrees, the crank angle for a piston that is at top dead center (TDC) of its compression stroke is zero crankshaft angle degrees (CAD). The crank angle is critical in determining ignition timing, valve opening and closing sequencing and fuel delivery in fuel injection applications. While not critical to the average auto owner or mechanic, the angle of the crankshaft is crucial in the mathematical equations and formulas that are used to determine piston speed, maximum piston velocity and other piston and connecting rod data in racing engines.

Many mechanics understand the relation of the piston to its TDC position within the cylinder wall as it pertains to ignition timing. Setting the ignition timing to fire the spark plug a few degrees before or after TDC can be an invaluable tool for obtaining the utmost performance from an internal combustion engine. It is not, however, understood by most amateur mechanics, what the relation of the crank angle has on the performance of an engine at any given speed, nor how this information can be used to adjust the power of the engine.

One of the most critical factors inside of any combustion engine is piston speed. This determines the ability — as well as the time — it takes an engine to pull in a fresh mixture of fuel and air, purge the exhaust gasses out of a cylinder and compress the fuel and air mixture for combustion. With this knowledge, the proper valve opening and closing rates can be factored as well as the cam lobe design to take the fullest advantage of this critical time. This information on crank angle is especially critical on the newest stroker motors.

The stroker motors, so named because of the altered piston stroke dimensions, are designed to take advantage of the optimum crank angle. They use improved piston speed to empty and fill the combustion chambers. The improved crank angle dynamics act as a primitive supercharger, utilizing the fastest part of the piston's stroke to pack the cylinders with fuel and air. Conversely, the crank angle aids in determining the proper time to open the exhaust valves to best use the power stroke while remaining capable of clearing the spent exhaust gases from the cylinder. Understanding the crank angle allows a custom engine builder to design an engine using the optimum connecting rod length and piston pin height on a crankshaft with the proper throw dimensions to gain the utmost in horsepower and torque."

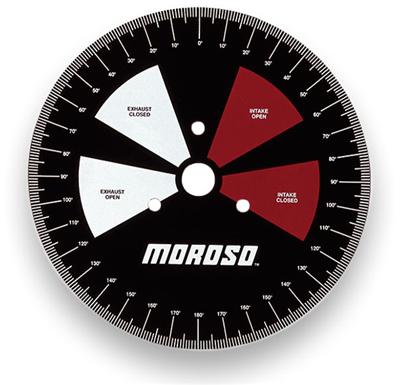

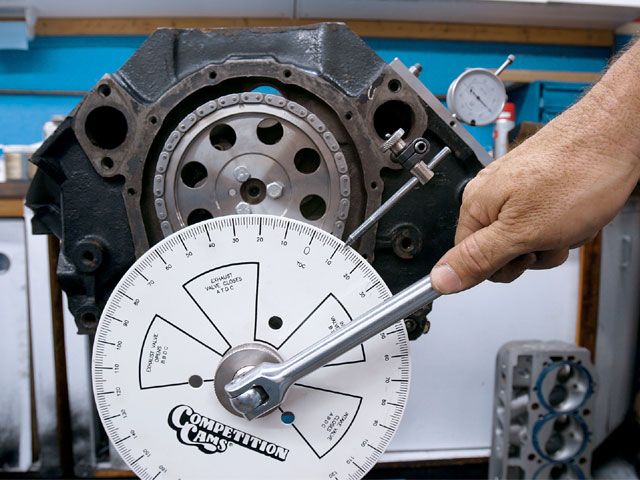

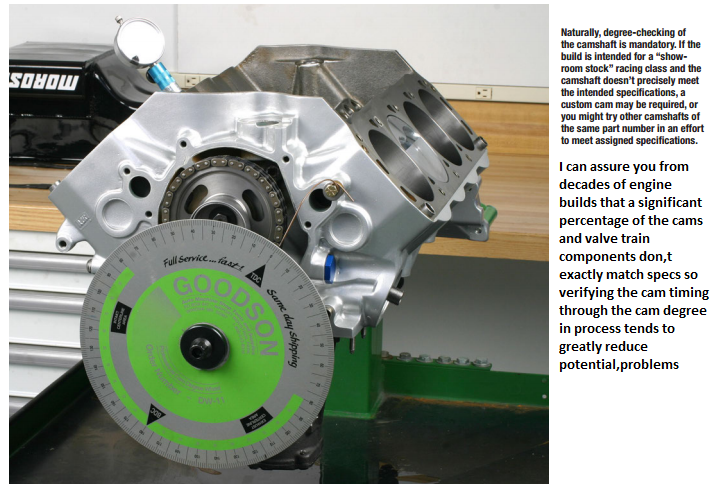

anyone whose spent time with an accurate dial indicator and a piston bridge, and a 18" diameter degree wheel that bothered to check more than the #1 piston, will tell you that its rare to find all the crank journals exactly spaced at 90 degrees

but Ill also point out that theres manufacturing tolerance variations in cam shafts that are off a degree or two so technically if you don,t check its a crap shoot as to what your building, but on the plus side I rarely find the crank journal index off by more than 1 -1.2 degrees,max and most are closer except on a few reground cranks I looked at a few years ago. on the forged SCAT cranks I generally use in performance builds, they are usually pretty close to correct.

a few related links below

http://www.iskycams.com/techinfo_index.html

http://marinewiki.org/index.php/Main_en ... inspection

http://www.epi-eng.com/piston_engine_te ... issues.htm

http://www.epi-eng.com/piston_engine_te ... orbers.htm

viewtopic.php?f=59&t=1390&p=12997&hilit=measuring+tools#p12997

http://www.epi-eng.com/piston_engine_te ... ngines.htm

http://www.epi-eng.com/piston_engine_te ... basics.htm

viewtopic.php?f=52&t=90

http://tuning.mbs.id.au/Engine/crank_index.htm

viewtopic.php?f=52&t=399&p=1499&hilit=+degree+wheel#p1499

viewtopic.php?f=52&t=966&p=1682&hilit=+degree+wheel#p1682

viewtopic.php?f=52&t=974&p=1699&hilit=+degree+wheel#p1699

http://en.wikipedia.org/wiki/Crankpin