Yes... there are lots of threads about the crossfire. And yes, I could have swapped in an LSx and been done, but the goal here has been to retain the character of the car- to include the twin TBI set up. The car has been in my family for 27 years (we were the second owners). It was also the car I learned how to drive on. Lots of sentimental value.

And that's where making it a sleeper of sorts comes in. I wanted it to LOOK factory as much as possible- yet run like a totally different car. That meant a lot of trade-offs, but I think I have it where I want it.

It's been about two years since I started on the 82 Vette. I posted a couple of times about it and have some updates on it.

Well, I have squeezed out 5.2- 5.4 0-60mp times on a 325hp/373lbs-ft torque motor with a bigger cam, 255/60/15s, stock heads, stock suspension, and stock exhaust pipes (sans converter). It will run closed loop nicely at idle and cruise and then 12.2-ish : 1 AFR at WOT using a tweaked iron head '86 Vette spark table.

•Custom Bored 690 CFM TBI Units (retain the balance ports)

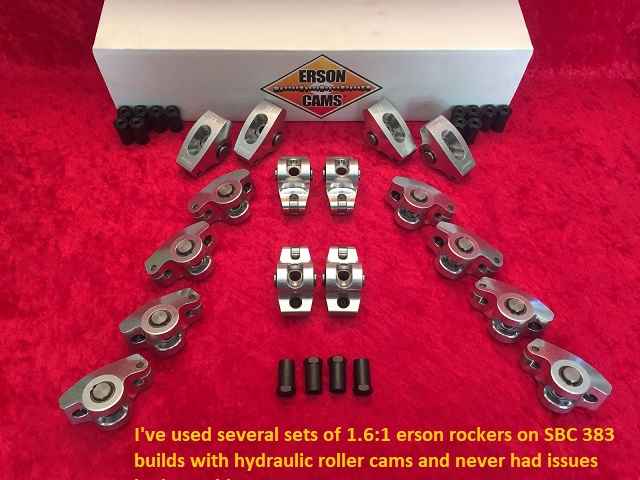

•.465” IN /.488” EX 112 LSA Erson Cam

•Dynamic EFI EBL Flash ECM

•Custom Variable Air Fuel Pressure Regulator (VAFPR)

•Dynamic Crossfire Solutions Renegade Intake

•90lb Fuel Injectors

•TT-1 Wideband O2 Sensor

•B&M Governor (5,400rpm 1-2 Shift)

•31gph 1985 Corvette Fuel Pump

•IAT Sensor

•Dewitt’s Aluminum Radiator

•Custom 140mph Speedometer & 5,500rpm Red Line Tachometer

•3.73 : 1 Axle Ratio

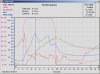

Attached is an edited screenshot of the WUD data log (Dynamic EFI EBL) where you can see at the 2 second mark where I push it to WOT from a dead stop and then at 7.4 second mark it hits 60mph. This was on a 90* day and a warm transmission.

FYI- It was in closed loop and leaning out the mixture right before I went to WOT, consequently the AFR went a little lean just as the ECM went into AE ahead of PE mode. But it settles real quick into & around the desired AFR.

And that's where making it a sleeper of sorts comes in. I wanted it to LOOK factory as much as possible- yet run like a totally different car. That meant a lot of trade-offs, but I think I have it where I want it.

It's been about two years since I started on the 82 Vette. I posted a couple of times about it and have some updates on it.

Well, I have squeezed out 5.2- 5.4 0-60mp times on a 325hp/373lbs-ft torque motor with a bigger cam, 255/60/15s, stock heads, stock suspension, and stock exhaust pipes (sans converter). It will run closed loop nicely at idle and cruise and then 12.2-ish : 1 AFR at WOT using a tweaked iron head '86 Vette spark table.

•Custom Bored 690 CFM TBI Units (retain the balance ports)

•.465” IN /.488” EX 112 LSA Erson Cam

•Dynamic EFI EBL Flash ECM

•Custom Variable Air Fuel Pressure Regulator (VAFPR)

•Dynamic Crossfire Solutions Renegade Intake

•90lb Fuel Injectors

•TT-1 Wideband O2 Sensor

•B&M Governor (5,400rpm 1-2 Shift)

•31gph 1985 Corvette Fuel Pump

•IAT Sensor

•Dewitt’s Aluminum Radiator

•Custom 140mph Speedometer & 5,500rpm Red Line Tachometer

•3.73 : 1 Axle Ratio

Attached is an edited screenshot of the WUD data log (Dynamic EFI EBL) where you can see at the 2 second mark where I push it to WOT from a dead stop and then at 7.4 second mark it hits 60mph. This was on a 90* day and a warm transmission.

FYI- It was in closed loop and leaning out the mixture right before I went to WOT, consequently the AFR went a little lean just as the ECM went into AE ahead of PE mode. But it settles real quick into & around the desired AFR.