A recurring theme has been replayed over and over,

READ THE LINKED INFO CAREFULLY

THERES NOT A DAMN THING YOU CAN'T FIND AND FIX WITH A FEW TOOLS,

AND SOME FAMILIARITY WITH THE CORVETTE< A SHOP MANUAL IS A HUGE HELP

Id strongly suggest you systematically verify the cause rather than making random guesses

this requires a few basic tools and ideally a shop manual and code reader

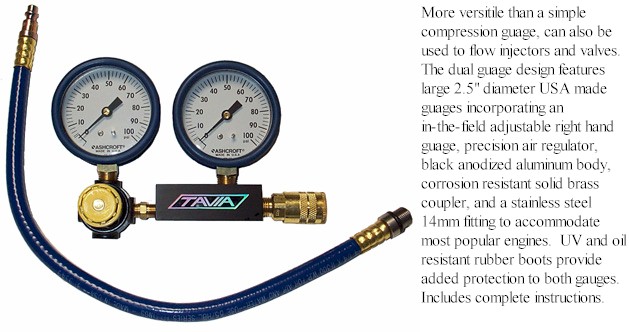

certainly a multi meter and vacuum/fuel pressure gauge may help

as usual break the issue down to its basic components, if it won.t spin over its most likely a fuse, a short circuit or a loose or corroded battery connection or the starter needs to be rebuilt/replaced.

if it spins you need to verify fuel delivery and pressure, ignition, and sensors like the oil pressure sensor

pull trouble codes get out the shop manual, and get a decent code reader and multi meter

what trouble codes are present?

will the engine spin on the starter?

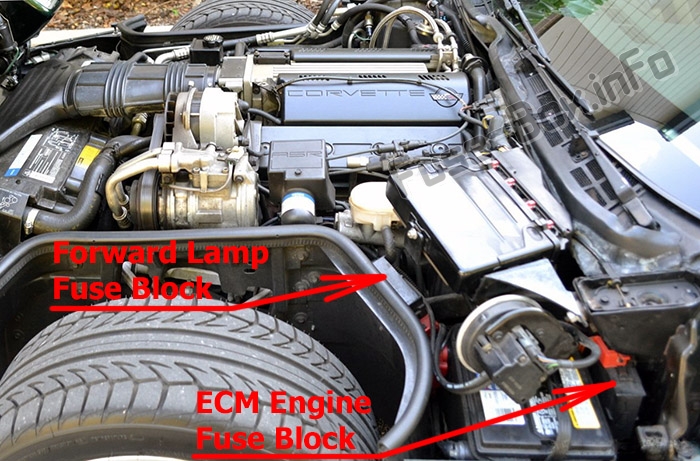

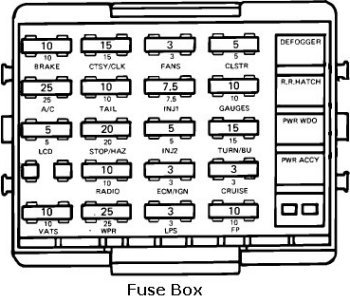

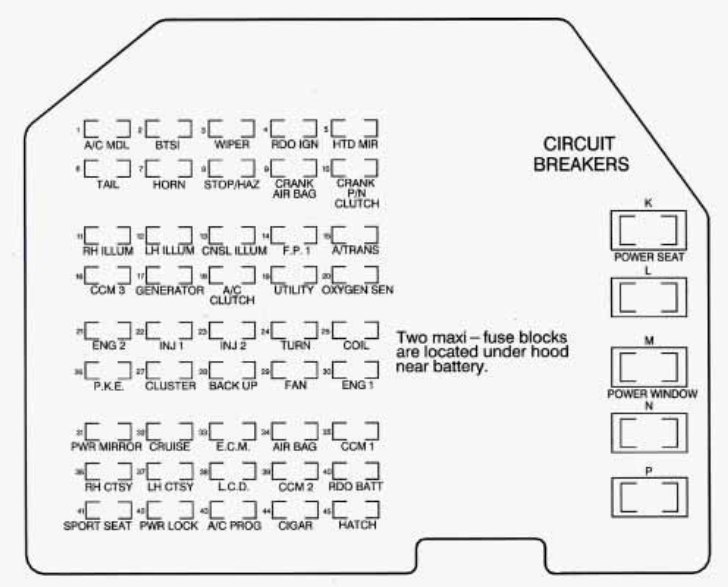

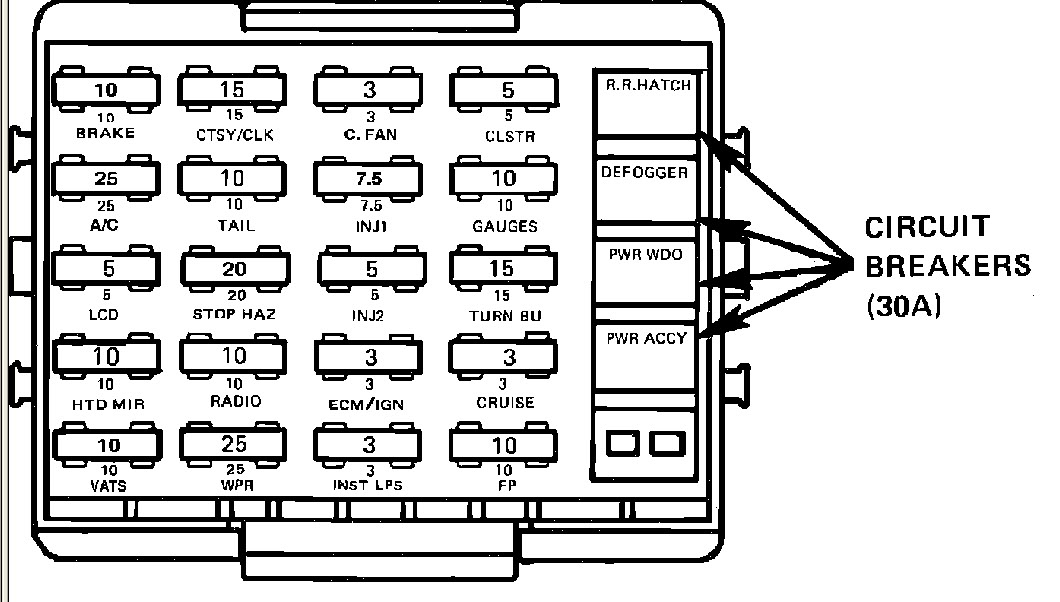

have you check all the fuses

are you getting ignition spark at the plugs?

have you checked all the fuses on the pass dash side panel?

step one pull trouble codes there's no problem you can't isolate and correct in an hours time,

unless its mechanical like a busted cam, or blown head gasket or cracked block etc. if you go about the problem logically

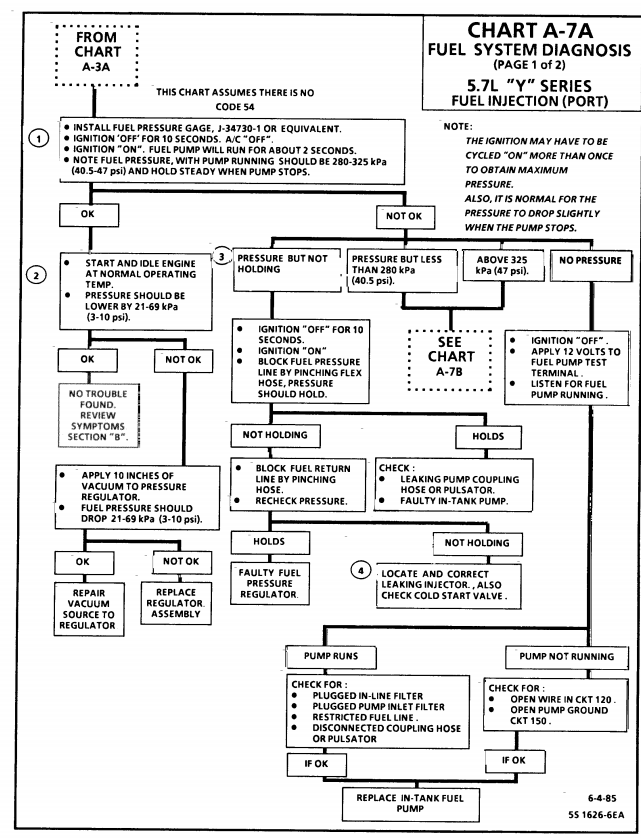

step two, verify you have at least 40 psi of fuel pressure in the injector manifold within 7 seconds of turning on the ignition key to start and you have at least 15 psi of oil pressure and don't have vacuum leaks at hose connections and all sensors are functional and connected

step three

verify you are or are not getting spark at several spark plugs when cranking

some guy or gal posts questions concerning why his or her c4 corvette,

is difficult too start, why it won't accelerate or why it misses

or has less than the power it used to have.

some guy will mention he's having issues and expect me to instantly know whats wrong,

from rather vague references to the symptoms, and how its to be corrected , frequently..

without seeing the car or opening the hood....

it does not work that way, in the real world,

yes I'm well aware most guys don't have deep financial pockets,

dropping the car off at a local dealership can cost you hundreds,

\ or thousands of dollars,

if your the average guy who owns and drives a 23 year old or older car,

you want to save a great deal of that cash by learning to fix the car yourself!

isolate and test and find the problems sources, you need to think logically,

its usually going to be related too low compression,

mal-functional ignition, lack of proper fuel delivery, engine cooling, electrical connections ,

a blown fuse a bad ground, oil pressure or a sensor function in most cases,

you may simply have a TPS or IAC thats out of adjustment!

you may have a loose vacuum hose or the cars long over due for a tune-up

your job is to play detective and find the problems source.

the basic cause is almost always far easier to diagnose and cure than most owners of the cars would believe,

a scan tool, A MULTI METER, and a SHOP MANUAL,

A FUEL PRESSURE AND VACUUM GAUGE,

and pulling codes gives you a place to start,

but it requires you to go through a check list and ,

most people have the absurd concept ,

that you can diagnose and isolate the problem with out testing.

guessing does not generally work out, dealing in proven facts does

the issues very likely to be related to a defective sensor,

a worn valve train component, low or inconsistent fuel delivery or ignition related,

but partly clogged catalytic converters, vacuum leaks, loose vacuum hoses,

mal-functioning injectors, corrosion on wiring,

worn ignition wires, fouled spark plugs, defective sensors,

loose connections

and corrosion on electrical connections, clogged fuel and oil filters are all suspect.

you need to isolate and test to find the cause.

Ive had guys so frustrated they wanted to sell the corvette at a significant financial loss,

only to find a simple valve adjustment and a couple sensors being replaced made the car run almost like new!

theres really nothing in the c4 corvette,

the average guy can,t find and fix ,

if hes willing to logically test and isolate each component.

don,t get frustrated or over whelmed, isolate and test

https://www.championradiators.com/Chevrolet-Corvette-radiator-3-row-1984-1990

https://www.corvettecentral.com/c4-84-96/96-shop-service-manual-cd-rom-114143?returnurl=/c4-84-96/?count=9

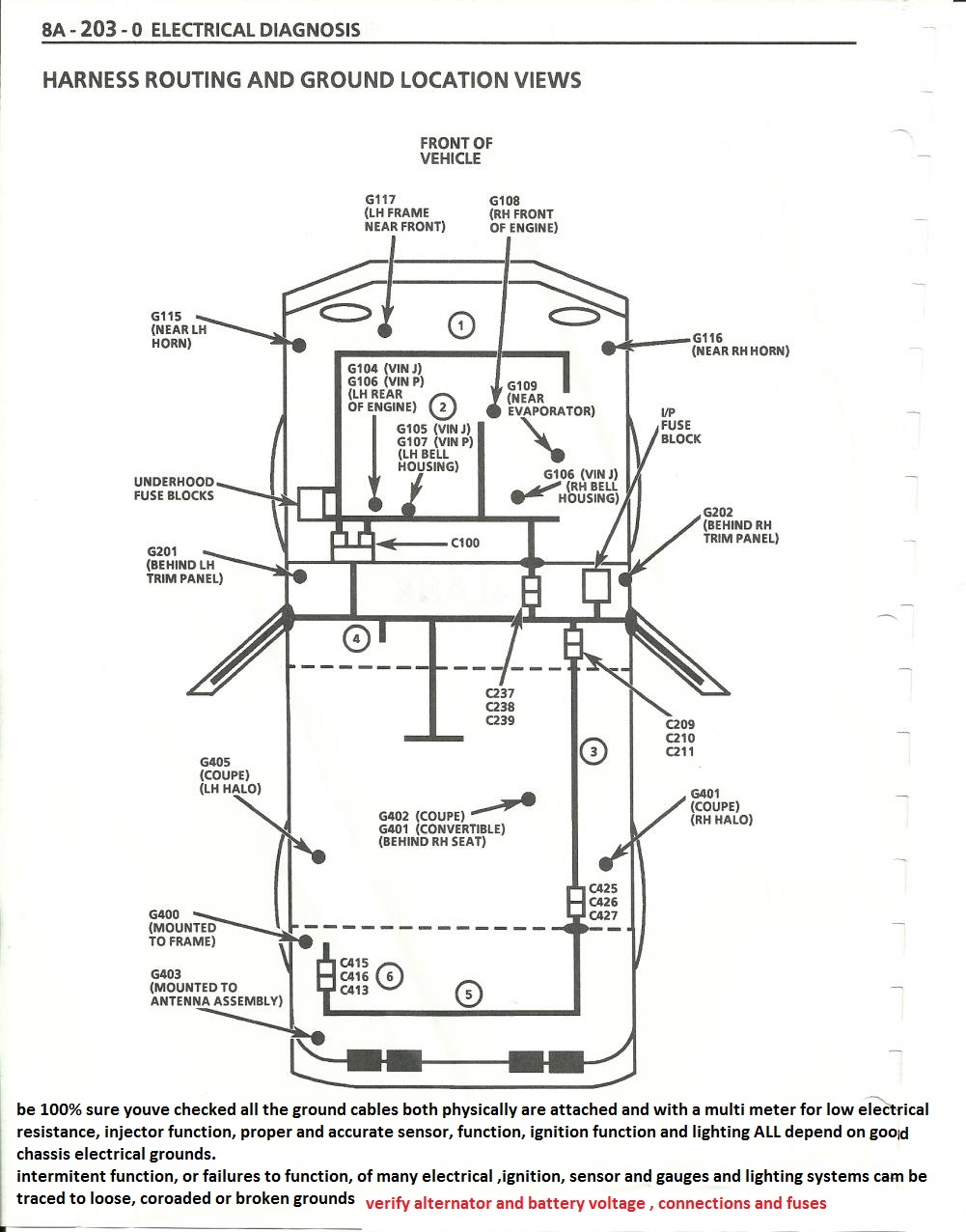

a failed SENSOR, A BAD ELECTRICAL GROUND , a worn out alternator,or battery,

(YES YOULL NEED TO PULL TROUBLE CODES AND USE A MULTI METER)

yes the issue can be major like a blown head gasket, a worn out opti-spark ignition,

or worn cam, or a clogged catalytic converter

or its just as likely minor and easily cured like a bad sensor,

a worn out fuel pump or fuel injector or fuel pressure regulator,

or clogged fuel filter. or you simply need a tune up

BUY A SHOP MANUAL,

and refer to it often,

for you particular year corvette

USE THE TOOLS REQUIRED

THINK LOGICALLY ,NEVER ASSUME .

.TEST, DEAL IN FACTS

get,

AND LEARN TO USE a decent code reader,

and scan tool and multi meter

and leak down tester , fuel pressure gauge, noid lights

http://www.helminc.com/helm

isolate the cause to mechanical, (compression , VALVE TIMING AND LIFT)

fuel delivery (consistent fuel pressure)

ignition (ARE YOU GETTING CONSISTENT SPARK AT THE PLUGS)

all the answers are readily available, theres known testing procedures and listed test results you can expect, and procedures listed in the shop manual for isolating and testing components, you don,t need to be a genius, you just need to be logical and persistent and not afraid to learn new things while getting your hands dirty at times, don,t get overwhelmed , break everything down too easy individual problems and tests, verify and test all the sensors,and test for factors like consistent fuel pressure, known temps,expected voltage or ohms resistance, and vacuum readings and don,t randomly start replacing parts as that gets expensive and its rarely the most efficient way to eliminate problems(unless you get really lucky) with modern computer diagnostic software you,ll have some advantages but think logically, most automotive problems still concern, loose electrical connectors, defective sensors, lack of compression, fuel delivery issues ,fuel pressure, vacuum, temperature or electrical issues.

https://www.zip-corvette.com/85-89-high-performance-adjustable-maf-sensor.html

85-89 High Performance Adjustable MAF Sensor

don,t get over whelmed,

simply break the problem down to testing each basic sub system,

test each related sensor and electrical component and electrical sensor and connection.

some reading on the threads posted below, a bit of logic and deductive reasoning, and a multi meter and a shop manual will go a long way toward finding and fixing the problem.

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

Oil Pressure Sender/Switch. 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F, 15,000 Ohms @ 40 F.

Outside Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

In Car Temp Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

MAF (Mass Air Flow) Sensor. .4 Volts @ idle, 5 Volts @ Full Throttle.

Oxygen (O2) Sensor. .1 Volt Lean Mixture, .9 Volt Rich Mixture.

TPS (Throttle Position Sensor). .54 Volts Idle, ~ 5 Volts Full Throttle.

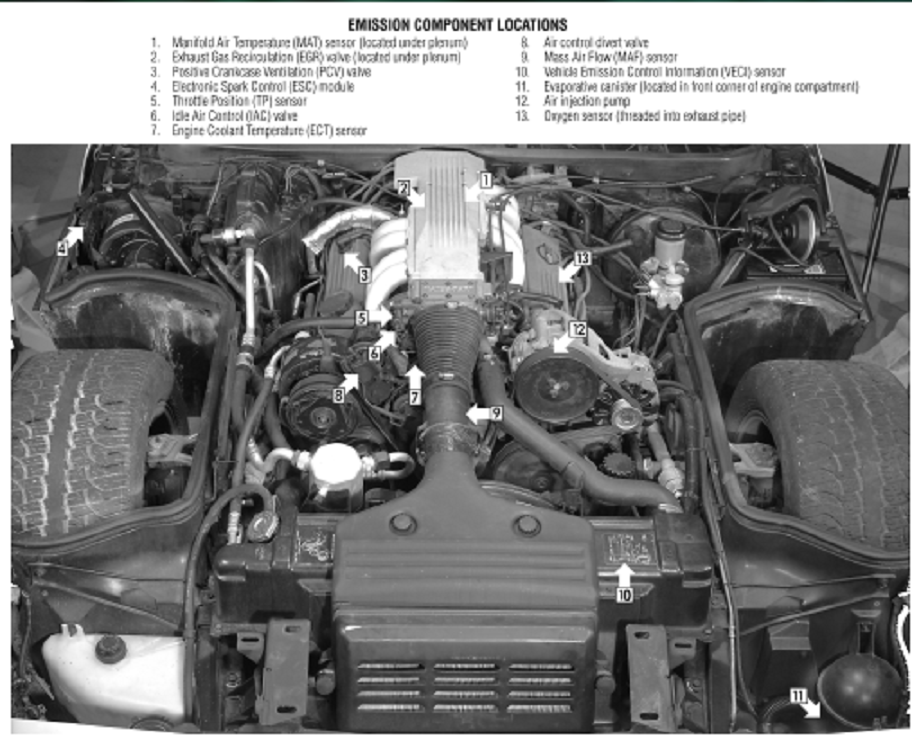

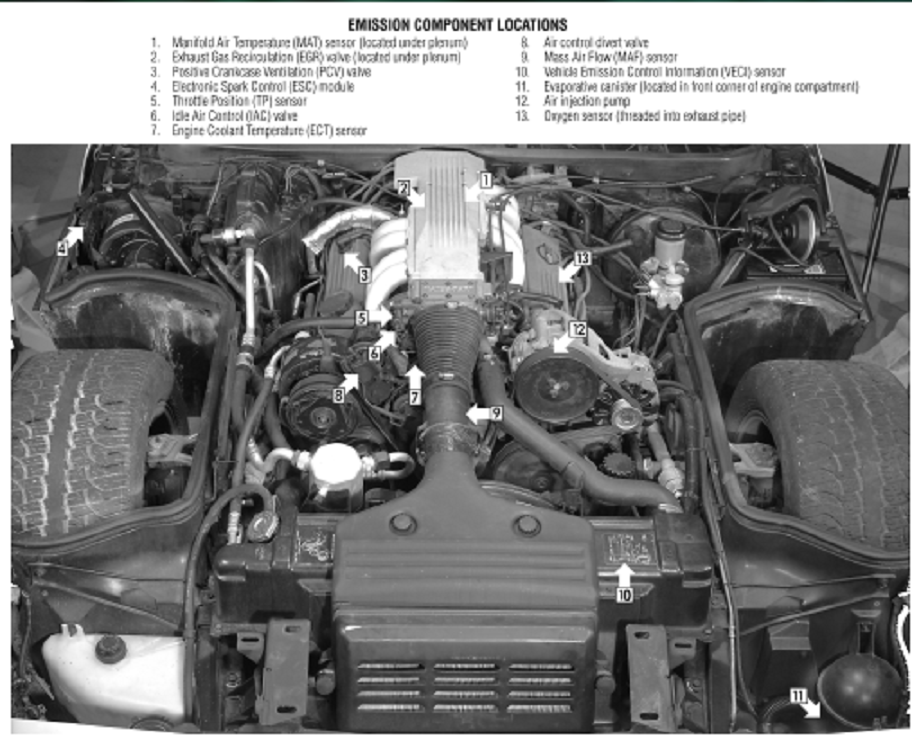

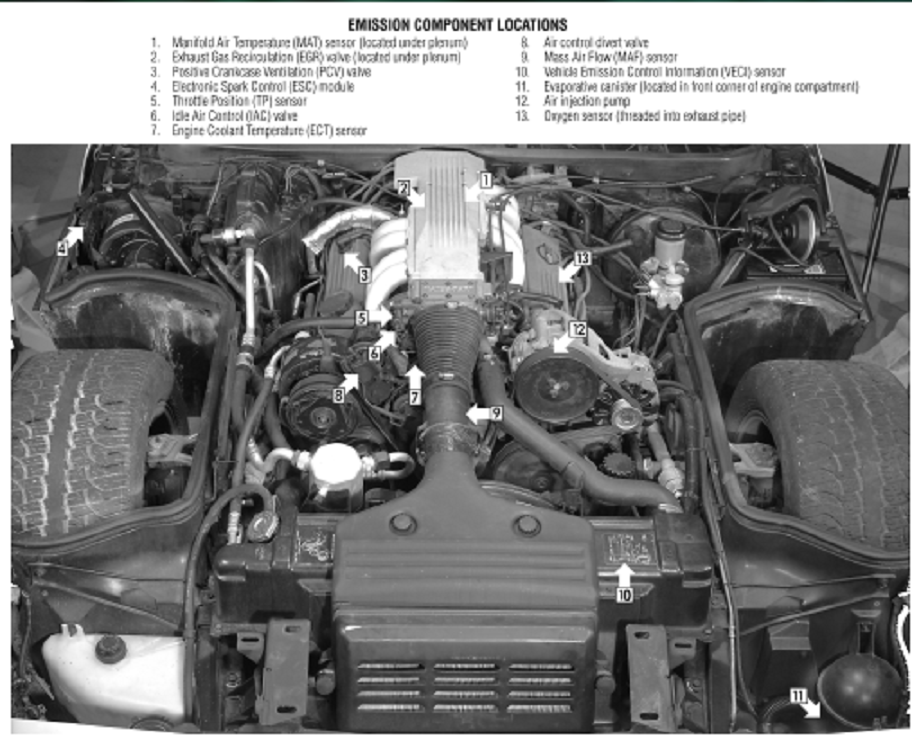

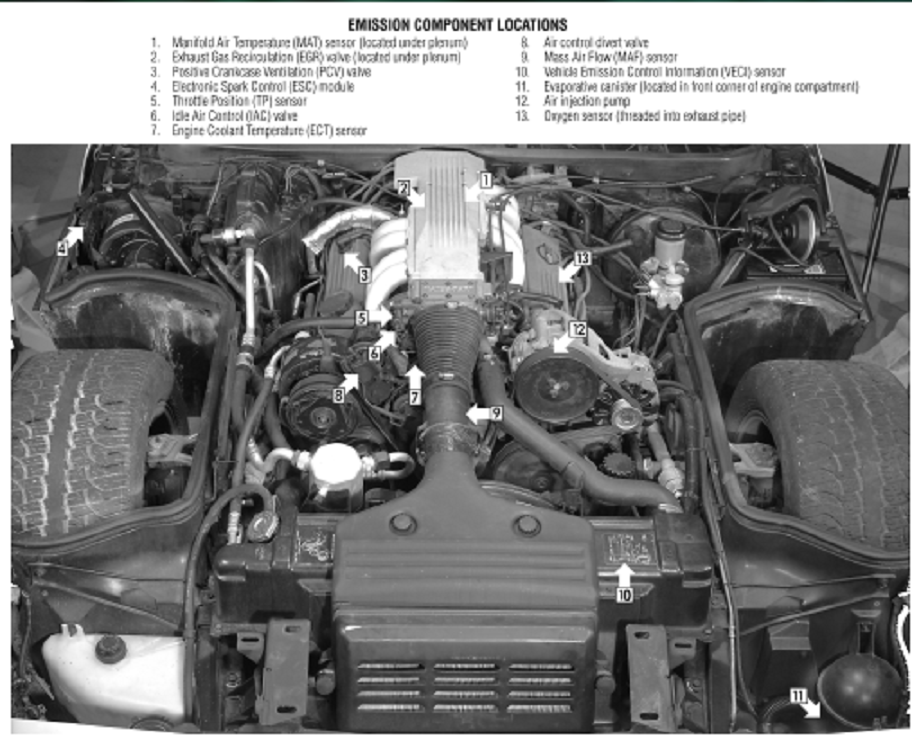

Sensor Locations

Sensor

Location

Engine Coolant Temperature Sensor. Front of engine, below Throttle Body.

Engine Oil Temperature Sensor. Left rear of engine, just above the oil filter.

Oil Pressure Sender/Switch. Top, left hand rear of engine.

Fuel Quantity Sender. Top of fuel tank, beneath filler pipe escutcheon panel.

MAT (Manifold Absolute Temperature Sensor). Underside of manifold air plenum at rear.

Outside Temperature Sensor. Right side of engine, top right corner of radiator.

In Car Temp Temperature Sensor. Coupe: above left seat near interior courtesy light, Convertible: center of cargo compartment lid.

MAF (Mass Air Flow) Sensor. Front of engine ahead of throttle body.

Oxygen (O2) Sensor. Left side of engine, in exhaust pipe.

TPS (Throttle Position Sensor). Right side of throttle body at the front.

sensor locations

heres a rather useful addition to the older c4 corvette tuning world, its a new (yes expensive)

but adjustable and thus some what tune-able MASS AIR FLOW SENSOR for the TPI corvettes

without pulling trouble codes and testing your simply guessing at best,

break the issue down into separate issues,

check ignition strength and timing,and voltage

check fuel supply/delivery pressure and volume

check cam timing and cylinder compression.

check valve train control and valve adjustment

check firing order and spark plug gap

check the valve lift, and for work lobes

check for vacuum leaks

adjust your iac and tps

check your exhaust back

pressure

verify sensors correct function

https://www.harborfreight.com/catal...core,f,EAFeatured+Weight,f,Sale+Rank,f&q=zr13

all the answers are readily available, theres known testing procedures and listed test results you can expect, and procedures listed in the shop manual for isolating and testing components, you don,t need to be a genius, you just need to be logical and persistent and not afraid to learn new things while getting your hands dirty at times, don,t get overwhelmed , break everything down too easy individual problems and tests, verify and test all the sensors,and test for factors like consistent fuel pressure, known temps,expected voltage or ohms resistance, and vacuum readings and don,t randomly start replacing parts as that gets expensive and its rarely the most efficient way to eliminate problems(unless you get really lucky) with modern computer diagnostic software you,ll have some advantages but think logically, most automotive problems still concern, loose electrical connectors, defective sensors, lack of compression, fuel delivery issues ,fuel pressure, vacuum, temperature or electrical issues.

http://www.helminc.com/helm

the correct matching SHOP MANUAL

TIMING LIGHT

IR TEMP GUN

VACUUM GAUGE

MULTI METER

FUEL PRESSURE GAUGE

COMPRESSION TEST GAUGE

keep in mind the basics you need to verify the fuel pressure is at about 40 psi if your dealing with a C4 corvette,

you should NOT have significant exhaust back pressure, clogged catalytic converters,

are a common problem on older c4 corvettes,

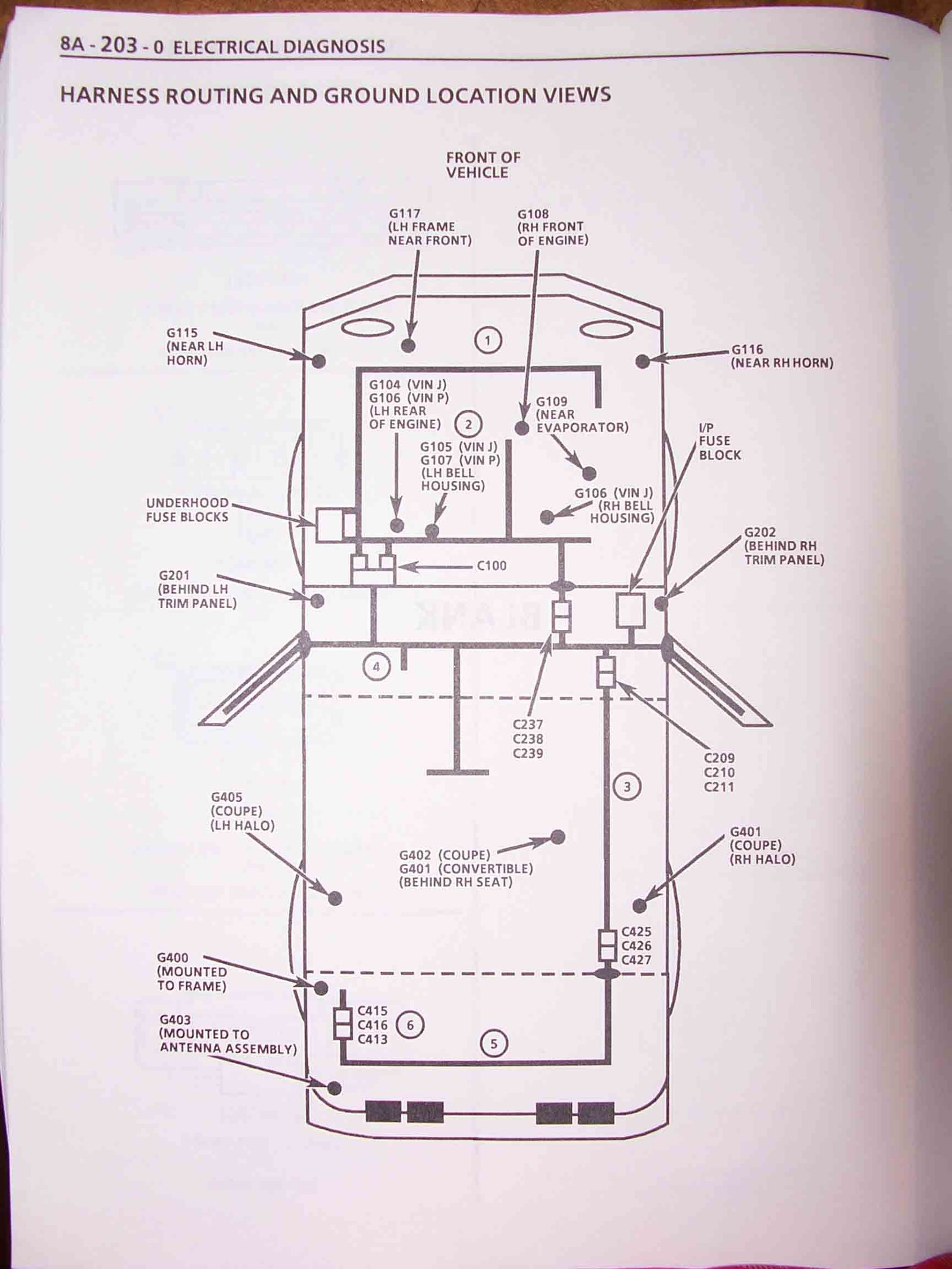

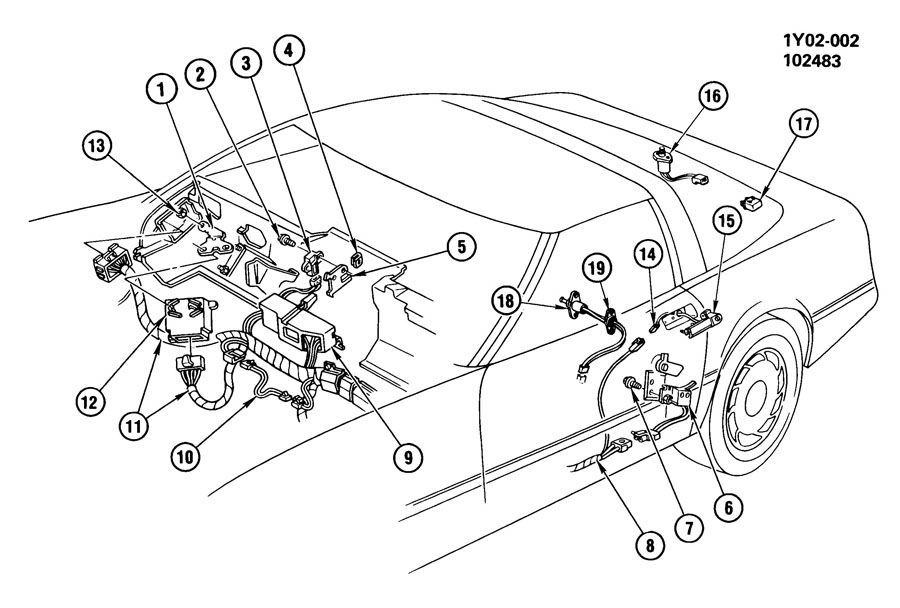

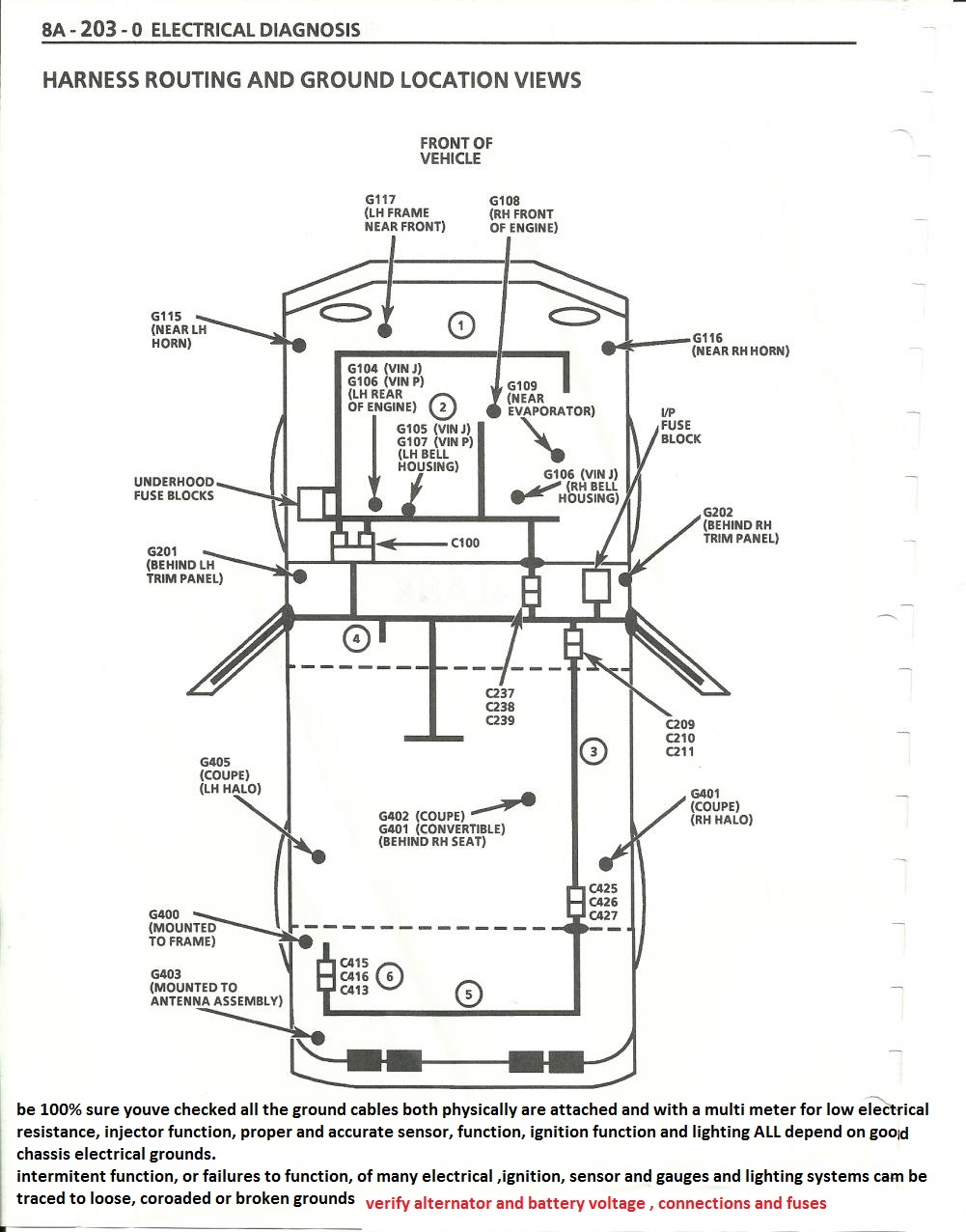

verify the fuses are not blown, the trouble codes do not show any problems,

all electrical grounds are reading good,

verify theres at least 14.5 volts at the battery while its running, so you know the alternator functions,

and all the injectors are functional with a noid light,

all cylinders should read within 10% and show about 150 psi or greater.,

on a compression test, verify the firing order,

set the spark plug gaps at .045 ,

and verify all the listed sensor values,

verify the cam lobes are not worn, verify you have at least 10 psi of oil pressure per 1000 rpm.verify theres no vacuum leaks

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

viewtopic.php?f=55&t=109

you might have clogged catalytic converters, the ignition timing may be way off, you might have a worn out cam, the fuel pump may be defective, some injector(s) may be defective,check the alternator out-put check the fuel rail pressure use a noid light on the injector wiring, check the fuses,

Ive found that the one most commonly over looked in my experience is that the stock exhaust system, is highly restrictive, especially if the catalytic converters are partly plugged and the stock fuel delivery system is not adequate,for the potential power, the heads and intake, allowable air flow potential, are all restrictive, and the stock cam timing and lift is already near max as it was designed to produce about 260 hp,and operate at under 5700 rpm, if you try too add an additional 100-200 hp, and 1000 rpm-2000 rpm to the engines power band, and too the engines output youll quickly find this to be a factor.

I've also occasionally seen guys, improperly index or install a cam without degreeing it in correctly and thus have power band limitations.

Id suggest you buy a factory shop manual, multi meter and a timing light, fuel pressure and vacuum gauge and start checking.

reading these links will be helpful

yes I know it will take some time and effort to isolate and test

but its the only 100% sure route to finding and fixing your problem,

don,t get over whelmed,

simply break the problem down to testing each basic sub system,

test each related sensor and electrical component and electrical sensor and connection.

some reading on the threads posted below, a bit of logic and deductive reasoning, and a multi meter and a shop manual will go a long way toward finding and fixing the problem.

this is the most consistently accurate I.R temp gun I've used for testing[/img]

http://www.testequipmentdepot.com/extech/thermometers-and-humidity-meters/infrared-thermometers/high-temperature-infrared-thermometer-58to1832f-50to1-laser-pointer-42545.htm?utm_source=bing&utm_medium=cpc&utm_campaign=NEXT - Bing Shopping - Extech&utm_term=1100200223789&utm_content=All Extech Products

INFRARED TEMP GUN

you always need a base line to start from, on a corvette.

a logical step by step approach and keeping accurate notes helps.

youll NEED a multi meter, a shop manual

and a timing light and fuel pressure gauge at a minimum,

set and verify your ignition timing, pull trouble codes,set your tps and iac,, then check for vacuum leaks on the lines and intake,then get out your multi meter and verify all the sensors, chances are good a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful

basic fuel injector test

(pull your trouble codes and check battery voltage ,alternator output and ignition spark first)

(BTW it rarely hurts to drain old fuel thats over 4 months old and replace the cars fuel filter, then add two different brands of fuel injection cleaner and 6 oz of marvel mystery oil to as full tank of fresh high test gas to the car if its been sitting un-used for very long before you start testing for fuel injection related issues

now Ill assume your battery reads over 12 volts and the starter works, and easily spins the engine

the first step

find the fuel rail shrader valve and remove the cap and connect the fuel pressure gauge

if you turn on the ignition key to get the dash and accessories to light up but don,t start the engine,the fuel pump,

should briefly run to pressurize the fuel rail to about 38psi-42 psi,

this should stay at this pressure level for at least 5 minutes minimum, if it drops slowly your fuel rail is leaking fuel.

now the fuel pressure regulator may be defective or leaking, or in very rare cases the fuel pump may be defective ,

but the most likely cause is a fuel injector(s) stuck in the open position.

next pull the injector harness,

off a single injector at a time, press the wire bar to release the clip, retention, then pull it up and off, the noid light plugs into the harness,

use the spare injector pig tail

on the now disconnected injector ,connect the multi meter on ohms setting and it should read 11-13 ohms injector on each injector tested.

if it reads under 9 ohms or over 20 ohms its a defective injector

now use a couple 3 ft long test leads connect one too one of the pig tail test leads

https://www.walmart.com/ip/Uxcell-2...-Clips-Test-Jumper-Wire-1-5m-2-Color/45588242

and to 12 volts, connect the other pig tail lead too a different test lead and watch the fuel pressure gauge,with the key out of the ignition , you should have 38-42 psi of fuel rail pressure, watch carefully while you tap the second test lead to ground (the plenum or alternator case works) the fuel pressure should drop as you tap the ground pig tail lead, this verifies the injector function at least partially, if you don,t see the pressure drop the injectors not allowing fuel flow through it and should be replaced.

after you complete each injector test , turn the ignition key on, to re-pressurize the fuel trail and reconnect the harness to the previously tested injector,

repeat the noid light and pig-tail function fuel pressure test on each of the other injectors individually.

youll need a fuel pressure gauge and multi meter

it helps if you have a spare fuel injector pig-tail for testing

having a NOID light injector harness tester wont hurt either

https://www.harborfreight.com/11-piece-noid-light-and-iac-tester-set-97959.html

on the TPI and LT1 efi and many other EFI intakes,

theres a shrader valve,

that can be easily accessed to check fuel rail pressure,

dealing in facts you verify is always preferable.

GM part number for the complete fuel rail o-ring kit is 17111696

if your TPI FUEL PRESSURE REGULATOR DIAPHRAGM LEAKS youll find it difficult or impossible to be starting your car

heres a link to the correct o-rings they are light blue

NAPA sells them at times

all the o-rings on the fuel rails and injectors need to be dipped in thin oil so they insert and slide into place with less friction, this tends to greatly reduce the chance of the o-rings ripping, and yes you need the correct o-rings that fit correctly to begin with if you expect the rings to seal correctly

http://tpiparts.net/inc/sdetail/10950/300

17113544 - Injector Seals

17111696 - O-Ring Kit

22514722 - Fuel Inlet O-Ring

22516256 - Fuel Inlet O-Ring

if you have a cylinder or two not functioning correctly or a injector thats barely functional, an infrared temp gun checking the exhaust port temps will generally allow you to find and isolate its location as it will be usually be running at a lower average temperature,

infrared thermometers are a very useful tool to track down issues with tuning, or mal functioning sensors , without verified facts your guessing.

this is the most consistently accurate I.R temp gun I've used for testing[/img]

http://www.testequipmentdepot.com/e...1100200223789&utm_content=All Extech Products

INFRARED TEMP GUN

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

any time that your dealing with a potential temperature issue or a trouble issue where , knowing the exact temperature vs what a gauge might say, it helps to have a handy and accurate infrared temp gun handy to locate and confirm heat, levels.

http://garage.grumpysperformance.co...dding-a-fuel-pressure-gauge.15264/#post-88472

http://garage.grumpysperformance.co...njection-at-start-up-problem.7309/#post-24862

http://garage.grumpysperformance.co...oven-facts-if-your-in-doubt.13051/#post-84695

http://garage.grumpysperformance.com/index.php?threads/tpi-fuel-pressure-issue.10385/#post-42943

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://garage.grumpysperformance.com/index.php?threads/diagnoseing-tpi-lt1-problems.1241/

http://garage.grumpysperformance.com/index.php?threads/gm-tpi-stalling-diagnosis.15194/#post-86991

http://users.erols.com/srweiss/tableifc.htm

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.co...ng-high-flow-cats-on-exhaust.8401/#post-29318

http://garage.grumpysperformance.co...s-cause-a-bad-idle-in-drive.14203/#post-72114

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

http://garage.grumpysperformance.co...le-shooting-flow-chart-info.11536/#post-71845

http://garage.grumpysperformance.co...ittent-cylinder-miss-problem.9478/#post-57225

http://garage.grumpysperformance.com/index.php?threads/previous-owner-butchered-wiring.3439/

http://garage.grumpysperformance.co...and-verify-each-possibility.11219/#post-50643

http://garage.grumpysperformance.co...g-your-tpi-maf-and-cpu-links.2825/#post-56790

http://garage.grumpysperformance.co...-you-failed-emmision-testing.3522/#post-52999

http://garage.grumpysperformance.co...oven-facts-if-your-in-doubt.13051/#post-84695

http://garage.grumpysperformance.co...and-verify-each-possibility.11219/#post-50643

http://garage.grumpysperformance.co...h-a-1988-vette-after-prolonged-storage.16112/

http://garage.grumpysperformance.co...-idles-and-sometimes-stalls.10688/#post-46303

http://garage.grumpysperformance.com/index.php?threads/1991-c4-runs-like-crap.10616/#post-45635

http://garage.grumpysperformance.co...rical-glitches-in-newer-cars.5492/#post-18411

http://garage.grumpysperformance.co...ing-c-4-or-tpi-fuel-injectors.1378/#post-9085

Sensor

Location

Engine Coolant Temperature Sensor. Front of engine, below Throttle Body.

Engine Oil Temperature Sensor. Left rear of engine, just above the oil filter.

Oil Pressure Sender/Switch. Top, left hand rear of engine.

Fuel Quantity Sender. Top of fuel tank, beneath filler pipe escutcheon panel.

MAT (Manifold Absolute Temperature Sensor). Underside of manifold air plenum at rear.

Outside Temperature Sensor. Right side of engine, top right corner of radiator.

In Car Temp Temperature Sensor. Coupe: above left seat near interior courtesy light, Convertible: center of cargo compartment lid.

MAF (Mass Air Flow) Sensor. Front of engine ahead of throttle body.

Oxygen (O2) Sensor. Left side of engine, in exhaust pipe.

TPS (Throttle Position Sensor). Right side of throttle body at the front.

Sensor Outputs:

Sensor

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

Oil Pressure Sender/Switch. 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F, 15,000 Ohms @ 40 F.

Outside Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

In Car Temp Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

MAF (Mass Air Flow) Sensor. .4 Volts @ idle, 5 Volts @ Full Throttle.

Oxygen (O2) Sensor. .1 Volt Lean Mixture, .9 Volt Rich Mixture.

TPS (Throttle Position Sensor). .54 Volts Idle, ~ 5 Volts Full Throttle

related threads

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.co...ard-starting-tpi-crossfire-or-lt1-vette.1401/

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://garage.grumpysperformance.com/index.php?threads/1991-c4-runs-like-crap.10616/

http://garage.grumpysperformance.co...too-common-questions-can-be-found-here.12892/

http://garage.grumpysperformance.com/index.php?threads/locating-a-ignition-miss-in-the-engine.14591/

http://garage.grumpysperformance.com/index.php?threads/odd-exhaust-temps-and-failed-smog-test.15817/

http://garage.grumpysperformance.co...t-of-logic-to-locate-a-problems-source.14297/

http://garage.grumpysperformance.com/index.php?threads/c4-hesitation.10451/

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/

http://garage.grumpysperformance.com/index.php?threads/c-4-exhaust-system.1174/

http://garage.grumpysperformance.com/index.php?threads/l98-corvette-wire-diagrams.11835/

READ THE LINKED INFO CAREFULLY

THERES NOT A DAMN THING YOU CAN'T FIND AND FIX WITH A FEW TOOLS,

AND SOME FAMILIARITY WITH THE CORVETTE< A SHOP MANUAL IS A HUGE HELP

Id strongly suggest you systematically verify the cause rather than making random guesses

this requires a few basic tools and ideally a shop manual and code reader

certainly a multi meter and vacuum/fuel pressure gauge may help

as usual break the issue down to its basic components, if it won.t spin over its most likely a fuse, a short circuit or a loose or corroded battery connection or the starter needs to be rebuilt/replaced.

if it spins you need to verify fuel delivery and pressure, ignition, and sensors like the oil pressure sensor

pull trouble codes get out the shop manual, and get a decent code reader and multi meter

what trouble codes are present?

will the engine spin on the starter?

have you check all the fuses

are you getting ignition spark at the plugs?

have you checked all the fuses on the pass dash side panel?

step one pull trouble codes there's no problem you can't isolate and correct in an hours time,

unless its mechanical like a busted cam, or blown head gasket or cracked block etc. if you go about the problem logically

c4 & c5 corvette trouble codes

if your corvette won,t start or run, don,t panic its usually easy to locate the problems source, buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE! RULE#1 never assume a damn thing ISOLATE ,TEST AND VERIFY...

garage.grumpysperformance.com

step two, verify you have at least 40 psi of fuel pressure in the injector manifold within 7 seconds of turning on the ignition key to start and you have at least 15 psi of oil pressure and don't have vacuum leaks at hose connections and all sensors are functional and connected

step three

verify you are or are not getting spark at several spark plugs when cranking

curing that problem with how your c4 corvette runs badly or won't start

A recurring theme has been replayed over and over, READ THE LINKED INFO CAREFULLY THERES NOT A DAMN THING YOU CAN'T FIND AND FIX WITH A FEW TOOLS, AND SOME FAMILIARITY WITH THE CORVETTE< A SHOP MANUAL IS A HUGE HELP Id strongly suggest you systematically verify the cause rather than making...

garage.grumpysperformance.com

hard starting TPI, crossfire or LT1 vette

one of the more frequent complaints I hear about is c-4 corvettes that have difficulty or intermittent start problems. or occasionally I hear about intermittent missing, that needs to be isolated and tracked down to be corrected. READ THE THREAD THRU TO THE END AND BE AWARE THAT THIS THREAD...

garage.grumpysperformance.com

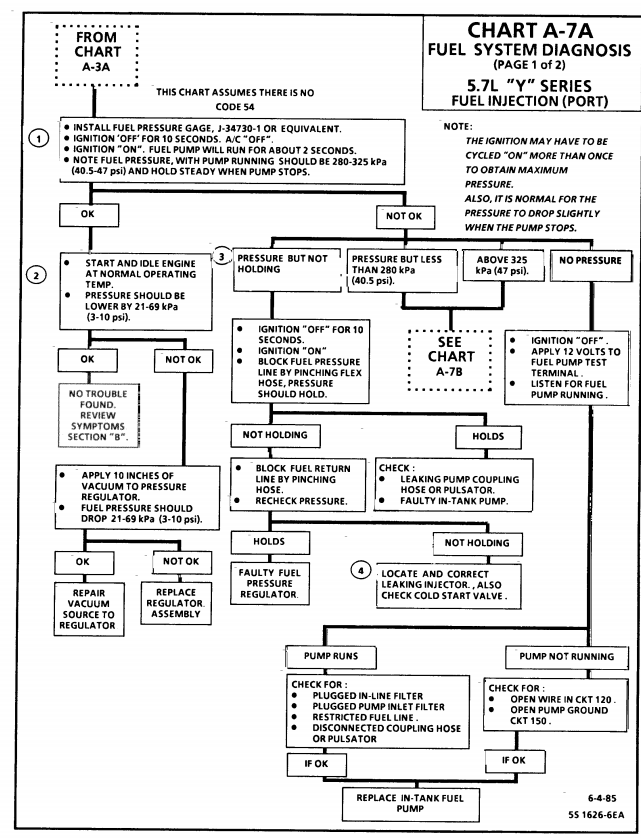

handy fuel system trouble shooting flow chart & info

IF youve purchased a vette thats been sitting awhile and it won,t start and run youll need to verify the fuel pump has electricity and its at least running, if it is at that point,drain the fuel tank, replace the fuel filter and fill the tank with fresh high test gas and two cans of fuel...

garage.grumpysperformance.com

is difficult too start, why it won't accelerate or why it misses

or has less than the power it used to have.

some guy will mention he's having issues and expect me to instantly know whats wrong,

from rather vague references to the symptoms, and how its to be corrected , frequently..

without seeing the car or opening the hood....

it does not work that way, in the real world,

yes I'm well aware most guys don't have deep financial pockets,

dropping the car off at a local dealership can cost you hundreds,

\ or thousands of dollars,

if your the average guy who owns and drives a 23 year old or older car,

you want to save a great deal of that cash by learning to fix the car yourself!

isolate and test and find the problems sources, you need to think logically,

its usually going to be related too low compression,

mal-functional ignition, lack of proper fuel delivery, engine cooling, electrical connections ,

a blown fuse a bad ground, oil pressure or a sensor function in most cases,

you may simply have a TPS or IAC thats out of adjustment!

you may have a loose vacuum hose or the cars long over due for a tune-up

your job is to play detective and find the problems source.

the basic cause is almost always far easier to diagnose and cure than most owners of the cars would believe,

a scan tool, A MULTI METER, and a SHOP MANUAL,

A FUEL PRESSURE AND VACUUM GAUGE,

and pulling codes gives you a place to start,

but it requires you to go through a check list and ,

most people have the absurd concept ,

that you can diagnose and isolate the problem with out testing.

guessing does not generally work out, dealing in proven facts does

the issues very likely to be related to a defective sensor,

a worn valve train component, low or inconsistent fuel delivery or ignition related,

but partly clogged catalytic converters, vacuum leaks, loose vacuum hoses,

mal-functioning injectors, corrosion on wiring,

worn ignition wires, fouled spark plugs, defective sensors,

loose connections

and corrosion on electrical connections, clogged fuel and oil filters are all suspect.

you need to isolate and test to find the cause.

Ive had guys so frustrated they wanted to sell the corvette at a significant financial loss,

only to find a simple valve adjustment and a couple sensors being replaced made the car run almost like new!

theres really nothing in the c4 corvette,

the average guy can,t find and fix ,

if hes willing to logically test and isolate each component.

don,t get frustrated or over whelmed, isolate and test

Do You Stop And Logically Isolate And Test Or Just Start Swapping Parts?

Honestly, I have to wonder at times about the thought process or in many cases the lack of thought and research that I see going on.I don,t know about the guys you might know, but it seems all too common for guys I know to find something amiss, or out of adjustment and they immediately just...

garage.grumpysperformance.com

code scanners/software

http://garage.grumpysperformance.com/index.php?threads/i-want-some-suggestions-on-potential-problem-sources-1987-corvette.15596/#post-93277 owning a decent code scanner helps youll want to own an infrared temp gun and a decent multi meter...

garage.grumpysperformance.com

https://www.championradiators.com/Chevrolet-Corvette-radiator-3-row-1984-1990

https://www.corvettecentral.com/c4-84-96/96-shop-service-manual-cd-rom-114143?returnurl=/c4-84-96/?count=9

a failed SENSOR, A BAD ELECTRICAL GROUND , a worn out alternator,or battery,

(YES YOULL NEED TO PULL TROUBLE CODES AND USE A MULTI METER)

yes the issue can be major like a blown head gasket, a worn out opti-spark ignition,

or worn cam, or a clogged catalytic converter

or its just as likely minor and easily cured like a bad sensor,

a worn out fuel pump or fuel injector or fuel pressure regulator,

or clogged fuel filter. or you simply need a tune up

BUY A SHOP MANUAL,

and refer to it often,

for you particular year corvette

USE THE TOOLS REQUIRED

THINK LOGICALLY ,NEVER ASSUME .

.TEST, DEAL IN FACTS

get,

AND LEARN TO USE a decent code reader,

and scan tool and multi meter

and leak down tester , fuel pressure gauge, noid lights

http://www.helminc.com/helm

isolate the cause to mechanical, (compression , VALVE TIMING AND LIFT)

fuel delivery (consistent fuel pressure)

ignition (ARE YOU GETTING CONSISTENT SPARK AT THE PLUGS)

all the answers are readily available, theres known testing procedures and listed test results you can expect, and procedures listed in the shop manual for isolating and testing components, you don,t need to be a genius, you just need to be logical and persistent and not afraid to learn new things while getting your hands dirty at times, don,t get overwhelmed , break everything down too easy individual problems and tests, verify and test all the sensors,and test for factors like consistent fuel pressure, known temps,expected voltage or ohms resistance, and vacuum readings and don,t randomly start replacing parts as that gets expensive and its rarely the most efficient way to eliminate problems(unless you get really lucky) with modern computer diagnostic software you,ll have some advantages but think logically, most automotive problems still concern, loose electrical connectors, defective sensors, lack of compression, fuel delivery issues ,fuel pressure, vacuum, temperature or electrical issues.

https://www.zip-corvette.com/85-89-high-performance-adjustable-maf-sensor.html

85-89 High Performance Adjustable MAF Sensor

don,t get over whelmed,

simply break the problem down to testing each basic sub system,

test each related sensor and electrical component and electrical sensor and connection.

some reading on the threads posted below, a bit of logic and deductive reasoning, and a multi meter and a shop manual will go a long way toward finding and fixing the problem.

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

Oil Pressure Sender/Switch. 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F, 15,000 Ohms @ 40 F.

Outside Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

In Car Temp Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

MAF (Mass Air Flow) Sensor. .4 Volts @ idle, 5 Volts @ Full Throttle.

Oxygen (O2) Sensor. .1 Volt Lean Mixture, .9 Volt Rich Mixture.

TPS (Throttle Position Sensor). .54 Volts Idle, ~ 5 Volts Full Throttle.

Sensor Locations

Sensor

Location

Engine Coolant Temperature Sensor. Front of engine, below Throttle Body.

Engine Oil Temperature Sensor. Left rear of engine, just above the oil filter.

Oil Pressure Sender/Switch. Top, left hand rear of engine.

Fuel Quantity Sender. Top of fuel tank, beneath filler pipe escutcheon panel.

MAT (Manifold Absolute Temperature Sensor). Underside of manifold air plenum at rear.

Outside Temperature Sensor. Right side of engine, top right corner of radiator.

In Car Temp Temperature Sensor. Coupe: above left seat near interior courtesy light, Convertible: center of cargo compartment lid.

MAF (Mass Air Flow) Sensor. Front of engine ahead of throttle body.

Oxygen (O2) Sensor. Left side of engine, in exhaust pipe.

TPS (Throttle Position Sensor). Right side of throttle body at the front.

sensor locations

- Mass Air Flow (MAF), mounts in intake ducting between air filter and throttle body.

- Throttle Position Sensor (TPS), mounts on right side of throttle body.

- Idle Air Control valve (IAC), mounts in small manifold on bottom of throttle body.

- MAF power relay, in relay center on firewall beside master cylinder.

- MAF burn off relay, in relay center on firewall beside master cylinder.

- Manifold Air Temperature sensor (MAT), mounts in bottom of plenum near the back

- Coolant Temperature Sensor (CTS), mounts on front right of intake manifold base, below IAC valve

- Cold start switch, front right of intake manifold base, below CTS

- Exhaust Gas Recirculation valve(EGR), on top of intake manifold base, centered under plenum

- EGR solenoid, on top of intake manifold, rear, between distributor and valve cover.

- EGR diagnostic switch, on base of EGR valve.

- Electronic Spark Control (ESC)knock sensor, bottom right of engine block, in front of starter just above oil pan rail, in the coolant drain boss.

- ESC module, in relay center on firewall beside master cylinder

- Electronic Spark Timing (EST) module, on distributor.

- Oxygen (O2) sensor, in left exhaust manifold.

- Air Injection Reactor (AIR) convertor divert solenoid and port solenoid, both together at front of right valve cover.

- Oil pressure switch, on Y fitting with oil pressure gauge sender mounted in the oil pressure boss on the top left rear of the engine block behind intake manifold base. (applies power to fuel pump if fuel pump relay or relay circuit fails).

- Fuel pump relay, in relay center on firewall beside master cylinder.

- Fuel vaper canister (charcoal can) solenoid, on top of charcoal can in front left corner of engine bay.

- Air Conditioner (AC) pressure switch, in boss on AC high pressure side aluminum tube beside right strut tower.

- vehicle speed sensor, back of speedometer.

- Cooling fan relay, on core support beside battery.

heres a rather useful addition to the older c4 corvette tuning world, its a new (yes expensive)

but adjustable and thus some what tune-able MASS AIR FLOW SENSOR for the TPI corvettes

without pulling trouble codes and testing your simply guessing at best,

break the issue down into separate issues,

check ignition strength and timing,and voltage

check fuel supply/delivery pressure and volume

check cam timing and cylinder compression.

check valve train control and valve adjustment

check firing order and spark plug gap

check the valve lift, and for work lobes

check for vacuum leaks

adjust your iac and tps

check your exhaust back

pressure

verify sensors correct function

https://www.harborfreight.com/catal...core,f,EAFeatured+Weight,f,Sale+Rank,f&q=zr13

all the answers are readily available, theres known testing procedures and listed test results you can expect, and procedures listed in the shop manual for isolating and testing components, you don,t need to be a genius, you just need to be logical and persistent and not afraid to learn new things while getting your hands dirty at times, don,t get overwhelmed , break everything down too easy individual problems and tests, verify and test all the sensors,and test for factors like consistent fuel pressure, known temps,expected voltage or ohms resistance, and vacuum readings and don,t randomly start replacing parts as that gets expensive and its rarely the most efficient way to eliminate problems(unless you get really lucky) with modern computer diagnostic software you,ll have some advantages but think logically, most automotive problems still concern, loose electrical connectors, defective sensors, lack of compression, fuel delivery issues ,fuel pressure, vacuum, temperature or electrical issues.

http://www.helminc.com/helm

the correct matching SHOP MANUAL

TIMING LIGHT

IR TEMP GUN

VACUUM GAUGE

MULTI METER

FUEL PRESSURE GAUGE

COMPRESSION TEST GAUGE

keep in mind the basics you need to verify the fuel pressure is at about 40 psi if your dealing with a C4 corvette,

you should NOT have significant exhaust back pressure, clogged catalytic converters,

are a common problem on older c4 corvettes,

verify the fuses are not blown, the trouble codes do not show any problems,

all electrical grounds are reading good,

verify theres at least 14.5 volts at the battery while its running, so you know the alternator functions,

and all the injectors are functional with a noid light,

all cylinders should read within 10% and show about 150 psi or greater.,

on a compression test, verify the firing order,

set the spark plug gaps at .045 ,

and verify all the listed sensor values,

verify the cam lobes are not worn, verify you have at least 10 psi of oil pressure per 1000 rpm.verify theres no vacuum leaks

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

viewtopic.php?f=55&t=109

you might have clogged catalytic converters, the ignition timing may be way off, you might have a worn out cam, the fuel pump may be defective, some injector(s) may be defective,check the alternator out-put check the fuel rail pressure use a noid light on the injector wiring, check the fuses,

Ive found that the one most commonly over looked in my experience is that the stock exhaust system, is highly restrictive, especially if the catalytic converters are partly plugged and the stock fuel delivery system is not adequate,for the potential power, the heads and intake, allowable air flow potential, are all restrictive, and the stock cam timing and lift is already near max as it was designed to produce about 260 hp,and operate at under 5700 rpm, if you try too add an additional 100-200 hp, and 1000 rpm-2000 rpm to the engines power band, and too the engines output youll quickly find this to be a factor.

I've also occasionally seen guys, improperly index or install a cam without degreeing it in correctly and thus have power band limitations.

Id suggest you buy a factory shop manual, multi meter and a timing light, fuel pressure and vacuum gauge and start checking.

reading these links will be helpful

yes I know it will take some time and effort to isolate and test

but its the only 100% sure route to finding and fixing your problem,

don,t get over whelmed,

simply break the problem down to testing each basic sub system,

test each related sensor and electrical component and electrical sensor and connection.

some reading on the threads posted below, a bit of logic and deductive reasoning, and a multi meter and a shop manual will go a long way toward finding and fixing the problem.

this is the most consistently accurate I.R temp gun I've used for testing[/img]

http://www.testequipmentdepot.com/extech/thermometers-and-humidity-meters/infrared-thermometers/high-temperature-infrared-thermometer-58to1832f-50to1-laser-pointer-42545.htm?utm_source=bing&utm_medium=cpc&utm_campaign=NEXT - Bing Shopping - Extech&utm_term=1100200223789&utm_content=All Extech Products

INFRARED TEMP GUN

you always need a base line to start from, on a corvette.

a logical step by step approach and keeping accurate notes helps.

youll NEED a multi meter, a shop manual

and a timing light and fuel pressure gauge at a minimum,

set and verify your ignition timing, pull trouble codes,set your tps and iac,, then check for vacuum leaks on the lines and intake,then get out your multi meter and verify all the sensors, chances are good a logical step by step approach will lead you to the problem, youll be amazed at what youll learn reading links. use of a shop manual and multi meter can be very helpful

basic fuel injector test

(pull your trouble codes and check battery voltage ,alternator output and ignition spark first)

(BTW it rarely hurts to drain old fuel thats over 4 months old and replace the cars fuel filter, then add two different brands of fuel injection cleaner and 6 oz of marvel mystery oil to as full tank of fresh high test gas to the car if its been sitting un-used for very long before you start testing for fuel injection related issues

now Ill assume your battery reads over 12 volts and the starter works, and easily spins the engine

the first step

find the fuel rail shrader valve and remove the cap and connect the fuel pressure gauge

if you turn on the ignition key to get the dash and accessories to light up but don,t start the engine,the fuel pump,

should briefly run to pressurize the fuel rail to about 38psi-42 psi,

this should stay at this pressure level for at least 5 minutes minimum, if it drops slowly your fuel rail is leaking fuel.

now the fuel pressure regulator may be defective or leaking, or in very rare cases the fuel pump may be defective ,

but the most likely cause is a fuel injector(s) stuck in the open position.

next pull the injector harness,

off a single injector at a time, press the wire bar to release the clip, retention, then pull it up and off, the noid light plugs into the harness,

use the spare injector pig tail

on the now disconnected injector ,connect the multi meter on ohms setting and it should read 11-13 ohms injector on each injector tested.

if it reads under 9 ohms or over 20 ohms its a defective injector

now use a couple 3 ft long test leads connect one too one of the pig tail test leads

https://www.walmart.com/ip/Uxcell-2...-Clips-Test-Jumper-Wire-1-5m-2-Color/45588242

and to 12 volts, connect the other pig tail lead too a different test lead and watch the fuel pressure gauge,with the key out of the ignition , you should have 38-42 psi of fuel rail pressure, watch carefully while you tap the second test lead to ground (the plenum or alternator case works) the fuel pressure should drop as you tap the ground pig tail lead, this verifies the injector function at least partially, if you don,t see the pressure drop the injectors not allowing fuel flow through it and should be replaced.

after you complete each injector test , turn the ignition key on, to re-pressurize the fuel trail and reconnect the harness to the previously tested injector,

repeat the noid light and pig-tail function fuel pressure test on each of the other injectors individually.

youll need a fuel pressure gauge and multi meter

it helps if you have a spare fuel injector pig-tail for testing

having a NOID light injector harness tester wont hurt either

https://www.harborfreight.com/11-piece-noid-light-and-iac-tester-set-97959.html

on the TPI and LT1 efi and many other EFI intakes,

theres a shrader valve,

that can be easily accessed to check fuel rail pressure,

dealing in facts you verify is always preferable.

GM part number for the complete fuel rail o-ring kit is 17111696

if your TPI FUEL PRESSURE REGULATOR DIAPHRAGM LEAKS youll find it difficult or impossible to be starting your car

heres a link to the correct o-rings they are light blue

NAPA sells them at times

all the o-rings on the fuel rails and injectors need to be dipped in thin oil so they insert and slide into place with less friction, this tends to greatly reduce the chance of the o-rings ripping, and yes you need the correct o-rings that fit correctly to begin with if you expect the rings to seal correctly

http://tpiparts.net/inc/sdetail/10950/300

17113544 - Injector Seals

17111696 - O-Ring Kit

22514722 - Fuel Inlet O-Ring

22516256 - Fuel Inlet O-Ring

if you have a cylinder or two not functioning correctly or a injector thats barely functional, an infrared temp gun checking the exhaust port temps will generally allow you to find and isolate its location as it will be usually be running at a lower average temperature,

infrared thermometers are a very useful tool to track down issues with tuning, or mal functioning sensors , without verified facts your guessing.

this is the most consistently accurate I.R temp gun I've used for testing[/img]

http://www.testequipmentdepot.com/e...1100200223789&utm_content=All Extech Products

INFRARED TEMP GUN

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

any time that your dealing with a potential temperature issue or a trouble issue where , knowing the exact temperature vs what a gauge might say, it helps to have a handy and accurate infrared temp gun handy to locate and confirm heat, levels.

http://garage.grumpysperformance.co...dding-a-fuel-pressure-gauge.15264/#post-88472

http://garage.grumpysperformance.co...njection-at-start-up-problem.7309/#post-24862

http://garage.grumpysperformance.co...oven-facts-if-your-in-doubt.13051/#post-84695

http://garage.grumpysperformance.com/index.php?threads/tpi-fuel-pressure-issue.10385/#post-42943

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://garage.grumpysperformance.com/index.php?threads/diagnoseing-tpi-lt1-problems.1241/

http://garage.grumpysperformance.com/index.php?threads/gm-tpi-stalling-diagnosis.15194/#post-86991

http://users.erols.com/srweiss/tableifc.htm

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.co...ng-high-flow-cats-on-exhaust.8401/#post-29318

http://garage.grumpysperformance.co...s-cause-a-bad-idle-in-drive.14203/#post-72114

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

http://garage.grumpysperformance.co...le-shooting-flow-chart-info.11536/#post-71845

http://garage.grumpysperformance.co...ittent-cylinder-miss-problem.9478/#post-57225

http://garage.grumpysperformance.com/index.php?threads/previous-owner-butchered-wiring.3439/

http://garage.grumpysperformance.co...and-verify-each-possibility.11219/#post-50643

http://garage.grumpysperformance.co...g-your-tpi-maf-and-cpu-links.2825/#post-56790

http://garage.grumpysperformance.co...-you-failed-emmision-testing.3522/#post-52999

http://garage.grumpysperformance.co...oven-facts-if-your-in-doubt.13051/#post-84695

http://garage.grumpysperformance.co...and-verify-each-possibility.11219/#post-50643

http://garage.grumpysperformance.co...h-a-1988-vette-after-prolonged-storage.16112/

http://garage.grumpysperformance.co...-idles-and-sometimes-stalls.10688/#post-46303

http://garage.grumpysperformance.com/index.php?threads/1991-c4-runs-like-crap.10616/#post-45635

http://garage.grumpysperformance.co...rical-glitches-in-newer-cars.5492/#post-18411

http://garage.grumpysperformance.co...ing-c-4-or-tpi-fuel-injectors.1378/#post-9085

Sensor

Location

Engine Coolant Temperature Sensor. Front of engine, below Throttle Body.

Engine Oil Temperature Sensor. Left rear of engine, just above the oil filter.

Oil Pressure Sender/Switch. Top, left hand rear of engine.

Fuel Quantity Sender. Top of fuel tank, beneath filler pipe escutcheon panel.

MAT (Manifold Absolute Temperature Sensor). Underside of manifold air plenum at rear.

Outside Temperature Sensor. Right side of engine, top right corner of radiator.

In Car Temp Temperature Sensor. Coupe: above left seat near interior courtesy light, Convertible: center of cargo compartment lid.

MAF (Mass Air Flow) Sensor. Front of engine ahead of throttle body.

Oxygen (O2) Sensor. Left side of engine, in exhaust pipe.

TPS (Throttle Position Sensor). Right side of throttle body at the front.

Sensor Outputs:

Sensor

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

Oil Pressure Sender/Switch. 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F, 15,000 Ohms @ 40 F.

Outside Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

In Car Temp Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

MAF (Mass Air Flow) Sensor. .4 Volts @ idle, 5 Volts @ Full Throttle.

Oxygen (O2) Sensor. .1 Volt Lean Mixture, .9 Volt Rich Mixture.

TPS (Throttle Position Sensor). .54 Volts Idle, ~ 5 Volts Full Throttle

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.co...ard-starting-tpi-crossfire-or-lt1-vette.1401/

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://garage.grumpysperformance.com/index.php?threads/1991-c4-runs-like-crap.10616/

http://garage.grumpysperformance.co...too-common-questions-can-be-found-here.12892/

http://garage.grumpysperformance.com/index.php?threads/locating-a-ignition-miss-in-the-engine.14591/

http://garage.grumpysperformance.com/index.php?threads/odd-exhaust-temps-and-failed-smog-test.15817/

http://garage.grumpysperformance.co...t-of-logic-to-locate-a-problems-source.14297/

http://garage.grumpysperformance.com/index.php?threads/c4-hesitation.10451/

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/

http://garage.grumpysperformance.com/index.php?threads/c-4-exhaust-system.1174/

http://garage.grumpysperformance.com/index.php?threads/l98-corvette-wire-diagrams.11835/

Last edited: