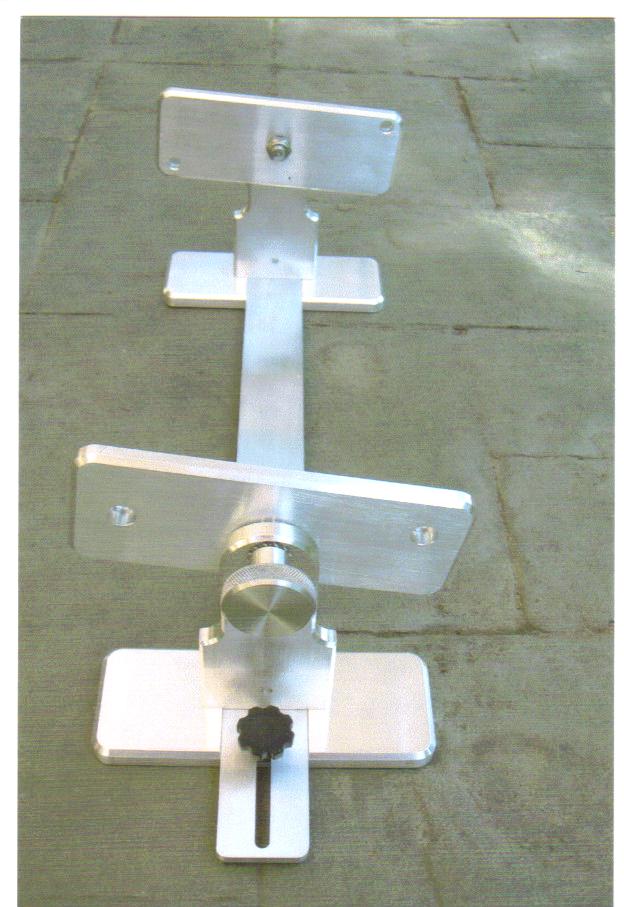

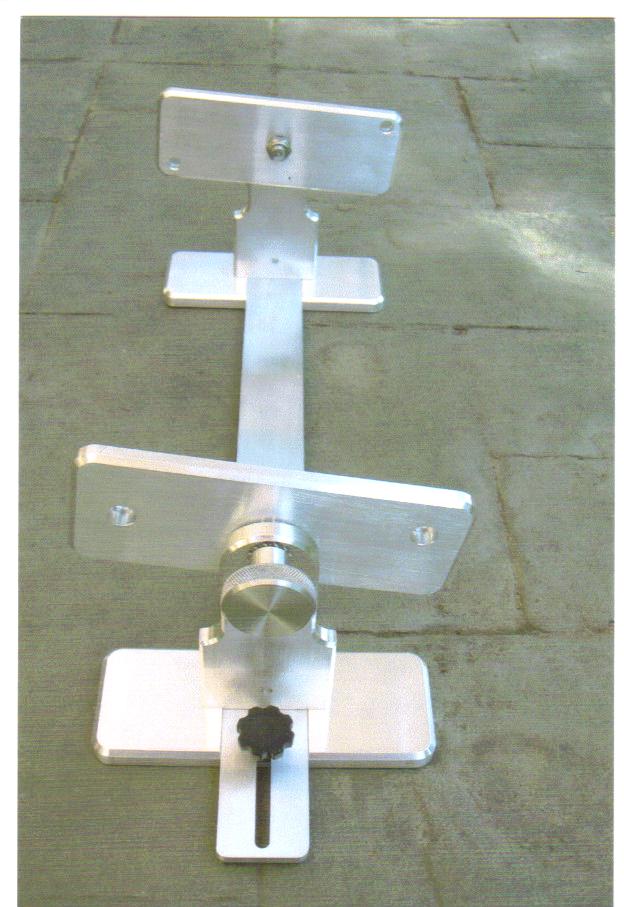

OK LETS FIND A DESIGN, ON LINE OR COME UP WITH A DESIGN WE CAN WORK WITH

http://www.hotrod.com/how-to/additional-how-to/hppp-1010-cylinder-head-stand/

https://goodson.com/collections/por...otary-files-for-cast-iron?variant=39401084230

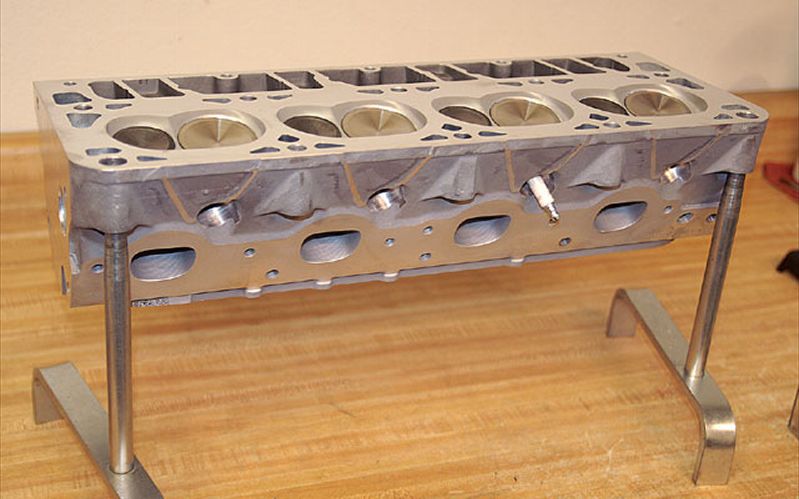

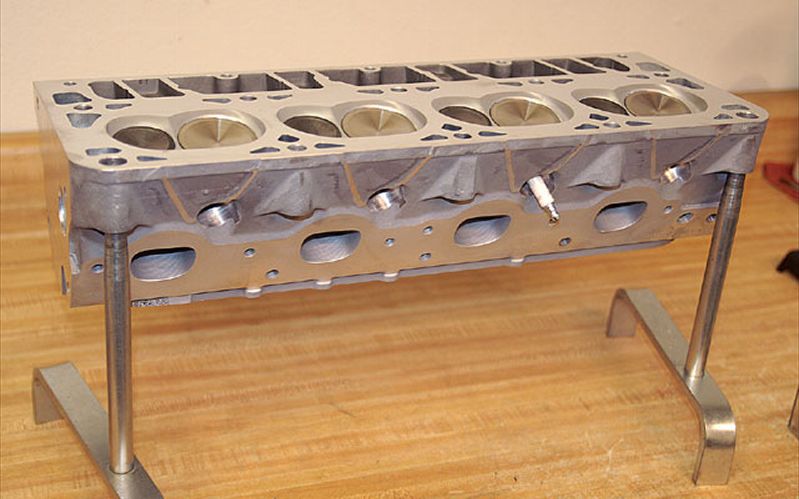

Ive used this proform cylinder head stand and while it works its not ideal as its not infinitely adjustable as to angles and at about $160 not all that cheap

if you've ever ported heads , you'll find that you need a shop vacuum on the other end of the port to collect metallic debris, and getting the ideal lighting and grinder burr angle at times is a P.I.T.A., so an infinitely adjustable cylinder head holder stand that allows locking the head in any position would be a huge advantage. If you ever lapped valve seats or CC ed heads you quickly found that you,ll need some type of cylinder head stand to position the heads and lock them in the exact location and angle you need to easily access the ports and combustion chambers to maintain the correct angle and if you bothered to shop around you'll find the cheap commercial cylinder head stands available are either pure crap, or better ones are far too expensive so you generally find you use sand bags or fabricate your own custom cylinder head holding stands once you get fed up with them moving while your working on the heads.

btw it helps a great deal to dip the burr in a shot glass of WD.40 about every 20-30 seconds as it helps keep it from picking up crud sticking to the burrs cutting edges,the little bars of soap from the hotel bathrooms or beeswax, can be used as those melt, because the burrs heat up and as a result the melted bits get thrown over the surfaces

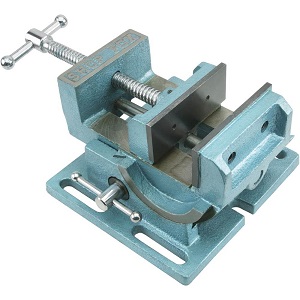

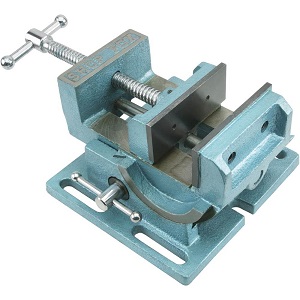

http://www.grizzly.com/products/Angle-Vise/D2933

maybe this helps

http://garage.grumpysperformance.co...ing-tools-abrasives-sources.10683/#post-46209

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-2#post-17490

http://garage.grumpysperformance.com/index.php?threads/air-die-grinders.1831/#post-4763

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50238

http://garage.grumpysperformance.com/index.php?threads/shop-vacuum-cleaner.3379/#post-8946

http://garage.grumpysperformance.com/index.php?threads/calculating-ideal-port-size.624/#post-2352

http://garage.grumpysperformance.com/index.php?threads/die-grinders.1266/#post-2717

http://garage.grumpysperformance.co...d-position-adjustable-stand.11744/#post-55394

http://www.hotrod.com/how-to/additional-how-to/hppp-1010-cylinder-head-stand/

https://goodson.com/collections/por...otary-files-for-cast-iron?variant=39401084230

Ive used this proform cylinder head stand and while it works its not ideal as its not infinitely adjustable as to angles and at about $160 not all that cheap

if you've ever ported heads , you'll find that you need a shop vacuum on the other end of the port to collect metallic debris, and getting the ideal lighting and grinder burr angle at times is a P.I.T.A., so an infinitely adjustable cylinder head holder stand that allows locking the head in any position would be a huge advantage. If you ever lapped valve seats or CC ed heads you quickly found that you,ll need some type of cylinder head stand to position the heads and lock them in the exact location and angle you need to easily access the ports and combustion chambers to maintain the correct angle and if you bothered to shop around you'll find the cheap commercial cylinder head stands available are either pure crap, or better ones are far too expensive so you generally find you use sand bags or fabricate your own custom cylinder head holding stands once you get fed up with them moving while your working on the heads.

btw it helps a great deal to dip the burr in a shot glass of WD.40 about every 20-30 seconds as it helps keep it from picking up crud sticking to the burrs cutting edges,the little bars of soap from the hotel bathrooms or beeswax, can be used as those melt, because the burrs heat up and as a result the melted bits get thrown over the surfaces

http://www.grizzly.com/products/Angle-Vise/D2933

maybe this helps

http://garage.grumpysperformance.co...ing-tools-abrasives-sources.10683/#post-46209

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-2#post-17490

http://garage.grumpysperformance.com/index.php?threads/air-die-grinders.1831/#post-4763

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50238

http://garage.grumpysperformance.com/index.php?threads/shop-vacuum-cleaner.3379/#post-8946

http://garage.grumpysperformance.com/index.php?threads/calculating-ideal-port-size.624/#post-2352

http://garage.grumpysperformance.com/index.php?threads/die-grinders.1266/#post-2717

http://garage.grumpysperformance.co...d-position-adjustable-stand.11744/#post-55394

Last edited: