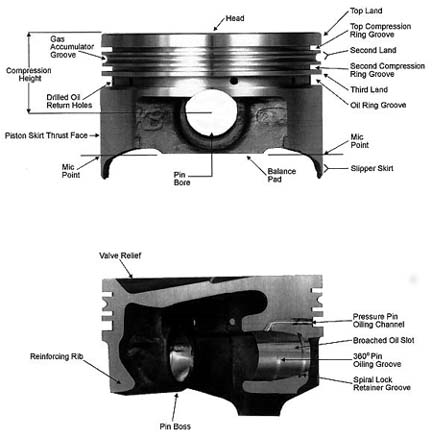

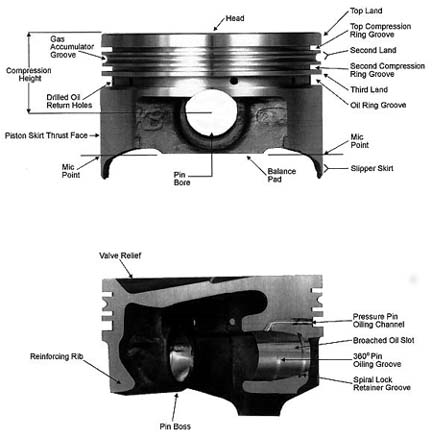

on all piston engines the rings seal to the bore walls by sliding up and down as the piston reciprocates on the rod and crank, but the top and lower ring always stop the wear before the top of the cylinder is reached because the rings seat about 1/4" down from the top of the piston, thus the top 1/4" of the bore has zero wear from the rings, and over time if the lubrication is marginal the bore walls wear, and as a result a upper cylinder ridge is formed , making removing the piston more difficult if its worn more than a few thousands,if you can feel the step from the worn cylinder wall to the un-worn ridge its a sure indication that the piston to cylinder wall clearance has increased, that normally results in increased oil consumption, and usually some oil smoke under hard acceleration.

now if its worn that much your piston to wall side clearance has increased and youll more than likely need a new set of larger pistons and rings and the block bored and deck plate honed to the next larger bore size. if you think you can just install new rings and the old pistons or slightly over size pistons you may and most likely will find that the bores are no longer perfectly round and you won,t get a good ring seal. but it was fairly common years ago to just cut the ridge out with a tool, designed to do that like pictured below and to order a slightly over sized piston and file to fit ring set, to do a cheap refresh on the older engines.

YES it can be done, if wear is minimal, on low stress low rpm street engines but its rarely going to work nearly as well as the current way of bore, hone and match piston side clearances and ring size that most machine shops will suggest

the reason is pistons never wear the bore evenly theres ALWAYS a slight taper or oval in the worn bore due to the stress levels in a running engine not being 100% centered in the bore as the rods thrust angle changes as the crank journal sweeps under and past the piston pin center line

http://www.amazon.com/Lisle-Ridge-Reame ... B000X04N28

BORING and HONING a blocks bore are best done at a local machine shop where clearances and surface finish are more accurately controlled, BUT, IF your going to be honing the bores for MOLY rings I,d suggest a 240-280 grit hone a 45 degree cross hatch angle and a constant flow of flushing liquid washing over the stones and bore surface to keep the stones from clogging with micro grit trash, that gets removed from the high points in the bore surface.

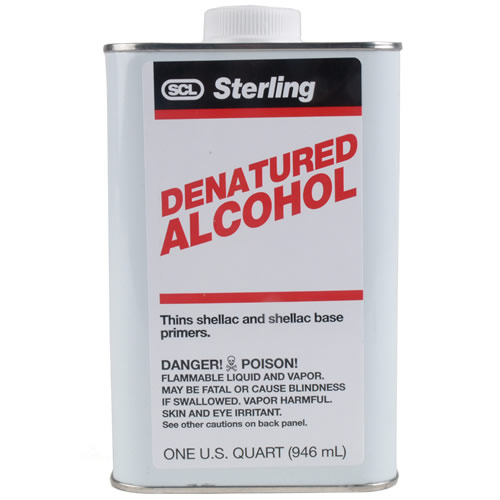

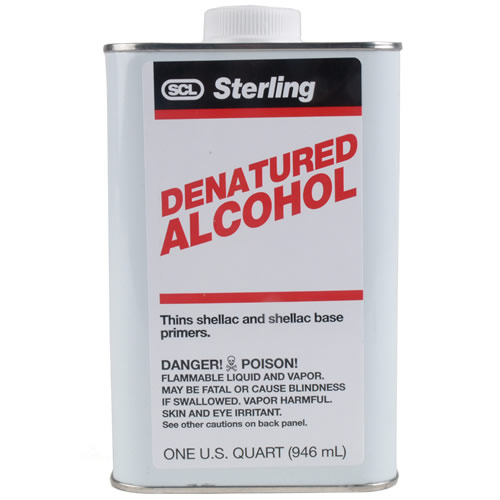

Ive used both a flush of 90% diesel fuel mixed with 10% marvel mystery oil, as a flush and Ive used hot water with a couple teaspoons of dawn dish washing soap, both work, but I think the hot water and dawn solution produced the most uniform result, on the bore surface but that requires a good deal of cleaning and washing the block just like the diesel fuel mix as you darn sure want to remove all traces of grit and prevent rust forming from moisture so after hone work I power wash the block with a pressure washer,, flush the surface with alcohol paint thinner as it tends to get under and lift out micro crud and speed surface dry time ,then I spray it over with WD40 and heat it with a heat gun to remove moisture traces then re-spray it with WD, 40 [/b]

washing the blocks surface with alcohol, and drying with high pressure air helps dry a lock after a pressure washing

http://www.harborfreight.com/1600-watt- ... 69342.html

Instructions

Things You'll Need

Ridge reamer

Motor oil

Wrenches

Shop vacuum

Magnet

1

Using regular motor oil (any weight will do, some good but the thinner the viscosity and the higher the flow rate washing over the hone stones the better,), liberally lubricate the cylinder walls and the ridge reamer. This is a very important step. It's impossible to use too much oil.

2

Position the ridge reamer in the top of the cylinder bore. Set the reamer fully into the cylinder until the stops on the top of the ridge reamer bottom out against the top of the engine block.

3

Adjust the ridge reamer to the cylinder size. Adjustments vary with the make and model of ridge reamer.

4

Adjust the ridge reamer to the proper height. Again, adjustments vary with the make and model of ridge reamer. Begin cutting the ridge from the bottom and work your way to the top of the cylinder wall.

5

Using a wrench on the large hex at the top of the ridge reamer, turn it in the cylinder bore. Some ridge reamers turn clockwise, and some counterclockwise, so check the instructions for your particular model. Turn the ridge reamer one full revolution, then check the condition of the cylinder wall. When the ridge is gone or nearly gone, you are done. Relubricate the cylinder wall as necessary during this process.

6

Use a shop vacuum and a magnet to remove the debris from the cylinder bore before removing the piston.

viewtopic.php?f=53&t=3897

http://arrc.epnet.com/autoapp/9110/9110 ... HONING.htm

now if its worn that much your piston to wall side clearance has increased and youll more than likely need a new set of larger pistons and rings and the block bored and deck plate honed to the next larger bore size. if you think you can just install new rings and the old pistons or slightly over size pistons you may and most likely will find that the bores are no longer perfectly round and you won,t get a good ring seal. but it was fairly common years ago to just cut the ridge out with a tool, designed to do that like pictured below and to order a slightly over sized piston and file to fit ring set, to do a cheap refresh on the older engines.

YES it can be done, if wear is minimal, on low stress low rpm street engines but its rarely going to work nearly as well as the current way of bore, hone and match piston side clearances and ring size that most machine shops will suggest

the reason is pistons never wear the bore evenly theres ALWAYS a slight taper or oval in the worn bore due to the stress levels in a running engine not being 100% centered in the bore as the rods thrust angle changes as the crank journal sweeps under and past the piston pin center line

http://www.amazon.com/Lisle-Ridge-Reame ... B000X04N28

BORING and HONING a blocks bore are best done at a local machine shop where clearances and surface finish are more accurately controlled, BUT, IF your going to be honing the bores for MOLY rings I,d suggest a 240-280 grit hone a 45 degree cross hatch angle and a constant flow of flushing liquid washing over the stones and bore surface to keep the stones from clogging with micro grit trash, that gets removed from the high points in the bore surface.

Ive used both a flush of 90% diesel fuel mixed with 10% marvel mystery oil, as a flush and Ive used hot water with a couple teaspoons of dawn dish washing soap, both work, but I think the hot water and dawn solution produced the most uniform result, on the bore surface but that requires a good deal of cleaning and washing the block just like the diesel fuel mix as you darn sure want to remove all traces of grit and prevent rust forming from moisture so after hone work I power wash the block with a pressure washer,, flush the surface with alcohol paint thinner as it tends to get under and lift out micro crud and speed surface dry time ,then I spray it over with WD40 and heat it with a heat gun to remove moisture traces then re-spray it with WD, 40 [/b]

washing the blocks surface with alcohol, and drying with high pressure air helps dry a lock after a pressure washing

http://www.harborfreight.com/1600-watt- ... 69342.html

Instructions

Things You'll Need

Ridge reamer

Motor oil

Wrenches

Shop vacuum

Magnet

1

Using regular motor oil (any weight will do, some good but the thinner the viscosity and the higher the flow rate washing over the hone stones the better,), liberally lubricate the cylinder walls and the ridge reamer. This is a very important step. It's impossible to use too much oil.

2

Position the ridge reamer in the top of the cylinder bore. Set the reamer fully into the cylinder until the stops on the top of the ridge reamer bottom out against the top of the engine block.

3

Adjust the ridge reamer to the cylinder size. Adjustments vary with the make and model of ridge reamer.

4

Adjust the ridge reamer to the proper height. Again, adjustments vary with the make and model of ridge reamer. Begin cutting the ridge from the bottom and work your way to the top of the cylinder wall.

5

Using a wrench on the large hex at the top of the ridge reamer, turn it in the cylinder bore. Some ridge reamers turn clockwise, and some counterclockwise, so check the instructions for your particular model. Turn the ridge reamer one full revolution, then check the condition of the cylinder wall. When the ridge is gone or nearly gone, you are done. Relubricate the cylinder wall as necessary during this process.

6

Use a shop vacuum and a magnet to remove the debris from the cylinder bore before removing the piston.

viewtopic.php?f=53&t=3897

http://arrc.epnet.com/autoapp/9110/9110 ... HONING.htm