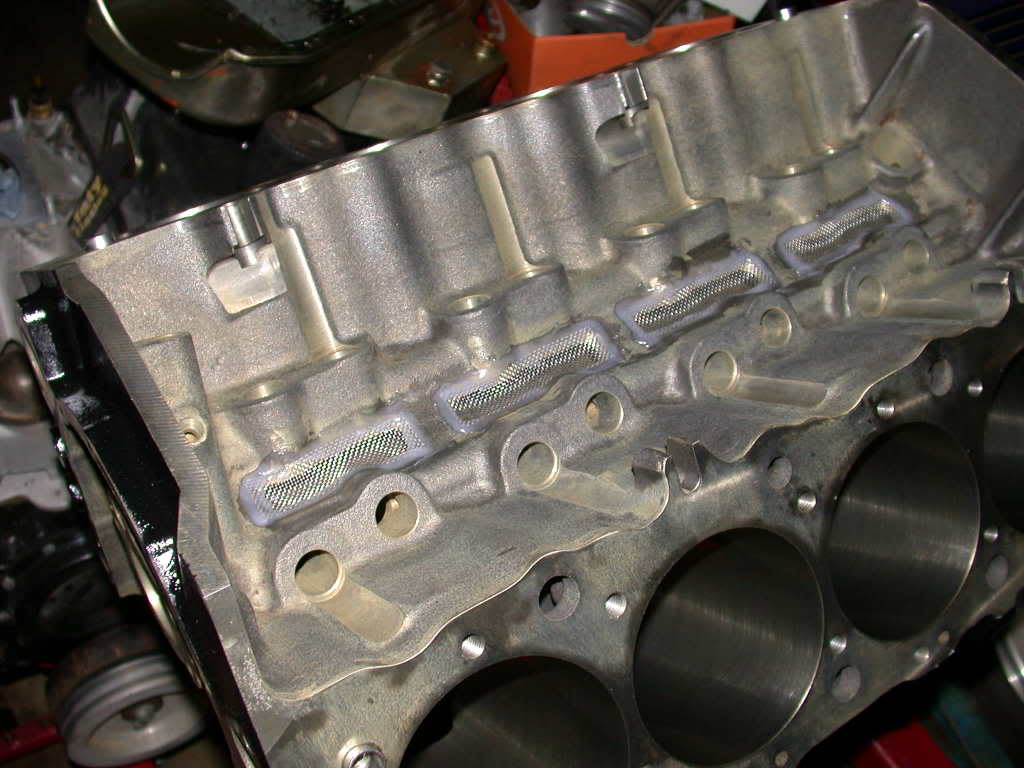

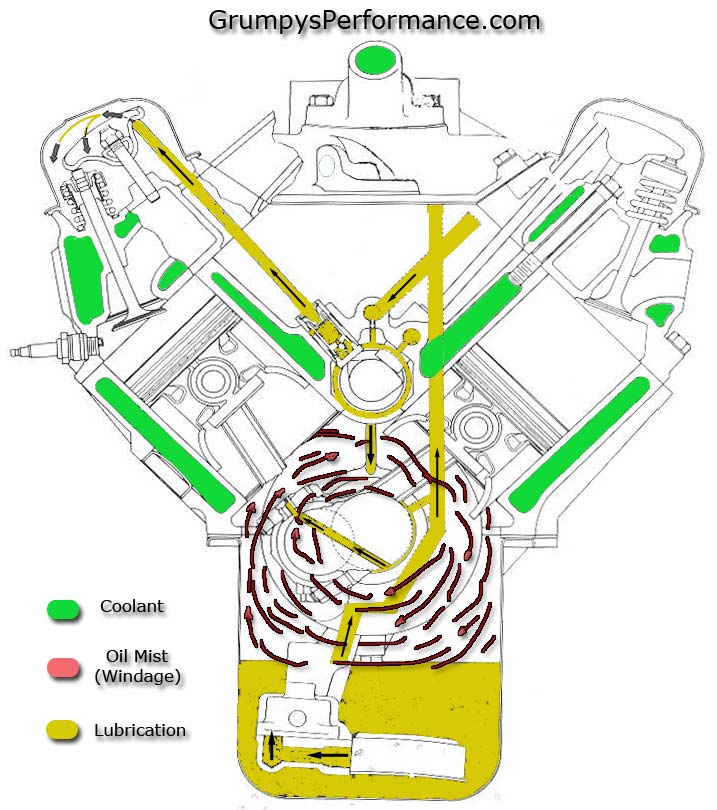

There is no place for oil to return to the pan except down thru the middle over the

camshaft and on to the crankshaft. With the concern over windage it seems there would

be places in the front and rear of the valley for oil to drain like in a stock SBC.

Now this should help the camshaft and lifters, but is it too much for a street engine with a

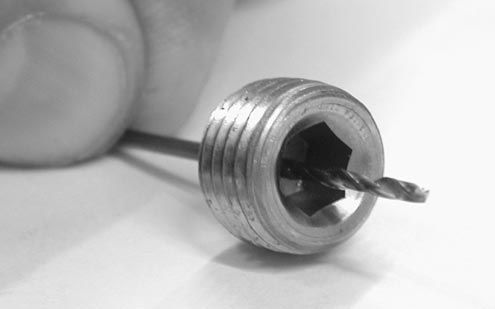

hydraulic roller to have this much oil draining onto the crankshaft ??? Holes could be drilled from

the valley to the timing area, that looks to be pretty simple.