the first step is to verify that the crank center line to deck height is parallel too and square with the block deck as if its not your wasting your time.

especially if the decks not at 90 degrees with the crank center-line and equal distant from the crank center-line along its total length.

next is

you'll need to consistently measure the piston quench area and the wrist pin center-line heights on the pistons, keeping in mind that rod and pistons dimensions vary slightly so you'll want to mix/match to minimize the combined differences, placing taller pin height pistons on shorter rods, etc.

piston-to-head clearance & piston rock

Post by pparaska » "

I use a magnetic base and dial indicator, and find TDC by tapping the piston down on the way up to TDC from both directions using a rubber mallet in the center of the piston (make sure to watch at the edge for the rod bearing bouncing off the crank - I tap it down just enough to take up the clearance.) Do this from both directions to about 0.020" below TDC, record degree wheel readings, split difference, move to that degree reading.

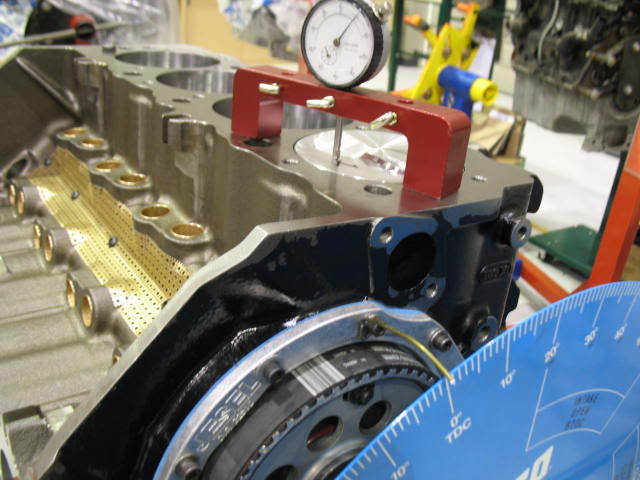

Then I use the bridge and dial indicator to measure the front and rear (above the pin) near the piston edge.

For/Aft deck height measurement (front and rear edges of piston):

Rear (towards flywheel end of crank):

I rock the piston about the for/aft direction (yes, the pin allows this to happen) by tapping the piston down at the rear, measuring for max reading at the front, then move the bridge to where I was just tapping (the rear) and measure the height relative to the deck next to it - that's the minimum or lowest deck height for that position around the piston. Then I tap the opposite diametrical position on the edge of the piston (the front) to get the highest reading with the bridge, and record that.

Front:

Move the bridge/indicator to the diametrically opposed position at the (front) edge of the piston and record the deck height there which will be the minimum or furthest down. I know that just-tapped area is at it's lowest, so I record that as the minimum. Tap at the rear of the piston, and record the max registered on the dial indicator (highest).

Deck Height near valley and near block outer edge:

Repeat the above, but measure at the piston edge near the lifter valley, rocking piston both ways, and then measure near the block outer edge, rocking piston both ways."

http://www.summitracing.com/parts/PRO-66797/

http://www.chevyhiperformance.com/techa ... index.html

http://www.circletrack.com/techarticles ... index.html

http://www.faliconcranks.com/pdf/rodlen ... height.pdf

http://www.abs-products.com/measuring-t ... uges.shtml

viewtopic.php?f=53&t=3759

http://www.hotrod.com/howto/69883_strok ... index.html

http://www.pontiacstreetperformance.com ... ssion.html