Hi i just very successfully mig welded my new pick up pipe to my new oil pump... Set it at the right height as well...

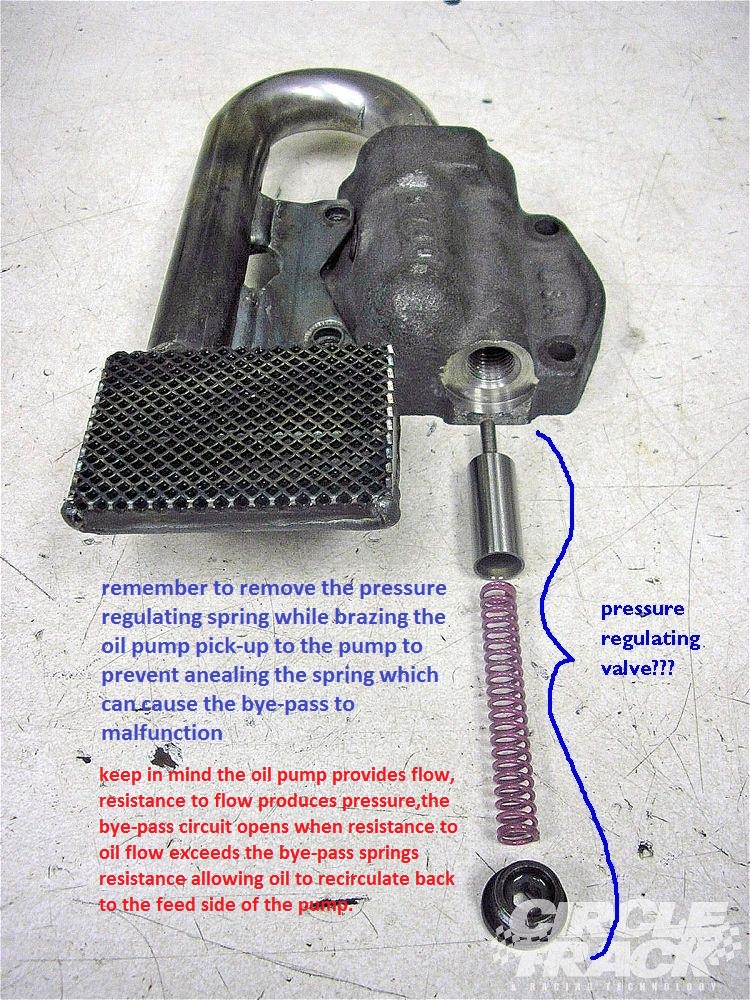

Then a friend turned up whos built a few small blocks and told me that i should of removed the pressure relief spring as they can be affected by the heat and can lose some of their spring rate.

Can anyone confirm or deny this please . I didnt let it get excessively hot so im pretty sure ill be ok.... Need advice asap as i wanna put the sump back on shortly... Thanks in advance guys n gals...

yes it is "POSSIBLE" to anneal the pressure relief spring but its UNLIKELY, springs are unlikely to be damaged, and are cheap and easily replaced, if thats required

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

http://garage.grumpysperformance.com/index.php?threads/testing-a-chevy-oil-pump.6479/

you should NEVER shim an oil pumps pressure relief spring as it may prevent the piston it holds from moving down its bore far enough to allow it to open the bay-pass passage, that allows the pressure on the high pressure side of the oil pump from bleeding off back into the intakes side of the oil pump

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

Last edited: