stingraymax said:I am rebuilding my front end and am got the control arms of and am tried to remove the bushings.

Now I tried an air chissel but they would not move, I tried burning the rubber out but couldn't get enough heat to it as the did not burn, then I drilled out the rubber around it and got the inner spindle off.

Now for the outer spindle on one side it was frozen solid to the control arm shaft so I used a hacksaw to get it out but on one side I went a bit too deep

The cut itself is about 1-2 mm deep it is not thru the arm

Now will I be ok when I re-press new bushings in there or do I need to weld the cut and file it out again ?

As you can see from my control arm shaft it was rusted solid. ( another thing to replace...)

]

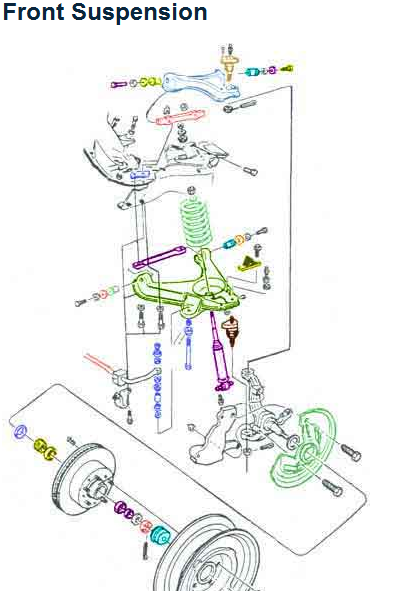

While I applaud your desire to do work on your corvette yourself rather than farm it out, doing so requires some tools and knowledge that you may need to acquire before you start...

in my opinion your not using common sense here, you've obviously damaged the control arm,by not using a press thats designed to do the job, and youve cut the stamp steel,more than likely, induced stress risers in the forging,...your LIFE might depend on it NOT FAILING while you drive at high speed, and the availability and cost of replacement parts is just not that high

http://www.vette2vette.com/

http://www.ikerds.com/

http://www.ecklerscorvette.com/diagram/ ... ex/id/133/

http://www.corvetteamerica.com/corvette/corvetteBrakes/

THESE GUYS HAVE USED PARTS AVAILABLE

Id strongly suspect a local machine shop could have pressed out and inserted and reconditioned parts as required, at lower cost than youll now incure and in less time!, its a choice you make, you either research the tools required, ( like a cheap hydraulic press and a shop manual) before you start or you pay a qualified machine shop to do the work.

buying a 20 ton press when they go on sale might seem like a great deal of money spent for a single tool, but machine shop charges alone for replacing all the u-joints and ball joints in your corvette even once would go a long way to paying for one ! in fact on my corvette. thats the reason I bought the press, I simply asked what the local machine shop charged if I brought the parts to them and supplied the new replacement parts , the cost of the labor alone was 80% of the press cost, and after replacing parts for dozens of cars the press has paid for itself many times over.

http://www.harborfreight.com/20-ton-sho ... 32879.html