read, the linked info, because understanding the concept and the correct use of the linked calculators will effect your engines power curve, doing it correctly helps to provide a wide power band, doing it wrong tends to significantly reduce power potential.

now keep in mind if your cam timing does not match your headers intended scavenging power range, and the rpm its designed for , the engines displacement and intake flow rates, so that all factors are designed to maximize flow in a set rpm band and flow rate, (IE, complement each other) you'll have a marked reduction in the power potential,

and NO header will function correctly with significant back pressure beyond the header collectors

in most applications

if both collectors feed an X pipe in front of a very low flow restriction exhaust, you widen the power curve,

in an ideal world, the x-pipe is withing 18"-24" of the collectors exit

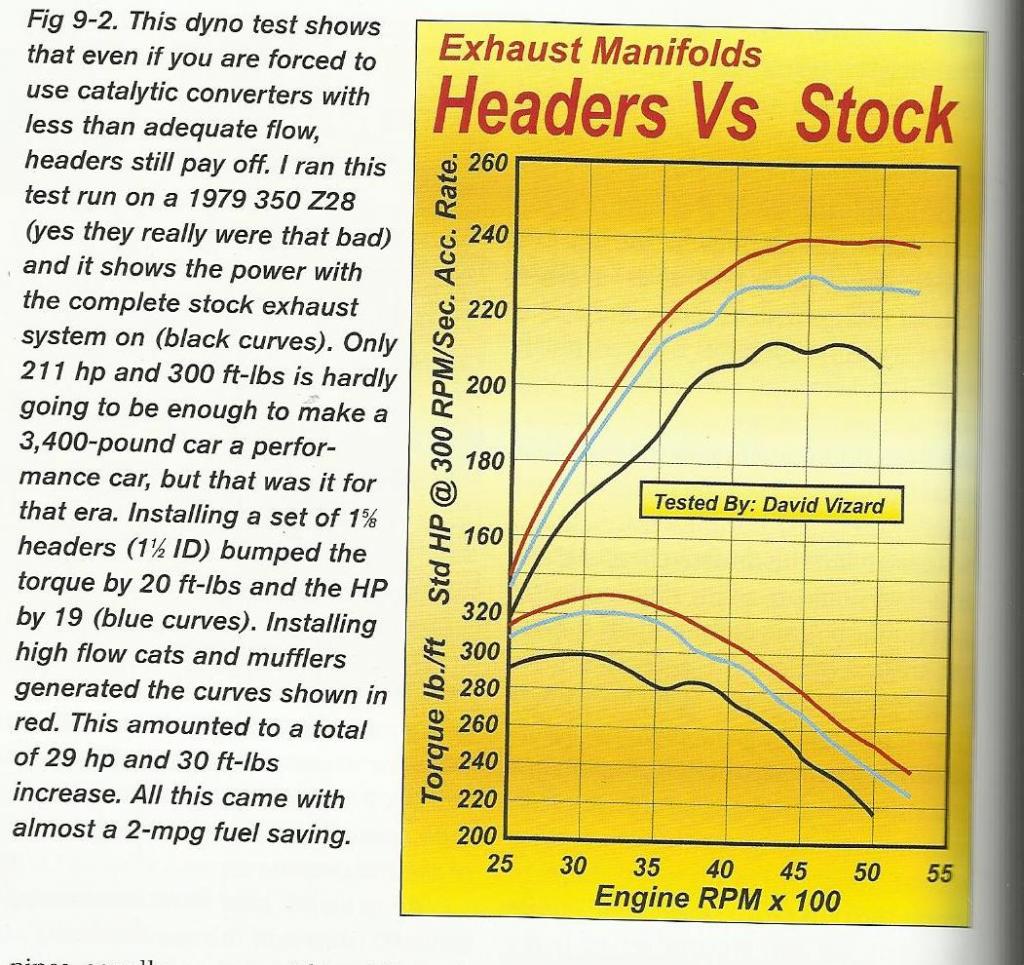

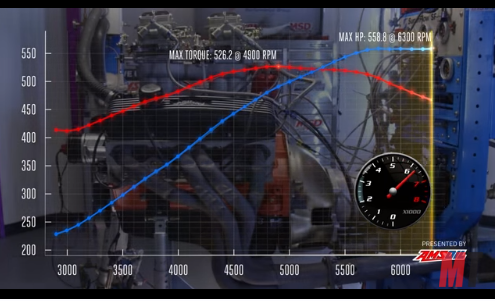

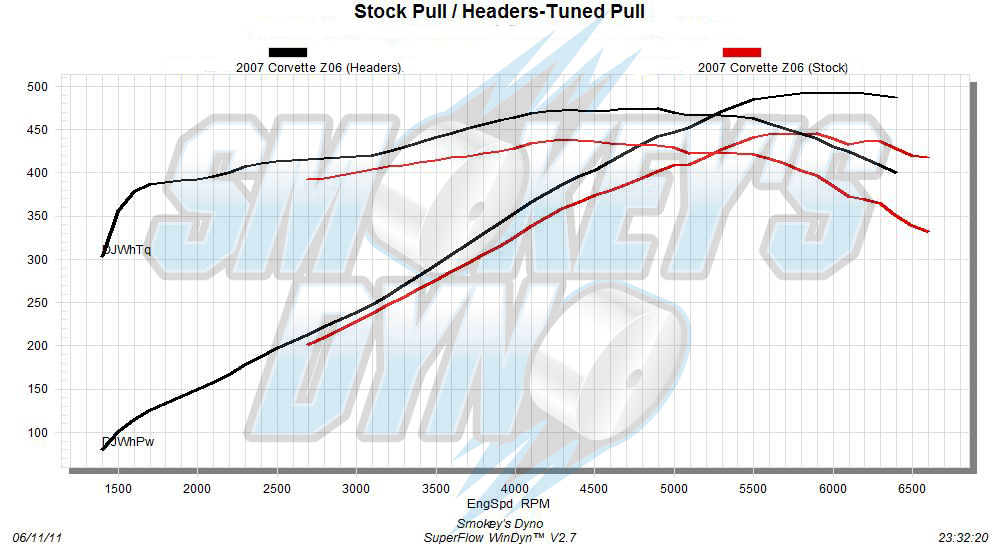

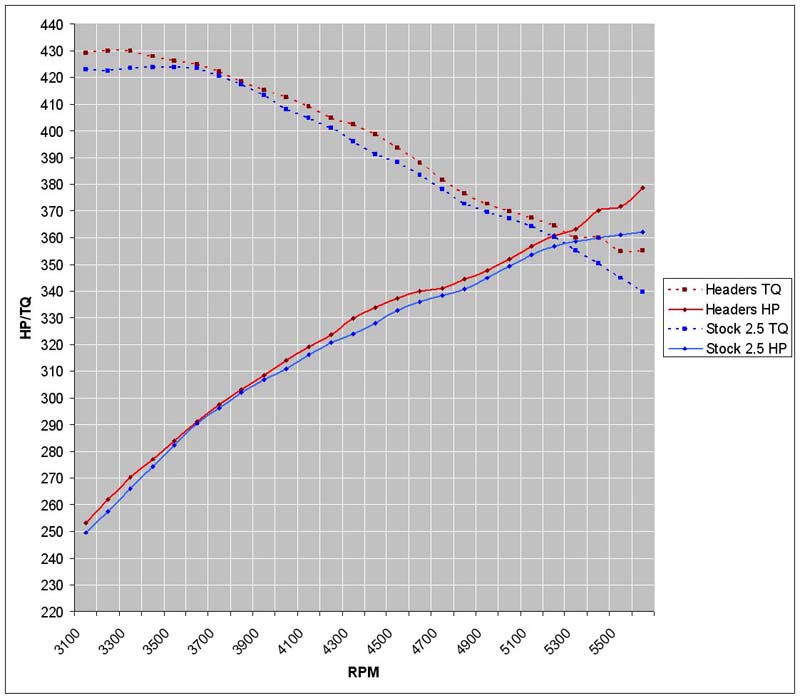

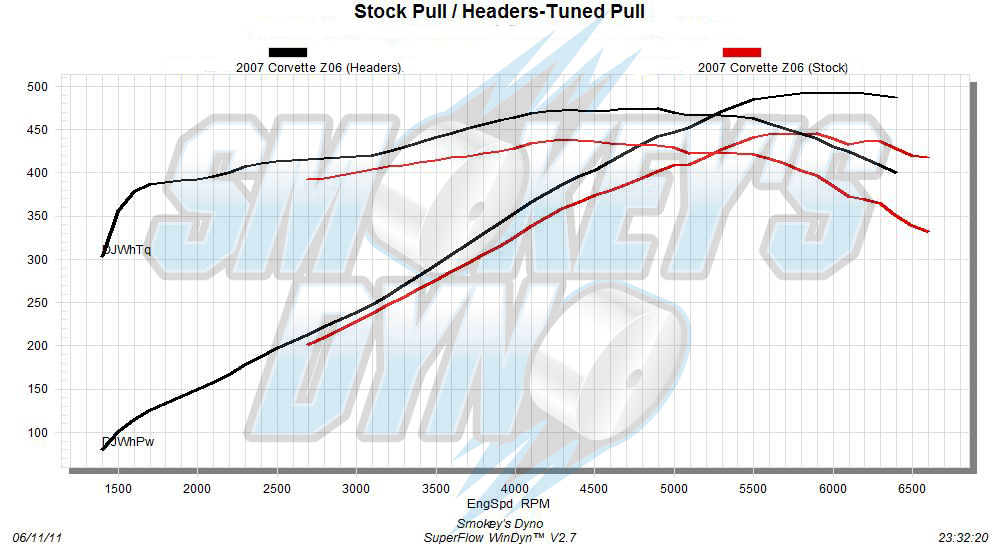

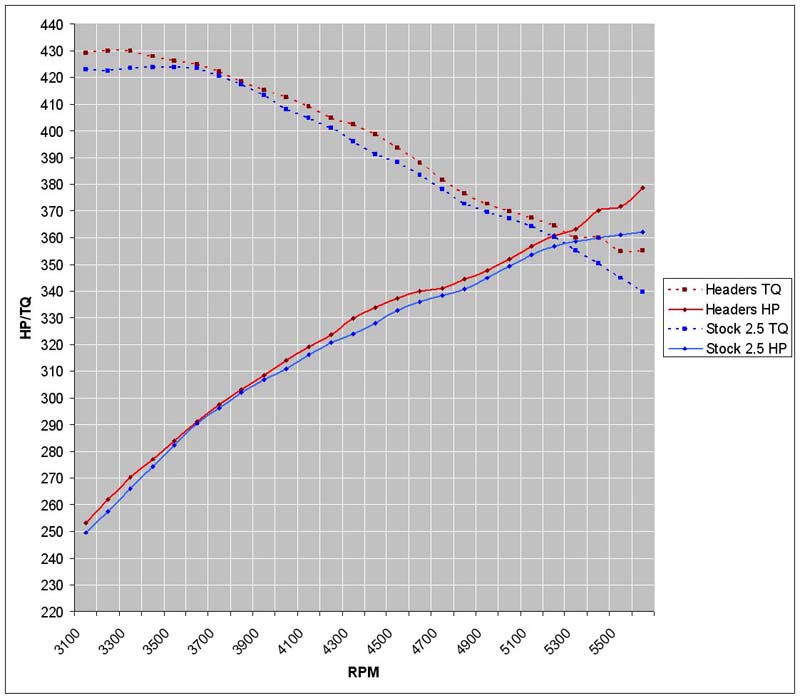

, on the extremes ,I've seen several dyno tests where carefully tuned headers allowed to engine to produce 50-70 more horse power, than the stock exhaust manifolds, and I've seen tests where adding a restrictive exhaust to open headers resulted in 70-80 horsepower losses,, as in most component choices selecting the correct matching parts adds a good deal to the results but mis-matched components can hurt your power curve noticeably.

, on the extremes ,I've seen several dyno tests where carefully tuned headers allowed to engine to produce 50-70 more horse power, than the stock exhaust manifolds, and I've seen tests where adding a restrictive exhaust to open headers resulted in 70-80 horsepower losses,, as in most component choices selecting the correct matching parts adds a good deal to the results but mis-matched components can hurt your power curve noticeably.

that one reason you need to read dyno tests in magazines very carefully, because its rather easy to make any headers or exhaust, cam, or intake manifold look good or bad by simply carefully selecting the parts... in the test that they are compared too, by carefully selecting the other components that favor the parts your trying to sell or parts the restrict the competitions components, from reaching their potential.

a great set of tuned headers on a killer engine combo with a restricted exhaust, or a mis-matched cam, or a mis-match intake will show little if any power gains, and removing those components, and swapping in the correct matched components will boost hp on even mediocre headers.

The question always comes up about , choosing the header primary pipe diameter, as in should you get 2" or 2.125" or 2.25" primary's headers on that big block, or 1.675" ,or 1.75" on your small block ETC. the rule of thumb is to match the exhaust port size or use only slightly larger, the restriction the exhaust system you place behind any size header will pose a much greater chance of costing you potential performance than the change in primary pipe diameter, in most cases simply because most commercial headers are designed more for low cost and ease of production than to maximize performance.

Now that does not mean you can't get good commercial headers or that your choice in header type, diam. or length won't effect your results, but unless you match the header design that you install to the application, displacement, compression, cam timing and other factors your already working at a disadvantage.

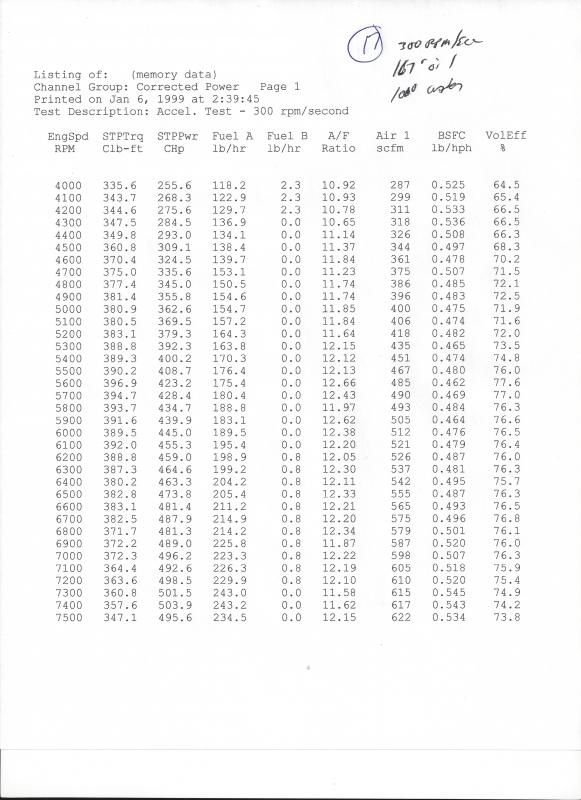

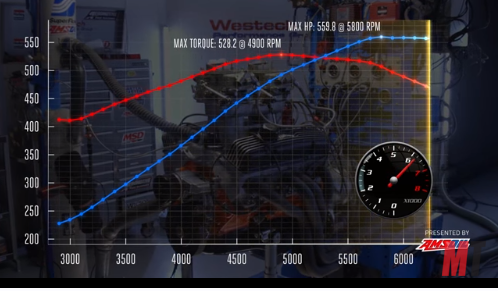

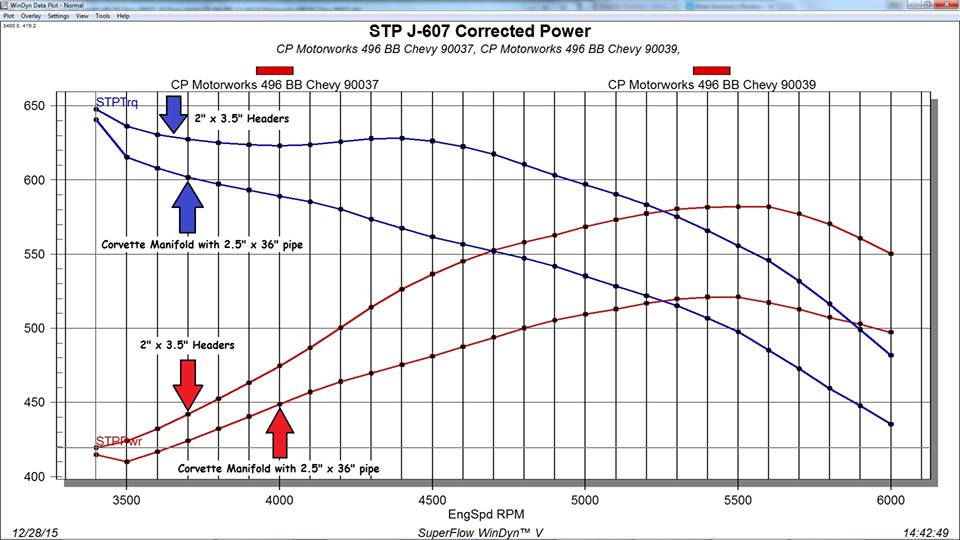

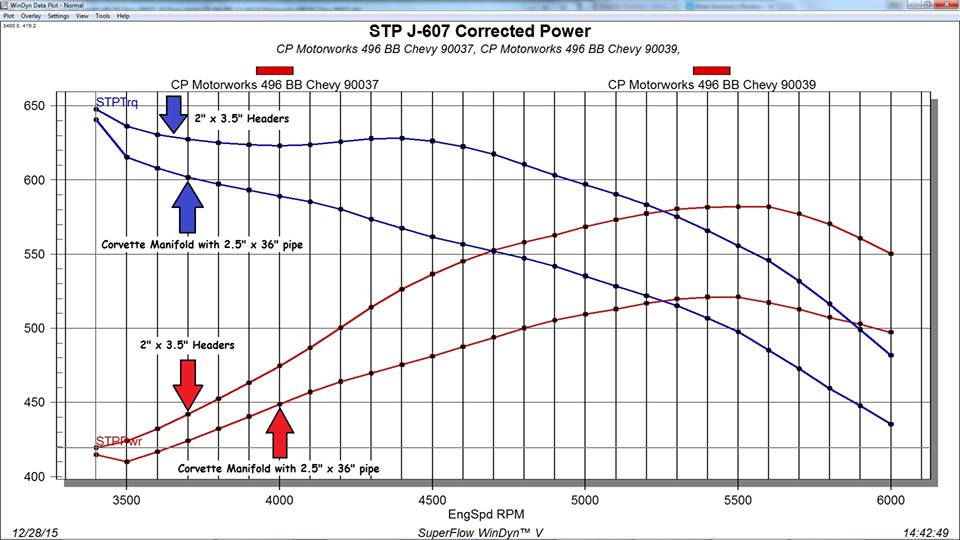

I find this graph very useful, it shows stock corvette exhaust manifolds vs headers on the same 496 BBC engine dyno test

I think 99.8% of the guys in this hobby are forced to work on a rather limited budget, your certainly not alone in that regard, so I would not be all that worried about breaking the cam in or running it awhile with restrictive stock exhaust manifolds,

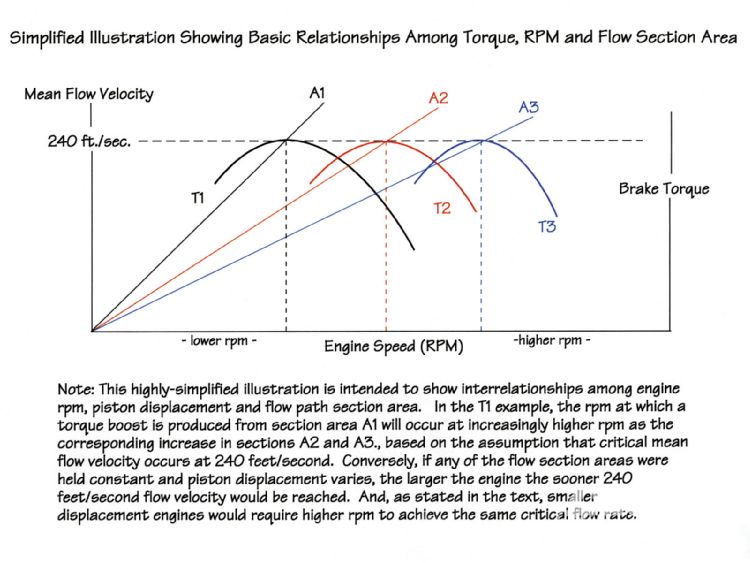

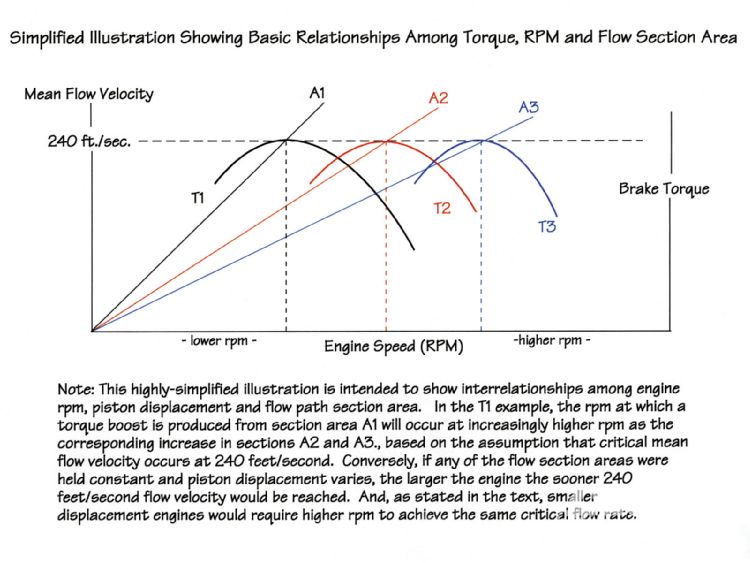

while its certainly true it will cost you peak horse power below about 4000 rpm its restrictive effect won't be all that critical if the rest of the exhaust systems not all that restrictive, keep in mind headers are designed to increase cylinder scavenging efficiency and as the rpms increase both the volume of the exhaust gases exiting the engine (goes up rapidly) and the time lag between cylinders firing changes (gets far shorter) thus the volume of gases and the cross sectional area restricting the gas flow becomes much more restrictive and the ability of the inertia of those gases effect to help drag the mass of following exhaust pulses tends to become more effective in a properly tuned header and collector as the rpms increase

ONLY IF THE EXHAUST SYSTEM PAST THE HEADERS COLLECTOR IS VIRTUALLY NON RESTRICTIVE, TO EXHAUST FLOW IN THE HEADERS DESIGNED RPM OPERATIONAL POWER BAND,

which is almost always found in the 3500rpm-7500rpm range and covering generally a 1500rpm-2000rpm wide rpm ,

sweet spot where its most efficient.

your engines rpm range, compression, displacement, cam timing, header primary length and cross sectional area, plus the fuel/air ratio, intake manifold design, carburetor, or throttle body flow rates, ignition timing and several other factors will effect your engine performance and how effectively headers scavenge the cylinders

A COUPLE HOURS SPENT READING CAN SAVE YOU MONEY AND EFFORT

the one thing you should rapidly come to realize, if you compare the suggested dimensions vs the measured dimensions,

is that most lower cost headers are designed with ease of manufacture,and low cost, as the prime criteria,

and significantly shorter and smaller diameter primary and collector dimensions,are used,

than might be ideal ,to allow a single header design to fit as many different chassis applications as can be done,

with a single nearly interchangeable design, to simplify both marketing and inventory reduction

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/header-dimension-calculator.15013/

http://www.hotrod.com/articles/headers-dyno-test/

http://www.superchevy.com/how-to/148-0404-best-headers-shootout/

http://www.superchevy.com/how-to/49178-headers-power-increase/

http://www.mustangandfords.com/how-to/engine/29618-short-long-tube-headers-test/

http://www.carcraft.com/techarticles/header_basics/

http://www.sandersonheaders.com/Lets-Get-Technical.html

http://www.airflowresearch.com/hot-rod-nov-2013-305cc-bbc.php

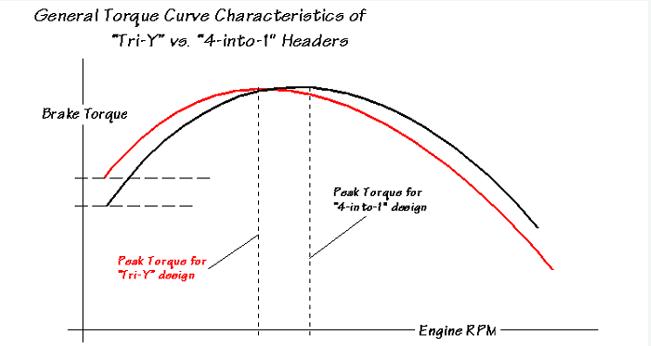

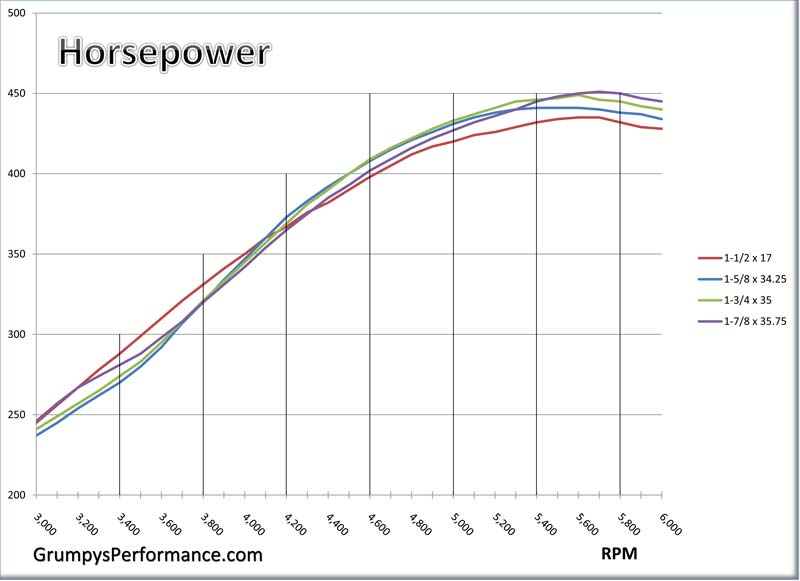

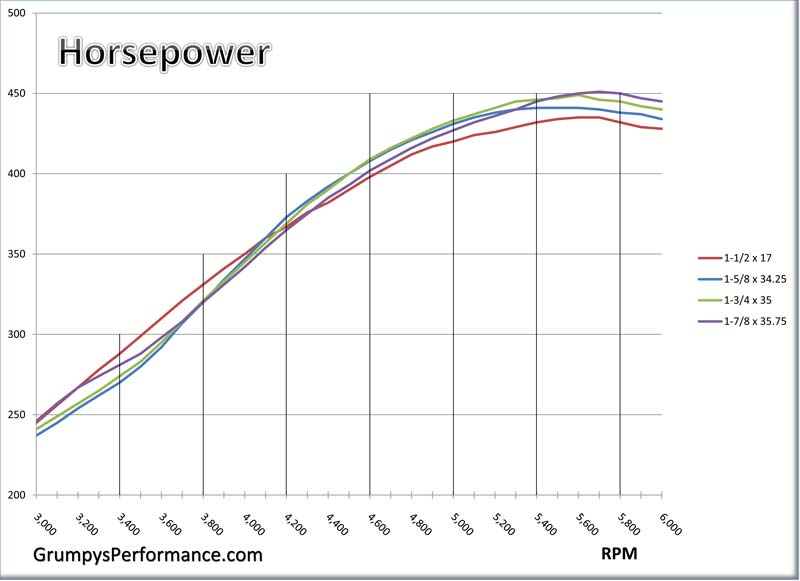

you will occasionally see dyno test results similar to this, that show about a 20 hp spread in the power curve, that seem to indicate that the difference in header configuration is not overly critical,but keep in mind these results are almost always done on 350-383 displacement engines with fairly mild compression , below 9.5:1 and fairly low duration cams ( example ,below 230 deg @.050 lift )and stock or mildly restricted exhaust systems, an engine with a fairly tight LSA and high compression and a low restriction or open exhaust can take full advantage of the headers scavenging the cylinders in a tuned rpm range significantly boosting the power produced, the tuned exhaust header has a greater effect on a higher compression ratio engine of larger displacement with a tighter LSA cam

http://www.bgsoflex.com/bestheader.html

http://www.wallaceracing.com/header_length.php

http://maxracesoftware.com/pipemax36xp2.htm

http://victorylibrary.com/mopar/header-tech-c.htm

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://maxracesoftware.com/pipemax36xp2.htm

http://stockcarracing.automotive.com/49 ... sions.html

http://www.carcraft.com/techarticles/03 ... index.html

http://www.racingbeat.com/2001header/headertest.htm

http://www.carcraft.com/techarticles/he ... usion.html

http://www.hotrod.com/techarticles/engi ... index.html

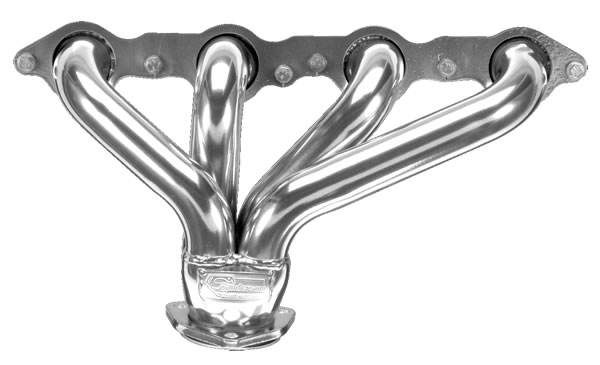

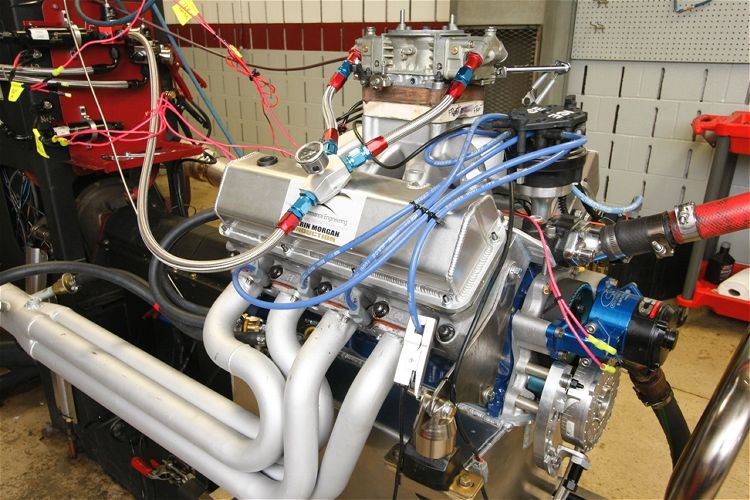

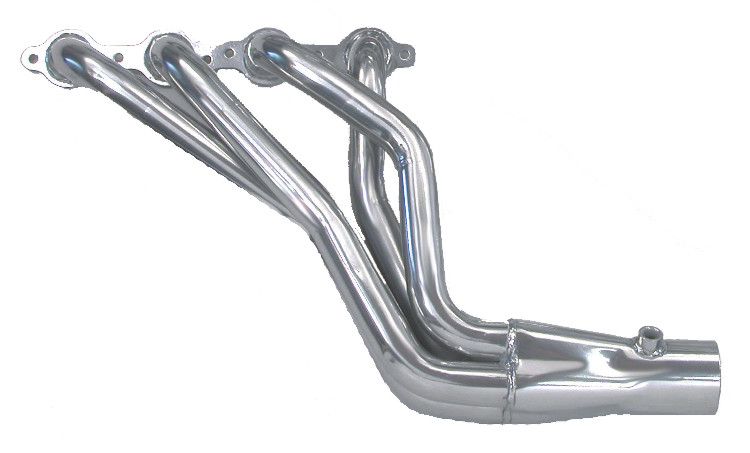

shorty or block hugger designs

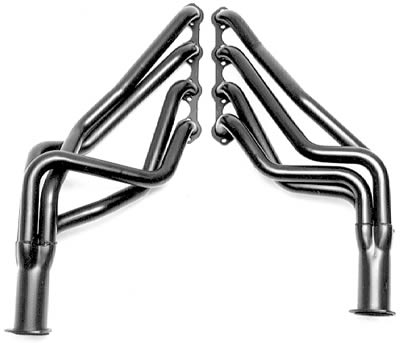

long tube full size headers

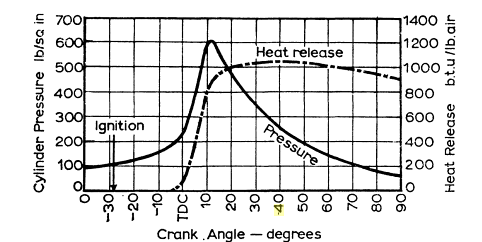

theres a great deal of info on the site about selecting or building headers, but one major factor is that a NON-RESTRICTIVE exhaust system MUST be installed with ANY HEADERS to allow them to work correctly. for headers to work correctly they require an exhaust pulse to allow its inertial energy to drag the following charge along with it out the exhaust.

if you can,t visualize that it might help to find a 3 ft long section of 2.5" pvc pipe and wrap a bit of tape around a full coke can so it slides easily thru the PVC, pipe but fills its interior diam., now place the pipe horizontally insert the coke can and drop the opposite end strait down while you hold your hand over the end the coke can was inserted into, as the mass of the coke can falls you'll feel air dragged with it , the same basic thing happens with an exhaust pulse, its mass is far less but its traveling much much faster, and depending on the rpm and displacement it does generate significant energy that can be used to draw the next intake runners charge into the cylinder as it draws out the next exhaust charge during the cams overlap duration (LOOK INTO CAM TIMING)

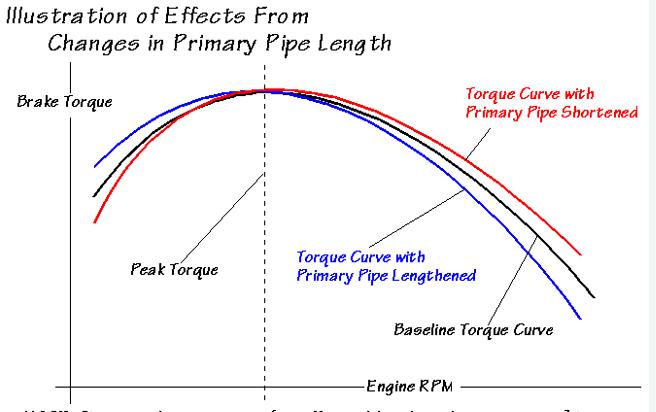

keep in mind the LENGTH of the header tube effects the rpm levels and energy transferred as it takes time for that mass of hot exhaust gas to travel thru the primary tube, naturally a longer distance tends to require a longer time and the longer duration tends to impart a longer and stronger negative pressure wave to assist the next pulse IF ITS TIMED CORRECTLY and the header primary tube is the correct dia. and length for the engines displacement,compression, cam timing, and several other factors, but again, it works far more effectively if the exhaust system is a low restriction design that doesn,t reduce the scavenging effect of the pulse waves, and the tubing is long enough to work effectively

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=333

viewtopic.php?f=52&t=480

viewtopic.php?f=56&t=352

viewtopic.php?f=56&t=1166

http://www.slowgt.com/Calc2.htm#Header

http://www.bgsoflex.com/auto.html

viewtopic.php?f=80&t=10730&p=46843#p46843

these threads might help

http://www.pontiacracing.net/js_header_length1.htm

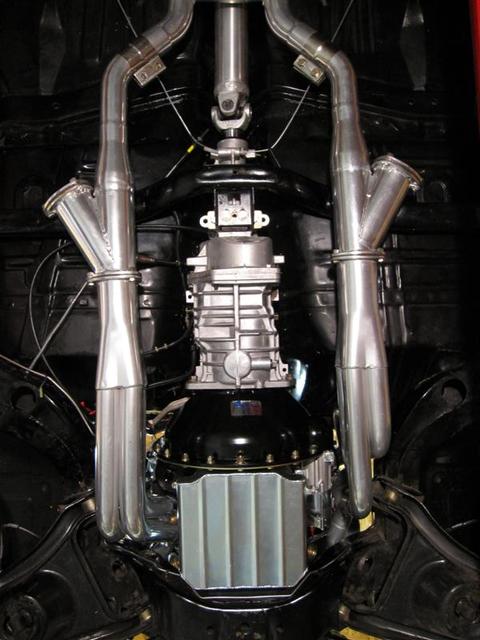

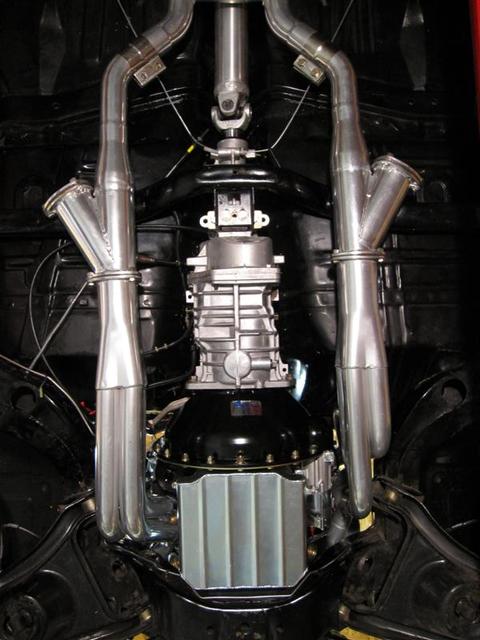

this MELROSE

exhaust is well designed and should give a good idea as to what your trying to do,when building a custom exhaust,or if your not into welding and fabrication you could buy one

http://www.melroseheaders.com/products/ ... ms/c-4.php

a well thought thru design on an (X) pipe and cut outs

keep in mind headers loose a great deal of their potential horsepower gains if there matched up to a restrictive exhaust

http://www.melrosecorvette.com/1984-199 ... ic-option/

INSTALLING AN (X) PIPE IN THE EXHAUST ON A DUAL EXHAUST CAR

keep in mind that a properly designed exhaust system and headers goes a very long way towards increasing the efficiency of the intake manifold and head flow , and remember that the better the heads and the more effective the exhaust scavenging the less duration the cam used will require!

what goes in, needs to flow out with near zero flow restriction

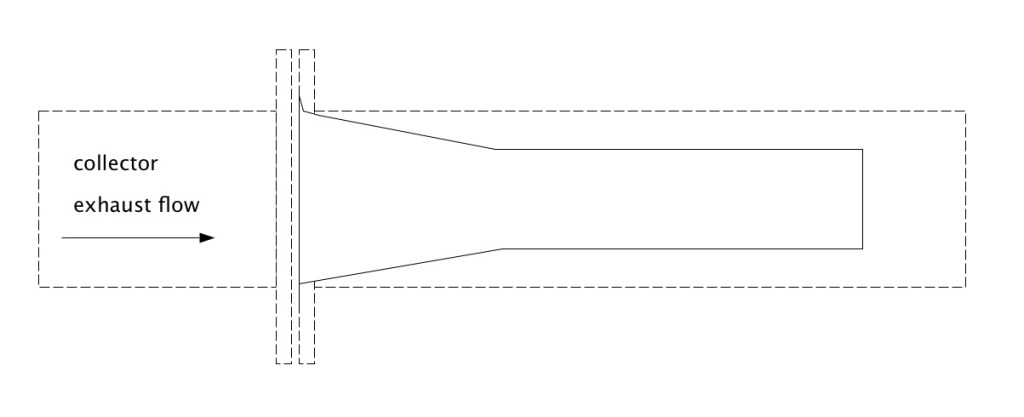

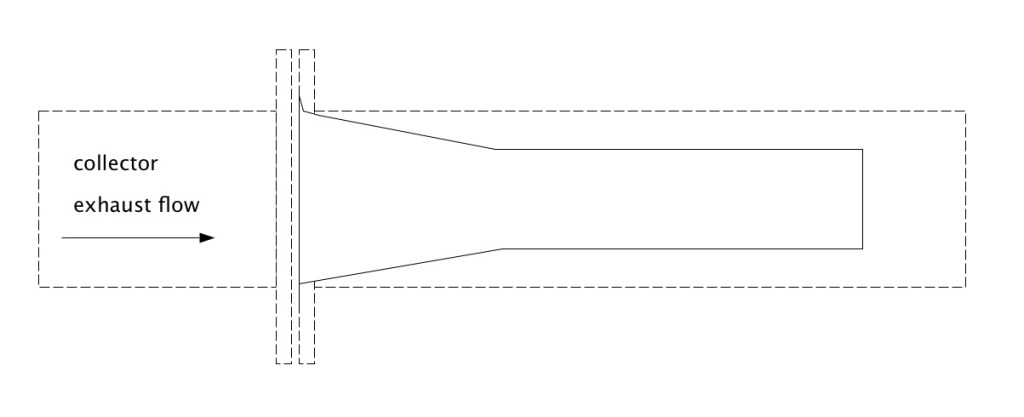

adding an anti-reversion baffle to a 18"-24" longer collector on open headers with the internal pipe about 1/2 the collector length tends to help scavenging on some engines

if you want max engine performance under predictable conditions,

it will take some testing, measuring and thought,

could you give us some idea as too,

engine displacement"

bore and stroke ?

connecting rod length,

engines intended power band?

transmission shift points?

the cam timing, (lift ,duration)?

cylinder head flow rates,?

static compression ratio,?

ignition advance curve,?

intake valve diameter?

intake port cross sectional area?

intake runner length?

exhaust valve diameter?

, and header primary tube diameter?

and length?

fuel/air ratio every 1000 rpm?

exhaust back pressure in the collector every 1000 rpm?

intake plenum vacuum every 1000 rpm?

with that data we can stop random guess work,

and have at least some facts to work with,

to make a semi logical guess as to what changes might help.

guessing is fast and easy, getting a few facts and working out the details is a bit harder but more productive

http://www.wallaceracing.com/Calculators.htm

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://garage.grumpysperformance.co...ful-exhaust-valve-size-and-header-info.11265/

http://garage.grumpysperformance.com/index.php?threads/dyno-testing-headers.3529/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.co...-guys-that-just-slap-on-factory-headers.3155/

reading these threads and sub links may help

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://garage.grumpysperformance.co...-between-shorty-and-full-length-headers.1303/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/header-dimension-calculator.15013/

http://www.bgsoflex.com/auto.html

http://www.mk5cortinaestate.co.uk/calculator5.php

now keep in mind if your cam timing does not match your headers intended scavenging power range, and the rpm its designed for , the engines displacement and intake flow rates, so that all factors are designed to maximize flow in a set rpm band and flow rate, (IE, complement each other) you'll have a marked reduction in the power potential,

and NO header will function correctly with significant back pressure beyond the header collectors

in most applications

if both collectors feed an X pipe in front of a very low flow restriction exhaust, you widen the power curve,

in an ideal world, the x-pipe is withing 18"-24" of the collectors exit

that one reason you need to read dyno tests in magazines very carefully, because its rather easy to make any headers or exhaust, cam, or intake manifold look good or bad by simply carefully selecting the parts... in the test that they are compared too, by carefully selecting the other components that favor the parts your trying to sell or parts the restrict the competitions components, from reaching their potential.

a great set of tuned headers on a killer engine combo with a restricted exhaust, or a mis-matched cam, or a mis-match intake will show little if any power gains, and removing those components, and swapping in the correct matched components will boost hp on even mediocre headers.

The question always comes up about , choosing the header primary pipe diameter, as in should you get 2" or 2.125" or 2.25" primary's headers on that big block, or 1.675" ,or 1.75" on your small block ETC. the rule of thumb is to match the exhaust port size or use only slightly larger, the restriction the exhaust system you place behind any size header will pose a much greater chance of costing you potential performance than the change in primary pipe diameter, in most cases simply because most commercial headers are designed more for low cost and ease of production than to maximize performance.

Now that does not mean you can't get good commercial headers or that your choice in header type, diam. or length won't effect your results, but unless you match the header design that you install to the application, displacement, compression, cam timing and other factors your already working at a disadvantage.

GRUMPY?

From what I was reading having the header inlet smaller than the exhaust port is a very bad thing... I was hoping to run the factory exhaust for a short time, mostly during camshaft break-in and for me to pay down my credit card for a month or two...

Thoughts?

I think 99.8% of the guys in this hobby are forced to work on a rather limited budget, your certainly not alone in that regard, so I would not be all that worried about breaking the cam in or running it awhile with restrictive stock exhaust manifolds,

while its certainly true it will cost you peak horse power below about 4000 rpm its restrictive effect won't be all that critical if the rest of the exhaust systems not all that restrictive, keep in mind headers are designed to increase cylinder scavenging efficiency and as the rpms increase both the volume of the exhaust gases exiting the engine (goes up rapidly) and the time lag between cylinders firing changes (gets far shorter) thus the volume of gases and the cross sectional area restricting the gas flow becomes much more restrictive and the ability of the inertia of those gases effect to help drag the mass of following exhaust pulses tends to become more effective in a properly tuned header and collector as the rpms increase

ONLY IF THE EXHAUST SYSTEM PAST THE HEADERS COLLECTOR IS VIRTUALLY NON RESTRICTIVE, TO EXHAUST FLOW IN THE HEADERS DESIGNED RPM OPERATIONAL POWER BAND,

which is almost always found in the 3500rpm-7500rpm range and covering generally a 1500rpm-2000rpm wide rpm ,

sweet spot where its most efficient.

your engines rpm range, compression, displacement, cam timing, header primary length and cross sectional area, plus the fuel/air ratio, intake manifold design, carburetor, or throttle body flow rates, ignition timing and several other factors will effect your engine performance and how effectively headers scavenge the cylinders

A COUPLE HOURS SPENT READING CAN SAVE YOU MONEY AND EFFORT

the one thing you should rapidly come to realize, if you compare the suggested dimensions vs the measured dimensions,

is that most lower cost headers are designed with ease of manufacture,and low cost, as the prime criteria,

and significantly shorter and smaller diameter primary and collector dimensions,are used,

than might be ideal ,to allow a single header design to fit as many different chassis applications as can be done,

with a single nearly interchangeable design, to simplify both marketing and inventory reduction

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/header-dimension-calculator.15013/

http://www.hotrod.com/articles/headers-dyno-test/

http://www.superchevy.com/how-to/148-0404-best-headers-shootout/

http://www.superchevy.com/how-to/49178-headers-power-increase/

http://www.mustangandfords.com/how-to/engine/29618-short-long-tube-headers-test/

http://www.carcraft.com/techarticles/header_basics/

http://www.sandersonheaders.com/Lets-Get-Technical.html

http://www.airflowresearch.com/hot-rod-nov-2013-305cc-bbc.php

you will occasionally see dyno test results similar to this, that show about a 20 hp spread in the power curve, that seem to indicate that the difference in header configuration is not overly critical,but keep in mind these results are almost always done on 350-383 displacement engines with fairly mild compression , below 9.5:1 and fairly low duration cams ( example ,below 230 deg @.050 lift )and stock or mildly restricted exhaust systems, an engine with a fairly tight LSA and high compression and a low restriction or open exhaust can take full advantage of the headers scavenging the cylinders in a tuned rpm range significantly boosting the power produced, the tuned exhaust header has a greater effect on a higher compression ratio engine of larger displacement with a tighter LSA cam

http://www.bgsoflex.com/bestheader.html

http://www.wallaceracing.com/header_length.php

http://maxracesoftware.com/pipemax36xp2.htm

http://victorylibrary.com/mopar/header-tech-c.htm

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://maxracesoftware.com/pipemax36xp2.htm

http://stockcarracing.automotive.com/49 ... sions.html

http://www.carcraft.com/techarticles/03 ... index.html

http://www.racingbeat.com/2001header/headertest.htm

http://www.carcraft.com/techarticles/he ... usion.html

http://www.hotrod.com/techarticles/engi ... index.html

shorty or block hugger designs

long tube full size headers

theres a great deal of info on the site about selecting or building headers, but one major factor is that a NON-RESTRICTIVE exhaust system MUST be installed with ANY HEADERS to allow them to work correctly. for headers to work correctly they require an exhaust pulse to allow its inertial energy to drag the following charge along with it out the exhaust.

if you can,t visualize that it might help to find a 3 ft long section of 2.5" pvc pipe and wrap a bit of tape around a full coke can so it slides easily thru the PVC, pipe but fills its interior diam., now place the pipe horizontally insert the coke can and drop the opposite end strait down while you hold your hand over the end the coke can was inserted into, as the mass of the coke can falls you'll feel air dragged with it , the same basic thing happens with an exhaust pulse, its mass is far less but its traveling much much faster, and depending on the rpm and displacement it does generate significant energy that can be used to draw the next intake runners charge into the cylinder as it draws out the next exhaust charge during the cams overlap duration (LOOK INTO CAM TIMING)

keep in mind the LENGTH of the header tube effects the rpm levels and energy transferred as it takes time for that mass of hot exhaust gas to travel thru the primary tube, naturally a longer distance tends to require a longer time and the longer duration tends to impart a longer and stronger negative pressure wave to assist the next pulse IF ITS TIMED CORRECTLY and the header primary tube is the correct dia. and length for the engines displacement,compression, cam timing, and several other factors, but again, it works far more effectively if the exhaust system is a low restriction design that doesn,t reduce the scavenging effect of the pulse waves, and the tubing is long enough to work effectively

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=333

viewtopic.php?f=52&t=480

viewtopic.php?f=56&t=352

viewtopic.php?f=56&t=1166

http://www.slowgt.com/Calc2.htm#Header

http://www.bgsoflex.com/auto.html

viewtopic.php?f=80&t=10730&p=46843#p46843

these threads might help

http://www.pontiacracing.net/js_header_length1.htm

this MELROSE

exhaust is well designed and should give a good idea as to what your trying to do,when building a custom exhaust,or if your not into welding and fabrication you could buy one

http://www.melroseheaders.com/products/ ... ms/c-4.php

keep in mind headers loose a great deal of their potential horsepower gains if there matched up to a restrictive exhaust

http://www.melrosecorvette.com/1984-199 ... ic-option/

INSTALLING AN (X) PIPE IN THE EXHAUST ON A DUAL EXHAUST CAR

keep in mind that a properly designed exhaust system and headers goes a very long way towards increasing the efficiency of the intake manifold and head flow , and remember that the better the heads and the more effective the exhaust scavenging the less duration the cam used will require!

what goes in, needs to flow out with near zero flow restriction

adding an anti-reversion baffle to a 18"-24" longer collector on open headers with the internal pipe about 1/2 the collector length tends to help scavenging on some engines

if you want max engine performance under predictable conditions,

it will take some testing, measuring and thought,

could you give us some idea as too,

engine displacement"

bore and stroke ?

connecting rod length,

engines intended power band?

transmission shift points?

the cam timing, (lift ,duration)?

cylinder head flow rates,?

static compression ratio,?

ignition advance curve,?

intake valve diameter?

intake port cross sectional area?

intake runner length?

exhaust valve diameter?

, and header primary tube diameter?

and length?

fuel/air ratio every 1000 rpm?

exhaust back pressure in the collector every 1000 rpm?

intake plenum vacuum every 1000 rpm?

with that data we can stop random guess work,

and have at least some facts to work with,

to make a semi logical guess as to what changes might help.

guessing is fast and easy, getting a few facts and working out the details is a bit harder but more productive

http://www.wallaceracing.com/Calculators.htm

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://garage.grumpysperformance.co...ful-exhaust-valve-size-and-header-info.11265/

http://garage.grumpysperformance.com/index.php?threads/dyno-testing-headers.3529/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.co...-guys-that-just-slap-on-factory-headers.3155/

reading these threads and sub links may help

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://garage.grumpysperformance.co...-between-shorty-and-full-length-headers.1303/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/header-dimension-calculator.15013/

http://www.bgsoflex.com/auto.html

http://www.mk5cortinaestate.co.uk/calculator5.php

Last edited by a moderator: