GRUMPY?

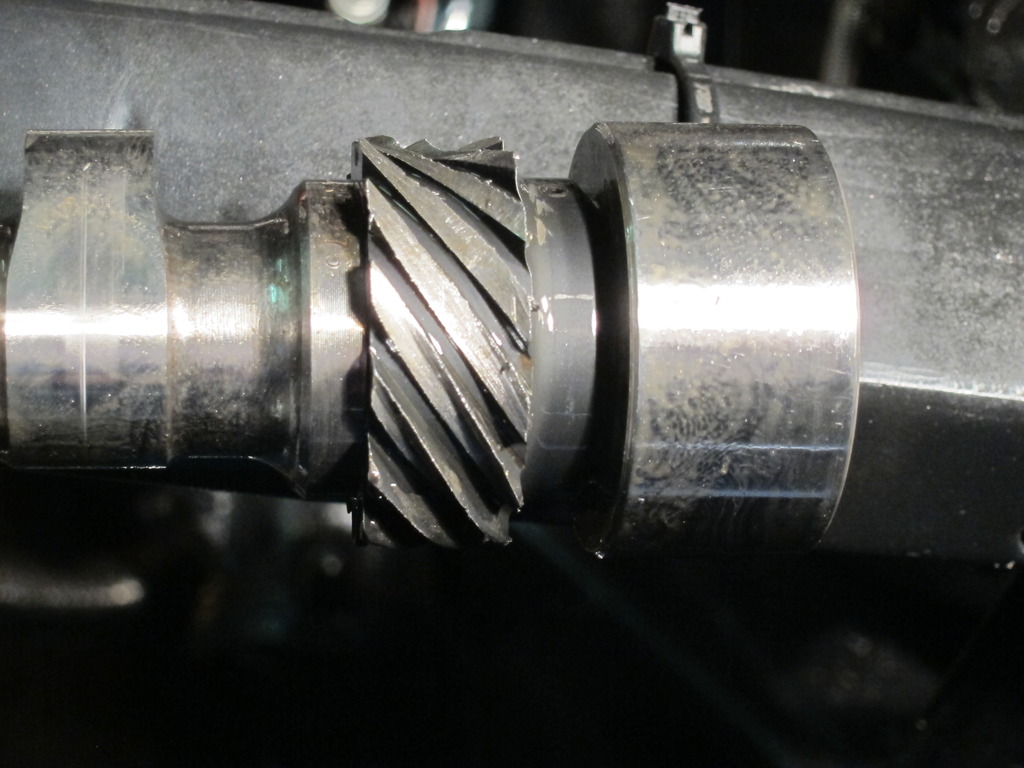

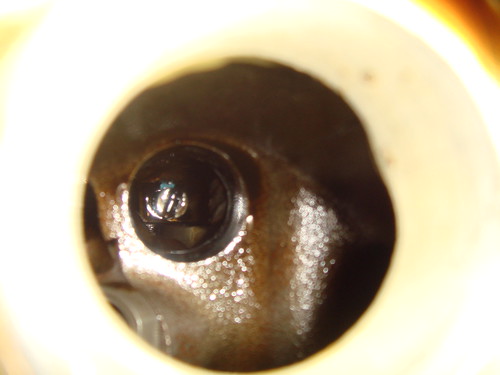

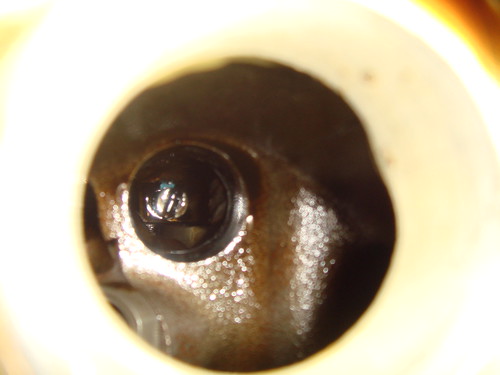

well done some tuning to the truck felt really good better then ever! Decided to go out for a nice drive tonight and had no spark so I started hunting this is what I found

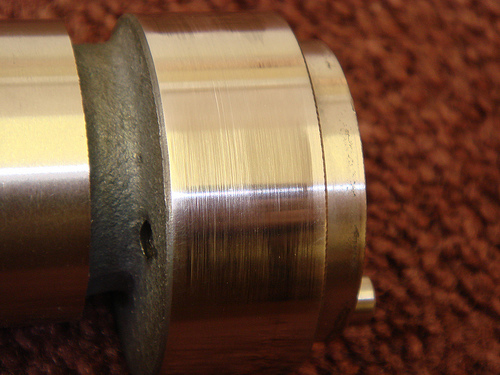

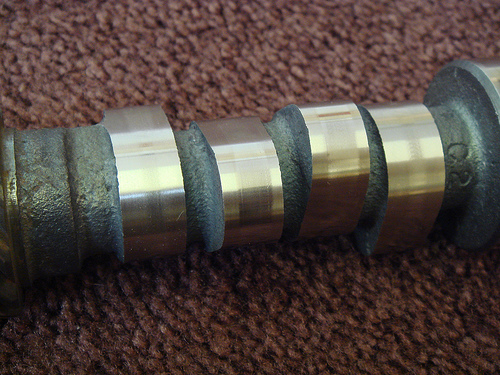

Can you tell me what caused this? And being the truck felt so good how much damage go’s along with this? I’m not sure if you can tell from the pictures is wear not broke or chunks missing, the dirt you see is from me wiping it down (not metal)

This is out of my 383 Stroker Roller Engine

READ THESE LINKS

http://www.carcraft.com/techarticles/di ... index.html

viewtopic.php?f=52&t=57&p=70&hilit=cast+cores#p70

check with the manufacturer anytime you have similar questions, on any valve train or ignition component.

but Id bet the stock distributor gear is what will be recommended,on any new engine build with a new cam installed.

this whole web site is designed to make it far FAR easier on guys wanting to build the required knowledge base required to learn the skills youll require to excell in this hobby.

coat any new cam and distributor gears with a good moly paste lube

READ THE RELATED INFO CAREFULLY AND USE A GOOD MOLY LUBE ON THE DISTRIBUTOR AND CAM GEARS

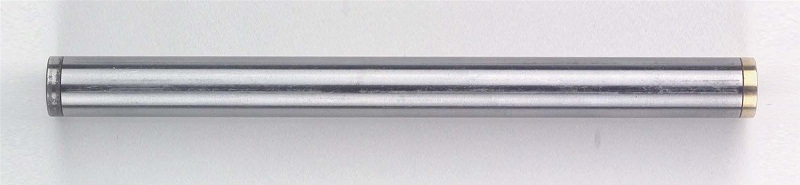

most stock chevy v8 distributors will use this gear. .491 diam.

https://www.summitracing.com/parts/ado-10456413/overview/make/chevrolet

many aftermarket distributors will use this gear .500 diam.

https://www.summitracing.com/parts/msd-8561/overview/make/chevrolet

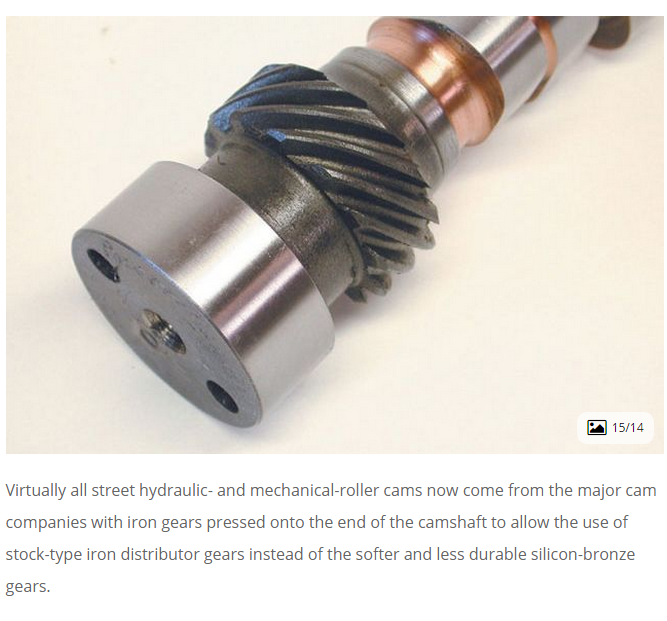

bronze distributor gears are generally used on billet steel roller cam cores

https://www.summitracing.com/parts/msd-8471/overview/make/chevrolet

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-wear.1701/#post-5252

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-info.1186/#post-4155

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/#post-5890

http://garage.grumpysperformance.co...stalling-the-intake-manifold-distributor.464/

http://garage.grumpysperformance.co...ear-articles-you-need-to-read.282/#post-61429

http://garage.grumpysperformance.co...ting-rebuilding-hei-ignitions.2798/#post-7247

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

THE CAM MANUFACTURER WILL BE ONLY TOO GLAD TO SELL THE CORRECT MATCHING DISTRIBUTOR GEAR TOO YOU

and like a lifter on a cam lobe it is usually going to last longer if both the cam and distributor gear are new, coated with moly assembly grease and allowed to lap in and mate surfaces , rather than use used worn distributor gears on new cams

viewtopic.php?f=70&t=251&p=299&hilit=shim+distributor#p299

viewtopic.php?f=54&t=2187&p=5890#p5890

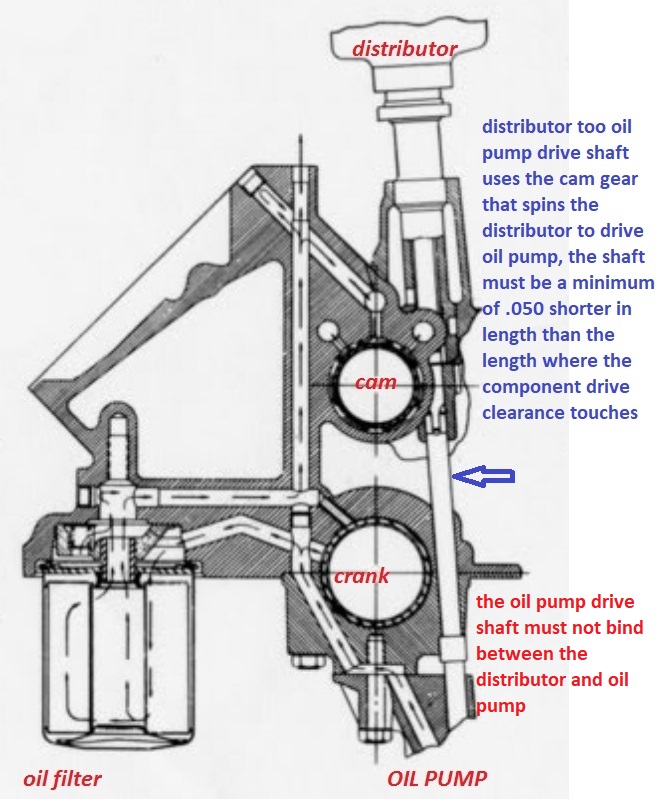

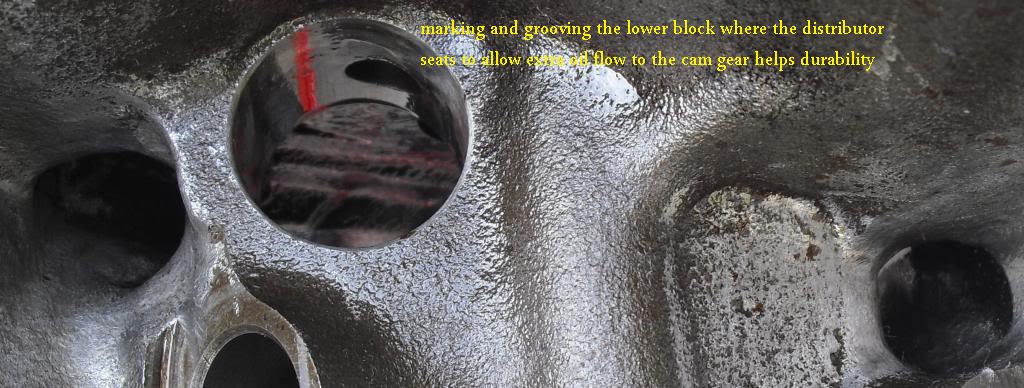

keep in mind the distributor base forms one wall of the lifter gallery oil passage

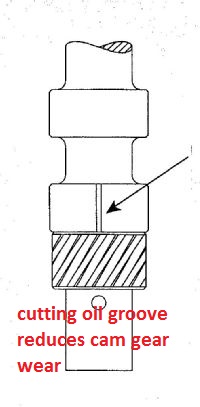

so grooving the lower oil band helps spray extra oil on the distributor/cam gears contact area

any time you change cams youll need to use a matching distributor gear, the cam manufacturer should be able to help tell you what matches, obviously checking clearances helps

and dipping the gear in moly assembly lube before it installed helps

be sure you inspect the distributor gear for excessive wear

especially if you changed from a flat tappet to a roller cam.

if your seeing the timing change a few degrees, back and forth,

slack in a worn, loose timing chain, worn distributor gear or not having the proper shim clearance on the distributor center shaft will provide slop that allows timing to vary several degrees

http://www.summitracing.com/parts/CCA-12200/

http://www.summitracing.com/parts/CCA-12140/

MOST of the chevy and after market cams will work with the standard replacement mellonized distributor gears

http://garage.grumpysperformance.com/index.php?threads/slowing-distributor-gear-wear.57/#post-70

http://garage.grumpysperformance.co...the-intake-manifold-distributor.464/#post-570

http://garage.grumpysperformance.com/index.php?threads/shiming-a-distributor.251/#post-299

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-wear.1701/#post-5252

well done some tuning to the truck felt really good better then ever! Decided to go out for a nice drive tonight and had no spark so I started hunting this is what I found

Can you tell me what caused this? And being the truck felt so good how much damage go’s along with this? I’m not sure if you can tell from the pictures is wear not broke or chunks missing, the dirt you see is from me wiping it down (not metal)

This is out of my 383 Stroker Roller Engine

READ THESE LINKS

http://www.carcraft.com/techarticles/di ... index.html

viewtopic.php?f=52&t=57&p=70&hilit=cast+cores#p70

check with the manufacturer anytime you have similar questions, on any valve train or ignition component.

but Id bet the stock distributor gear is what will be recommended,on any new engine build with a new cam installed.

this whole web site is designed to make it far FAR easier on guys wanting to build the required knowledge base required to learn the skills youll require to excell in this hobby.

coat any new cam and distributor gears with a good moly paste lube

READ THE RELATED INFO CAREFULLY AND USE A GOOD MOLY LUBE ON THE DISTRIBUTOR AND CAM GEARS

most stock chevy v8 distributors will use this gear. .491 diam.

https://www.summitracing.com/parts/ado-10456413/overview/make/chevrolet

many aftermarket distributors will use this gear .500 diam.

https://www.summitracing.com/parts/msd-8561/overview/make/chevrolet

bronze distributor gears are generally used on billet steel roller cam cores

https://www.summitracing.com/parts/msd-8471/overview/make/chevrolet

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-wear.1701/#post-5252

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-info.1186/#post-4155

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/#post-5890

http://garage.grumpysperformance.co...stalling-the-intake-manifold-distributor.464/

http://garage.grumpysperformance.co...ear-articles-you-need-to-read.282/#post-61429

http://garage.grumpysperformance.co...ting-rebuilding-hei-ignitions.2798/#post-7247

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

THE CAM MANUFACTURER WILL BE ONLY TOO GLAD TO SELL THE CORRECT MATCHING DISTRIBUTOR GEAR TOO YOU

and like a lifter on a cam lobe it is usually going to last longer if both the cam and distributor gear are new, coated with moly assembly grease and allowed to lap in and mate surfaces , rather than use used worn distributor gears on new cams

viewtopic.php?f=70&t=251&p=299&hilit=shim+distributor#p299

viewtopic.php?f=54&t=2187&p=5890#p5890

keep in mind the distributor base forms one wall of the lifter gallery oil passage

so grooving the lower oil band helps spray extra oil on the distributor/cam gears contact area

any time you change cams youll need to use a matching distributor gear, the cam manufacturer should be able to help tell you what matches, obviously checking clearances helps

and dipping the gear in moly assembly lube before it installed helps

be sure you inspect the distributor gear for excessive wear

especially if you changed from a flat tappet to a roller cam.

if your seeing the timing change a few degrees, back and forth,

slack in a worn, loose timing chain, worn distributor gear or not having the proper shim clearance on the distributor center shaft will provide slop that allows timing to vary several degrees

http://www.summitracing.com/parts/CCA-12200/

http://www.summitracing.com/parts/CCA-12140/

MOST of the chevy and after market cams will work with the standard replacement mellonized distributor gears

http://garage.grumpysperformance.com/index.php?threads/slowing-distributor-gear-wear.57/#post-70

http://garage.grumpysperformance.co...the-intake-manifold-distributor.464/#post-570

http://garage.grumpysperformance.com/index.php?threads/shiming-a-distributor.251/#post-299

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-wear.1701/#post-5252

Last edited by a moderator: