I get a question , very similar in content too this about every 6 weeks....

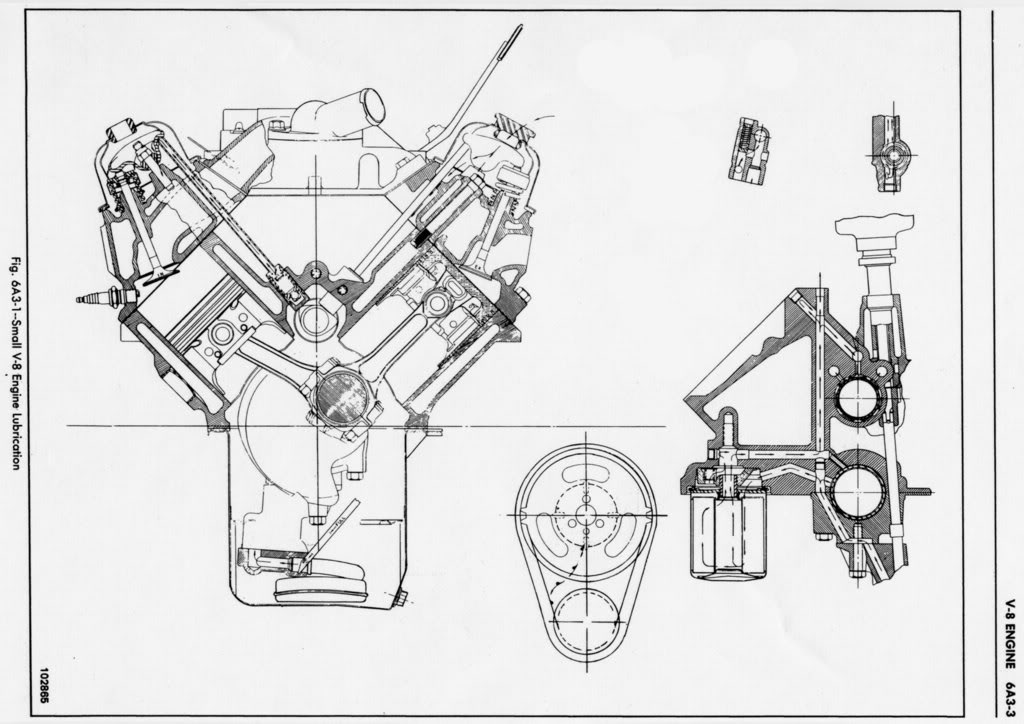

YES I'm only too well aware most of us operate on very low cash flow,

and Yes Im certain youll find a friend or two that has simply pulled the old defective cam,

and replaced it and the old lifters with new parts,

changed the oil, and swears he drove the car without experiencing any major problems.

Yes you could do that, but its almost always going to come back eventually and bite you in the butt!

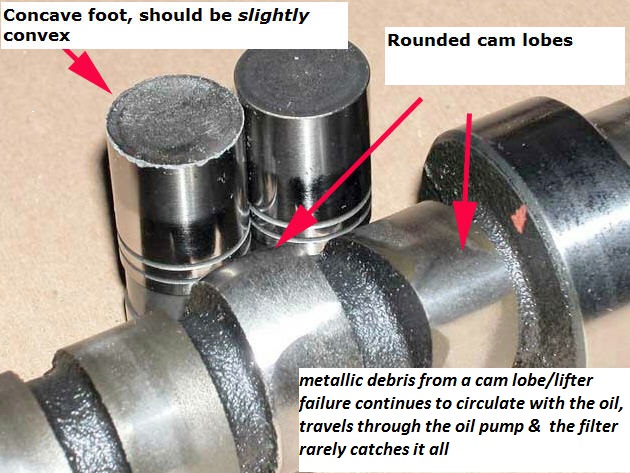

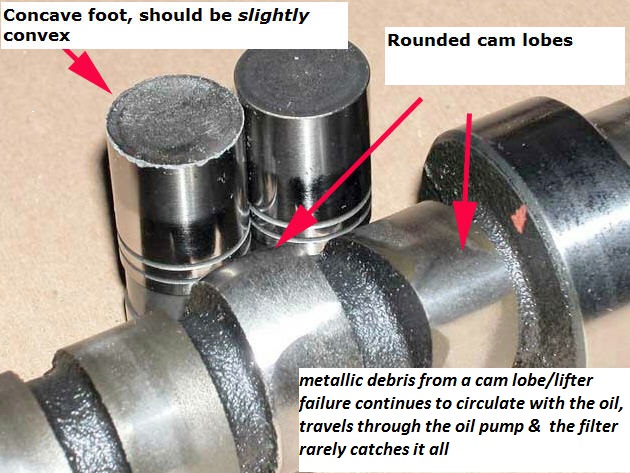

in most cases where Ive pulled an engine down after a cam lobe failed theres a noticeable amount of metallic trash embedded in the bearing surfaces, yes the engine still runs and may have decent oil pressure for thousands of miles, but its still damaged and now wearing at a faster rate as a result! how much faster of course depends on the amount and type of debris, how much got past the oil filter and how tight the engine tollerances are, but you can be sure debriss in the oil trapped between moviong surfaces like rings and bore walls ,the other lifter bases and cam lobes, rockers etc. will not be good for long term durability.

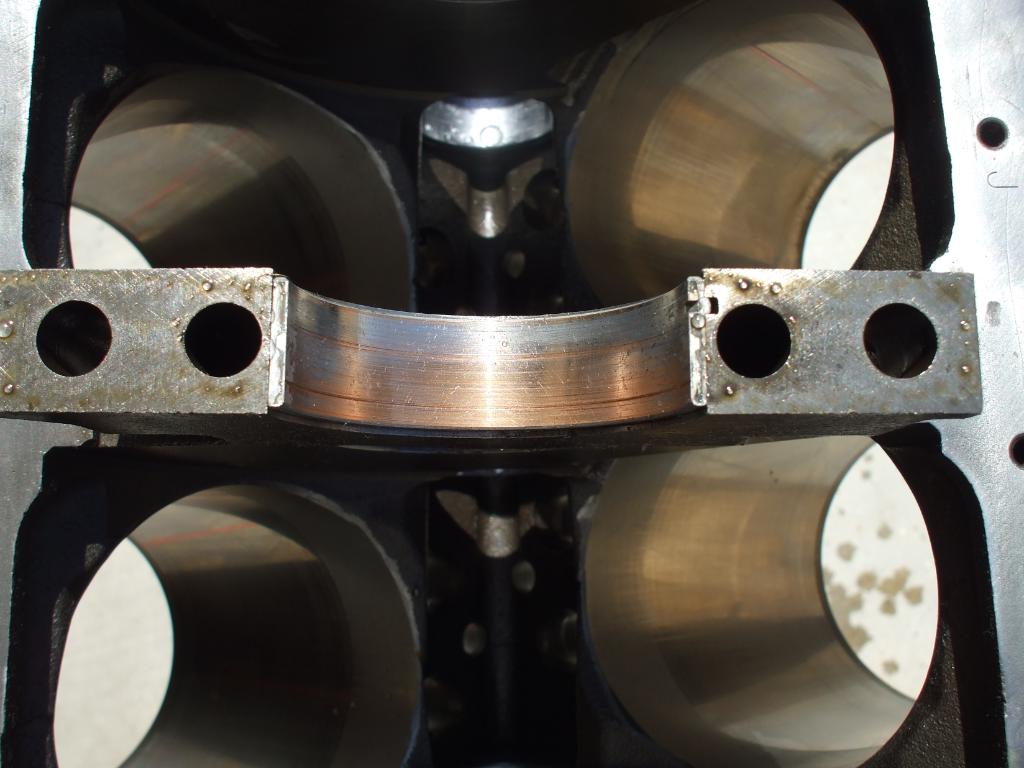

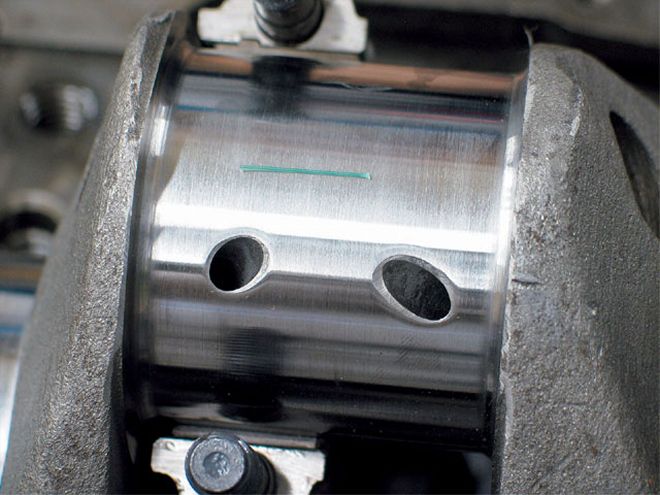

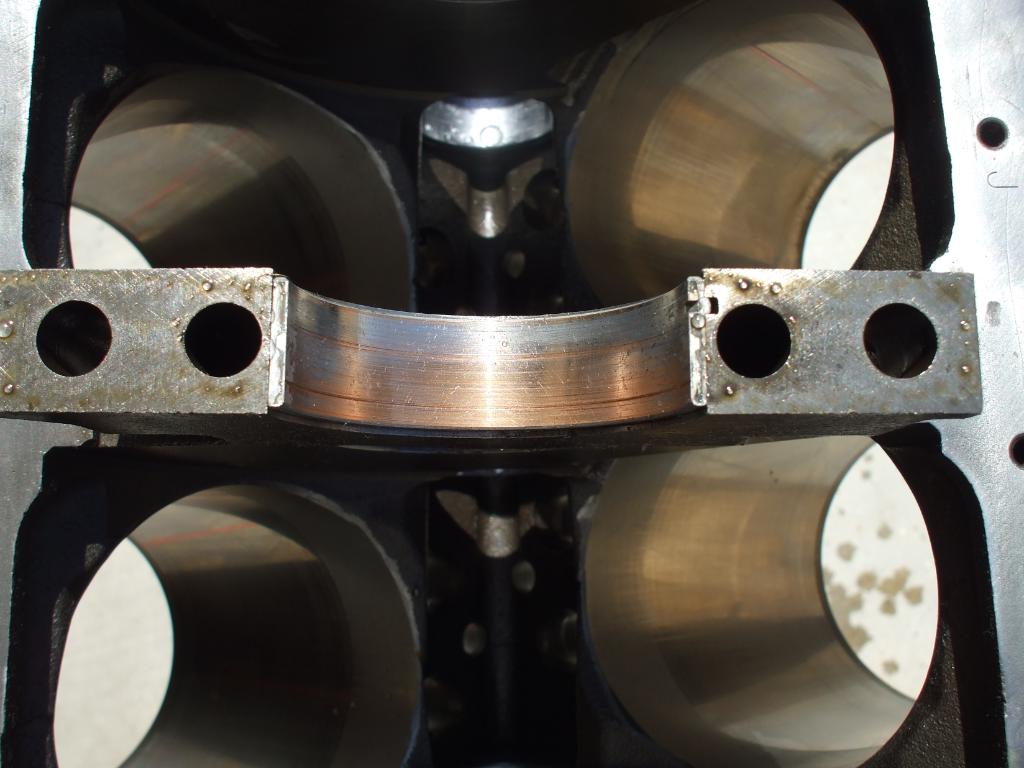

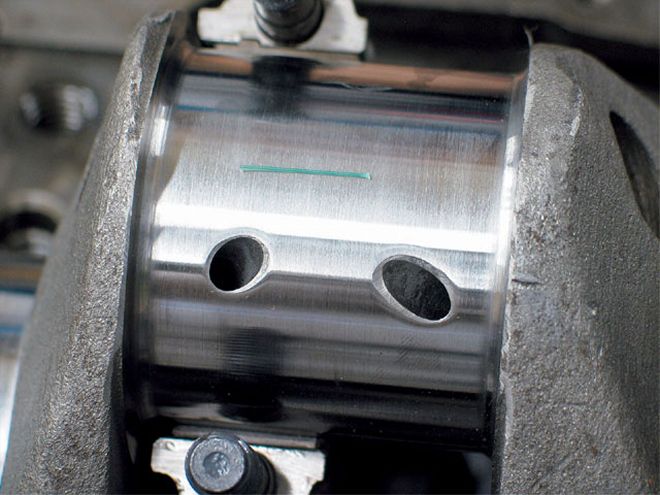

bearings that looked like this when installed...

look like this shortly after a cam lobe and lifter start to wear rapidly

Yes theres a strong tendency for newer guys to want to just install new parts, rather than research the reason the old part failed and that can lead too expensive mistakes and repeated failures,

if your cam wiped a lobe and lifter, or you spun a bearing or busted a timing chain ETC.

all that metalic debris is potentially circulating through the engine and the oil filter RARELY collects all of it before a significant amount gets embeded in bearings , so its best to remove the block, dissasemble it, clean out the oil passages and replace ALL the bearings and freeze plugs and oil passage plugs after a careful cleaning.

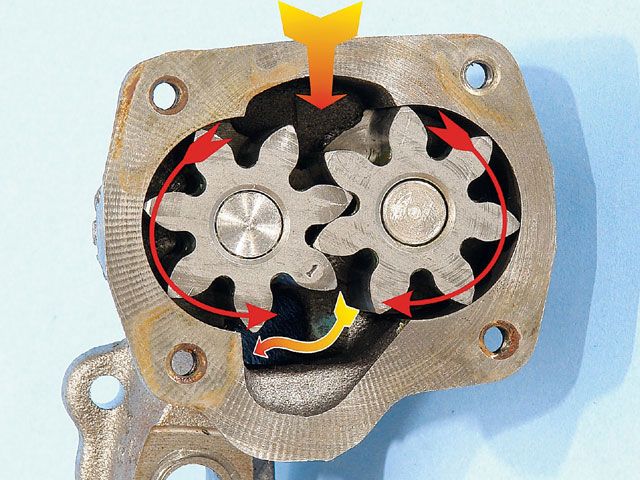

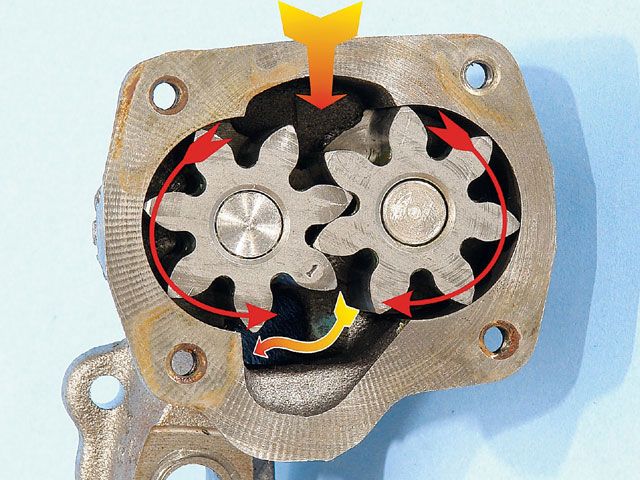

all that trash potentially goes through the oil pump gears long before it may enter the oil filter, and if your oil filter has a bye-pass valve you can bet your last dollar some of the fine metallic trash bye-passed the filter a few times as it circulated.

Bits of fine metallic trash will be embedded in the bearings ,some will be waiting in the oil passages , and yes that fine metalic trash will take some time to do more damage if you flushed out the majority, did an oil and filter change and just went ahead and installed a new cam and lifters.

MAJOR CAUSES OF PREMATURE BEARING FAILURE

Dirt ......................................... 45.4%

Misassembly .......................... 12.8%

Misalignment .......................... 12.6%

Insufficient Lubrication.............11.4%

Overloading .............................. 8.1%

Corrosion ................................ .3.7%

Improper Journal Finish ............ 3.2%

Other ....................................... .2.8%

YES VERIFYING BEARING CLEARANCE IS MANDATORY

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

http://garage.grumpysperformance.com/index.php?threads/oil-filters.11189/#post-50335

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://garage.grumpysperformance.com/index.php?threads/metal-in-oil.10875/#post-47688

http://garage.grumpysperformance.co...guess-on-clearances-and-journal-surface.9955/

http://garage.grumpysperformance.com/index.php?threads/measuring-crank-bearing-journals.5478/

http://garage.grumpysperformance.com/index.php?threads/causes-of-bearing-failure.2727/

http://garage.grumpysperformance.com/index.php?threads/engine-bearing-sources-related-info.2351/

http://garage.grumpysperformance.com/index.php?threads/bearings.88/

Grumpy? do I really need to do more than drain and flush the oil, change the oil filter and install a new cam and lifters, to get my car back up and running once I removed the old cam and lifters,when I'm doing a repair due too a cam/lifter having failed.. I really don,t want to pull the engine

YES I'm only too well aware most of us operate on very low cash flow,

and Yes Im certain youll find a friend or two that has simply pulled the old defective cam,

and replaced it and the old lifters with new parts,

changed the oil, and swears he drove the car without experiencing any major problems.

Yes you could do that, but its almost always going to come back eventually and bite you in the butt!

in most cases where Ive pulled an engine down after a cam lobe failed theres a noticeable amount of metallic trash embedded in the bearing surfaces, yes the engine still runs and may have decent oil pressure for thousands of miles, but its still damaged and now wearing at a faster rate as a result! how much faster of course depends on the amount and type of debris, how much got past the oil filter and how tight the engine tollerances are, but you can be sure debriss in the oil trapped between moviong surfaces like rings and bore walls ,the other lifter bases and cam lobes, rockers etc. will not be good for long term durability.

bearings that looked like this when installed...

look like this shortly after a cam lobe and lifter start to wear rapidly

Yes theres a strong tendency for newer guys to want to just install new parts, rather than research the reason the old part failed and that can lead too expensive mistakes and repeated failures,

if your cam wiped a lobe and lifter, or you spun a bearing or busted a timing chain ETC.

all that metalic debris is potentially circulating through the engine and the oil filter RARELY collects all of it before a significant amount gets embeded in bearings , so its best to remove the block, dissasemble it, clean out the oil passages and replace ALL the bearings and freeze plugs and oil passage plugs after a careful cleaning.

all that trash potentially goes through the oil pump gears long before it may enter the oil filter, and if your oil filter has a bye-pass valve you can bet your last dollar some of the fine metallic trash bye-passed the filter a few times as it circulated.

Bits of fine metallic trash will be embedded in the bearings ,some will be waiting in the oil passages , and yes that fine metalic trash will take some time to do more damage if you flushed out the majority, did an oil and filter change and just went ahead and installed a new cam and lifters.

MAJOR CAUSES OF PREMATURE BEARING FAILURE

Dirt ......................................... 45.4%

Misassembly .......................... 12.8%

Misalignment .......................... 12.6%

Insufficient Lubrication.............11.4%

Overloading .............................. 8.1%

Corrosion ................................ .3.7%

Improper Journal Finish ............ 3.2%

Other ....................................... .2.8%

YES VERIFYING BEARING CLEARANCE IS MANDATORY

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

http://garage.grumpysperformance.com/index.php?threads/oil-filters.11189/#post-50335

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://garage.grumpysperformance.com/index.php?threads/metal-in-oil.10875/#post-47688

http://garage.grumpysperformance.co...guess-on-clearances-and-journal-surface.9955/

http://garage.grumpysperformance.com/index.php?threads/measuring-crank-bearing-journals.5478/

http://garage.grumpysperformance.com/index.php?threads/causes-of-bearing-failure.2727/

http://garage.grumpysperformance.com/index.php?threads/engine-bearing-sources-related-info.2351/

http://garage.grumpysperformance.com/index.php?threads/bearings.88/

Last edited: