I got asked this and while I thought it was rather obvious after giving it a bit of thought I decided to answer this .

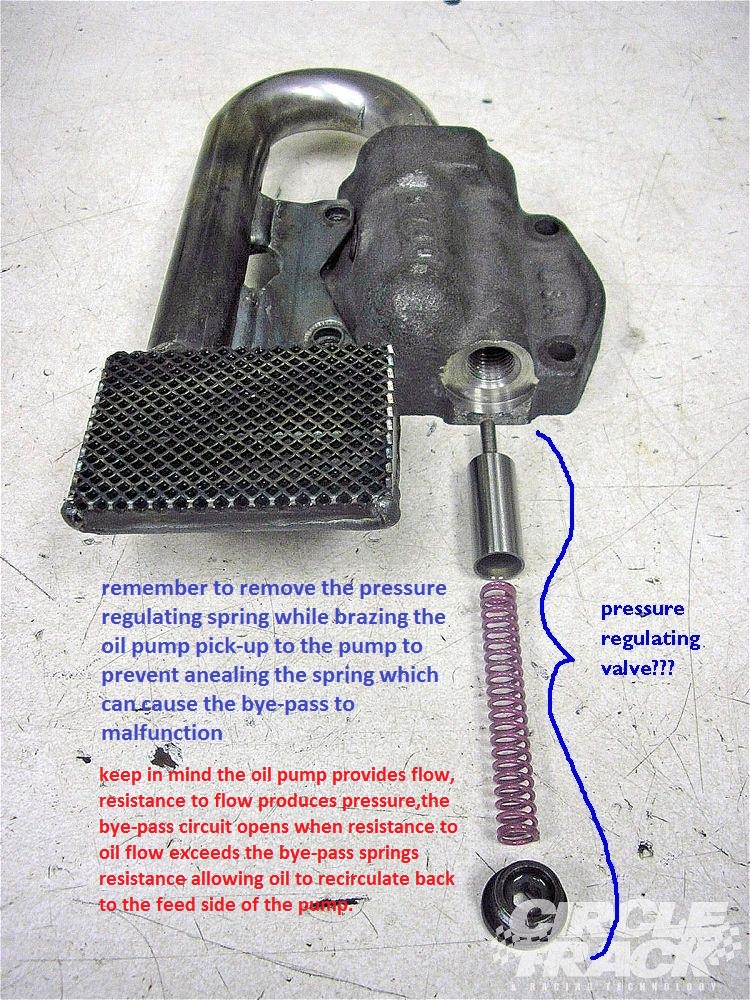

oil pumps provide oil flow almost directly related to the RPM they spin at UP TO THE POINT where pressure allows the bye-PASS circuit to allow some volume to RE-CIRCULATE back thru the oil pump, limiting oil pressure.

oil pumps provide FLOW VOLUME! its RESISTANCE TO OIL FLOW thru bearing clearances that REGISTERs ON THE GAUGE AS PRESSURE!

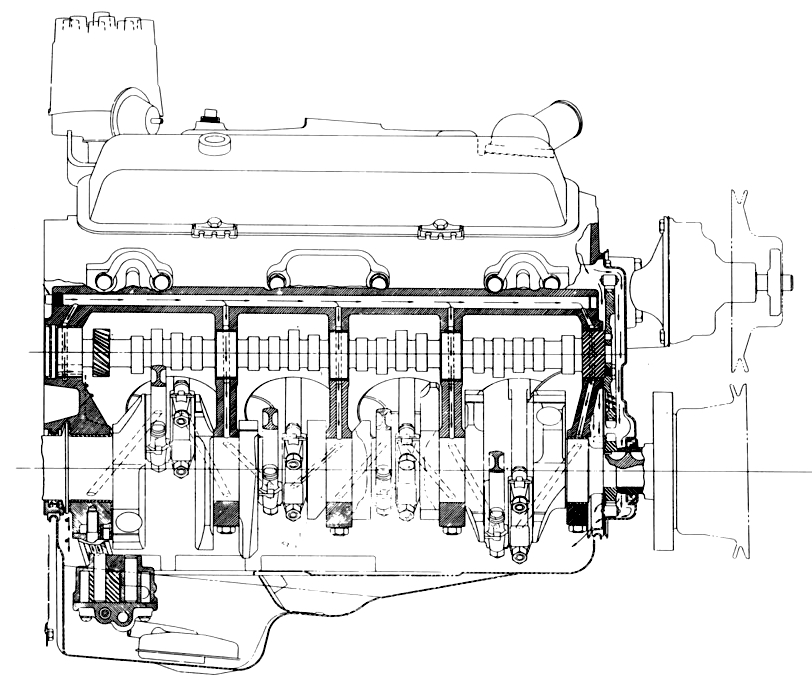

keep in mind the sbc oil pump has 7 tooth gears and the big block pumps have 12 teeth making the oil flow smoother and less pulsed, plus having larger gears they tend to supply more oil at lower rpms

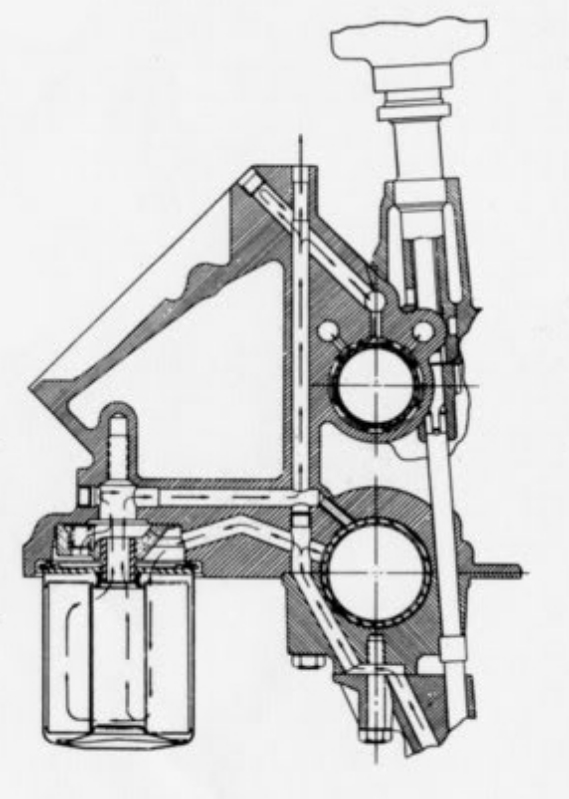

look closely and youll see the big block oil pump has a 5 bolt lower cover and the oil pump pick-up with its 3/4" feed seats into the main pump casting while the small block oil pump has a 4 bolt cover and the sbc oil pump pick-up with its 5/8" feed seats into the pumps cover plate

READ THIS THREAD

viewtopic.php?f=54&t=3536

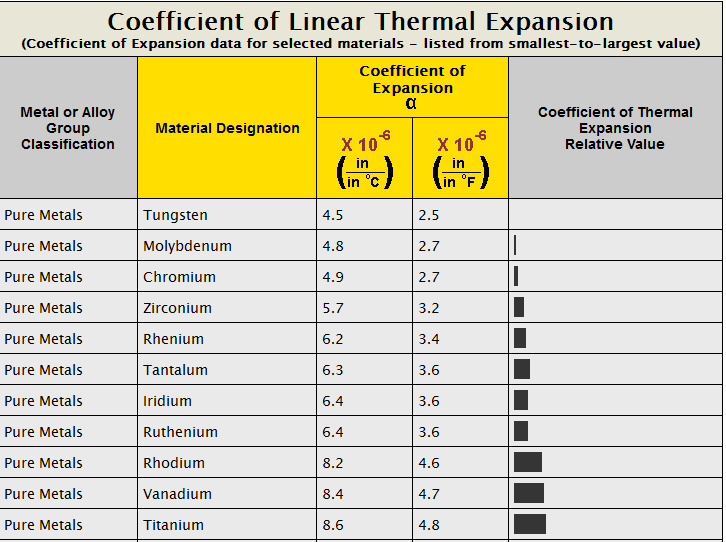

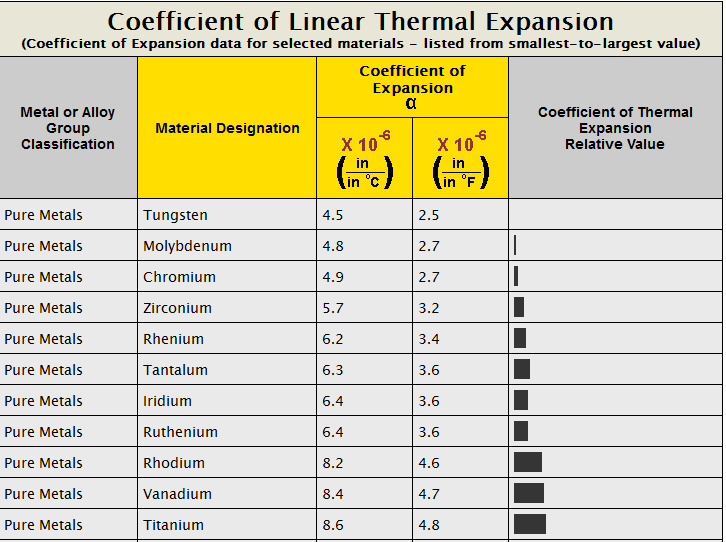

the contention of the person asking this was that since metal expands as its heated, both the block and crank obviously will slowly expand as they heat up so the clearances should remain rather consistent as both will remain at similar,even if elevated temps. but because cast iron expands at a different rate than forged steel, and the bearing shells are frequently aluminum., the bearing clearances may change

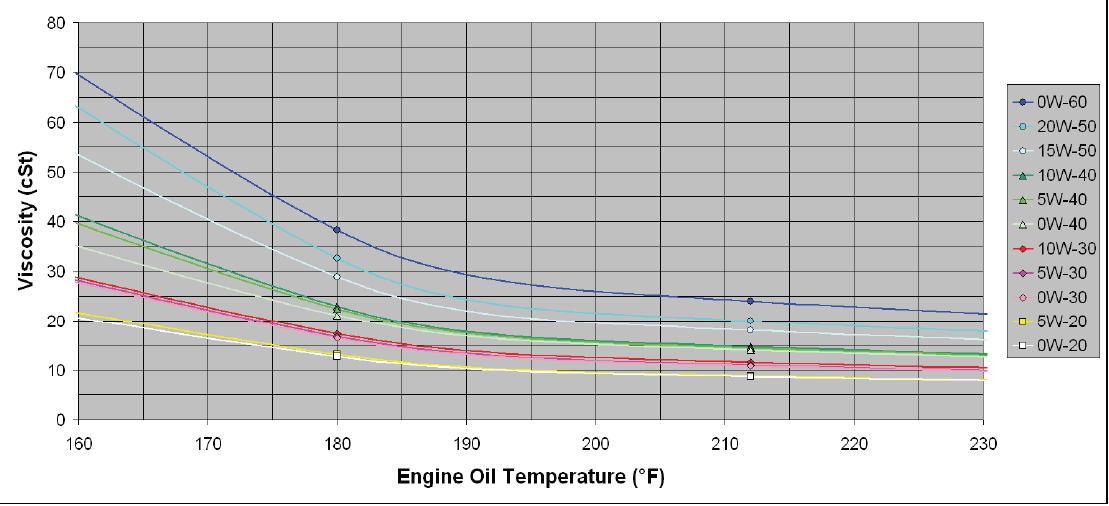

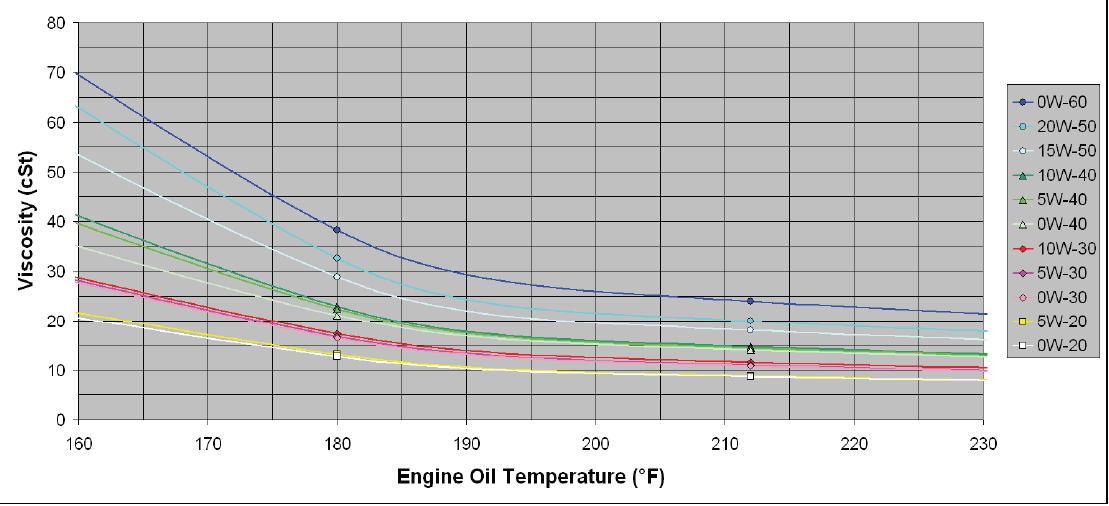

the first thing I'd point out is that oil being pumped thru the bearing clearances tends to loose viscosity or thin as its heated, and the thinner or lower the viscosity the lower the resistance it has to being forced thru bearing clearances so as a result hotter oil having a lower viscosity and a lower resistance to flow reduces the oil pressure reading on the oil pressure gauge.

as a general rule as your engine oil viscosity is reduced the effort required to pump the oil thru clearances is lower and the pressure reading on the gauge drops, thats not necessarily an indication of lower bearing protection, as thats generally a function of oil quality and its formula, and basic components used, in its design, and generally its increased flow rate increases bearing cooling, a good quality 10w30 should ideally provide 20-22 psi at 800rpm idle (anything over 15-17 psi at 800rpm is fine) and 60-75psi by 6000rpm and UP,AS LONG AS ITS CONSISTENT, which is all you can use

blocks are generally made from cast iron or aluminum, cranks from forged steel or cast nodular iron,now aluminum expands faster than either cast iron or forged steel, but in the temp ranges were talking about the expansion won,t be critical to the bearing clearances.

IF you care to do the math heres a chart, but youll find the oil viscosity change is a more significant factor than the metal expansion over the expected temp ranges in question

RELATED INFO

viewtopic.php?f=53&t=10213&p=40551&hilit=chart+heat#p40551

viewtopic.php?f=54&t=1334

viewtopic.php?f=53&t=2726

viewtopic.php?f=51&t=5945&p=34251&hilit=cast+aluminum#p34251

viewtopic.php?f=54&t=2294&p=13430&hilit=metal+expansion#p13430

viewtopic.php?f=32&t=10376&p=42845&hilit=+head+gasket+stored#p42845

oil pumps provide oil flow almost directly related to the RPM they spin at UP TO THE POINT where pressure allows the bye-PASS circuit to allow some volume to RE-CIRCULATE back thru the oil pump, limiting oil pressure.

oil pumps provide FLOW VOLUME! its RESISTANCE TO OIL FLOW thru bearing clearances that REGISTERs ON THE GAUGE AS PRESSURE!

keep in mind the sbc oil pump has 7 tooth gears and the big block pumps have 12 teeth making the oil flow smoother and less pulsed, plus having larger gears they tend to supply more oil at lower rpms

look closely and youll see the big block oil pump has a 5 bolt lower cover and the oil pump pick-up with its 3/4" feed seats into the main pump casting while the small block oil pump has a 4 bolt cover and the sbc oil pump pick-up with its 5/8" feed seats into the pumps cover plate

READ THIS THREAD

viewtopic.php?f=54&t=3536

the contention of the person asking this was that since metal expands as its heated, both the block and crank obviously will slowly expand as they heat up so the clearances should remain rather consistent as both will remain at similar,even if elevated temps. but because cast iron expands at a different rate than forged steel, and the bearing shells are frequently aluminum., the bearing clearances may change

the first thing I'd point out is that oil being pumped thru the bearing clearances tends to loose viscosity or thin as its heated, and the thinner or lower the viscosity the lower the resistance it has to being forced thru bearing clearances so as a result hotter oil having a lower viscosity and a lower resistance to flow reduces the oil pressure reading on the oil pressure gauge.

as a general rule as your engine oil viscosity is reduced the effort required to pump the oil thru clearances is lower and the pressure reading on the gauge drops, thats not necessarily an indication of lower bearing protection, as thats generally a function of oil quality and its formula, and basic components used, in its design, and generally its increased flow rate increases bearing cooling, a good quality 10w30 should ideally provide 20-22 psi at 800rpm idle (anything over 15-17 psi at 800rpm is fine) and 60-75psi by 6000rpm and UP,AS LONG AS ITS CONSISTENT, which is all you can use

blocks are generally made from cast iron or aluminum, cranks from forged steel or cast nodular iron,now aluminum expands faster than either cast iron or forged steel, but in the temp ranges were talking about the expansion won,t be critical to the bearing clearances.

IF you care to do the math heres a chart, but youll find the oil viscosity change is a more significant factor than the metal expansion over the expected temp ranges in question

RELATED INFO

viewtopic.php?f=53&t=10213&p=40551&hilit=chart+heat#p40551

viewtopic.php?f=54&t=1334

viewtopic.php?f=53&t=2726

viewtopic.php?f=51&t=5945&p=34251&hilit=cast+aluminum#p34251

viewtopic.php?f=54&t=2294&p=13430&hilit=metal+expansion#p13430

viewtopic.php?f=32&t=10376&p=42845&hilit=+head+gasket+stored#p42845