how many guys use personally cast bullets from the custom bullet mold companys?

back in the day, we could get LINOTYPE ingots fairly cheap, now that is not commonly available

now I use cast bullets almost exclusively in my hunting revolvers and several 458 caliber rifles , because it both significantly reduces cost and once your throwing a .357, 40, .416, 44,45,58,.62 caliber projectiles, its simple physics and a documented fact that,the larger the bore diameter, your dealing with,given a well designed projectile , the less critical small casting flaws will be to accuracy.

bullets with a sectional density of between .230-.310 are generally preferred, in most cases .260--.310 are closer to ideal, and of course you,ll need to match the rifle twist rate too the projectile design and velocity , and use the correct projectile design for the velocity and metal alloy used.

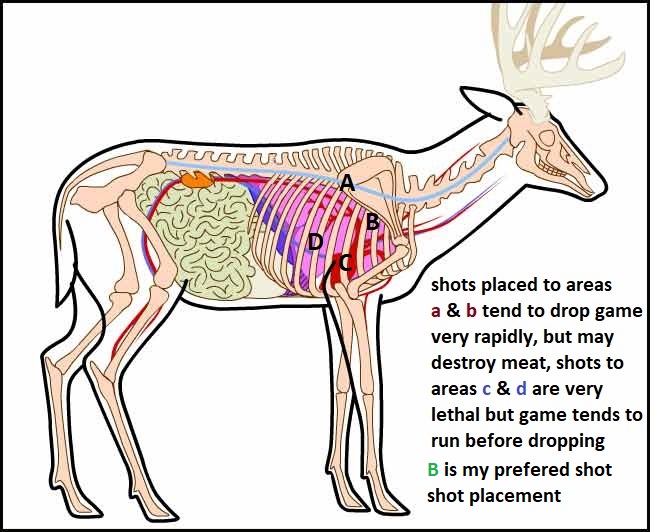

remember precise shot placement and a knowledge of the opponents anatomy is critical to its effective use,

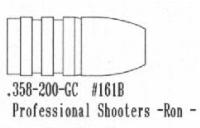

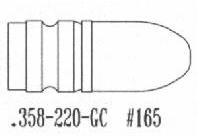

a 158-170 grain hard cast bullet , loaded to higher velocity in a 357 mag is very effective ,

in skilled hands as either a defensive tool or hunting weapon.

I've had zero issues using an 8" S&W revolver on hogs and deer out to 50-70 yards ,

with those loads, and its the combo my B.I.L. preferers to hunt with

RIFLE TWIST

http://www.bergerbullets.com/twist-rate-calculator/

http://www.jbmballistics.com/cgi-bin/jbmstab-5.1.cgi

sectional density

https://www.beartoothbullets.com/rescources/calculators/php/density.htm

http://www.chuckhawks.com/sd.htm

http://www.handloads.com/misc/linebaugh.penetration.tests.asp?year=all

http://garage.grumpysperformance.co...tance-to-use-hard-cast-lead-projectiles.9875/

theres a good many applications where cast bullets even at reduced velocities will do excellent work, I don,t know why but I just get a bit more satisfaction in using a revolver or rifle with bullets and hand loads I personally fabricated. I don,t remember using my 357,44 or 445 revolvers with anything else in years, and my 45/70 was used almost exclusively with hard cast gas check bullets.

and the elk and deer it killed died just as fast as with any jacketed projectiles Ive used.

and yeah! Ive spent a small fortune on custom molds and yes there are some really good ones out there!

if your going to learn too hunt with a hand-gun or rifle, learning too hand load and in the case of hand guns especially learning too cast and size and lube lead alloy projectiles is going to help you both gain skills and add to your practice time and ammo availability,by potentially reducing costs

If you find your not getting good groups with cast bullets look into changing the bullet, design your using , sizing, lube powder,load, velocity range, etc before assuming your gun just won,t shoot cast bullets. I had a rather similar experience, the first time I tried cast bullets, but my mentor had enough experience to change components until I found what worked,,use of gas checks,or lube or powder charge etc. can easily change the group size

I tried 300 gain gas check bullets in my 44 marlin carbine and get amazingly tight groups in the 1"-1.5" range off a good bench rest at 100 yards, with several powders, but the same bullet used without gas checks produced groups in the 7" range

http://handloads.com/loaddata/default.a ... pe=Handgun

just a question, why not cast and lube and size your own projectiles?

Ive tried a few dozen different brands and types of commercial cast bullets ,

over the decades and Ive yet to find any available that are really cast with a hard yet not brittle alloy

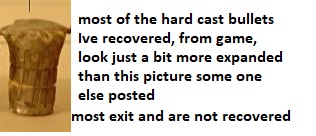

thus I cast my own, in my experience you want a projectile that expands slowly ,

but not one that is so hard its likely to fracture or break-up if it hits bone.

95% wheel weights plus 5% pure tin is in my experience close to ideal

it rivets out on impact marginally well, but won,t lead bores and the projectile penetrates very well on game,

bullets I've recovered that consistently chronograph-ed in the 1400-1800 fps range,

from various rifles and a few pistols rarely showed that much expansion,

(most exit and are not recovered) I,ve shot diagonally through dozens of deer and hogs ,

and a couple elk with out recovering a projectile as most exit.

in most cases you get exits, and excellent accuracy once you've developed proper loads matching the fire arms characteristics and preferences

yeah commercial alloys are expensive and finding a source of lead and tin is becoming much harder lately, but its still an option,

yes it requires extra and semi expensive molds lube/sizer and a furnace, yeah it can be a P.I.T.A. at times,

but its also far cheaper in the long term, and you get to fabricate projectiles that exactly match your firearms requirements,

not ideal but it works

https://www.rotometals.com/1-to-20-bullet-alloy-alloy-95-lead-5-tin/

this tends to be decent

https://www.rotometals.com/linotype-alloy-alloy-5-pounds-4-tin-12-antimony-and-84-lead/

https://www.rotometals.com/bullet-casting-alloys/

I provided the links for those few members who may not have other sources

I've over decades,fortunately ,I had the contacts and foresight,

too purchased hundreds of lbs of sail boat ballast ingots,

telephone cable lead sheath , used wheel weights, etc.

back when a lb sold for 10 cents a lb or less.

yes theres zero doubt commercial alloy is expensive,

but there are other sourced for suitable alloy components,

it just takes research and work to acquire

but thats not always the case

on my 45/70 gas check slugs produced 2" 100 yard groups and non-gas checked bullets of the same 405 grain weight over 45 grains of RL7 and very similar design produce,

nearly the same groups, but a bit more bore leading ,at least in that rifle with those loads,

the difference is you can shoot the gas check design all day, the non-gas check require you clean the bore about every 50 shots or accuracy suffers

btw most rifles chambered for bore sizes like 358, 375, .416, .430, and 458 caliber cartridges respond well to properly cast bullet use.

obviously rifle twist rates and bullet designs must match fairly well, to get the best results and velocity's kept under 2000 fps tend to produce decent accuracy

http://www.gunweek.com/2004/feature1201.html

http://www.handloads.com/loaddata/defau ... le&Source=

theres a ton of useful info in the sub links

http://www.lasc.us/Fryxell_Book_Contents.htm

http://www.tacticoolproducts.com/bullethardness/

http://www.lasc.us/CastBulletNotes.htm

http://www.rotometals.com/product-p/tinhighgradebar.htm

http://www.castpics.net/subsite2/MoldMo ... tation.pdf

http://www.midwayusa.com/product/645810 ... e-110-volt

basic cheap melter

http://www.midwayusa.com/product/698819 ... llet-molds

mold handles

http://www.neihandtools.com/catalog/index.html

THESE 260-270 grain bullet molds produce a great compromise providing good accuracy and penetration but a bit lower recoil than the 300-310 grain bullet designs that provide a bit deeper penetration in the 44 mag and 445 DWSM revolver

https://www.accuratemolds.com/bullet_detail.php?bullet=36-165MG

357 mag cast hunting bullet (link above)

http://www.justbulletmolds.com/lee-bullet-molds/

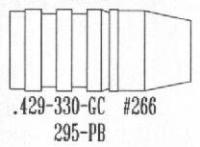

IF YOUR LOADING FOR A 44 MAG REVOLVER ,properly sized to about 1 thousandth over your bore size , cast from 95% wheel weights and 5% tin and well lubed, with hornady gas checks crimped in place,these NEI bullets are very accurate loaded over 21 grains of H110 in my revolvers

http://www.midwayusa.com/product/506726 ... -gas-check

http://www.midwayusa.com/Product/122093 ... -gas-check

Ive got at least 15 44 caliber molds but the more I cast and hunt the more I find the 300 grain bullets are most effective, and while its nice to have the fancier molds like NEI and LBT,HOCH,SEAKO etc. the rcbs and lyman designs work remarkably well and don,t cost nearly as much and theres been dozens of rather dead deer and hogs pass thru our kitchen to verify that they work, in both my 44 mag revolvers and marlin carbine

heres a partial list of potential mold suppliers

http://www.neihandtools.com/catalog.html

http://www.hochmoulds.com/

http://www.accuratemolds.com/bulletDesign.php

http://www.lymanproducts.com/lyman/main/

http://www.lbtmoulds.com/

http://www.noebulletmolds.com/

http://leeprecision.com/bullet-casting/

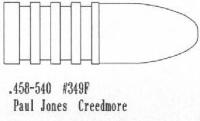

http://www.pauljonesmolds.com/

http://accuratemolds.com/bulletDesign.php

http://www.magmaengineering.com/bullet-molds/

http://www.mp-molds.com/index.php?pr=Molds

http://www.ranchdogoutdoors.com/index.p ... ath=1_5_12

viewtopic.php?f=90&t=2286&p=6103#p6103

MOLDS CAN BE MODIFIED TO HOLLOW POINT DESIGN

http://www.hollowpointmold.com/inset-ba ... re=650#650

youll ocasionally run into some one who tells you a 44 mags not powerful enough to hunt with, thats total B.S.!

I went thru a very similar scene with an obviously new too revolver hunting guy, and watching a clueless sales guy trying to sell a 500 S&W to this guy who admitted he had never shot anything larger than a 357 mag, who was looking to purchase a hunting revolver for hunting hogs here in Florida.

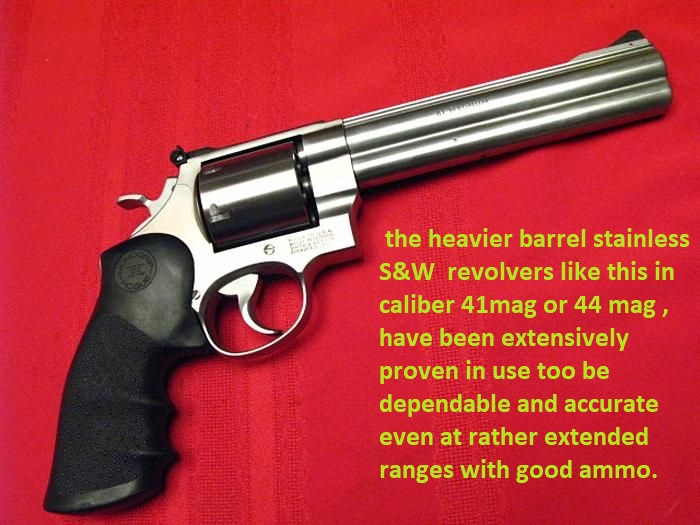

I suggested he buy a good 44 mag with at least a 6" and preferably a 7.5" barrel.

(something Ive done for well over 43 years now with a 44 mag, revolver)

44 mag ammos a great deal less expensive and theres no hog that will shrug off a well placed hit from a properly loaded 44 revolver.

the clerk tried to say that the 500 S&W hits a lot harder (which while true) is hardly the same thing as saying the 44 mag won,t easily do the job.

these guys behind the counter at my local bass pro, are obviously are either clueless in real world experience,or get a cut on the sales total.

Ill make your search for a good hunting load in 44 mag simple!, I tried dozens of combos and the two best I found use the same LEE 310 grain cast gas check bullet

http://www.midsouthshooterssupply.com/i ... 0000690858

over either 21 grains of H110 or 11.5 grains of blue dot, the H110 is slightly faster the blue dot powders slower velocity is still useful and a bit more accurate, the difference is very minor in either case, but keep in mind theres 7000 grains in a pound of powder, so use BLUE DOT for target loads as theres 600 cartridges worth per pound while the larger charge of h110 REDUCES A POUND TO JUST OVER 1/2 THAT OR 300 SHOTS PER POUND, BOTH POWDERS COST ABOUT THE SAME

just pick a load pushed to over 1300 fps with at least a 240 grain bullet

http://www.handloads.com/loaddata/defau ... pe=Handgun

heres the LEE 310 grain bullet I use in my 44 mag (ABOVE)

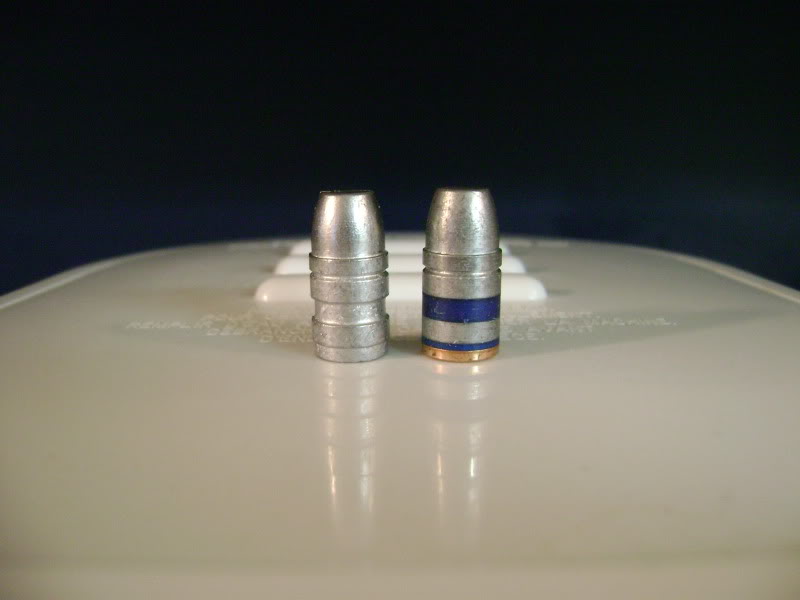

here below is a couple common 240-250 grain lyman and RCBS cast bullet designs that work reasonably well but I finf the LEE 310 more accurate and more effective on game

if you handload, 44 caliber for hunting a good cast /gas check bullet with a wide melplat that weights close to 270-300 grains, and cast from 96% wheel weights and 5% tin is what I,ve used for decades, I seldom fail to get exit wounds and rarely have game run far

both blue dot and H110 seem to provide good results in the 44 mag, blue dot gives up a bit of velocity but not much, and I seem to get better accuracy and many more cartridges per pound

just a tip from experience learned, size cast bullets at least .001 larger than bore diameter,

most pistol caliber carbines are reasonably accurate with typical copper jacketed 225-260 grain bullets,

but I vastly prefer the increased penetration, and far lower cost of heavy cast bullets,

in the 290-310 grain weight range.(but they (310 grain in 44 mag) (300 grain in 45 colt)

https://www.midsouthshooterssupply.com/item/0000690359/double-cavity-mold-c452-300-rf

must be sized, lubed and loaded to near top velocity)

before you purchase a 45 colt or 44 mag lever action ,check the rifles twist rate

I've hunted with a marlin 44 mag 1894 for 4 decades, in every case I tested the faster twist rates seem to work better with cast bullet designs

my rifles very accurate with heavy cast bullets but only at near max velocity,

and the twist rate is barely adequate to keep the preferred 310 grain hard cast bullets stable

you need a full 21 grain charge of H110 powder

https://www.midsouthshooterssupply.com/item/0000690858/double-cavity-mold-c430-310-rf

twist rates near 1/20 are much preferred , for better stability,

over slower twist rates in the 1/36 range and the rifles came with both/either,

twist rates at various times over the last few decades

back in the day, we could get LINOTYPE ingots fairly cheap, now that is not commonly available

now I use cast bullets almost exclusively in my hunting revolvers and several 458 caliber rifles , because it both significantly reduces cost and once your throwing a .357, 40, .416, 44,45,58,.62 caliber projectiles, its simple physics and a documented fact that,the larger the bore diameter, your dealing with,given a well designed projectile , the less critical small casting flaws will be to accuracy.

bullets with a sectional density of between .230-.310 are generally preferred, in most cases .260--.310 are closer to ideal, and of course you,ll need to match the rifle twist rate too the projectile design and velocity , and use the correct projectile design for the velocity and metal alloy used.

remember precise shot placement and a knowledge of the opponents anatomy is critical to its effective use,

a 158-170 grain hard cast bullet , loaded to higher velocity in a 357 mag is very effective ,

in skilled hands as either a defensive tool or hunting weapon.

I've had zero issues using an 8" S&W revolver on hogs and deer out to 50-70 yards ,

with those loads, and its the combo my B.I.L. preferers to hunt with

RIFLE TWIST

http://www.bergerbullets.com/twist-rate-calculator/

http://www.jbmballistics.com/cgi-bin/jbmstab-5.1.cgi

sectional density

https://www.beartoothbullets.com/rescources/calculators/php/density.htm

http://www.chuckhawks.com/sd.htm

http://www.handloads.com/misc/linebaugh.penetration.tests.asp?year=all

http://garage.grumpysperformance.co...tance-to-use-hard-cast-lead-projectiles.9875/

theres a good many applications where cast bullets even at reduced velocities will do excellent work, I don,t know why but I just get a bit more satisfaction in using a revolver or rifle with bullets and hand loads I personally fabricated. I don,t remember using my 357,44 or 445 revolvers with anything else in years, and my 45/70 was used almost exclusively with hard cast gas check bullets.

and the elk and deer it killed died just as fast as with any jacketed projectiles Ive used.

and yeah! Ive spent a small fortune on custom molds and yes there are some really good ones out there!

if your going to learn too hunt with a hand-gun or rifle, learning too hand load and in the case of hand guns especially learning too cast and size and lube lead alloy projectiles is going to help you both gain skills and add to your practice time and ammo availability,by potentially reducing costs

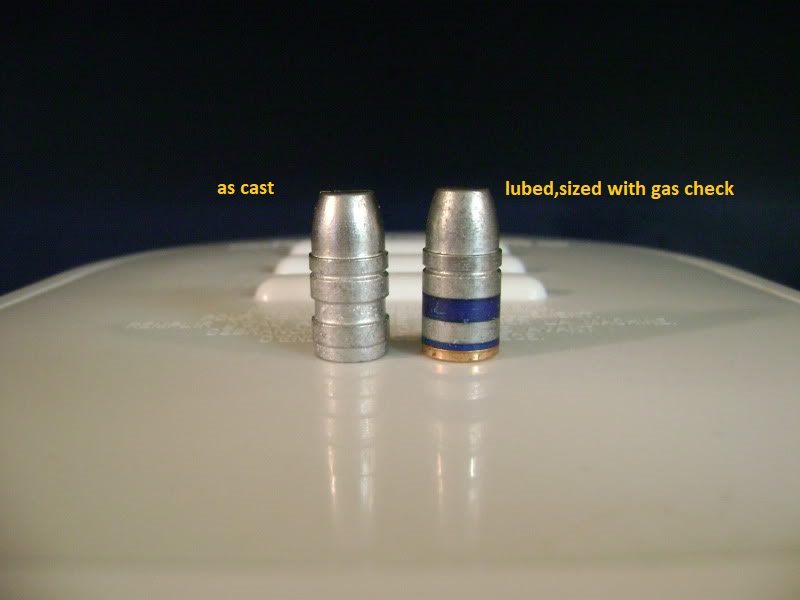

If you find your not getting good groups with cast bullets look into changing the bullet, design your using , sizing, lube powder,load, velocity range, etc before assuming your gun just won,t shoot cast bullets. I had a rather similar experience, the first time I tried cast bullets, but my mentor had enough experience to change components until I found what worked,,use of gas checks,or lube or powder charge etc. can easily change the group size

I tried 300 gain gas check bullets in my 44 marlin carbine and get amazingly tight groups in the 1"-1.5" range off a good bench rest at 100 yards, with several powders, but the same bullet used without gas checks produced groups in the 7" range

http://handloads.com/loaddata/default.a ... pe=Handgun

if you handgun hunt Like I DO you need to watch this video

I was out behind my sons home in texas killing a few coke cans at 30-40 yards with my 357 mag revolver, one of my sons friends suggested I might need a pistol scope even though my hit ratio was easily 80%-90% and yeah I might need more practice , but if you easily punch holes in a 2.2" wide coke...

garage.grumpysperformance.com

Ive tried a few dozen different brands and types of commercial cast bullets ,

over the decades and Ive yet to find any available that are really cast with a hard yet not brittle alloy

thus I cast my own, in my experience you want a projectile that expands slowly ,

but not one that is so hard its likely to fracture or break-up if it hits bone.

95% wheel weights plus 5% pure tin is in my experience close to ideal

it rivets out on impact marginally well, but won,t lead bores and the projectile penetrates very well on game,

bullets I've recovered that consistently chronograph-ed in the 1400-1800 fps range,

from various rifles and a few pistols rarely showed that much expansion,

(most exit and are not recovered) I,ve shot diagonally through dozens of deer and hogs ,

and a couple elk with out recovering a projectile as most exit.

in most cases you get exits, and excellent accuracy once you've developed proper loads matching the fire arms characteristics and preferences

yeah commercial alloys are expensive and finding a source of lead and tin is becoming much harder lately, but its still an option,

yes it requires extra and semi expensive molds lube/sizer and a furnace, yeah it can be a P.I.T.A. at times,

but its also far cheaper in the long term, and you get to fabricate projectiles that exactly match your firearms requirements,

not ideal but it works

https://www.rotometals.com/1-to-20-bullet-alloy-alloy-95-lead-5-tin/

this tends to be decent

https://www.rotometals.com/linotype-alloy-alloy-5-pounds-4-tin-12-antimony-and-84-lead/

https://www.rotometals.com/bullet-casting-alloys/

I provided the links for those few members who may not have other sources

I've over decades,fortunately ,I had the contacts and foresight,

too purchased hundreds of lbs of sail boat ballast ingots,

telephone cable lead sheath , used wheel weights, etc.

back when a lb sold for 10 cents a lb or less.

yes theres zero doubt commercial alloy is expensive,

but there are other sourced for suitable alloy components,

it just takes research and work to acquire

but thats not always the case

on my 45/70 gas check slugs produced 2" 100 yard groups and non-gas checked bullets of the same 405 grain weight over 45 grains of RL7 and very similar design produce,

nearly the same groups, but a bit more bore leading ,at least in that rifle with those loads,

the difference is you can shoot the gas check design all day, the non-gas check require you clean the bore about every 50 shots or accuracy suffers

btw most rifles chambered for bore sizes like 358, 375, .416, .430, and 458 caliber cartridges respond well to properly cast bullet use.

obviously rifle twist rates and bullet designs must match fairly well, to get the best results and velocity's kept under 2000 fps tend to produce decent accuracy

http://www.gunweek.com/2004/feature1201.html

http://www.handloads.com/loaddata/defau ... le&Source=

theres a ton of useful info in the sub links

http://www.lasc.us/Fryxell_Book_Contents.htm

http://www.tacticoolproducts.com/bullethardness/

http://www.lasc.us/CastBulletNotes.htm

http://www.rotometals.com/product-p/tinhighgradebar.htm

http://www.castpics.net/subsite2/MoldMo ... tation.pdf

http://www.midwayusa.com/product/645810 ... e-110-volt

basic cheap melter

http://www.midwayusa.com/product/698819 ... llet-molds

mold handles

http://www.neihandtools.com/catalog/index.html

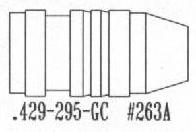

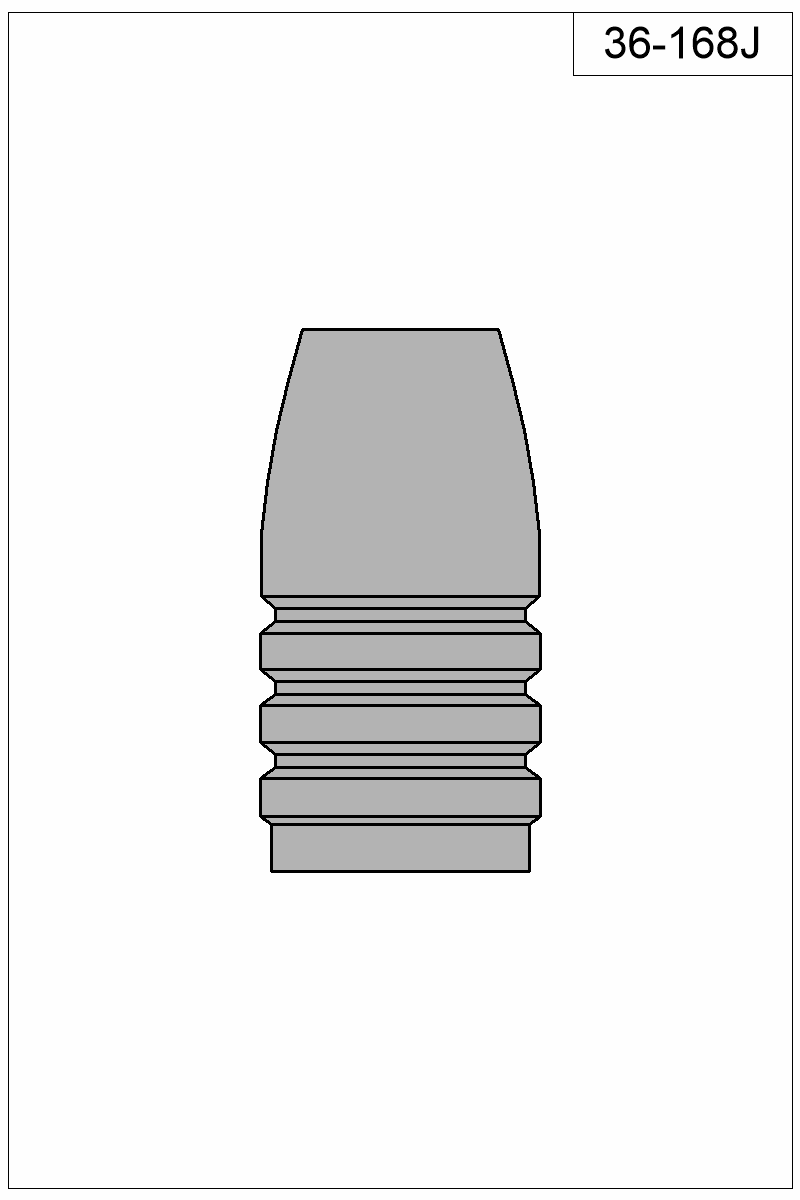

THESE 260-270 grain bullet molds produce a great compromise providing good accuracy and penetration but a bit lower recoil than the 300-310 grain bullet designs that provide a bit deeper penetration in the 44 mag and 445 DWSM revolver

https://www.accuratemolds.com/bullet_detail.php?bullet=36-165MG

357 mag cast hunting bullet (link above)

http://www.justbulletmolds.com/lee-bullet-molds/

IF YOUR LOADING FOR A 44 MAG REVOLVER ,properly sized to about 1 thousandth over your bore size , cast from 95% wheel weights and 5% tin and well lubed, with hornady gas checks crimped in place,these NEI bullets are very accurate loaded over 21 grains of H110 in my revolvers

http://www.midwayusa.com/product/506726 ... -gas-check

http://www.midwayusa.com/Product/122093 ... -gas-check

Ive got at least 15 44 caliber molds but the more I cast and hunt the more I find the 300 grain bullets are most effective, and while its nice to have the fancier molds like NEI and LBT,HOCH,SEAKO etc. the rcbs and lyman designs work remarkably well and don,t cost nearly as much and theres been dozens of rather dead deer and hogs pass thru our kitchen to verify that they work, in both my 44 mag revolvers and marlin carbine

heres a partial list of potential mold suppliers

http://www.neihandtools.com/catalog.html

http://www.hochmoulds.com/

http://www.accuratemolds.com/bulletDesign.php

http://www.lymanproducts.com/lyman/main/

http://www.lbtmoulds.com/

http://www.noebulletmolds.com/

http://leeprecision.com/bullet-casting/

http://www.pauljonesmolds.com/

http://accuratemolds.com/bulletDesign.php

http://www.magmaengineering.com/bullet-molds/

http://www.mp-molds.com/index.php?pr=Molds

http://www.ranchdogoutdoors.com/index.p ... ath=1_5_12

viewtopic.php?f=90&t=2286&p=6103#p6103

MOLDS CAN BE MODIFIED TO HOLLOW POINT DESIGN

http://www.hollowpointmold.com/inset-ba ... re=650#650

youll ocasionally run into some one who tells you a 44 mags not powerful enough to hunt with, thats total B.S.!

I went thru a very similar scene with an obviously new too revolver hunting guy, and watching a clueless sales guy trying to sell a 500 S&W to this guy who admitted he had never shot anything larger than a 357 mag, who was looking to purchase a hunting revolver for hunting hogs here in Florida.

I suggested he buy a good 44 mag with at least a 6" and preferably a 7.5" barrel.

(something Ive done for well over 43 years now with a 44 mag, revolver)

44 mag ammos a great deal less expensive and theres no hog that will shrug off a well placed hit from a properly loaded 44 revolver.

the clerk tried to say that the 500 S&W hits a lot harder (which while true) is hardly the same thing as saying the 44 mag won,t easily do the job.

these guys behind the counter at my local bass pro, are obviously are either clueless in real world experience,or get a cut on the sales total.

Ill make your search for a good hunting load in 44 mag simple!, I tried dozens of combos and the two best I found use the same LEE 310 grain cast gas check bullet

http://www.midsouthshooterssupply.com/i ... 0000690858

over either 21 grains of H110 or 11.5 grains of blue dot, the H110 is slightly faster the blue dot powders slower velocity is still useful and a bit more accurate, the difference is very minor in either case, but keep in mind theres 7000 grains in a pound of powder, so use BLUE DOT for target loads as theres 600 cartridges worth per pound while the larger charge of h110 REDUCES A POUND TO JUST OVER 1/2 THAT OR 300 SHOTS PER POUND, BOTH POWDERS COST ABOUT THE SAME

just pick a load pushed to over 1300 fps with at least a 240 grain bullet

http://www.handloads.com/loaddata/defau ... pe=Handgun

heres the LEE 310 grain bullet I use in my 44 mag (ABOVE)

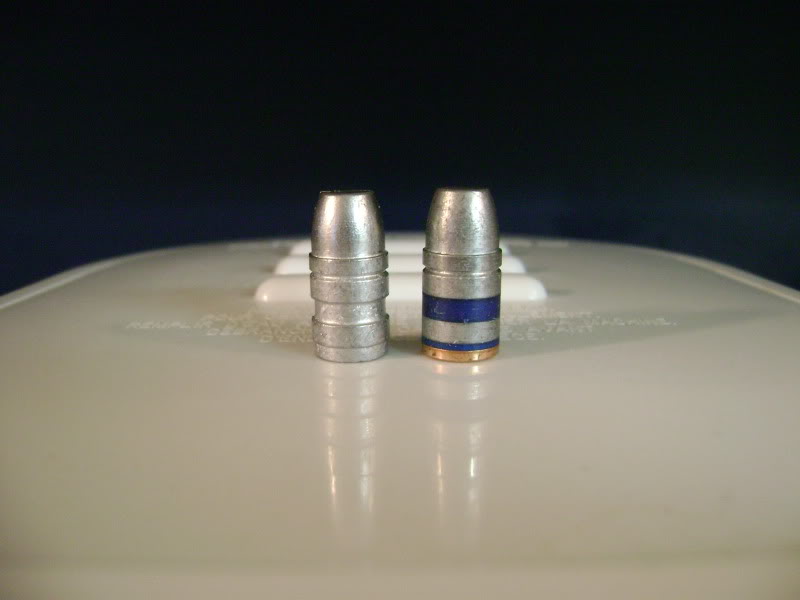

here below is a couple common 240-250 grain lyman and RCBS cast bullet designs that work reasonably well but I finf the LEE 310 more accurate and more effective on game

if you handload, 44 caliber for hunting a good cast /gas check bullet with a wide melplat that weights close to 270-300 grains, and cast from 96% wheel weights and 5% tin is what I,ve used for decades, I seldom fail to get exit wounds and rarely have game run far

both blue dot and H110 seem to provide good results in the 44 mag, blue dot gives up a bit of velocity but not much, and I seem to get better accuracy and many more cartridges per pound

just a tip from experience learned, size cast bullets at least .001 larger than bore diameter,

most pistol caliber carbines are reasonably accurate with typical copper jacketed 225-260 grain bullets,

but I vastly prefer the increased penetration, and far lower cost of heavy cast bullets,

in the 290-310 grain weight range.(but they (310 grain in 44 mag) (300 grain in 45 colt)

https://www.midsouthshooterssupply.com/item/0000690359/double-cavity-mold-c452-300-rf

must be sized, lubed and loaded to near top velocity)

before you purchase a 45 colt or 44 mag lever action ,check the rifles twist rate

I've hunted with a marlin 44 mag 1894 for 4 decades, in every case I tested the faster twist rates seem to work better with cast bullet designs

my rifles very accurate with heavy cast bullets but only at near max velocity,

and the twist rate is barely adequate to keep the preferred 310 grain hard cast bullets stable

you need a full 21 grain charge of H110 powder

https://www.midsouthshooterssupply.com/item/0000690858/double-cavity-mold-c430-310-rf

twist rates near 1/20 are much preferred , for better stability,

over slower twist rates in the 1/36 range and the rifles came with both/either,

twist rates at various times over the last few decades

Last edited by a moderator: