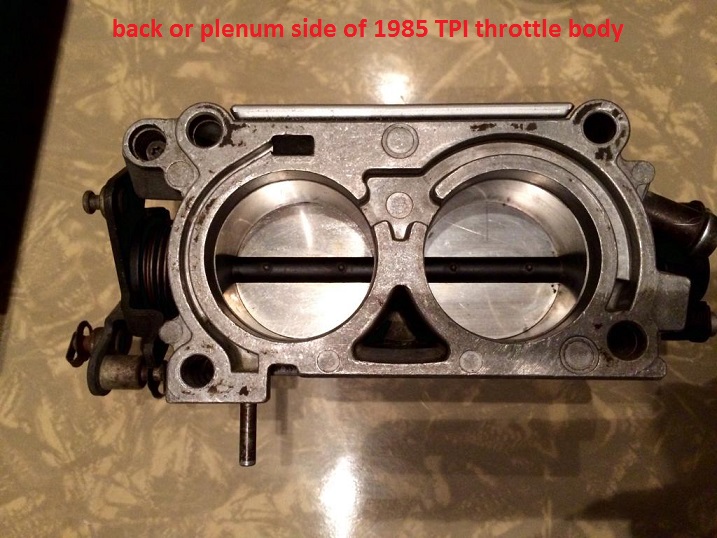

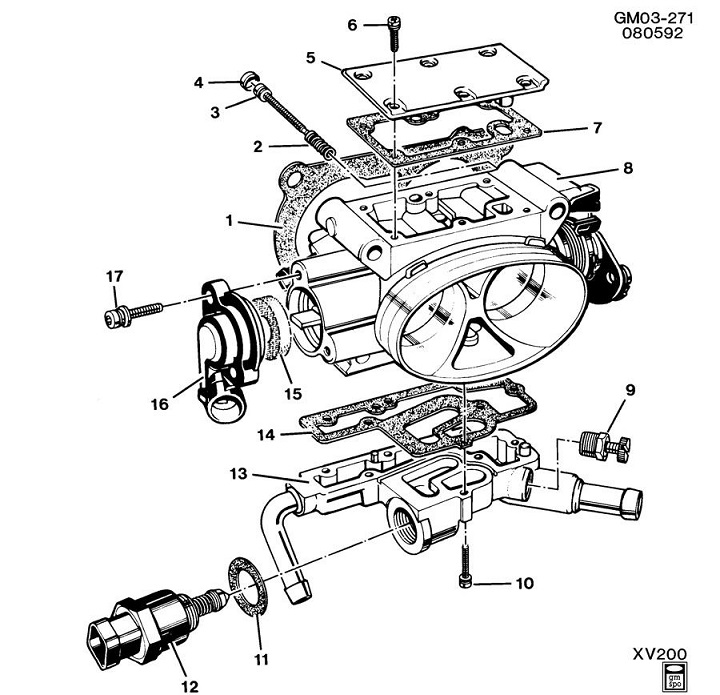

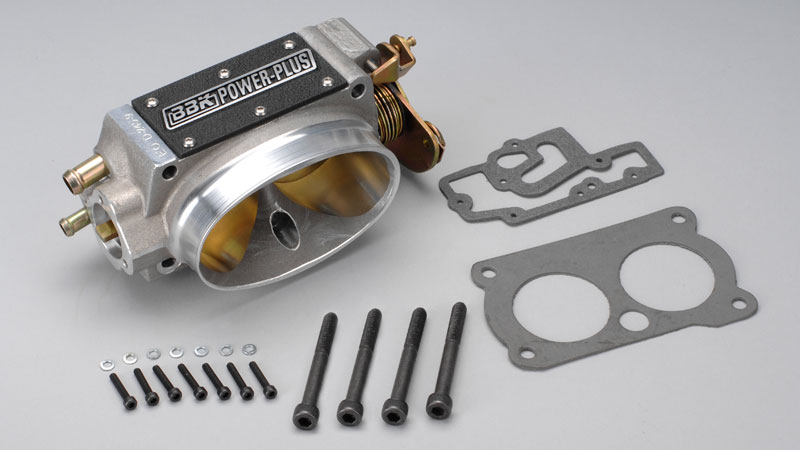

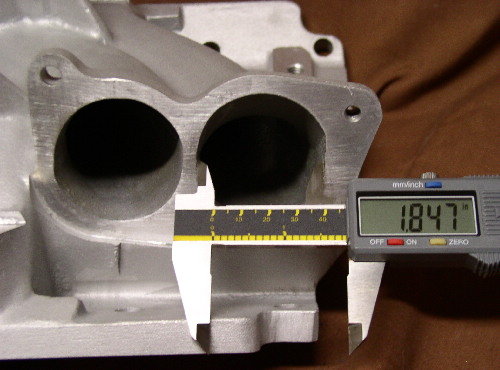

I get asked frequently if installing a larger than the stock 48mm TPI throttle body will significantly help on a corvette engine, Ill save you some reading right off if you want, yes a 58mm can potentially increase hp if your engines highly modified and your still useing a stock 48mm throttle body.

but the restriction a stock 48mm throttle body represents is not as significant and the gains to be had are not that large in most cases, your intake manifold and cam selection, plus your stock heads are the major restrictions. the stock 48mm throttle body flows about 650cfm-700cfm and has more than enough flow to support about 475hp-500hp,

(keep in mind as the plenum vacume, increased so does the effective flow)

rated flow is at a lower test vacume, than the engine produces

bored to 52mm it will support about 500hp,-525hp, a 58mm can support about 600hp, but keep in mind theres lots of factors other than just throttle body size that determine potential hp

Keep in mind even the factory 502 cubic inch big block used the stock L98 TPI throttle body size and made 500 horse power

yes a 58mm can potentially increase hp if your engines highly modified and your still using a stock 48mm throttle body, but its hardly a big restriction, and your probably going to gain more with other mods

using or modifying a throttle body to flow more than 1000cfm -1200 cfm like a 58mm twin bore potentially flows is a waste of money, heres why

the largest displacement sbc your likely to build is a 434cid, that requires a 4" stroke crank and youll be limited to about 6500rpm even with top quality parts if you want the engine to last any time at all, now you might not realize it but the time necessary to fill the cylinders gets limited very quickly at higher rpms and the volumetric efficiency falls off quickly after about 5000rpm simply because theres just not enough time to allow the cylinders to fill completely. at 5000 rpm theres 41.6 intake strokes per second, per cylinder, by 6500 rpm its up to 54 intake strokes per second, per cylinder thats only 0.018 seconds for the intake port to flow into the cylinder per intake stroke. but theres yet another factor!!! thats the time for the full intake stroke!!!, while theres 720 degrees in the repetitive cycle and Ive given you a full 360 degrees worth of time, the truth is that your cam/engine combo, seldom allows anywhere near that duration!!!! even a radical race cam seldom exceeds 250 degrees in effective duration for port flow, so youll need to knock about 45% off that time, now your down to only about 0.012 seconds or less of effective flow per intake stroke per cylinder, is it any wonder the cylinder can,t fully fill at high rpms??

now the theoretical 434 were working with here even if it could fill its cylinders 100% at 6500rpm which is totally impossiable at that rpm would require 434 (the displacement) x 3250(the number of intake strokes)=1410500 (the full 100% in cubic inches /1728(to change to cfm) = only 816cfm.... now even if you could ram tune the exhaust and intake pulse perfectly and get the cylinders to pack the cylinders to 120% (a total impossability without a supercharger or turbo) thats till only 979 fcm

but in the real world your volumetric efficincy falls off fast after 5000 rpm with a 4" stroke and youll be exceptionally lucky to pull 80% efficiency at over 5000rpm

drop your displacement to a more comon 383 and your rpm limit to the fairly comon 6500rpm and youll drop even the theoretical air flow requirement to below 875cfm

http://users.erols.com/srweiss/calchpaf.htm

http://users.erols.com/srweiss/calccarb.htm

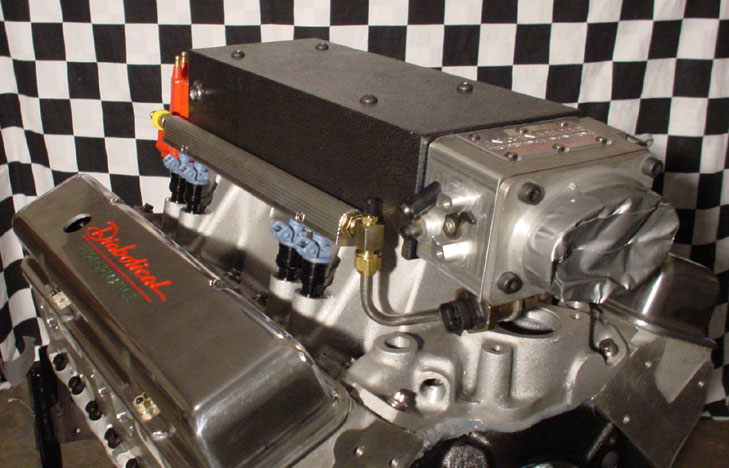

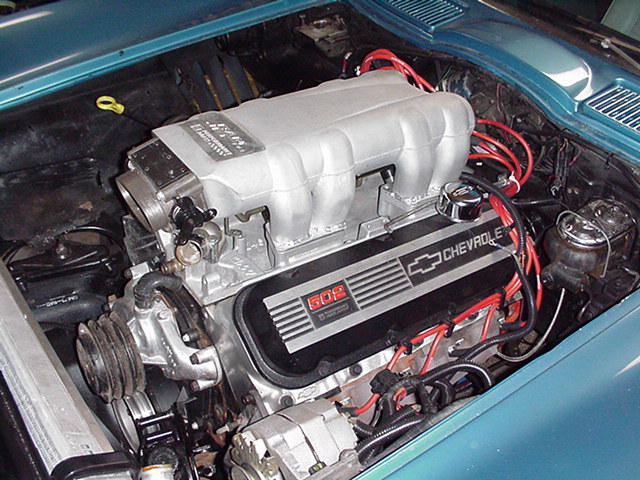

heres the ramjet ZL1 454

http://www.sallee-chevrolet.com/ChevyBigBlockV8s/ramjetzl1.html

viewtopic.php?f=55&t=1509

http://garage.grumpysperformance.co...rottle-body-size-52mm-vs-58mm.641/#post-26207

http://www.summitracing.com/parts/sum-227702

yeah you might not believe it but it's got a stock 48mm twin bore TPI style chevy throttle body feeding that 454 engine, do you think chevy would do that if it was a significant restriction to hp production??

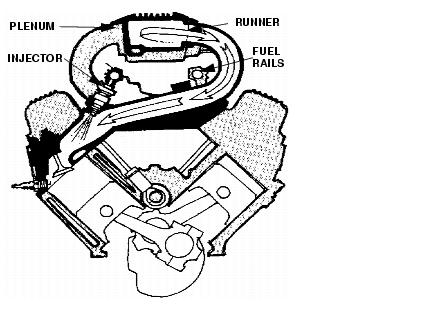

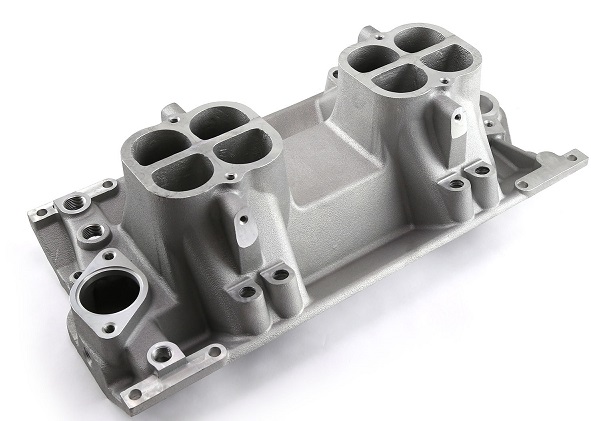

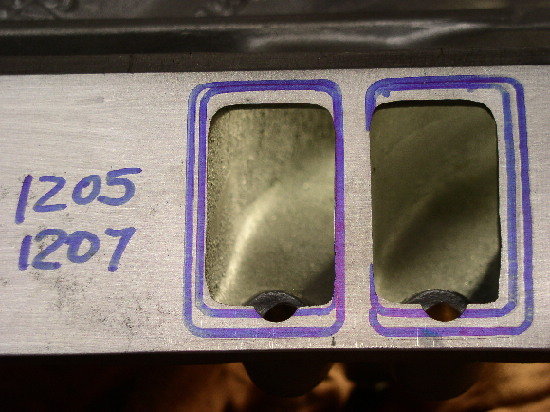

the restriction is not the throttle body its the port size, valve size and flow the heads have and intake manifold runers restriction,and cam lift and duration... install an intake manifold,cam and heads that can flow 300cfm and the 58mm aftermarket throttle body will still effectively feed the engine, remember that while even 300cfm ports at full flow only pull air about 250 degrees out of 720 degrees in the cycle and are spaced 90 degrees apart, that means that 1000cfm can feed all 8 cylinders a full 833cfm they could in theory flow ,and that 300cfm per port can support roughtly 600hp

but the restriction a stock 48mm throttle body represents is not as significant and the gains to be had are not that large in most cases, your intake manifold and cam selection, plus your stock heads are the major restrictions. the stock 48mm throttle body flows about 650cfm-700cfm and has more than enough flow to support about 475hp-500hp,

(keep in mind as the plenum vacume, increased so does the effective flow)

rated flow is at a lower test vacume, than the engine produces

bored to 52mm it will support about 500hp,-525hp, a 58mm can support about 600hp, but keep in mind theres lots of factors other than just throttle body size that determine potential hp

Keep in mind even the factory 502 cubic inch big block used the stock L98 TPI throttle body size and made 500 horse power

yes a 58mm can potentially increase hp if your engines highly modified and your still using a stock 48mm throttle body, but its hardly a big restriction, and your probably going to gain more with other mods

using or modifying a throttle body to flow more than 1000cfm -1200 cfm like a 58mm twin bore potentially flows is a waste of money, heres why

the largest displacement sbc your likely to build is a 434cid, that requires a 4" stroke crank and youll be limited to about 6500rpm even with top quality parts if you want the engine to last any time at all, now you might not realize it but the time necessary to fill the cylinders gets limited very quickly at higher rpms and the volumetric efficiency falls off quickly after about 5000rpm simply because theres just not enough time to allow the cylinders to fill completely. at 5000 rpm theres 41.6 intake strokes per second, per cylinder, by 6500 rpm its up to 54 intake strokes per second, per cylinder thats only 0.018 seconds for the intake port to flow into the cylinder per intake stroke. but theres yet another factor!!! thats the time for the full intake stroke!!!, while theres 720 degrees in the repetitive cycle and Ive given you a full 360 degrees worth of time, the truth is that your cam/engine combo, seldom allows anywhere near that duration!!!! even a radical race cam seldom exceeds 250 degrees in effective duration for port flow, so youll need to knock about 45% off that time, now your down to only about 0.012 seconds or less of effective flow per intake stroke per cylinder, is it any wonder the cylinder can,t fully fill at high rpms??

now the theoretical 434 were working with here even if it could fill its cylinders 100% at 6500rpm which is totally impossiable at that rpm would require 434 (the displacement) x 3250(the number of intake strokes)=1410500 (the full 100% in cubic inches /1728(to change to cfm) = only 816cfm.... now even if you could ram tune the exhaust and intake pulse perfectly and get the cylinders to pack the cylinders to 120% (a total impossability without a supercharger or turbo) thats till only 979 fcm

but in the real world your volumetric efficincy falls off fast after 5000 rpm with a 4" stroke and youll be exceptionally lucky to pull 80% efficiency at over 5000rpm

drop your displacement to a more comon 383 and your rpm limit to the fairly comon 6500rpm and youll drop even the theoretical air flow requirement to below 875cfm

http://users.erols.com/srweiss/calchpaf.htm

http://users.erols.com/srweiss/calccarb.htm

heres the ramjet ZL1 454

http://www.sallee-chevrolet.com/ChevyBigBlockV8s/ramjetzl1.html

viewtopic.php?f=55&t=1509

http://garage.grumpysperformance.co...rottle-body-size-52mm-vs-58mm.641/#post-26207

http://www.summitracing.com/parts/sum-227702

yeah you might not believe it but it's got a stock 48mm twin bore TPI style chevy throttle body feeding that 454 engine, do you think chevy would do that if it was a significant restriction to hp production??

the restriction is not the throttle body its the port size, valve size and flow the heads have and intake manifold runers restriction,and cam lift and duration... install an intake manifold,cam and heads that can flow 300cfm and the 58mm aftermarket throttle body will still effectively feed the engine, remember that while even 300cfm ports at full flow only pull air about 250 degrees out of 720 degrees in the cycle and are spaced 90 degrees apart, that means that 1000cfm can feed all 8 cylinders a full 833cfm they could in theory flow ,and that 300cfm per port can support roughtly 600hp

Last edited by a moderator: