Tech Tip - 2001

Compression Rules: "The Joker in the Deck"

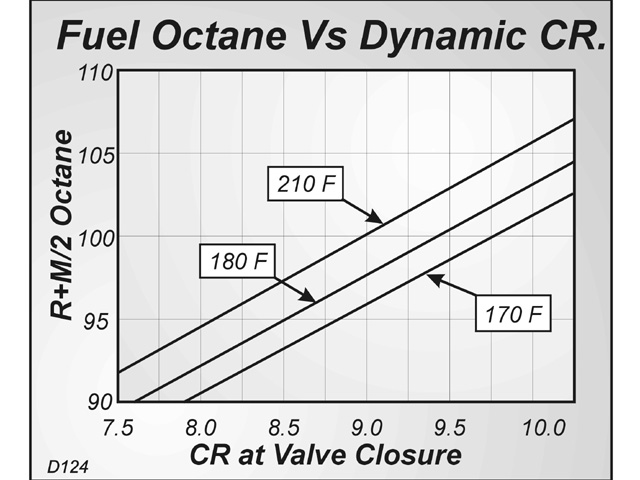

In order to hold costs down in oval track racing today we have numerous "RULE" classes. Cam "Lift" rules, engine "Vacuum" rules, "Carburation" rules and of course "Compression" rules. I for one, certainly have no quarrel with compression Ratio rules, because if you are talking true compression ratio, and it's properly measured and enforced, it is absolute. On the other hand, if it's a "compression effect" rule or the measurement of cranking compression in the cylinder as read on a compression gauge, then you have just pushed one of my buttons! However, before I begin my tirade, let us review why we have such rules as these in the first place. Do they exist so that we can go faster or slower; to make racing more or less competitive? And, are those who break such rules punished or rewarded? Well you say, the obvious answers to these questions are "slower", "more competitive" & "punished". Wrong! Not when it comes to compression "effect" rules!

Very simply, with a carburetor rule, he who installs a "bigger" one usually goes faster, can be detected and penalized. Likewise with a "cam lift" or "engine" vacuum rule. You cheat by installing a bigger cam and although you go faster, we can catch you and "you're outta there". Even with a compression ratio rule, you can have your "15 minutes of fame" if you like, but eventually you're going down because we can detect your indiscretion.

However, guess what happens to those who comply with a "compression effect" rule? Why, they are virtually always running a larger camshaft, go faster and of course can never be punished because they are within the rules!

Impossible you say? Quite possible I contend and in fact this is actually what happens virtually 100% of the time! I know, I'm in the camshaft business! Simply put, I believe compression effect rules are the single most ridiculous rules in existence. Rules that guarantee to keep speeds up, not down and actually penalize those with weaker engines and fewer resources. How can that be? Please read on...

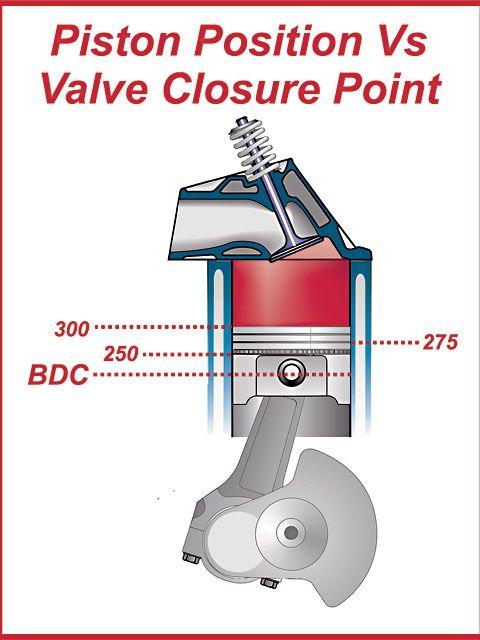

With a given static compression ratio, you will always have a higher reading on your compression tester gauge with a stock or low duration cam, because you will be closing the intake valve earlier on the compression stroke. The resultant longer effective compression stroke always delivers a higher gauge reading. Now switch to a longer duration cam. Your intake valve will close later, lowering your gauge reading because of the shorter effective compression stroke. Some people feel this is impossible, insisting that if it were true, why will you go faster with the bigger cam? The answer is, the bigger cam will have higher compression effect in the cylinder at higher engine speeds (where all that extra valve timing can do you some good), however at lower speeds and especially at starter-cranking speeds, the effect will be lower.

If you wish to prove this to yourself, simply recall how in the past you may have noticed losing bottom end torque when installing a longer duration cam. Do you think you lost that torque because of higher cylinder pressure? Of course not, but that is only the logic of deductive reasoning. Lord only knows what the "compression effect" rules people were thinking of when they came up with this stuff. It doesn't make sense and just about any cam grinder I know of, could have told them as much. On the other hand, there are some cam grinders who are confused about "compression effect" and cylinder flow dynamics. (Perhaps they consulted one of them.)

Tech Tip - 2003

Longer Exhaust Duration: Is this really necessary?

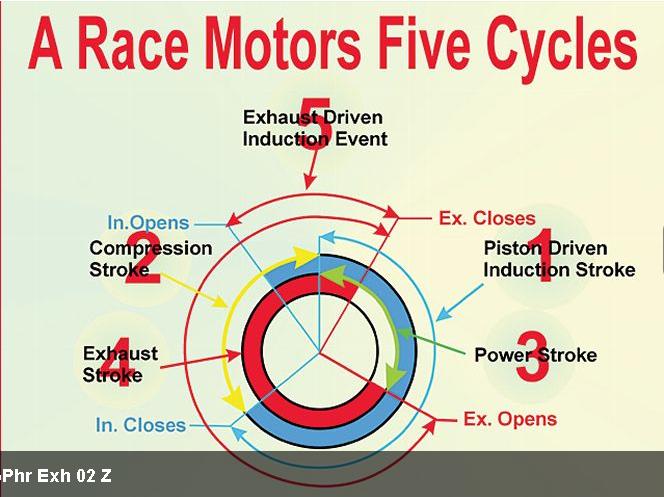

Most stock camshafts from American production V8, V6 and 4 cylinder engines manufactured today are ground with the longer exhaust lobe duration. Or, another way of looking at this is that they are ground with shorter intake durations! The former embraces the viewpoint that either the Exhaust Ports or Exhaust Pipe system is somewhat restrictive, and is in need of an assist. The latter suggests that the intake system is rather efficient and cam timing can be trimmed back a bit with out much sacrifice in power, in order to maximize throttle response and cruising efficiency.

Take your pick here. There is no absolutely correct viewpoint - because both are probably true! In a stock engine running at conservative RPM levels, for the sake of overall efficiency, fuel economy and a quiet smooth running engine, this staggering of intake and exhaust duration is quite common and appropriate.

However, High Performance is another thing entirely. Change one factor, let's say in this case, the exhaust system (installing headers and larger pipes) and you have just negated in most cases, the need for that longer exhaust lobe. Now couple this change with a different intake system and camshaft and you have really scrambled the equation. But, wait just a moment. Why is it that so many people (racers & cam grinders alike) insist on running a cam with longer exhaust duration regardless of what equipment is employed? The answer is "habit". Most of them have been somewhat successful in doing it their way and will probably never change unless virtually forced by circumstances to do so.

Before we go any further however let's review what it actually is we are trying to do with an engine when we attempt to make more power. Our best result comes when we are cognizant of the fact that an engine is basically an air pump. We pump it in and out (although in a different form) and we have problems when one side or the other is restricted. Balance or the equilibrium or flow should be our objective, unless of course we are not trying to make more horsepower!

Example #1 (Oval track racing) Here, I have often observed that the most experienced drivers are those who are most likely to run a single pattern (equal on intake and exhaust duration) cam. Why? Because such cams always, I repeat always make more torque! These veterans have a more educated foot and greater experience in feathering the throttle in the corners. They can therefore, utilize the benefit of added torque, in the lower to mid RPM range, to their advantage.

Their counterparts, the younger drivers on the circuit, generally are not as experienced and may at times actually get "crossed up" in the corners especially with a lighter car or when they are learning the ropes. In their case, a longer exhaust duration is often the more appropriate choice. It will often help them to drive better, more "flat footed" if you will, without consequence. But please for the sake of accuracy, let us be truthful. The benefit comes from an actual bleeding off of low to mid range torque, which is always what happens when Exh. Duration is lengthened, not from any improvement. The improvement, (if any) would come because of an improvement in scavenging at the extreme upper end of the power curve and would usually be marginal at best. Yet the so-called "extra power" potential of a longer Exh. Duration cam is most often why they are touted - power most people are backing away from at the end of the strait away!

Example #2 (Drag Racing) At the drag strip it's a little different and I feel more honest. Here, racers have long enjoyed longer exhaust and longer durations across the board (If I may add specifically for the purpose of "killing" low-end torque) to keep the tires from too easily breaking lose. This has been successful and sometimes actually results in a slight increase in top end power - something you can actually use in drag racing since it is a full throttle endeavor through the lights. Keep in mind here though, it's quite possible that a longer duration cam overall would have done just as well or better. In other words if you needed that longer exhaust for top end, perhaps the intake could have benefited from such a lengthening as well.

One of my favorite expressions is how "The Drag Racing mentality has infiltrated the ranks of Oval Track". Many have crossed over and made the switch in the past 10-15 years and some have brought their preconceived notions about how to cam an engine with them. A few may actually read these concepts and if they do so will at least come away with a better understanding of what they are doing. On the other hand they also could find that this information might actually help their cars to run just a bit faster!

Note: Readers may find Camfather Ed Iskenderian's Top Tuners Tip #33 "Can an Exhaust System Over-Scavenge the Combustion Chambers" to be a relevant precursor.