You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrical Wiring for a TBucket

- Thread starter Indycars

- Start date

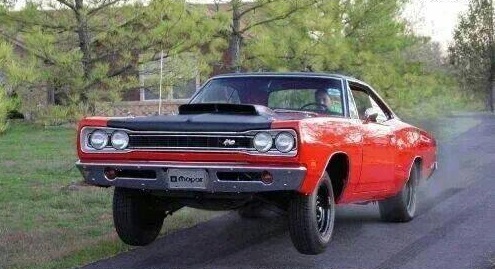

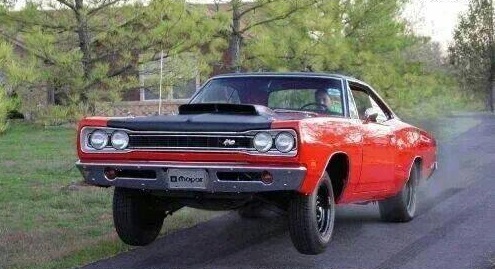

and that T-BUCKET ,cars frame thats shown jumping off the pavement and its suspension obviously need a great deal of improvement!

a properly set up cars suspension,with a decent engine and power to weight ratio,mated to high traction tires,and an experienced driver, allows a predictable and totally controlled launch WITHOUT frame twisting gymnastics and potential lack of directional stability and total predictability

a properly set up cars suspension,with a decent engine and power to weight ratio,mated to high traction tires,and an experienced driver, allows a predictable and totally controlled launch WITHOUT frame twisting gymnastics and potential lack of directional stability and total predictability

These two drawings were actually my first two drawings when I started planning

this project. The drawing below shows everything under the seat and is drawn to

scale. This helped me to decided to remove part of the two vertical braces shown

in the drawing.

I'm switching gears now and trying to go from the theoretical to the physical part

of the project. It's one thing to have it on paper, but now I have to actual run

wires and make physical connection. The drawing below tries to show where parts

are located in a general sense so I know how many wires to run to each location.

Attachments

all I can say is your skill at posting diagrams, posting clear photography and explaining the process are exceptional, I wish I had 10% of your skills in that area

https://www.rbracing-rsr.com/wiring_ecu.html

https://www.rbracing-rsr.com/wiring_ecu.html

Last edited by a moderator:

It's a matter of how much time you want to spend doing something. The more

time the better you get, but the biggest gains come early and tapper off.

Grumpy, if you would spend a couple of hours just playing with Visio, you wouldn't

have arrows with squiggly lines and funny looking circles. There is a lot that can be

done with lines, circles and rectangles in Visio. Watch a YouTube video, then try

some of the same operations, it will start to come to you.

bytor

Well-Known Member

I noticed the fuel pressure sensor in you diagram and realized you are planing on wiring up a fuel pressure gauge. Are you intending to also connect the fuel pressure signal to your AQ-1 data logger? I ran a fuel pressure sensor on my LM-2 setup and found it helpful to see what the fuel pressure is doing while logging AFR.

Visio is a great tool. I started using it at work years ago. It has come a long way since then. You diagrams look great Rick!

Visio is a great tool. I started using it at work years ago. It has come a long way since then. You diagrams look great Rick!

Yes I will be logging the fuel pressure.

I can log up to eight external channels and possibly speed from my SpeedHut

speedometer. So I will be logging Water Temp, Oil Temp, Trans Temp, Oil Pressure,

Fuel Pressure, AFR, Acceleration and Battery Voltage, I've been on the SpeedHut

forum trying to figure out if I use the cruise control output for speed. I had an

extra wire added and it outputs a 5 volt square wave at 4000 pulses/mile for a

cruise control system.

The AQ-1 wiring harness has alot of extra wires that I will never use on the

TBucket. So I decided to remove three cables or about 9 different wires and

two large connectors to simplify the harness.

First I had to open the clam shell with a small screw driver by unlatching the

three tangs.

As you can see the AQ-1 has a good size harness that is not welcome in the

small area I have under the seat for wiring.

Remove the clear guide and then remove the individual pins necessary to

remove the unwanted cables.

In the lower right had corner of the photo below you can see how much I was

able to remove.

Watch this video to see how you can remove the individual pins from the

main connector.

Decluttering AEM AQ-1 wiring harness for hayabusa

https://www.youtube.com/watch?v=p6b0pei-Ooc

Attachments

mathd

solid fixture here in the forum

Did you figure how to use the 4000 pulses/mile for logging speed?

Am just curious.

I guess you have to convert that to a variable voltage for the datalogger?

You could use the TC9400 IC to do a frequency to voltage converter.

http://pdf.datasheetcatalog.com/datashe ... 21483b.pdf

or the 4017B Decate(pulse) counter IC. but that will be more circuitry.

Am just curious.

I guess you have to convert that to a variable voltage for the datalogger?

You could use the TC9400 IC to do a frequency to voltage converter.

http://pdf.datasheetcatalog.com/datashe ... 21483b.pdf

or the 4017B Decate(pulse) counter IC. but that will be more circuitry.

I won't know until I try and that means the wiring project must be done first. But

for your info, below is the conversation I had at AEM who makes the AQ-1 data

logger. I don't know why, but AEM delated some post of my and his and then

answered my first post again. And he gives me no clues how, just that it can be

done.

Thanks for the suggestion, I will keep the TC9400 IC in mind.

Rick Said:

I have a SpeedHut GPS Speedometer with an ouput that has a square wave of

4000 pulses/mile and 0-5 volts.

Can I measure vehicle speed with an Analog/Freq input or will I have to use a

math channel?

Rick

http://www.speedhut.com/gauges/GPS-Speedometers/1:3

http://www.speedhut.com/instructions.i

AEM Said:

Yes, if you supply a variable frequency 5v square wave to the AQ-1, you can

record vehicle speed.

I suspect what AEM calls a Math Channel might be needed. Once you have the

data, then the software can perform math functions on the data and then display

the massaged data like any other channel.

Below are the math function available:

abs

sin

cos

tan

asin

acos

atan

atan2

sinh

cosh

tanh

asinh

acosh

atanh

pow

exp

ln

log

log2

floor

ceil

frac

sqr

sqrt

int

bool

real

raw

round

degtorad

radtodeg

max

min

sgn

mod

mask

combine

combine8

combine16

combine16_float32

reinterpret_float32

reinterpret_float64

complement

eswap16

eswap32

eswap64

bitrev8

bitrev16

bitrev32

bitrev64

can_decode_le

can_decode_be

avg

avg_nonzero

if

usecs

msecs

seconds

sample_pos

sample_count()

metres_abs

lap

lap_start_seconds

lap_seconds

lap_start_metres

lap_metres

is_lap_start

layer_seconds

layer_metres

integrate

integrate_lap

integrate_add

integrate_sum

derivative

declick

declick_if

prev

at_sample

at_seconds

at_seconds_lerp

filter_lp

filter_hp

filter_bs

filter_bp

filter_gaussian

filter_avg

g_correct_x

g_correct_y

g_correct_z

gps_haversine_metres

gps_haversine_delta

noise

noise_gaussian

layer

mathd

solid fixture here in the forum

Am reading the aq-1 manual right now, look like you can plug it directly to the Analog/Frequency 5-8 inputs

and it seem easy to setup, see page 11

http://aemelectronics.com/files/instruc ... System.pdf

Vehicule speed can be written as VSS or hall effect sensor sometime.

and it seem easy to setup, see page 11

http://aemelectronics.com/files/instruc ... System.pdf

Vehicule speed can be written as VSS or hall effect sensor sometime.

RICK!

YOUV'E GOT AMAZING PHOTOGRAPHIC SKILLS

YOUV'E GOT AMAZING PHOTOGRAPHIC SKILLS

mathd said:Am reading the aq-1 manual right now, look like you can plug it directly to the Analog/Frequency 5-8 inputs

and it seem easy to setup, see page 11

http://aemelectronics.com/files/instruc ... System.pdf

Vehicule speed can be written as VSS or hall effect sensor sometime.

I hope you are right, but sixty years of experience has taught me that it's never that easy!

I believe that was part of my post on the AEM forum, but they deleted that post for some reason.

grumpyvette said:RICK!

YOUV'E GOT AMAZING PHOTOGRAPHIC SKILLS

Thanks Grumpy, but right now I would easily trade the photographic skills for

some amazing electrical skills!

mathd

solid fixture here in the forum

Well its not really hard.

You just need to convert the squarewave to a sinewave (that can be done using some integrator circuit usually 2 of them in serie)

Use that frequency to voltage converter chip = LM2907/LM2917 (this one is better its meant for automotive use)

Then buffer the output(and set the output gain) with a transistor or op-amp since you use them to build the integrator circuit.

I could build all of that on a pcb for you if you really can't get the AEM to read the VSS. But i dont see why it will not work since it has that function build it.

The manual state it can be used for vehicule speed, the hard part will be the calibration. probably lots of math .

.

And your dealing with squarewave.. this has alot of high frequency content.. needs good wiring or the AEM will not recognize the signal.

You just need to convert the squarewave to a sinewave (that can be done using some integrator circuit usually 2 of them in serie)

Use that frequency to voltage converter chip = LM2907/LM2917 (this one is better its meant for automotive use)

Then buffer the output(and set the output gain) with a transistor or op-amp since you use them to build the integrator circuit.

I could build all of that on a pcb for you if you really can't get the AEM to read the VSS. But i dont see why it will not work since it has that function build it.

The manual state it can be used for vehicule speed, the hard part will be the calibration. probably lots of math

And your dealing with squarewave.. this has alot of high frequency content.. needs good wiring or the AEM will not recognize the signal.

mathd

solid fixture here in the forum

Rick, only 10 years ago i could barely read a electrical layout and probably not a electrical schematic..

I started y looking at alot of circuit layout, then schematic, and reading on how the component work.. basic electrical circuit design(amplifiers etc).

Am not going to lie and say its easy.. but its not really hard as many are expecting it to be. it just take a load of time.

About the squarewave.. if you have ever read about transmission lines.. you know that high frequency usually need a coax and matched input and output impedance.

So if your using a single wire.. and its a bit too long(inductance???).. you can get distorted waveform or even signal cancellation because of heavy reflection at the end of the cable or because of the inductance of that wire... and electromagnetic interferences, inductive/capacitive coupling.. When working with high frequency is alot more work that simple DC. Should use a short and high quality shielded wire as a minimum. (the shield will have some capacitance, it will help cancell the inductance and also shield the EMI and reduce coupling with nearby component.)

If you use 2 single wire.. twist them tight together it will help ALOT.(just like AC heater into a tube amp)

Even a 1khz squarewave have alot of high frequency component(harmonic).. if you could get a perfect squarewave with a perfect 0.0000(infinite)µS risetime.. you get infinite high frequency component.. but thats in a theorical perfect world. Getting a fast risetime for a squarewave is not really easy .

.

Looking a squarewave into a oscilloscope look like a single signal.. put it into a spectrum analyser and tada you see alot of different frequency signals(the original signal + harmonics.)

I started y looking at alot of circuit layout, then schematic, and reading on how the component work.. basic electrical circuit design(amplifiers etc).

Am not going to lie and say its easy.. but its not really hard as many are expecting it to be. it just take a load of time.

About the squarewave.. if you have ever read about transmission lines.. you know that high frequency usually need a coax and matched input and output impedance.

So if your using a single wire.. and its a bit too long(inductance???).. you can get distorted waveform or even signal cancellation because of heavy reflection at the end of the cable or because of the inductance of that wire... and electromagnetic interferences, inductive/capacitive coupling.. When working with high frequency is alot more work that simple DC. Should use a short and high quality shielded wire as a minimum. (the shield will have some capacitance, it will help cancell the inductance and also shield the EMI and reduce coupling with nearby component.)

If you use 2 single wire.. twist them tight together it will help ALOT.(just like AC heater into a tube amp)

Even a 1khz squarewave have alot of high frequency component(harmonic).. if you could get a perfect squarewave with a perfect 0.0000(infinite)µS risetime.. you get infinite high frequency component.. but thats in a theorical perfect world. Getting a fast risetime for a squarewave is not really easy

Looking a squarewave into a oscilloscope look like a single signal.. put it into a spectrum analyser and tada you see alot of different frequency signals(the original signal + harmonics.)