I built my first engine about a year ago,

but because I wasn't ready to install it in my car at the time,

I would start it and let it idle, rev it and tried to dial in my timing,

carb adjustments, etc. Over the course of a year it has probably run 8 hours total.

Talking to a buddy today, he said that for new rings to seat, they have to be put under load and I will likely have to replace them since I have so many hrs on my engine without "loading" it by driving.

Is there any truth to this? Last week, I installed the engine, transmission, rear end and feel I am very close to being ready to take it for its first drive in over 10 yrs.

your very likely too be fine as you are

,provided the bore walls were properly honed and the ring end gap,

and ring groove back clearance, in the pistons are correct,

rings tend to break-in in a properly honed bore in the first 30-45 minutes,

so while your lapping in the cam & lifters your rings seat.

and certainly in the first 7-8 hours regardless,

if the engine is in the car or on a dyno.

many engine builders break-in engines on their dyno, and that rarely takes them over 30-45 minutes.

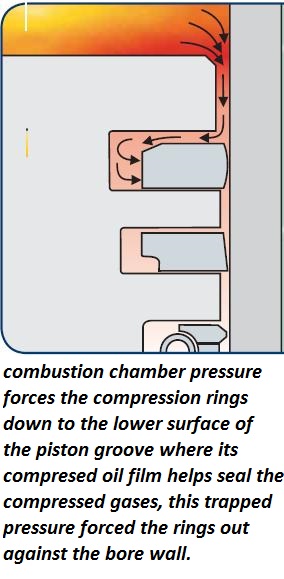

keep in mind cylinder pressure expands and holds the rings against the bore walls not load on the drive train.

more useful, related useful info

no one has mastered all the skills and going back over even rather common assembly skills and looking for tips on how to improve existing procedures seldom hurts.

as time progresses, theres always on-going documented testing, and in many cases the old established way of doing things has proven to be less than ideal as newer and more detailed testing proves.

I well remember the advice in the later 1960s to keep end gaps on upper piston rings in the .004-.005 per inch of bore diameter, and secondary compression rings , to a tighter .04 max per inch of bore diam, as they experience less heat related expansion, the gaps could be tighter, well testing over the last 40-50 years has proven that approach to be less than idea, a looser .005-.006 second compression ring end gap is now been rather conclusively proven to work a bit better as it tends to lower and trapped combustion pressure, that could reduce the top rings bore seal.

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://garage.grumpysperformance.com/index.php?threads/maximizing-piston-to-bore-ring-seal.3897/

http://garage.grumpysperformance.co...ng-piston-ring-grooves-and-related-info.1797/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

Last edited: