some free engine related downloads

http://www.powerperformancenews.com/for ... w-230.html

http://www.compcams.com/Camquest/default.asp

comp cams is now offering a free cam sellection software,

THIS IS A USEFUL TOOL,

this is useful in seeing the lift/duration/LCA they suggest for your application,

in most cases they get fairly close so its a tool thats useful

, now you don,t necessarily need to buy a COMP CAM but a cam with a similar lift/duration/LCA from your favorite manufacturer probably should be fairly close to whats recommended

keep in mind the software can,t differentiate between an off the shelf intake or one extensively port matched and ported,

, it can,t tell the difference between a crap valve job and a 5 angle valve job with a back cut valve,if port and bowl clean-up was done,

or headers blended entrances with matched length 38" primaries and 18"long 3.5" collectors and ones with

20 inch tube primaries and a 4"long 3" collector, and it certainly can,t account for a good tune vs one not so well balanced ETC.

and while you may enter factors like the cams LSA and LCA,

it generally won,t show how those changes effect scavenging efficiency.

soft ware dynos are generally accurate to within 5%-10% ,

but thats at times 30-hp to -40-hp, or more that is either potentially ignored or assumed.

some free, some NOT, but most are useful, and while in some cases the price seems steep the software can help make smarter choices and keep you from screwing up the build with badly mis-matched components

keep in mind predicted numbers will be suspect! but if you make changes and see a 5%-10% GAIN you can be reasonably sure that similar changes on a real engine will result is some change in a similar direction, obviously

GARBAGE INFO IN,

RESULTS IN,

GARBAGE INFO OUT,

in the predicted results,

so take the effort to verify what data your inputting

http://garage.grumpysperformance.com/index.php?threads/dyno-software.784/

http://www.virtualengine2000.com/

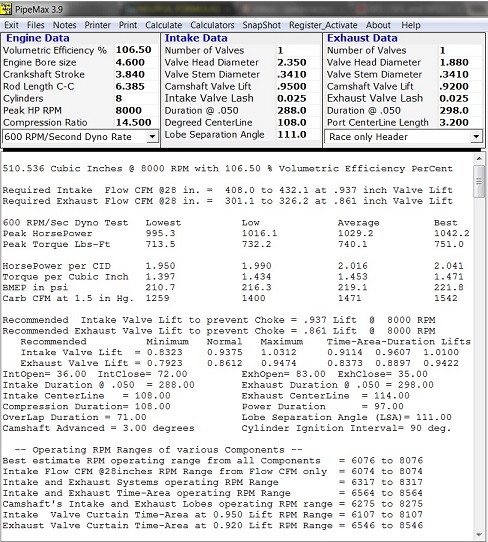

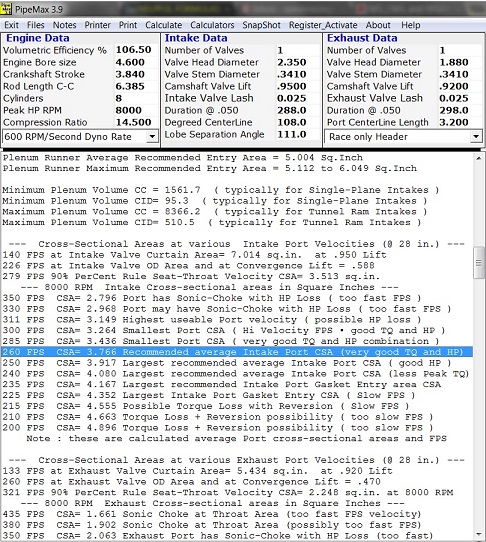

http://www.maxracesoftware.com/PIPE395.htm

http://www.virtualengine2000.com/Calculator.htm

http://www.virtualengine2000.com/?gc...FQYLbAodIEkP2A

http://racingdownloads.com/

http://www.audietech.com/

ITS not free at $460 but if youve got the patience too learn how to use it, and load all its requested input data its a great source of info on engines, and predicts results well, but it can be a P.I.T.A. to use at times

http://www.auto-ware.com/software/eap/eap.htm

IVE got EA PRO, its basically a P.I.T.A. and very time intensive to load all the data requested correctly, get lazy and guess on info and your results will be garbage, but it does tend to give reasonable results PROVIDED you input ALL the correct info,carefully, its the old "garbage info in=garbage info out"

http://performancetrends.com/Engine_Log_Book_v1.htm

more interesting stuff

http://www.performancetrends.com/cam_test_stand.htm

viewtopic.php?f=52&t=240&p=285&hilit=flow+numbers#p285

viewtopic.php?f=52&t=148&p=182&hilit=flow+numbers#p182

viewtopic.php?f=52&t=333&p=409&hilit=flow+numbers#p409

http://www.race-cars.net/calculators/et_calculator.html

http://www.camquest.com/

viewtopic.php?f=52&t=8460

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/chokepoint.php

http://www.powerperformancenews.com/for ... w-230.html

http://www.compcams.com/Camquest/default.asp

comp cams is now offering a free cam sellection software,

THIS IS A USEFUL TOOL,

this is useful in seeing the lift/duration/LCA they suggest for your application,

in most cases they get fairly close so its a tool thats useful

, now you don,t necessarily need to buy a COMP CAM but a cam with a similar lift/duration/LCA from your favorite manufacturer probably should be fairly close to whats recommended

keep in mind the software can,t differentiate between an off the shelf intake or one extensively port matched and ported,

, it can,t tell the difference between a crap valve job and a 5 angle valve job with a back cut valve,if port and bowl clean-up was done,

or headers blended entrances with matched length 38" primaries and 18"long 3.5" collectors and ones with

20 inch tube primaries and a 4"long 3" collector, and it certainly can,t account for a good tune vs one not so well balanced ETC.

and while you may enter factors like the cams LSA and LCA,

it generally won,t show how those changes effect scavenging efficiency.

soft ware dynos are generally accurate to within 5%-10% ,

but thats at times 30-hp to -40-hp, or more that is either potentially ignored or assumed.

some free, some NOT, but most are useful, and while in some cases the price seems steep the software can help make smarter choices and keep you from screwing up the build with badly mis-matched components

keep in mind predicted numbers will be suspect! but if you make changes and see a 5%-10% GAIN you can be reasonably sure that similar changes on a real engine will result is some change in a similar direction, obviously

GARBAGE INFO IN,

RESULTS IN,

GARBAGE INFO OUT,

in the predicted results,

so take the effort to verify what data your inputting

http://garage.grumpysperformance.com/index.php?threads/dyno-software.784/

http://www.virtualengine2000.com/

http://www.maxracesoftware.com/PIPE395.htm

http://www.virtualengine2000.com/Calculator.htm

http://www.virtualengine2000.com/?gc...FQYLbAodIEkP2A

http://racingdownloads.com/

http://www.audietech.com/

ITS not free at $460 but if youve got the patience too learn how to use it, and load all its requested input data its a great source of info on engines, and predicts results well, but it can be a P.I.T.A. to use at times

http://www.auto-ware.com/software/eap/eap.htm

IVE got EA PRO, its basically a P.I.T.A. and very time intensive to load all the data requested correctly, get lazy and guess on info and your results will be garbage, but it does tend to give reasonable results PROVIDED you input ALL the correct info,carefully, its the old "garbage info in=garbage info out"

http://performancetrends.com/Engine_Log_Book_v1.htm

more interesting stuff

http://www.performancetrends.com/cam_test_stand.htm

viewtopic.php?f=52&t=240&p=285&hilit=flow+numbers#p285

viewtopic.php?f=52&t=148&p=182&hilit=flow+numbers#p182

viewtopic.php?f=52&t=333&p=409&hilit=flow+numbers#p409

http://www.race-cars.net/calculators/et_calculator.html

http://www.camquest.com/

viewtopic.php?f=52&t=8460

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/chokepoint.php

Last edited by a moderator: