its very unlikely to be a defective set of rods , a bad damper or a badly machined crank thats at fault, carefull examination of the components will usually indicate the source but without careful examination of the stress fracture , and all components in the engine it will be hard to verify the source,

stress is cumulative having the engine balanced and correctly clearances is mandatory.

maintaining proper lubrication and valve train control is mandatory.

I see guys blame the crank and rods for failures that were really valve train or detonation related, no piston, rod or crank will successfully compress a bent valve or a busted chunk of piston ring land that broke loose due to lack of valve control or detonation damage, but dampers do go out of index, and cranks do occasionally have stress risers, bearings do occasionally get starved for oil, timing gets moved, detonation can result, etc.

I GOT THESE PICTURES OFF A DIFFERENT SITE, SHOWING A MASSIVE ENGINE FAILURE, CAUSE YET TO BE DETERMINED

HEY GRUMPYVETTE!

"I recently disassembled my engine because of rapidly dropping oil pressure, bearing clearances were larger than installed and bearing shells were loose in the main and rod caps and the crank was mildly scored,One very peculiar sight is the combustion chambers and exhaust ports which were polished when assembled,are rough and it feels , gritty almost like pool sand., and the Tops of pistons same way

No major damage to any of this, except the FROSTED appearance ,on the piston tops ,and combustion chamber surfaces, some it just scrapes off with fingernail. "

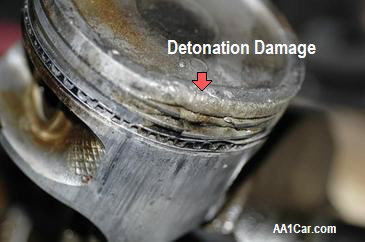

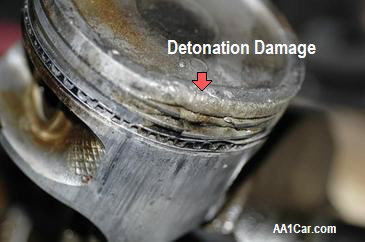

what your describing quite well is damage done or at least contributed too by DETONATION

http://www.thirskauto.net/BearingPics.html

if the edges of the piston lands look rounded off slightly and FROSTED that's the results of detonation, the rough stuff it micro sized bits of molten piston aluminum , that got transferred to the combustion chamber and exhaust port surfaces

a reasonable limit on cast pistons usually falls near 4000 feet per minute in piston speeds

so your stroke is a factor not just rpms

yes detonation can heat a piston up remarkably fast under some conditions resulting in rings locking in grooves and a sugary texture on the aluminum and melted piston lands

http://www.jegs.com/p/ATI/ATI-Super-Dam ... 7/10002/-1

MOST NASCAR TEAMS USE ATI DAMPERS AND THEY CERTAINLY HAVE THE TEST DATA TO SUPPORT THE CHOICE

heres a calculator

http://www.csgnetwork.com/pistonspeedcalc.html

a balanced set of quality forged pistons can probably handle 4500fpm, or a bit more

approximately 3500fpm at 6000rpm in a 350sbc IS well below any critical stress levels on the PISTONS, but be well aware its usually the valve train CONTROL ISSUES,or detonation issues not the pistons or rods that are the source of most problems BLAMED on rods and PISTON FAILURE, no rod or piston can compress a bent or broken valve,if you get into valve float, or chunk of piston ring land that overheated and broke loose, without massive component failure resulting

stress is cumulative having the engine balanced and correctly clearances is mandatory.

maintaining proper lubrication and valve train control is mandatory.

I see guys blame the crank and rods for failures that were really valve train or detonation related, no piston, rod or crank will successfully compress a bent valve or a busted chunk of piston ring land that broke loose due to lack of valve control or detonation damage, but dampers do go out of index, and cranks do occasionally have stress risers, bearings do occasionally get starved for oil, timing gets moved, detonation can result, etc.

I GOT THESE PICTURES OFF A DIFFERENT SITE, SHOWING A MASSIVE ENGINE FAILURE, CAUSE YET TO BE DETERMINED

HEY GRUMPYVETTE!

"I recently disassembled my engine because of rapidly dropping oil pressure, bearing clearances were larger than installed and bearing shells were loose in the main and rod caps and the crank was mildly scored,One very peculiar sight is the combustion chambers and exhaust ports which were polished when assembled,are rough and it feels , gritty almost like pool sand., and the Tops of pistons same way

No major damage to any of this, except the FROSTED appearance ,on the piston tops ,and combustion chamber surfaces, some it just scrapes off with fingernail. "

what your describing quite well is damage done or at least contributed too by DETONATION

http://www.thirskauto.net/BearingPics.html

if the edges of the piston lands look rounded off slightly and FROSTED that's the results of detonation, the rough stuff it micro sized bits of molten piston aluminum , that got transferred to the combustion chamber and exhaust port surfaces

a reasonable limit on cast pistons usually falls near 4000 feet per minute in piston speeds

so your stroke is a factor not just rpms

yes detonation can heat a piston up remarkably fast under some conditions resulting in rings locking in grooves and a sugary texture on the aluminum and melted piston lands

http://www.jegs.com/p/ATI/ATI-Super-Dam ... 7/10002/-1

MOST NASCAR TEAMS USE ATI DAMPERS AND THEY CERTAINLY HAVE THE TEST DATA TO SUPPORT THE CHOICE

heres a calculator

http://www.csgnetwork.com/pistonspeedcalc.html

a balanced set of quality forged pistons can probably handle 4500fpm, or a bit more

approximately 3500fpm at 6000rpm in a 350sbc IS well below any critical stress levels on the PISTONS, but be well aware its usually the valve train CONTROL ISSUES,or detonation issues not the pistons or rods that are the source of most problems BLAMED on rods and PISTON FAILURE, no rod or piston can compress a bent or broken valve,if you get into valve float, or chunk of piston ring land that overheated and broke loose, without massive component failure resulting