you can obviously buy a shop crane from several sources and theres a real difference in quality , size and capacity.

many of the shop cranes or hoists I see being used are BARELY functional, and don,t have the reach or capacity to easily do the job they were in theory designed for.

if you have a bit of fabrication skill and a welder, you can go to a local metal supply store and purchase the materials required to build your own custom engine crane,thats designed to exactly match your intended use.

and in some cases thats going to be almost mandatory, especially if you do a good deal of engine rebuild type work.

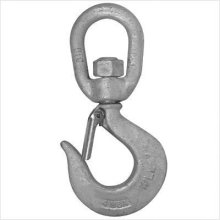

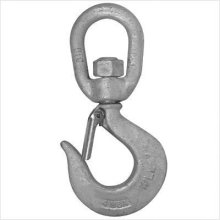

adding a swivel hook makes a crane far more user friendly, as the engine won,t constantly be trying to swing to some less than ideal angle

https://www.mfrexpress.com/alloy-swivel-hoist-hook-crane-hook-safety-latch-3-ton-p-701.html

http://www.ebay.com/itm/Build-your-...Fun-build-Save-Money-/291423148260?rmvSB=true

http://garage.grumpysperformance.co...-value-vs-price-and-options.12312/#post-60702

adding far larger rubber wheels and making the engine crane easier to roll AND adding them to your engine stands for the same reason is a good idea even if its expensive and one more in a near endless list of reasons too own a decent MIG or TIG welder

http://www.harborfreight.com/8-inch-cushion-tire-swivel-caster-with-brake-46819.html

http://www.northerntool.com/shop/tools/product_200640934_200640934?utm_source=CSE&utm_medium=Shopping.com&utm_campaign=Automotive > Engine Hoists + Stands > Engine Hoists&utm_content=46219

https://www.mfrexpress.com/alloy-swivel ... p-701.html

"If you are having a problem getting the engine stand to get in close enough to the engine swinging on the engine crane,its more than likely that your not doing anything wrong"

the sad fact is that about 90% of the less expensive engine cranes don,t have enough space between the support legs that extend out to support weight suspended by the cranes arm to allow the engine stands most guys use to roll into the point where the arm can easily transfer the engine to the engine stand.

if you fabricate an engine crane harbor freight sells 8 ton rated long reach hydraulic cylinders, the crane boom should be solidly built and adjustable for length , but remember the support, swivel hook should not extend within about 14" of the crans support legs outer wheels as any engine hanging from the support swivel hook , center of mass must remain well behind the support wheel centerlines to prevent tipping, and the extended boom must extend to within 24" of the floor to pick up an engine yet still lift it well over fender height, of the car or truck and easily reach deep enough to insert and align the engine with motor mounts and the transmission

of the car or truck

most guys mount the engine stand head to the engine then try to lift the engine, after its sitting on the shop floor after pulling it from a car, and slide the engine stand head support tube into the engine stand and only then find out that the smaller and lighter and cheaper engine cranes are a total P.O.S. that won,t allow the transfer. the larger more expensive engine cranes tend to have a longer reach and more clearance between the support legs to allow a stand to roll in closer

One factor I find absurd is that almost all, or most engine stands you buy , that youll be using to build an engine on, won,t roll inside or between the legs of most engine cranes far enough to allow easy access ,to mount an engine on that stand that the engine crane is supporting

http://www.northerntool.com/shop/tools/ ... _200305217

and most engine cranes don,t have the height or reach to easily allow you to pull a pick-up truck or vans engine as the stands reach and height is not tall enough or the reach long enough.

now you can obviously buy a commercial engine crane and just modify , or replace the required parts to get it to reach or fit the application, or just carefully measure an existing design and change the measurements on your custom fabricated engine stand design

adding much better quality casters increases the price considerably but will be making the engine crane far FAR more user friendly, because they roll far easier, and you can lock the wheels when working on the engine making torquing the bolts far safer and easier , on the negative side youll need to have the car up on jack stands to allow the crane legs to have clearance under the car as the taller casters increase the cranes support leg height noticeably, but if you use the (4) 12 ton jack stands UNDER THE CAR FRAME FOR SOLID SUPPORT, I use when doing this type of work both the access under the car with a mechanics creeper and the engine crane is MUCH easier

http://www.harborfreight.com/8-inch-cus ... 46819.html

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

New

personally Id build using telescoping 2.75"- 3"-3.5" sq box D.O.M. tube with a 0.250 or at least 3/16" inch wall, thickness.

yes its heavy, but its far less likely to bend than the 0.125" wall tube many guys use,

personally confirm that the 3" tube slides inside the outer tube

you can learn a great deal if you personally visit your local commercial metal supply

and tell them exactly what your planning to build with a diagram,

with carefully thought out dimensions accurately listed.

BE AWARE A PROPERLY DESIGNED AND BUILT ENGINE CRANE

IS VERY LIKELY TO COST AS MUCH OR MORE,

THAN THE COMMERCIALLY AVAILABLE ENGINE CRANES

BUT ITS VERY LIKELY TO BE SIGNIFICANTLY STRONGER

one more in an endless list of reasons to own a decent MIG or TIG welder

read these links and sub links

viewtopic.php?f=27&t=8566

viewtopic.php?f=27&t=1018

http://www.myks-tools.com/

http://www.harborfreight.com/8-ton-supe ... 36397.html

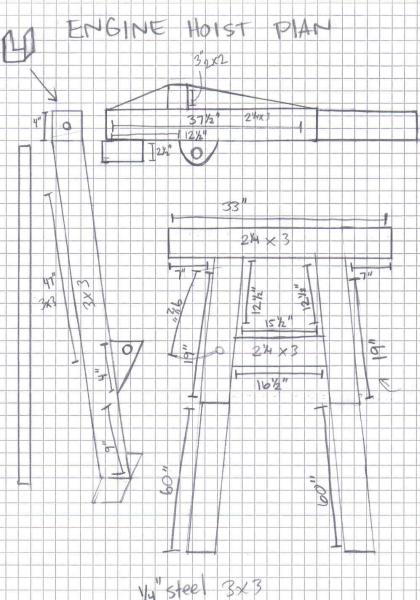

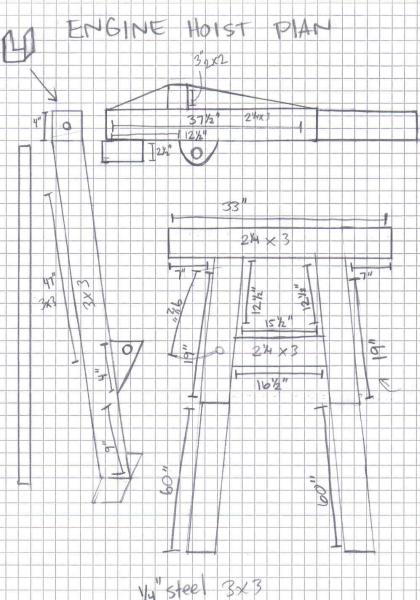

I FOUND THIS DRAWING ON THE INTERNET, obviously you would change dimensions a great deal to match your particular application or needs

heres a picture of a rather typical shop crane to let you design your own custom version

IF you don,t have a swivel hook,or engine leveler/tilter, trust me it makes the job far easier, to have both

once you do youll wonder why you ever attempted the job without those accessories, without the swivel hook the engine constantly wants to swing back to one location, it fights you constantly, the tilter makes clearing and indexing the engine angle so much easier

buy the 1.5-2 ton rated hook for your engine hoist and grease the swivel center pin on the hook

http://www.mfrexpress.com/alloy-swivel- ... p-699.html

adding a swivel like this between the leveler and crane GREATLY AIDS THE ENGINES REMOVAL, DON,T GET STUPID or CHEAP, GET THE 3000lb-3500lb rated one not the 1200lb size (REMEMBER YOULL BE UNDER THAT ENGINE SOMETIMES)

the picture above can be used as a teaching aid, this guys got the engine tilter he needs but its mounted with the tilter too far above the carburetor, limiting the distance the engine can be lifted above the fenders there should be about 2"-3" between the carburetor BASE MOUNT ON THE INTAKE, tilter at most,with the carb removed and the intake opening duct taped closed and lower edge of the engine, intake carburetor mounting pad and having the distributor still installed is still a small risk, that, is best avoided as it could be damaged, its best removed for safety, but the picture also does not have the swivel,hook, and hes using it with the crank handle at the wrong end as it will hit the wind shield in some applications while cranking in that location, rather than having the crank face the crane like it should

many of the shop cranes or hoists I see being used are BARELY functional, and don,t have the reach or capacity to easily do the job they were in theory designed for.

if you have a bit of fabrication skill and a welder, you can go to a local metal supply store and purchase the materials required to build your own custom engine crane,thats designed to exactly match your intended use.

and in some cases thats going to be almost mandatory, especially if you do a good deal of engine rebuild type work.

adding a swivel hook makes a crane far more user friendly, as the engine won,t constantly be trying to swing to some less than ideal angle

https://www.mfrexpress.com/alloy-swivel-hoist-hook-crane-hook-safety-latch-3-ton-p-701.html

http://www.ebay.com/itm/Build-your-...Fun-build-Save-Money-/291423148260?rmvSB=true

http://garage.grumpysperformance.co...-value-vs-price-and-options.12312/#post-60702

adding far larger rubber wheels and making the engine crane easier to roll AND adding them to your engine stands for the same reason is a good idea even if its expensive and one more in a near endless list of reasons too own a decent MIG or TIG welder

http://www.harborfreight.com/8-inch-cushion-tire-swivel-caster-with-brake-46819.html

http://www.northerntool.com/shop/tools/product_200640934_200640934?utm_source=CSE&utm_medium=Shopping.com&utm_campaign=Automotive > Engine Hoists + Stands > Engine Hoists&utm_content=46219

https://www.mfrexpress.com/alloy-swivel ... p-701.html

"If you are having a problem getting the engine stand to get in close enough to the engine swinging on the engine crane,its more than likely that your not doing anything wrong"

the sad fact is that about 90% of the less expensive engine cranes don,t have enough space between the support legs that extend out to support weight suspended by the cranes arm to allow the engine stands most guys use to roll into the point where the arm can easily transfer the engine to the engine stand.

if you fabricate an engine crane harbor freight sells 8 ton rated long reach hydraulic cylinders, the crane boom should be solidly built and adjustable for length , but remember the support, swivel hook should not extend within about 14" of the crans support legs outer wheels as any engine hanging from the support swivel hook , center of mass must remain well behind the support wheel centerlines to prevent tipping, and the extended boom must extend to within 24" of the floor to pick up an engine yet still lift it well over fender height, of the car or truck and easily reach deep enough to insert and align the engine with motor mounts and the transmission

of the car or truck

most guys mount the engine stand head to the engine then try to lift the engine, after its sitting on the shop floor after pulling it from a car, and slide the engine stand head support tube into the engine stand and only then find out that the smaller and lighter and cheaper engine cranes are a total P.O.S. that won,t allow the transfer. the larger more expensive engine cranes tend to have a longer reach and more clearance between the support legs to allow a stand to roll in closer

One factor I find absurd is that almost all, or most engine stands you buy , that youll be using to build an engine on, won,t roll inside or between the legs of most engine cranes far enough to allow easy access ,to mount an engine on that stand that the engine crane is supporting

http://www.northerntool.com/shop/tools/ ... _200305217

and most engine cranes don,t have the height or reach to easily allow you to pull a pick-up truck or vans engine as the stands reach and height is not tall enough or the reach long enough.

now you can obviously buy a commercial engine crane and just modify , or replace the required parts to get it to reach or fit the application, or just carefully measure an existing design and change the measurements on your custom fabricated engine stand design

adding much better quality casters increases the price considerably but will be making the engine crane far FAR more user friendly, because they roll far easier, and you can lock the wheels when working on the engine making torquing the bolts far safer and easier , on the negative side youll need to have the car up on jack stands to allow the crane legs to have clearance under the car as the taller casters increase the cranes support leg height noticeably, but if you use the (4) 12 ton jack stands UNDER THE CAR FRAME FOR SOLID SUPPORT, I use when doing this type of work both the access under the car with a mechanics creeper and the engine crane is MUCH easier

http://www.harborfreight.com/8-inch-cus ... 46819.html

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

New

personally Id build using telescoping 2.75"- 3"-3.5" sq box D.O.M. tube with a 0.250 or at least 3/16" inch wall, thickness.

yes its heavy, but its far less likely to bend than the 0.125" wall tube many guys use,

personally confirm that the 3" tube slides inside the outer tube

you can learn a great deal if you personally visit your local commercial metal supply

and tell them exactly what your planning to build with a diagram,

with carefully thought out dimensions accurately listed.

BE AWARE A PROPERLY DESIGNED AND BUILT ENGINE CRANE

IS VERY LIKELY TO COST AS MUCH OR MORE,

THAN THE COMMERCIALLY AVAILABLE ENGINE CRANES

BUT ITS VERY LIKELY TO BE SIGNIFICANTLY STRONGER

one more in an endless list of reasons to own a decent MIG or TIG welder

read these links and sub links

viewtopic.php?f=27&t=8566

viewtopic.php?f=27&t=1018

http://www.myks-tools.com/

http://www.harborfreight.com/8-ton-supe ... 36397.html

I FOUND THIS DRAWING ON THE INTERNET, obviously you would change dimensions a great deal to match your particular application or needs

heres a picture of a rather typical shop crane to let you design your own custom version

IF you don,t have a swivel hook,or engine leveler/tilter, trust me it makes the job far easier, to have both

once you do youll wonder why you ever attempted the job without those accessories, without the swivel hook the engine constantly wants to swing back to one location, it fights you constantly, the tilter makes clearing and indexing the engine angle so much easier

buy the 1.5-2 ton rated hook for your engine hoist and grease the swivel center pin on the hook

http://www.mfrexpress.com/alloy-swivel- ... p-699.html

adding a swivel like this between the leveler and crane GREATLY AIDS THE ENGINES REMOVAL, DON,T GET STUPID or CHEAP, GET THE 3000lb-3500lb rated one not the 1200lb size (REMEMBER YOULL BE UNDER THAT ENGINE SOMETIMES)

the picture above can be used as a teaching aid, this guys got the engine tilter he needs but its mounted with the tilter too far above the carburetor, limiting the distance the engine can be lifted above the fenders there should be about 2"-3" between the carburetor BASE MOUNT ON THE INTAKE, tilter at most,with the carb removed and the intake opening duct taped closed and lower edge of the engine, intake carburetor mounting pad and having the distributor still installed is still a small risk, that, is best avoided as it could be damaged, its best removed for safety, but the picture also does not have the swivel,hook, and hes using it with the crank handle at the wrong end as it will hit the wind shield in some applications while cranking in that location, rather than having the crank face the crane like it should

Last edited by a moderator: