ptydafwl said:

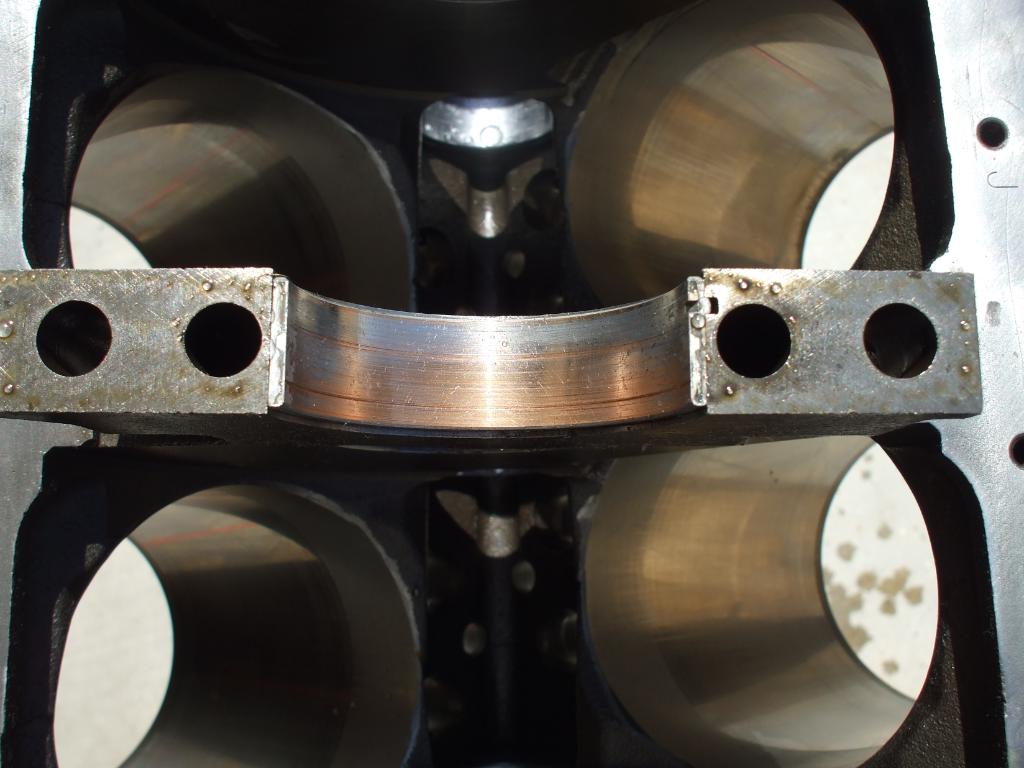

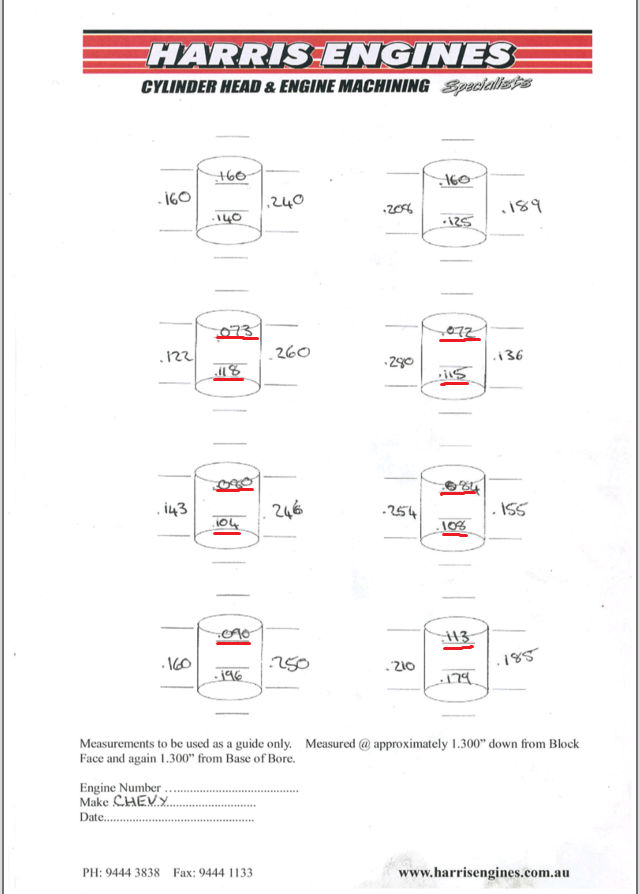

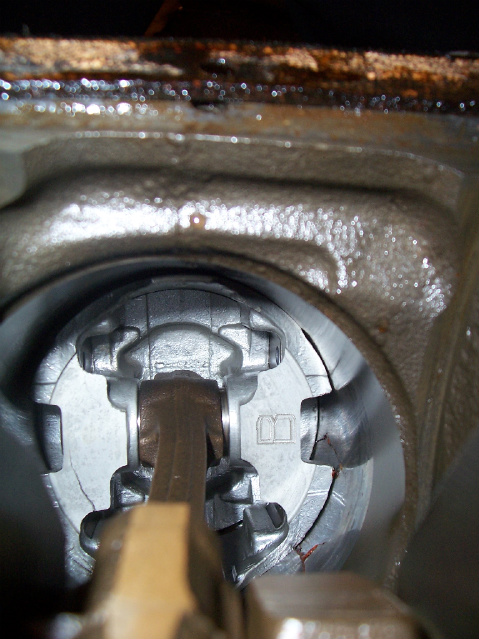

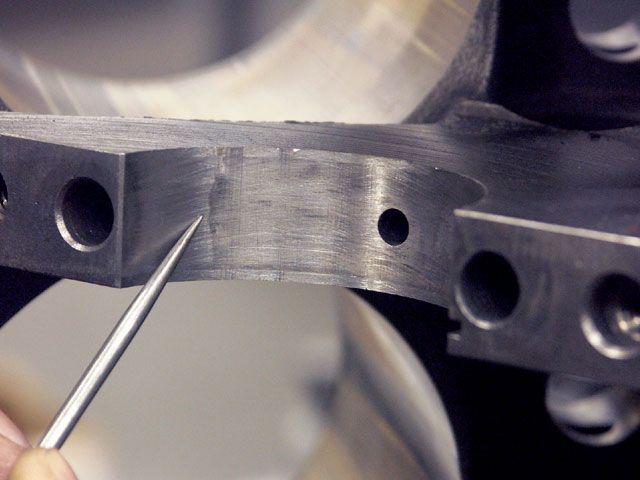

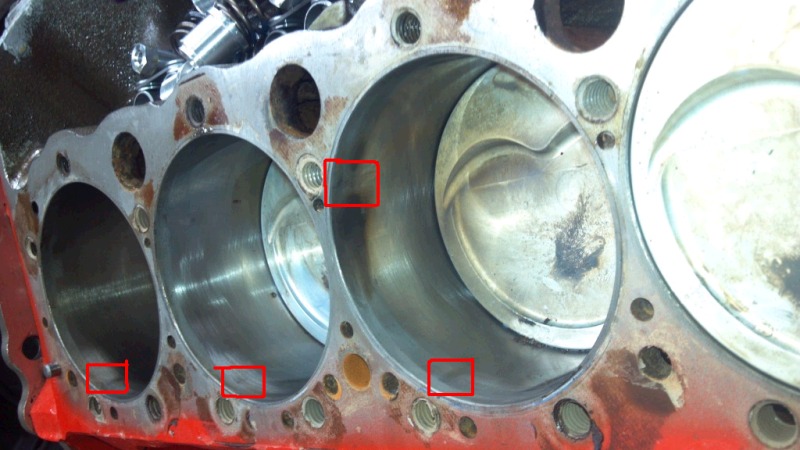

Here are the results from sonic testing.

A few of the walls are thinner than .080 but according to machinist because of where they are it should be fine.

it's getting the following done:

- New core/welch plugs fitted

- New cam bearings

- Fully cleaned

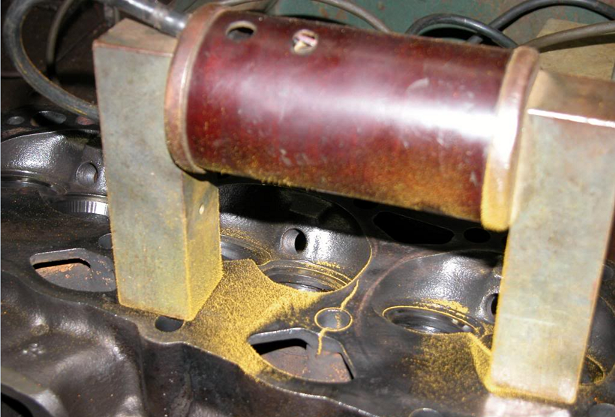

- torque plate hone

- deck faces machined

Now I have to start organising parts.

I would like to purchase everything in one go through summitracing.com but if theres a place cheaper?

I will need verification that the parts list I order will be 100% compatible with my engine. I still have to choose a combo...

if your going to build a performance engine and your machinist is ok with .072 thick cylinder walls,you need a new machinist badly, get out a feeler gauge and look at what .072 looks like

before you dismiss this friendly advice get out a micrometer or feeler gauge and look at just how thin your sonic test results show your bore wall to be , and remember it will be hit with several hundred PSI pressure thousands of times an hour then think about how long it take you to bend a paper clip back and forth until it fails

Engine Building Basics

There isn't a universal set of rules that govern all engine building. The following is information that has worked successfully and should be considered when building a performance engine.

A high performance race engine, by its definition, indicates that limits are going to be pushed. The limit that is of most concern, as far as pistons are concerned, is peak operating cylinder pressure. Maximizing cylinder pressure benefits horsepower and fuel economy. Considering the potential benefit, owners of non-race engines, from motor homes to street rods, also look to increasing cylinder pressure. Increasing the compression ratio is one sure way of increasing cylinder pressure but its not the only way. Camshaft selection, carburetion, nitrous and supercharging can all alter cylinder pressures dramatically.

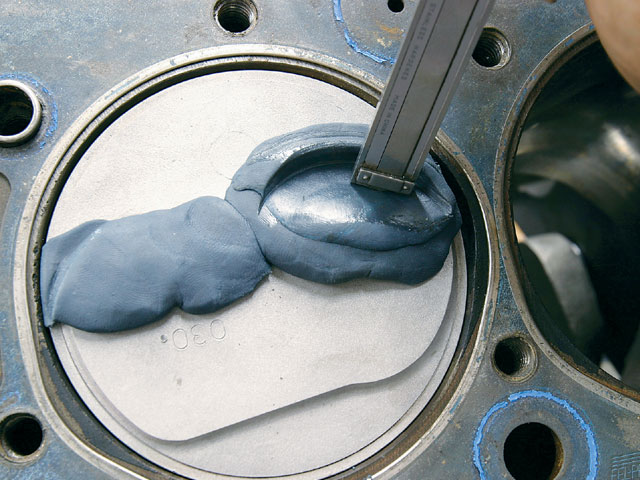

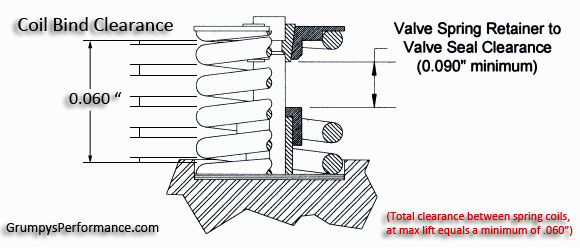

Excessive cylinder pressure will encourage engine destroying detonation with no piston immune to its effects. The goal of performance engine builders should be to build their products with as much detonation resistance as possible. An important first step is to set the assembled quench distance to .035". The quench distance is the compressed thickness of the head gasket plus the deck height, (the distance your piston is down in the bore). If your piston height, (not dome height), is above the block deck, subtract the overage from the gasket thickness to get a true assembled quench distance. The quench area is the flat part of the piston that would contact a similar flat area on the cylinder head if you had .000" assembled quench height. In a running engine, the .035" quench decreases to a close collision between the piston and cylinder head. The shock wave from the close collision drives air at high velocity through the combustion chamber. This movement tends to cool hot spots, average the chamber temperature, reduce detonation and increase power. Take note, on the exhaust cycle, some cooling of the piston occurs due to the closeness to the water cooled head.

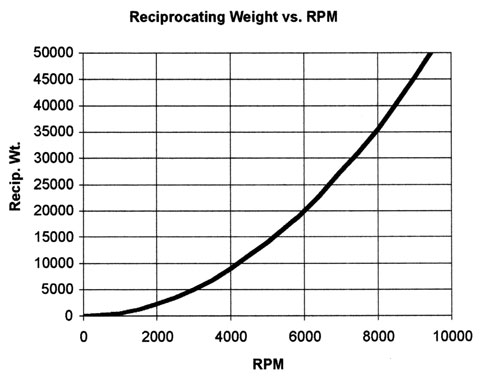

If you are building an engine with steel rods, tight bearings, tight pistons, modest RPM and automatic transmission, a .035" quench is the minimum practical to run without engine damage. The closer the piston comes to the cylinder head at operating speed, the more turbulence is generated. Turbulence is the main means of reducing detonation. Unfortunately, the operating quench height varies in an engine as RPM and temperature change. If aluminum rods, loose pistons, (they rock and hit the head), and over 6000 RPM operation is anticipated, a static clearance of .055" could be required. A running quench height in excess of .060" will forfeit the benefits of the quench head design and can cause

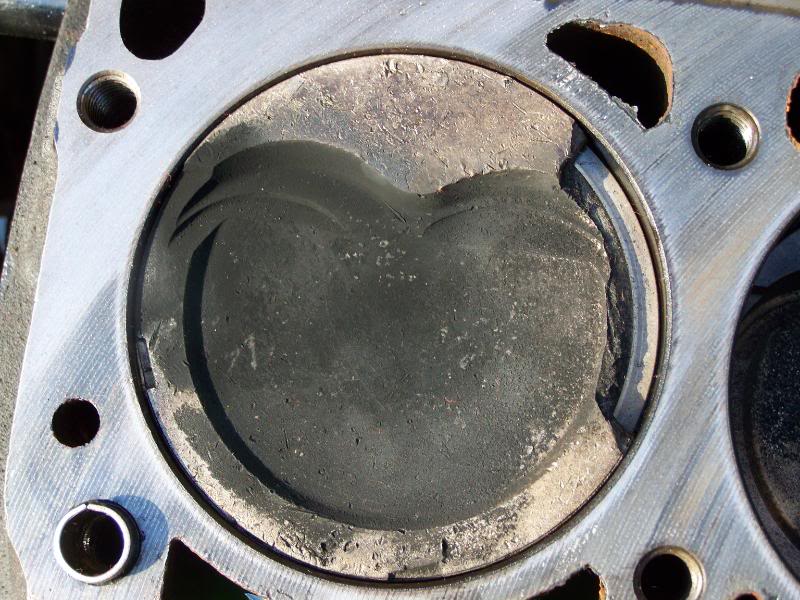

severe detonation. The suggested .035" static quench height is recommended as a good usable dimension for stock rod engines up to 6500 RPM. Above 6500 RPM rod selection becomes important. Since it is the close collision between the piston and the cylinder head that reduces the prospect of detonation, never add a shim or head gasket to lower compression on a quench head engine. If you have 10:1 with a proper quench and then add an extra .040" gasket to give 9.5:1 and .080" quench, you will create more ping at 9.5:1 than you had at 10:1. The suitable way to lower the compression is to use a dish piston. Dish (reverse combustion chamber), pistons are designed for maximum quench, (sometimes called squish), area. Having part of the combustion chamber in the piston improves the shape of the chamber and flame travel. High performance motors will see some detonation, which leads to preignition. Detonation occurs at five to ten degrees after top-dead-center. Preignition occurs before top-dead-center. Detonation damages your engine with impact loads and excessive heat. The excessive heat part of detonation is what causes preignition. Overheated combustion chamber parts start acting as glow plugs. Preignition induces extremely rapid combustion and welding temperatures melt down is only seconds away!

For a successful performance engine, use a compression ratio and cam combination to keep your cylinder pressure in line with the fuel you are going to use. Drop compression for continuous load operation, such as motor homes and heavy trucks, to around 8.5:1. Run a cool engine with lots of radiator capacity. Consider propylene glycol coolant and low temperature thermostats. Reduce total ignition advance 2 to 4 degrees. A setting that gives a good HP reading on a 5 second Dyno run is usually too advanced for continuous load applications. Normally aspirated Drag Race engines have been built with high RPM spark retard. The retard is used to counter the effect of increased flame travel speed with increased engine heat. "Seat of the pants" spark adjustment at low RPM will almost always cause detonation in mid to high compression engines once they are rung out and start making serious horsepower. Set spark advance to make best quarter mile speed not best ET, usually 34 degrees total advanced timing.

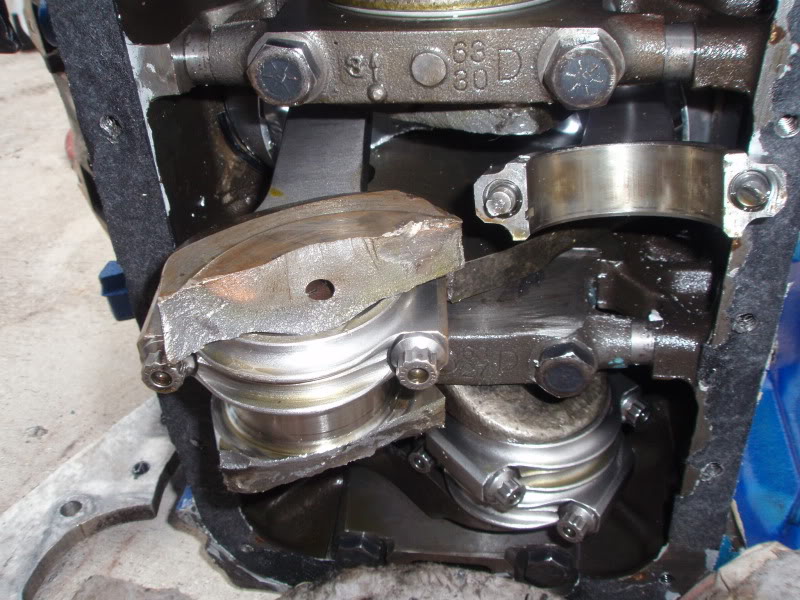

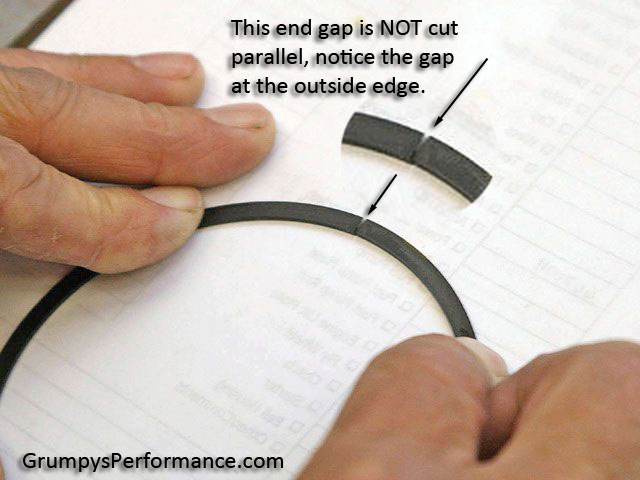

Top Ring End Gap is often a major player when it comes to piston problems. Top ring butting under high load and heat conditions can destroy the piston top land. Most top land damage on race pistons appears to lift into the combustion chamber. The reason is that the top ring ends butt and stick tight at top-dead-center. Crank rotation pulls the piston down the cylinder while leaving at least part of the ring and top land at top-dead. Actual end gap will vary depending on the engine heat load.

Lean mixture, excessive spark advance, high compression, low capacity cooling system, detonation and high HP per cubic inch all combine to increase an engine's heat load. Most new generation pistons incorporate the top compression ring high on the piston. The high ring location cools the piston top more effectively, reduces detonation and smog, and increases horsepower. If detonation or other excess heat situations develop, a top ring end gap set to the close side will quickly butt, with piston and cylinder damage to follow immediately. High location rings require extra end gap because they stop at a higher temperature portion of the cylinder at top-dead-center and they have less shielding from the heat of combustion. At top-dead-center the ring is above the cylinder water jacket.

If a ring end gap is measured on the high side, you improve detonation tolerance in two ways. One, the engine will run longer under detonation before rings butt. Two, some leak down appears to benefit oil control by clearing the oil rings of oil build up. Clean, open oil rings are necessary to prevent from reaching the combustion chamber, which is also why we do not like gapless rings. A very small amount of chamber oil will cause detonation and produce significant horsepower loss. Top ring gaps can be increased 50% with hypereutectic pistons.

Ring Options of 1/16" or stock 5/64" are offered on most performance pistons. The 1/16" option reduces friction slightly and seals better above 6,500 RPM, while being considerably more expensive. Stock, (usually 5/64" compression rings), work well and help with the budget.

Piston to Bore Clearance for hypereutectic pistons were Dyno tested at wide open throttle with .0015", .0020", .0035" and .0045" piston to bore clearance. After 7-1/2 hours the pistons were examined and they all looked as new, except the tops had normal deposit color. Even with 320 degrees Fahrenheit oil temperature, the inside of the piston remained shiny silver and completely clean. Excessive clearance has been shown to be safe with hypereutectic pistons. Loose Hypereutectic pistons over .0020" do make noise. As they get up to temperature they still make noise because they have very restricted expansion rate and do not swell up in the bore. The Hypereutectic alloy not only expands 15% less, it insulates the skirts from combustion chamber heat. If the skirt stays cool piston expansion is drastically reduced. Running close clearances is beneficial to piston ring seal and ring life. A small short term HP improvement can be had by running additional piston clearance because friction is reduced. To obtain actual piston diameter, measure the piston from skirt to skirt level with the balance pad.

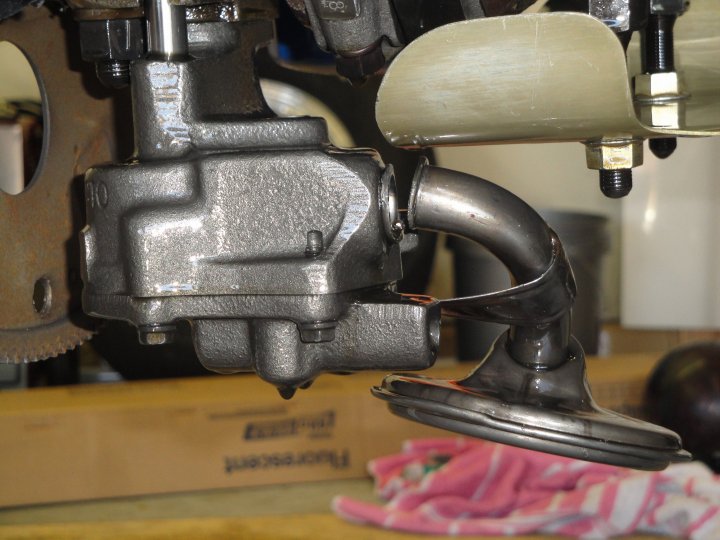

Pin Oiling should be done at pin installation, whether it is pressed or full floating, prelube the piston pin hole with oil or liquid prelube, never use a grease. If you are using a pressed pin rod be sure to discard spiral pin retainers. A smooth honed pin bored surface with a reliable oil supply is necessary to control piston expansion. A dry pin bore will add heat to the piston rather than remove heat. Pistons are designed to run with a hot top surface, and cool skirts and pin bores. High temperature at the pin bore will quickly cause a piston to grow to the point of seizure in the cylinder.

Marine Applications require an extra .001"-.003" clearance because of the possible combination of high load operation and cold water to the block. A cold block with hot pistons is what dictates the need for extra marine clearance.

"Compression Ratio" as a term sounds very descriptive. However, compression ratio by itself is like torque without RPM or tire diameter without a tread with. Compression ratio is only useful when other factors accompany it. Compression pressure is what the engine actually sees. High compression pressure increases the tendency toward detonation, while low compression pressure reduces performance and economy. Compression pressure varies in an engine every time the throttle is moved. Valve size, engine RPM, cylinder head, manifold and cam design, carburetor size, altitude, fuel, engine and air temperature and compression ratio all combine to determine compression pressure. Supercharging and turbo-charging can drastically alter compression pressures.

The goal of most performance engine designs is to utilize the highest possible compression pressure without causing detonation or a detonation related failure. A full understanding of the interrelationship between compression ratio, compression pressure, and detonation is essential if engine performance is to be optimized. Understanding compression pressure is especially important to the engine builder that builds to a rule book that specifies a fixed compression ratio. The rule book engine may be restricted to a 9:1 ratio but is usually not restricted to a specific compression pressure. Optimized air flow and cam timing can make a 9:1 ratio but is usually not restricted to a specific compression pressure. Optimized air flow and cam timing can make a 9:1 engine act like a 10:1 engine. Restrictor plate or limited size carburetor engines can often run compression ratios impractical for unlimited engines. A 15:1 engine breathing through a restrictor plate may see less compression pressure than an 11:1 unrestricted engine. The restrictor plate reduces the air to the cylinder and limits the compression pressure and lowers the octane requirements of the engine significantly.

At one time compression pressure above a true 8:1 was considered impractical. The heat of compression, plus residual cylinder head and piston heat, initiated detonation when 8:1 was exceeded. Some of the 60's 11:1 factory compression ratio engines were 11:1 in ratio but only 8:1 in compression pressure. The pressure was reduced by closing the intake valve late. The late closing, long duration intake caused the engine to back pump the air/fuel mix into the intake manifold at speeds below 4500 RPM. The long intake duration prevented excess compression up to 4500 RPM and improved high RPM operation. Above 4500 RPM detonation was not a serious problem because the air/fuel mix entering the cylinder was in a high state of activity and the high RPM limited cylinder pressure due to the short time available for cylinder filling.

Before continuing with theory, a little practical compression information is in order. If you have a 10:1 engine with a proper .040" assembled quench and then add an extra .040" gasket to give 9.5:1 and .080" quench you will usually experience more ping at the new 9.5:1 ratio than you had at 10:1. Non quench engines are the exception to this rule. Some racers make the effort to convert non-quench engines to quench type engines, as with our Mopar Squish Deck Heads. Compression ratios that work are as follows:

PUMP FUEL

8.5:1- Non-quench head road use standard sedan, without knock sensor.

8.5:1- Quench head engine for tow service, motorhome and truck.

9.0:1- Street engine with proper .040" quench, 200° @ .050" lift cam, iron head, sea level operation.

9.5:1- Same as 9:1 except aluminum head used.

Light vehicle and no towing.

10:1- Used and built as the 9.5:1 engine with more than 220° @ .050" lift cam. A knock sensor retard is recommended with 10:1engines.

RACE GAS

12.5:1- Is the highest compression ratio suggested with unrestricted race gas engines.

ALCOHOL

15.5:1- Is the highest compression ratio suggested for unrestricted alcohol fuel engines.

Satisfactory use of 14:1 - 17:1 compression engines can be made when restrictor plate or small carburetor use is mandated by the race sanctioning. High altitude reduces cylinder pressure so if you only drive at high (above 4500 feet altitude) a 10:1 engine can be substituted for a 9:1 compression engine. General compression rules can be violated but is usually a very special case such as a 600 HP normally aspirated engine in a 1500 lb. street car with a 12:1 compression ratio. The radical cam timing necessary for this level of performance keeps low and medium RPM cylinder pressure fairly low. At high RPM detonation is less of a problem due to chamber turbulence, reduced cylinder fill time, and the fact that you just can't leave the above combination turned on very long without serious non-engine related consequences.

Piston temperature and horsepower are interrelated. High horsepower per cubic inch engines not only make more horsepower but they make more heat. How the excess heat is handled has a significant effect on total engine power and longevity.

Various piston, cam, valve, chamber and port configurations have been and are currently being tested to optimize engine internal temperatures. Some engines have ceramic exhaust port insulation coatings that allow cooler cylinder head operation while keeping exhaust temperatures elevated for efficient catalytic converter operation. The same ceramic type insulation on a piston top has been quite successful. Ideal piston temperatures in an operating engine would suggest refrigeration during the intake and compression stroke, and incandescence during the combustion and exhaust stroke. The advantage of a hot piston on the power stroke is that less combustion energy is going to be absorbed by the piston. So far, it is not practical to heat and refrigerate a piston 6000 times a minute. However, if the incoming air is not heated by the piston and the piston reflects the heat of combustion, you start to approach ideal conditions. A polished hypereutectic piston will reflect combustion heat back into the combustion process. This reflection, combined with the insulating qualities of the hypereutectic alloy, keeps the heat in the cylinder during the power stroke. A smooth polished piston runs cooler than a non-polished piston, even after combustion deposits have turned both pistons black. A cool, smooth piston will transmit a minimum of heat to the incoming fuel air mix.

The Hypereutectic piston gives the racer a real out of the box advantage with smooth diamond turned piston heads. A polish is relatively easy to achieve and does improve the already excellent reflectivity of the hypereutectic piston. If a buffing wheel is used, you will note a gray cast to the finished piston. The gray results from the exposure of the Silicon particles that are dispersed through the piston.

Experimental work to reduce piston heating of the incoming fuel mix has been very limited but, in theory, a thin ceramic coating may prove to be beneficial. A thin, smooth coating over a polished piston should still reflect combustion heat while reducing carbon buildup and protecting the piston polish. It is easier for a thin film to change temperature with each engine cycle than it is for the whole piston to do the same. A thin film can be cooled by the first small percentage of inlet fuel mix, allowing the main quantity of fuel mix to remain relatively cool. Tests have shown that polishing the combustion chamber, valves and piston top can increase horsepower and fuel economy by 6%.

All this polishing probably sounds counter to the practice of cimpling the combustion chamber. Dimpling has been show to put wet flow back into the air flow and improve combustion. We do not recommend dimpling, but do suggest cutting a small discontinuity close to the valve seat to turbulate wet flow. Some bench flowed cylinder heads encourage fuel separation at the inlet pot. If a small step is added at the valve seat to force the wet flow over the resulting sharp edge, fuel will reenter the air stream and give you the same affect as dimpling only without losing the benefit of a completely polished chamber. As you reduce wet flow you will improve combustion and most likely need to install leaner carburetor jets. Leaner jets compensate for the excess fuel that is available when wet flow is put back into the air/fuel mix. Significant additional horsepower gains can be had with careful attention to cylinder-to-cylinder fuel distribution by allowing all cylinders to be set "just right".

Combustion chamber design work has increased steadily the last ten years. Some of the work is mandated by the EPA and some is the result of race engine development. Some of the smog work has actually enhanced race engine development. Combustion chamber science is now more concerned with the effects of swirl, tumbling, shrouding of the valve, quench, flame travel, wet flow and spark location. A combustion chamber shaped dished piston can improve the flame travel in the combustion chamber. A dish allows the flame to travel further and expand more before it is stopped by a metal surface. This rapid flame travel makes it unnecessary to run big spark advance numbers. Ideally, we would like to be able to initiate ignition at top dead center since this would reduce negative torque in the engine that is now cause by spark advance. We are some time away from a practical spark ignition system that will make optimum power with a TDS setting. Some day it will happen. Don't go out and buy dished pistons for your open chamber 454. The advantage in flame travel is more than offset by the low compression ratio this combination yields. Small combustion chambers respond well to dished pistons, especially reversed dome or "D" cups. A 400 small block Chevy can use a 22CC D Cup piston and still have 10.4:1 compression. The trend in modern engine design seems to be smaller combustion chambers with recessed piston tops for more HP per cubic inch.

Ignition timing on most installations should be 34 degrees total with full mechanical advance dialed in. More advance may feel better off the line but the engine lays down as the combustion chamber components come up to temperature. At the drag strip set timing for maximum MPH not best ET. Too much spark advance will shorten the life of any performance engine, sometimes drastically.

Nitrous oxide can double the horsepower of most engines with less effort and money being spent than any other modification. Even the "smog people" are usually happy, as the nitrous is activated only during full throttle "open loop".

A nitrous engine can be built as a stock rebuild or it can be a dedicated effort to maximize the total performance package. As more power is generated, more waste heat, exhaust air flow and combustion pressures push the limits of engine strength. Often more beef is needed in the drive train and tires.

All stock factory engines are built with a safety factor when it comes to RPM, HP produced, cylinder pressure, engine cooling, etc. If you are only going to use a 100 HP nitrous setup on a 300 cubic inch or larger engine, built in factory safety factors are probably sufficient. As power output levels are raised engine modifications are usually prudent.

The most common mistake made when using nitrous oxide injection concerns ignition timing. A normally aspirated engine makes its best power when peak cylinder pressures occur between 14 and 18 degrees after TDC. Pistons usually require 34 degrees BTDC ignition timing at full mechanical advance to achieve proper ATDC peak cylinder pressure. The total time from spark flash to the point of peak pressure is typically 48 to 52 degrees. If an engine is producing 30% of its power from nitrous, the maximum cylinder pressure will occur too close to TDC to avoid run away to detonation. If ignition does not get retarded, good-bye horsepower and head gaskets. The key to getting max HP from a max nitrous engine is to shift the maximum cylinder pressure event progressively further after TDC.

Cylinder pressure of 1000 PSI at TDC, (FIG. 1), can drop to 500 PSI with less than 3/8" of piston travel, (FIG. 2). If you can manage to get 1000 PSI in the same engine after the 3/8" travel, (FIG. 3), the pistons will have to travel an additional 3/4" to lower the cylinder pressure to 500 PSI, (FIG. 4). Work is defined as a force times distance. An average pressure, (750 PSI X 12-1/2 sq. in.), times distance in feet, (3/8" divided by 12), equals 293 foot pounds of work. Our second example, because it has twice the chamber volume above the piston location, must move twice as far to lower the cylinder pressure by 1/2. Since all the other numbers, by our own definition are the same, the force multiplied by a distance twice that of the first example will equal twice the work done, 586 foot pounds of work. There is no free lunch in horsepower equations because to get 1000 PSI above the piston in the second example takes twice as much fuel and energy as the 1000 PSI in the first example. What this offsetting of the peak pressure does is allow us to use the extra fuel mix available to a nitrous engine without breaking and melting things. The system that allows us to postpone maximum cylinder pressure is ignition timing retard. To a lessor extent short rod ratios, lower compression ratios, high RPM, aluminum heads, a tight quench, a rich fuel mixture, a small carburetor and hotter cams tend to delay maximum cylinder pressure.

Understand that, in our quest to delay cylinder pressure's peak time, more is not necessarily better. Instead, consider that the ideal cylinder pressure would be just short of detonation pressure and this pressure would be maintained from top dead center, and as long as possible after TDC. If timing is really late, you won't build enough cylinder pressure to start the car, let alone drive it. The 1000 PSI pressure in the example is not the maximum allowable combustion pressure but, rather, a comfortable pressure for illustration of the work principle.

Some nitrous manufacturers recommend, "retard the timing two degrees for each fifty horse power of nitrous". Other nitrous kits have the flame speed artificially slowed by the intentional use of a rich fuel to nitrous ratio. The maximum performance engine with a heavy nitrous load must achieve peak cylinder pressures, with the combustion chamber size being drastically increased due to the piston being on its way toward bottom dead center. The strongest engines have less compression ratio, less spark advance, and more nitrous.

Many people just don't like the idea of any retard. They say, "retard timing and exhaust heat goes up". It usually does in a stock non-nitrous engine because lower peak cylinder pressure slows the burning. If the timing is retarded in a non-nitrous engine, the exhaust opens before the fuel mix is finished burning and exhaust temperatures go up. Piston temperatures usually go down and exhaust valve temperature goes up. In the nitrous engine, exhaust temperature goes up for several reasons. The first is that the power output has gone up considerably. More power usually produces more waste heat. Second, the need to keep maximum cylinder pressures within reason has dictated that the biggest part of the fire happens closer to the exhaust valve opening time. There just isn't enough piston travel to extract all the energy out of the charge before the exhaust valve opens. Now, we could and sometimes do, open the exhaust valve later so more combustion pressure energy can be used to turn the crank. The trade off is negative torque on the exhaust stroke. If we still have significant cylinder pressure in the cylinder as the piston moves from BDC to TDC on the exhaust stroke, your net HP falls drastically. A real problem at higher RPM.

You can improve maximum power stroke efficiency and minimize exhaust pumping losses by running the engine at lower RPM and/or improving the exhaust valve size, lift and port design. A big nitrous engine likes everything about the exhaust to be big. If it flows good enough the cylinder will blow down by bottom dead center, even at high RPM with relatively mild exhaust valve timing. There are many variables in the design and development of an all out nitrous engine. A mistake will cause the melt down of any piston. The high strength of the hypereutectic piston will withstand detonation and severe abuse. Unfortunately, all pistons, even forged will melt and when cylinder pressure limits are exceeded, run away detonation can occur. The excess detonation heat makes the plugs, valves and pistons so hot the ignition system alone cannot be used to shut the engine down. Continued operation worsens the situation to the point of a total melt down. Designing a maximum performance nitrous engine is more of an exercise in heat management than it is in engine building. Serious nitrous users should review our list of ceramic coatings.

A lack of a sufficient fuel supply is probably the most common killer of the nitrous engine. If you add a 300 HP kit to your present 300 HP engine, your fuel requirements roughly double and a shortage doesn't just slow you down, it melts things. An electric fuel pump and fuel line devoted entirely to the nitrous equipment is recommended. If you are using a diaphragm mechanical pump to supply fuel to the carburetor, it is worth while to increase the fuel line I.D. If the carburetor goes lean while the nitrous is on, the pistons can melt even with a rich fuel line trick (1/2" dia.) only makes a major improvement in the operation of diaphragm mechanical pump is not recommended and does not do well at high engine RPM. A large size line is effective with a mechanical pump, even if you use smaller fittings at the tank, fuel pump and carburetor. The advantage of the 1/2" large line is not related to the steady state flow rate of the line.

The advantage relates to the acceleration time and displacement of the pulsating flow common to the mechanical pump.

High compression ratios can be used with nitrous but shifting the maximum pressure after top dead center becomes more and more difficult. I prefer to use street compression ratios and then just work with adding more nitrous to get desired horsepower levels.

We are currently testing some pistons specifically designed for Nitrous use. Current "off the shelf" pistons have been successfully run with a 500 HP nitrous kit combined with a nitrous control system. Most of our effort has been to develop new ideas that will push the limit of nitrous technology. More testing is planned with a piston especially coated to reduce detonation.

When choosing piston rings for an engine the most important factor is the intended use of the vehicle. A piston ring set that delivers excellent street performance may not be correct for an engine that will see competitive action, or for one that will be used with nitrous oxide.

Piston rings serve two purposes - to contain the cylinder pressure, and to prevent oil from getting into the combustion chamber. Sealing against pressure leakage, or "blow by", is the responsibility of the top ring. The keys to good ring sealing are cylinder wall finish and piston ring groove condition. If pressure gets past the top ring it is already "lost". Any such leakage will not be ignited by the spark plug, and is unlikely to produce any significant power, even if captured between the first and second ring. The second ring is primarily an oil control device. If the top ring is doing the job, the second ring will see fairly limited combustion pressure. Some companies sell second rings that use complex or fragile designs for sealing. These are prone to premature wear and have unpredictable behavior at high RPM levels. Cylinder leakage test percentages are only useful for comparison to data generated when an engine was fresh. Unfortunately this kind of information can be misrepresented to show very low leakage numbers by folks trying to sell "trick" parts. Leakage tests are steady state - they do not account for time, piston movement, or true operating pressures. "Blow-by" measurement will give a better picture of ring condition, but on track performance is the only real measurement of success. Our moly rings are intended for applications where cost is of prime importance.

Engines being built for serious competition will be far better off using Plasma Moly ring sets. These feature an extremely durable ductile iron top ring with Plasma Moly facing. This design allows the ring to seat quickly and to maintain its sealing integrity under the severe stress of racing. The second ring is a special low tension plain iron design. These taper faced rings are specifically designed to break in quickly and to keep oil from migrating into the combustion chamber. The SS50U stainless steel oil control rings are the absolute best in the high performance industry. This ring combustion gives dependable sealing and allows maximum power production.

RING TENSION

Piston ring sets are available with either standard or low tension oil rings. The standard tension rings are recommended for street driven applications, and for race vehicles which may see frequent open to closed throttle transitions in use - such as road racing. They are also useful in engines that may experience cylinder bore distortion during operation.

Low tension oil rings deliver increased performance due to their reduction in cylinder wall drag. These are highly recommended for many racing applications. Engines using low tension rings should be built with particular attention to cylinder concentricity, and often benefit from the use of a crankcase vacuum system.

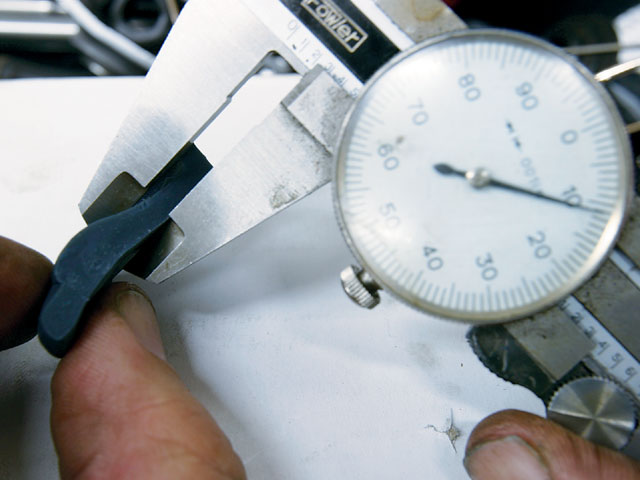

RING END GAP CLEARANCE

The piston ring's end gap can have a significant effect on an engine's horsepower output. Rings are available both in standard gap sets, and in special "file fit" sets. The file fit sets allows the engine builder to tailor the ring end gaps to each individual cylinder. Ring gaps should be set differently dependent upon the vehicles use, within the range of .003" (for the 2nd. ring) to .004" (for the top ring) per inch of cylinder diameter. The more severe the use, the greater the required end gap (assuming the use of similar fuels and induction systems). Engines having low operating temperatures, such as those in marine applications is too small. The chart below is a general guideline for cylinders with a 4.00" bore, adjust the figures to match your engine's cylinder diameter:

Top Rings (ductile iron, 4" bore)

Supercharged

Nitromethane .022 - .024"

Alcohol .018 - .020"

Gasoline .022 - .024"

Normally Aspirated - Gasoline

Street, Moderate Performance .016 - .018"

Drag Racing, Oval Track .018 - .020"

Nitrous Oxide - Street .024 - .026"

Nitrous Oxide - Drag .032 - .034"

2nd Rings (plain iron, 4" bore)

Supercharged

Nitromethane .014 - .016"

Alcohol .012 - .014"

Gasoline .012 - .014"

Normally Aspirated - Gasoline

Street, Moderate Performance .010 - .012"

Oval Track .012 - .014"

Pro Stock, Comp. .012 - .014"

Nitrous Oxide - Street .018 - .020"

Nitrous Oxide - Drag .024 - .026"

INSTALLATION NOTES -

CYLINDER WALL FINISH

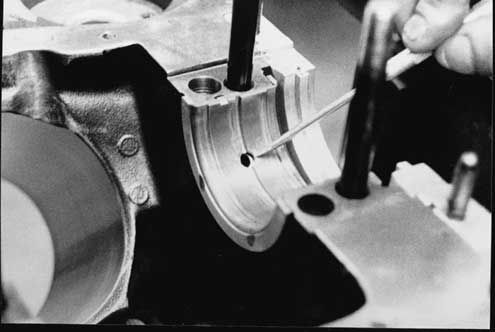

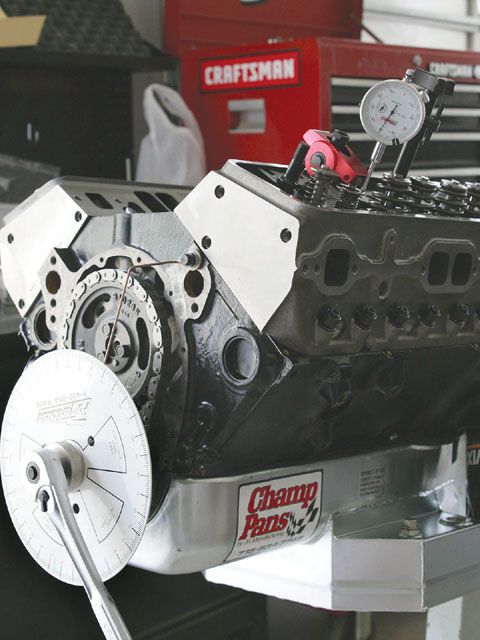

When installing new rings, the single greatest concern is the cylinder wall condition and finish. If the cylinders are not properly prepared, the rings will not be able to perform as designed. The use of a torque plate, head gasket, and corresponding bolts are necessary to simulate the stress that the cylinder head will put on the block. Main bearing caps should also be torqued in place. The correct procedure has three steps. First the cylinder is bored to approximately .003" less than the desired final size. Next it is rough honed within .0005" of the final diameter. Then a finer finish hone is used to produced the desired "plateau" wall texture. Use a 280 - 400 grit stone to finish cylinder walls for Plasma Moly rings.

Note - the "grit" number we are referring to is a measurement of roughness, it is not the manufacturers stone part number (a Sunnen CK-10 automatic hone stone set #JHU-820 is 400 grit). The cylinder bores should be thoroughly scrubbed with soap and hot water and then oiled before piston and ring installation.

Piston ring grooves are also sealing surfaces, and must be clean, smooth and free of defects. Ring side clearance, measured between the ring and the top of the groove, should be between, .001" and .004".

SPECIAL! THANKS TO JOHN ERB CHIEF ENGINEER AT UNITED ENGINES

the first few rule's of GRUMPY'S engine assembly

(1) THINK THINGS THROUGH CAREFULLY ,

WRITE DOWN A LIST OF COMPONENTS ,

MAKE DARN SURE THE LIST IS COMPATIBLE WITH,

and AT LEAST SEMI-REASONABLY PRICED WITHIN YOUR BUDGET.

FOR WHAT YOU INTEND TO BUILD AND RESEARCH THE RELATED MACHINE WORK,

RESEARCH CAREFULLY THE COMPONENT INSTALLATION AND INTENDED USE ,

AND POWER BAND THE PARTS WILL REQUIRE

AND FIND AN EXPERIENCED MENTOR.

(2) if in doubt, about how to do anything, on an engine, do some detailed research,

find and compare at least 3-5 valid trust worthy sources info,

read the instructions over again, several time's very carefully

and if available watch several related videos.

(3) if any component will not easily function as designed or requires a good bit of physical force to install ,

or your not 100% sure your doing something CORRECTLY

STOP, FIND OUT EXACTLY HOW THE PARTS SUPPOSED TO FIT AND FUNCTION,& WHY! YOUR HAVING PROBLEMS

theres a reason, and you better verify your clearances are correct , and your following the instructions before you proceed.

(4) never assume the parts you purchased can be used without carefully , cleaning them prior too,

checking the physical condition, verifying clearances and using the correct sealant, lubricants etc.

(5) the quality of a component is generally at least loosely related to the cost to produce it,

and the amount of detailed research and quality machine work that went into its production.

if you got a significant reduced price, theres typically a reason.

it might simply be because a new improved part superseded the one you purchased,

but it might be a far lower quality imported clone with lower quality materials and machine work.

its the purchasers responsibility to research quality.

(6) if you did not do the work personally or at least take the effort to verify it was done correctly and personally verify clearances

ITS almost a sure thing that it was NOT done , correctly, and yes that mandates you fully understand what your looking at,

and how the components are supposed to function and have high quality precision measuring tools.

(7) ITS ALMOST ALWAYS FASTER AND LESS EXPENSIVE , AND PRODUCES BETTER RESULTS IF YOU,

BUY FEWER HIGH QUALITY PARTS & DO THINGS CORRECTLY THE FIRST TIME