if you compare the 195cc vs 210cc AFR heads, all the way

theres a significant improvement in flow and a negligible decrease in port flow speed

theres always a compromise made between cost and potential power,

and obviously you want to match components to the intended power and rpm range,

but having seen a bunch of 383 builds use both AFR heads,

I think the 210cc choice here, is a no brainer if you can afford the price.

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

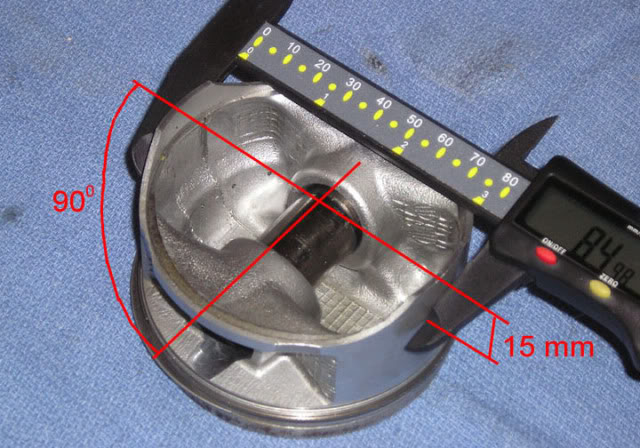

if we compare the head air flow rates between a 195cc and 210cc head on a 383-406 SBC and assuming a decent roller cam with the lift and duration,required, and intake that allows the heads to flow at their full potential,

195cc Street Head Flow Chart

.200 .300 .400 .500 .550

Int 146 201 247 275 280

Exh 119 166 197 213 218

210cc Race Ready Head Flow Chart

.200 .300 .400 .500 .550 .600 .650

Int 145 199 255 292 301 309 311

Exh 110 158 192 210 214 220 222

if you compare peak intake rated flow at .550 lift

280 cfm vs 301 cfm (about a 9% increase) youll see why

thats in theory potentially a 43 hp gain