Strictly Attitude

solid fixture here in the forum

I second the 210s

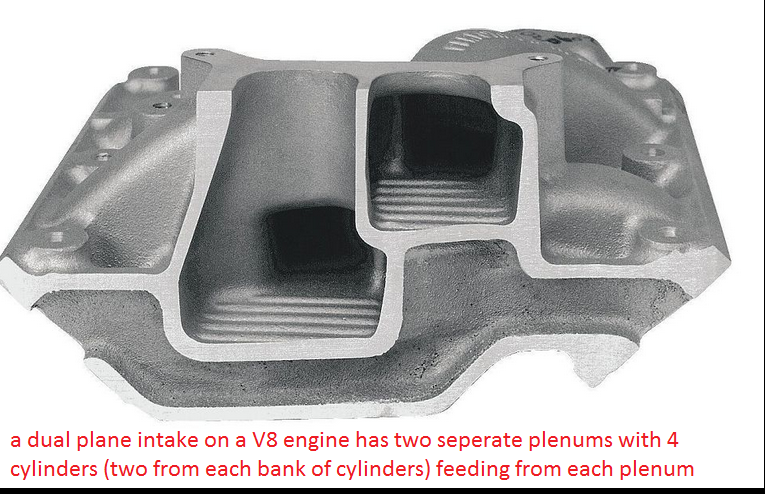

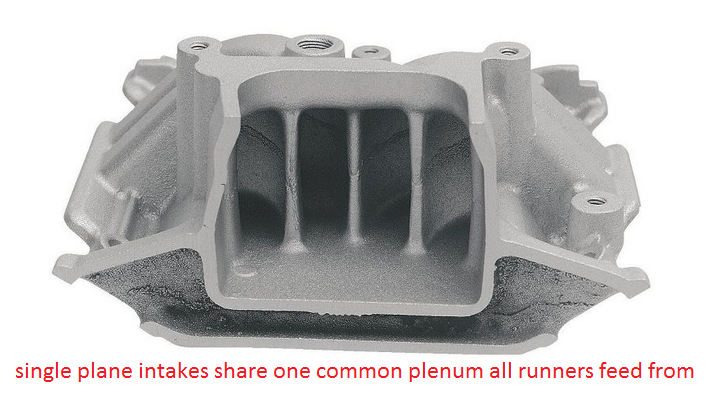

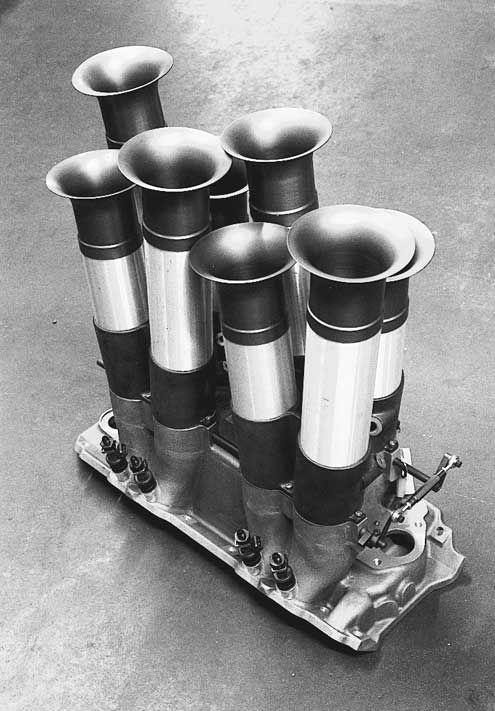

The edelbrock rpm air gap is pretty tall dual plane, hood clearance is an issue in allot of builds but I loved that intake.I am wondering about the viability of a high rise dual plane manifold something like a tall tunnel ram, I am certain I am not the only person to think of this, is it unworkable or just unprofitable for mass production. considering fabricating one after I am through with this project if it is not a bad idea, you have the experience I just had a thought about it.

I have an open engine bay hood is removed, I was thinking of tall runners like a weiand tunnel ram only twist the runners just enough to make a true dual plane manifold divided plenum. have not seen anything like it but I am sure I am not the first to think about it.

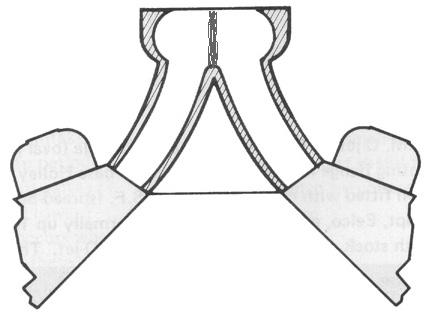

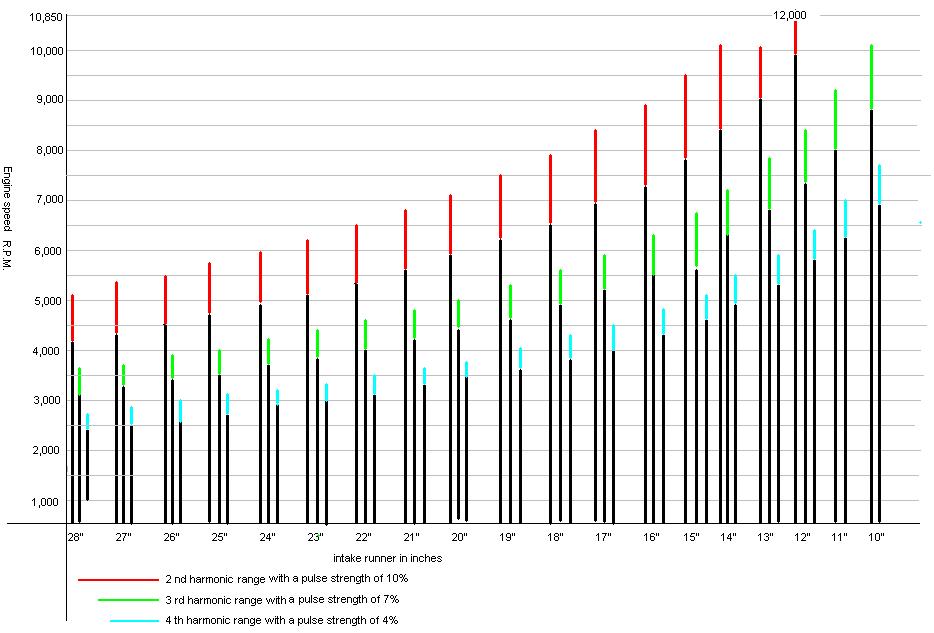

Damn my scientific calculator must be wrongBut schools don't teach real math anymore. For example, there is a war all over the internet

over the following equation:

View attachment 8685

If your answer is "1", then according to today's math, you are wrong.

Damn my scientific calculator must be wrong