You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

first hotrod build

- Thread starter hotrod coupe

- Start date

Loves302Chevy

"One test is worth a thousand expert opinions."

I don't think the rest of us can access pictures from someone's email account.

hotrod coupe

Well-Known Member

hotrod coupe

Well-Known Member

hotrod coupe

Well-Known Member

hate computers. tried to post picts. one is bore with weird bulleye tiny pic is crank and large one next to it is 3rd main cap

Strictly Attitude

solid fixture here in the forum

wow some one let that go for a little too long must have been one hell of a knock

yes that crank looks like its beyond the limit for a reasonable repair, at a reasonable price, you can of course have a machine shop , weld it up and re-cut and polish it but , between the cost and the probable stress and cumulative fatigue , I'd suggest that,s not the smart route, especially when, at a minimum, the two rods on that journal should be pitched in the nearest dumpster.

the smart route would be to buy and install a new crank and connecting rods, after carefully cleaning the block.

(and if your going to buy a new crank and rods a 383 with its slightly longer stroke won,t cost a great deal more)

read the links

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.com/index.php?threads/tweaking-a-350-383.13087/#post-68195

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-35#post-23579

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55571

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-26314

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/

the smart route would be to buy and install a new crank and connecting rods, after carefully cleaning the block.

(and if your going to buy a new crank and rods a 383 with its slightly longer stroke won,t cost a great deal more)

read the links

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.com/index.php?threads/tweaking-a-350-383.13087/#post-68195

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-35#post-23579

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55571

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-26314

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/

Last edited:

these links may help

http://www.scatcrankshafts.com/rods/chevy-rods/

http://www.scatcrankshafts.com/about-crankshafts/chevy-crankshafts/

http://www.scatcrankshafts.com/rotating-assembies/chevy-rotating-assemblies/

http://garage.grumpysperformance.com/index.php?threads/why-build-a-383-vs-a-350.715/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-68837

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-68651

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

http://www.scatcrankshafts.com/rods/chevy-rods/

http://www.scatcrankshafts.com/about-crankshafts/chevy-crankshafts/

http://www.scatcrankshafts.com/rotating-assembies/chevy-rotating-assemblies/

http://garage.grumpysperformance.com/index.php?threads/why-build-a-383-vs-a-350.715/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-68837

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-68651

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

Last edited:

hotrod coupe

Well-Known Member

I showed the pics to the machinist that I will be working with and he thinks the block should be good with a line bore and a new 3rd main cap, two new rods and recondition the rest. we will see after clean and test to see what I have. I started out with plans for a 383 but went back when informed I should not do it with a 2 bolt main, your opinion on having splayed 4 bolts installed or stay with my 350 plans. keep having build creep, should I get the dart block-need the rotating assy- aftermarket heads....

keep in mind you can buy a 4 bolt main cap block for less cash than the machine work costs in many cases and you should have the block sonic checked for cracks and bore wall thickness BEFORE you invest in much machine work.

ID install ARP main studs and keep the two bolt main cap block after its line honed , keep in mind the vast majority of the cost of installing splayed main caps is the required line hone which your going to do anyway, so adding the splayed caps should not add more than about $200-$300 and be worth the cost.

personally I throw ALL sbc O.E.M. connecting rods in the trash or give them away!

TAKE THE EFFORT TO READ THE LINKS, and SUB LINKS IT WILL BE A COUPLE HOURS WELL SPENT

http://garage.grumpysperformance.co...-the-rabbit-hole-with-alice.10933/#post-66925

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/

http://garage.grumpysperformance.com/index.php?threads/blocks-from-summitt-or-comp-products.10174/

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-68837

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/#post-51651

http://garage.grumpysperformance.co...ould-you-build-a-350-or-a-383-sbc-combo.8310/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/

http://garage.grumpysperformance.com/index.php?threads/rods-that-don-t-destroy-your-budget.10958/

http://garage.grumpysperformance.co...trong-will-a-scat-rotating-assembly-be.11495/

ID install ARP main studs and keep the two bolt main cap block after its line honed , keep in mind the vast majority of the cost of installing splayed main caps is the required line hone which your going to do anyway, so adding the splayed caps should not add more than about $200-$300 and be worth the cost.

personally I throw ALL sbc O.E.M. connecting rods in the trash or give them away!

TAKE THE EFFORT TO READ THE LINKS, and SUB LINKS IT WILL BE A COUPLE HOURS WELL SPENT

http://garage.grumpysperformance.co...-the-rabbit-hole-with-alice.10933/#post-66925

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/

http://garage.grumpysperformance.com/index.php?threads/blocks-from-summitt-or-comp-products.10174/

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-68837

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/#post-51651

http://garage.grumpysperformance.co...ould-you-build-a-350-or-a-383-sbc-combo.8310/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/

http://garage.grumpysperformance.com/index.php?threads/rods-that-don-t-destroy-your-budget.10958/

http://garage.grumpysperformance.co...trong-will-a-scat-rotating-assembly-be.11495/

Last edited:

Strictly Attitude

solid fixture here in the forum

It was $800 here in Albany, NY to have the splayed caps installed, bore and hone done, and line bore. Zero decking the block is $168 Options include craigslist to look for a better block to build and start with or peak into the rabbit hole tumble in. I would use the block you currently have running instead of that one. Ditch the swap out idea just have all your parts ready when you remove it to make things smooth.

Loves302Chevy

"One test is worth a thousand expert opinions."

My vote: ARP main studs, 4 bolt splayed caps, line bore & hone, new 383 balanced rotating assy.

That 2 bolt main block with the splayed caps will be stronger than the factory 4 bolt block.

There is more "meat" in the web areas for the outer angled studs to hold.

That 2 bolt main block with the splayed caps will be stronger than the factory 4 bolt block.

There is more "meat" in the web areas for the outer angled studs to hold.

hotrod coupe

Well-Known Member

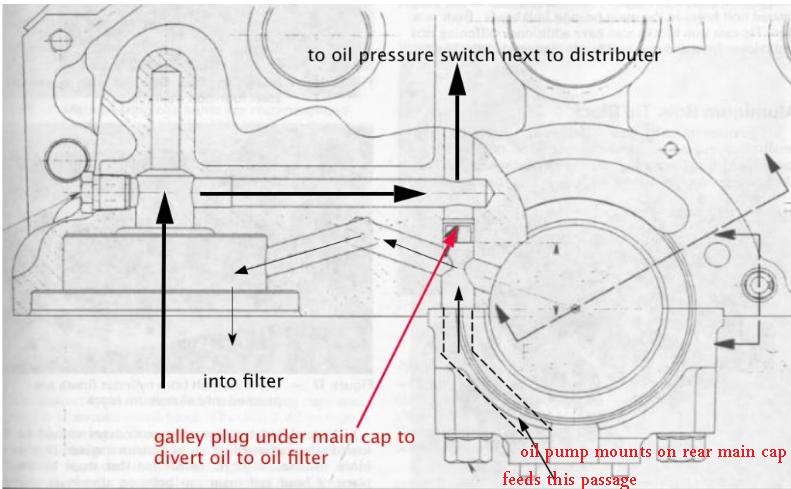

ok I thought I read everything for removing plugs from block and got to the last plug at the rear main, went from the top and drove out the plug only it was not a plug but a large ball bearing. now can you tell me what I just did wrong.

theres not supposted too be any ball bearings in that rear main oil passage

useful related, info

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

http://garage.grumpysperformance.com/index.php?threads/cam-bearing-install-tools-install-info.1479/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/#post-42954

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

Last edited:

hotrod coupe

Well-Known Member

one ball bearing that fits perfectly, it was clean below the engine and that was all that dropped out. my valvetrain tray got hit and half of the hydraulic roller tappets got scattered out of place, are these like flat tappets and have to be kept in their bores or can I still use them.

like flat tappet lifters in an ideal world they should be placed back on their original lobes,so ideally they should stay matched,

BUT roller lifters are MUCH less likely to cause wear issues if they get mis-matched,

on the re-install if the wheel and lobe surfaces are still looking new,

I would not be overly concerned if the cam lobes and lifter wheel surfaces look new

BUT roller lifters are MUCH less likely to cause wear issues if they get mis-matched,

on the re-install if the wheel and lobe surfaces are still looking new,

I would not be overly concerned if the cam lobes and lifter wheel surfaces look new

Loves302Chevy

"One test is worth a thousand expert opinions."

A ball bearing?

Never heard of that one before.

Never heard of that one before.

hotrod coupe

Well-Known Member

well scoggin dickey has changed my plans, 2 grand for a new vortec is cheaper than doing the short block i'm working with. all new and 4 bolt mains, just cant see putting more money into an engine with the problems this one has had. looks like the old heads are good though, I will have a spare set.

Loves302Chevy

"One test is worth a thousand expert opinions."

Check this out before buying:

http://www.competitionproducts.com/weekly.asp

http://www.competitionproducts.com/Short-Blocks-Chev-SB/departments/1224/

Watch for their Broom Sheet Specials.

http://www.competitionproducts.com/weekly.asp

http://www.competitionproducts.com/Short-Blocks-Chev-SB/departments/1224/

Watch for their Broom Sheet Specials.