why does everyone I talk to despise keith black pistons, all say they are cheep junk.

keith black makes a wide selection of pistons and they vary a good deal in quality and price.

Its the guy who builds the engine's responsibility to do the required research and select the correct parts for the particular application and thats

NOT SOMETHING YOU DO BASED ON COST ALONE!

expecting a set of their $199 pistons to have the same quality as the $600 set would be about as logical as expecting a

$14000 car to have all the quality and features of a $50,000 car

you tend to get what you pay for! and your expected to know and understand the difference in the components you select and what your options are well before you order parts.

Ive used the KB hypereutectic pistons in several daily driver replacement engine builds with complete success.

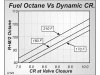

but I would think it rather silly to install a set of similar pistons in a high compression engine you intended to regularly spin up to 6500 rpm, and then expect the pistons to stand up long term, but thats a rather common mistake made by some guys who want to keep cost low , who don,t understand nor want to research the differences in piston materials and design limitations.

one more reason that doing your research before you purchase components really helps avoid problems, and why a couple days of reading carefully could save you weeks of work and thousands of wasted dollars

http://garage.grumpysperformance.com/index.php?threads/forged-or-not.13226/#post-69018

http://garage.grumpysperformance.com/index.php?threads/new-hypers-or-used-forged.7302/#post-24845

http://garage.grumpysperformance.com/index.php?threads/piston-related-info.110/#post-1671

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/

http://garage.grumpysperformance.com/index.php?threads/maximizing-piston-to-bore-ring-seal.3897/

http://garage.grumpysperformance.co...trong-will-a-scat-rotating-assembly-be.11495/

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

https://www.uempistons.com/installation_instructions/kb_installation.pdf

https://www.summitracing.com/search...cm_mmc=ppc-google-_-search-_-brands-_-keyword

http://www.speedwaymotors.com/KB-Claimer-Chevy-350-Hypereutectic-Pistons-150-Dome-57-Rod,34225.html

http://www.jegs.com/p/KB-Performanc...tic-Small-Block-Chevy-Pistons/747247/10002/-1

Last edited: