Strictly Attitude points out an important factor here, a street car engine needs too be both totally dependable and drive-able in the rpm range it will spend 96 % plus of its life operating in, rather than the 2%-5% of of the time where peak power is the major goal.

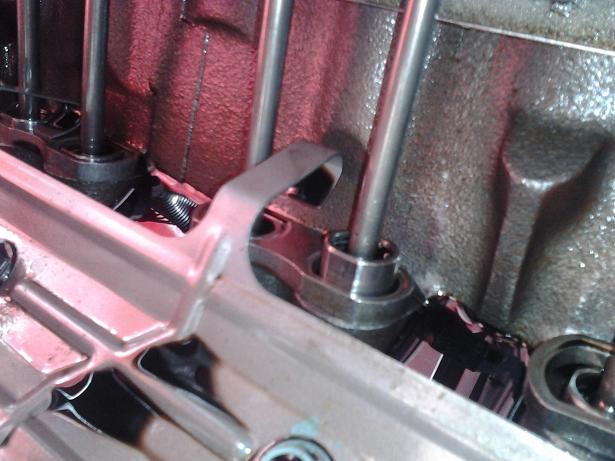

there's a good bit of discussion on cam selection in the thread links posted above and in this thread,I,ll post below, notice the cam selected in that t-bucket engine build up, is

far from the most radical cam that could be used, that might fit the application,and there's discussion on the differential gearing intake selection and trans gearing and converter stall speed, and while the cam and heads selected

were not (BY DESIGN) the components that would cost the least or produce the best peak power numbers

YET they ARE well matched and can quite easily do two things,

provide dependable and instantly available and impressive torque,

and allow the car to drive without problems on the street,

something, purposely designed into the cars drive-able characteristics,by selecting matched components,

that a much more aggressive cam, that makes a bit more peak power would most likely not provide.

this is a factor that a great many people don,t grasp or understand, and thats correctly matching the combos characteristics to the true intended application, it makes no sense to build a 600 hp sbc that produces peak power at 6700 rpm if your car has a transmission and gearing that restrict its operation to the 1500 rpm-6300 rpm range, yet I constantly see guys read the magazine articles in places like stock car magazine and decide to try and duplicate some 600 hp plus combo they read about on a street car engine build, then they proceed to really screw it up further because they decide that the expensive cylinder heads and block machine work can be ignored to save money, so they substitute much less expensive components and don,t match the drive train and gearing and act stunned and amazed when the combo of mis-matched components runs like crap, gets into detonation issues and surges and bucks at anything under 4500 rpm.

that t-bucket engine should produce just a bit under or over 500 hp,once correctly tuned ,(Ive seen a very similar combo,(on a dyno test)

I built have 473 rear wheel hp,

(thats about 540 flywheel)

(the only major change was a tunnel ram with dual quads)

which in a 2000 lb t-bucket will be brisk performance yet retain decent street

drive-ability

put 2200 lbs (car and driver and 500 flywheel hp in the calculators)

http://www.wallaceracing.com/et-hp-mph.php

https://robrobinette.com/et.htm

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/