thank you for posting the pictures

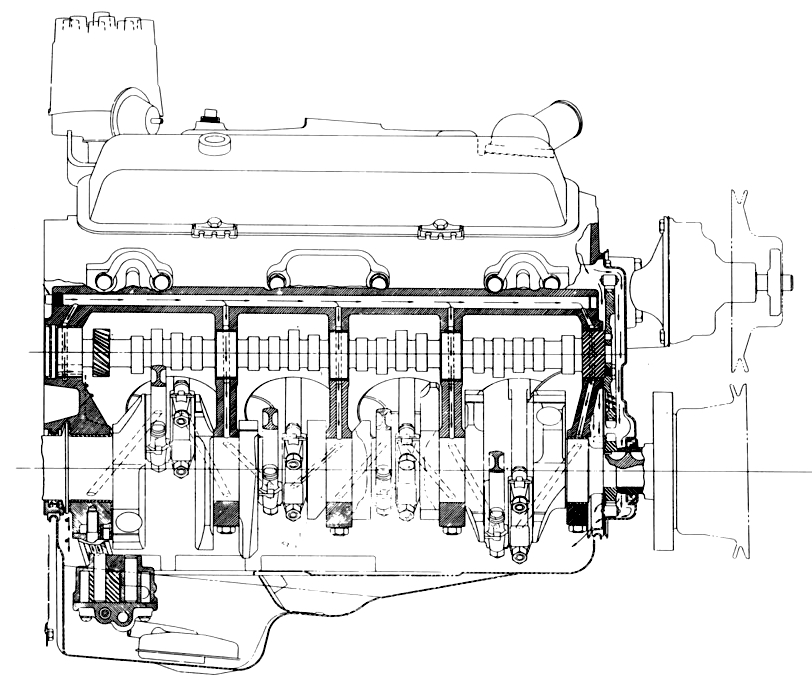

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

Last edited:

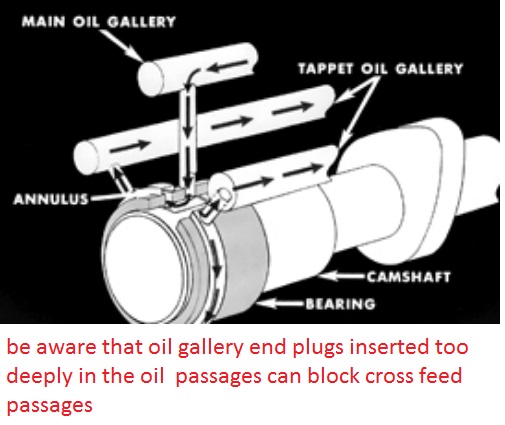

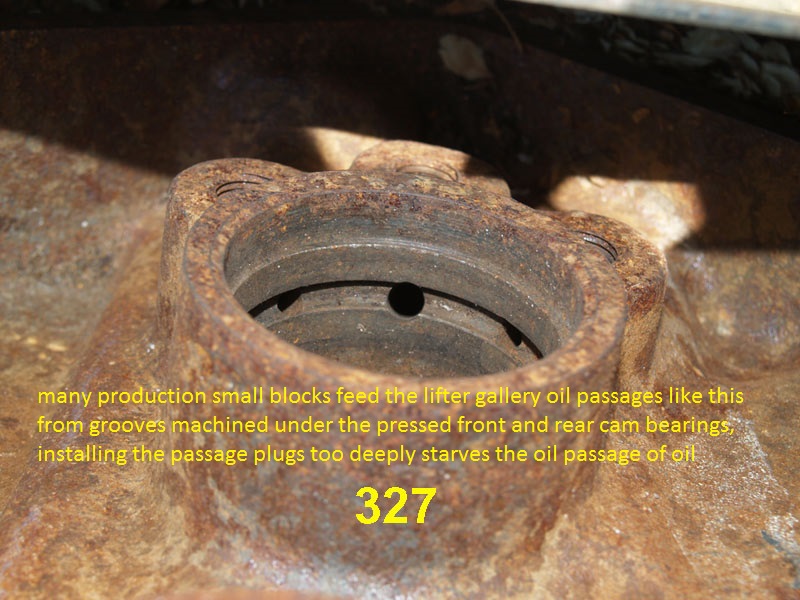

don't understand the rear bearing with two oil holes and one oil groove.

I Agree.the only thing I have found is that maybe they where 1955-56 cam bearings with the early oiling system for cam?