both the STEALTH RAM AND FIRST INTAKES are high flow rate improvements over the basic TPI system, the FIRST has the huge advantage that it fits under the stock c4 hood line!

you should read this, but keep in mind that the cam timing and engine compression , and the drive train gearing MUST match the intakes designed rpm range and the head flow, and exhaust flow, scavenging rpm bands must, match the intakes designed rpm band and flow for the intake to work to its full potential,

example

a TPI is designed to operate in the 1600rpm-4500rpm band, so a cam that matches that power band will have significantly lower duration than a cam (something in about the 215-220 intake duration range, and a 9:1 cpr) matching a stealth ram that's ideally running in the 3500rpm-6500rpm band with a cam in about the 235-240 duration range with about a 10.5:1 compression ratio, obviously the power bands will make the stock TPI look pretty feeble, if compared but that's not really a fair comparison, as the stall speed and rear gearing, and engine compression ratio, head flow, and headers need to be changed to allow the stealthram to obtain its true power potential increase, while its easy to show a 150 hp increase or more with those changes its comparing apples to oranges

read this but keep that in mind

http://www.compcams.com/Community/Artic ... 1737510521

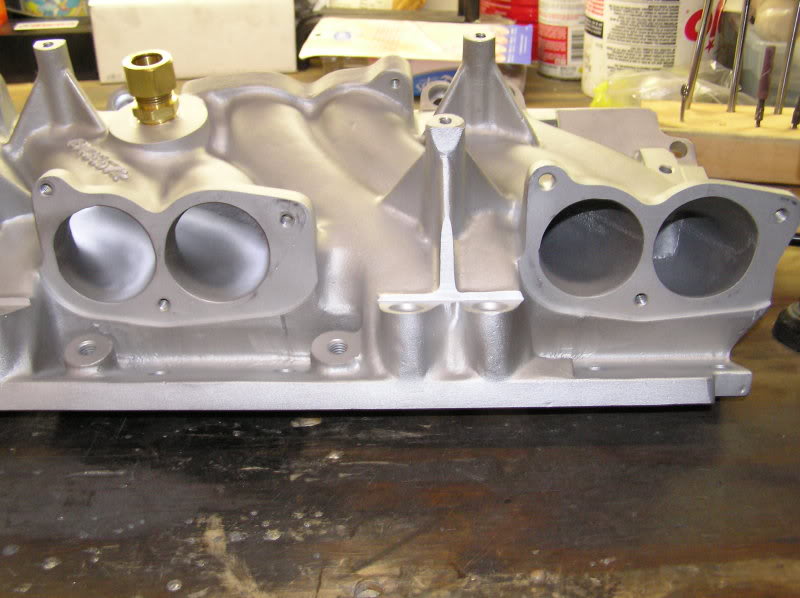

Ive tested a bunch of IMPROVE TPI REPLACEMENT style intakes on my cars, one of the best is the ported HOLLEY STEALTH RAM, but theres CLEARANCE ISSUES on some cars as its 10" tall and a corvette for example has only 9" of hood clearance so a CUSTOM PLENUM or a HOOD SCOOP is MANDATORY TO RUN ONE on a corvette for example !

both can be ported and BOTH can produce very good hp numbers. both work in approximately the same 3000rpm-6000rpm band with the FIRST coming in at about 2500rpm-5500rpm, and the Holley at about 3500rpm-6500rpm , due to runner length and other factors, but both require the correct matched components, to maximize thier potential, and that increased air flow will require a matching increase in fuel injector size if you want to reach decent hp levels, youll want a MINIMUM of a 30lb to take advantage of the increased flow rates and might need a 36#-42# injector size in each port depending on your combo

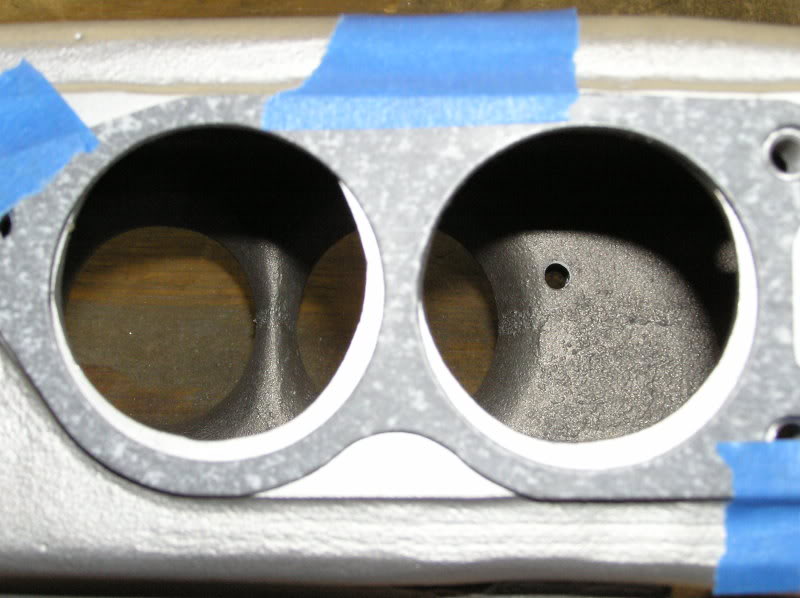

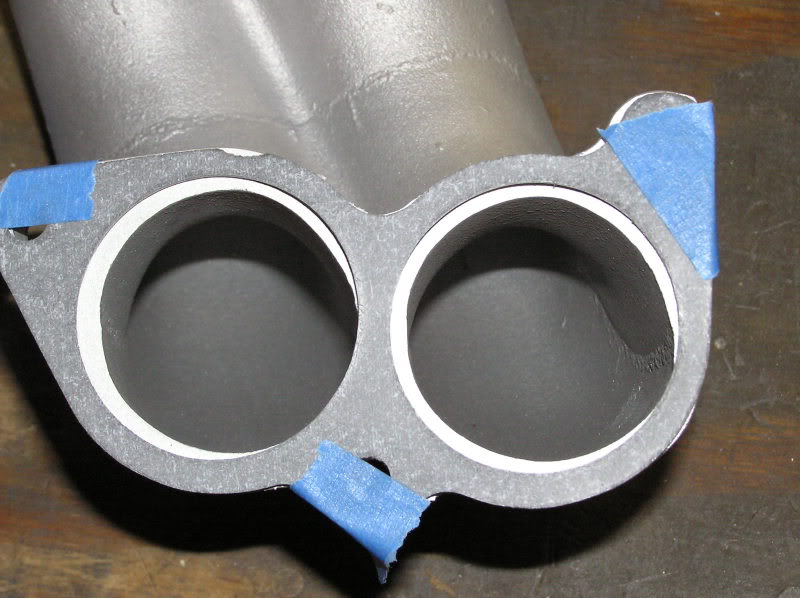

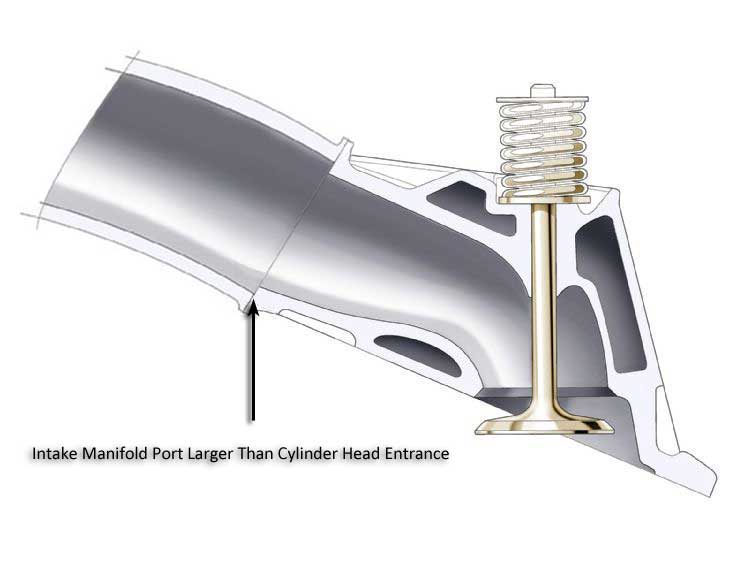

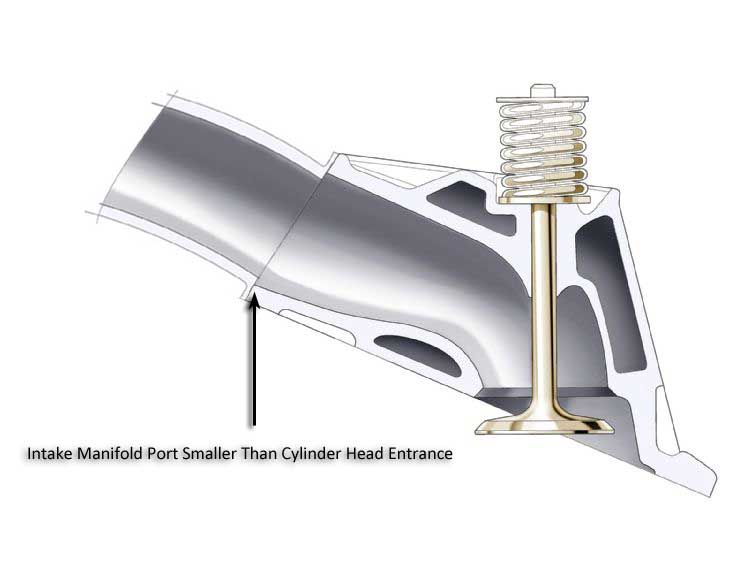

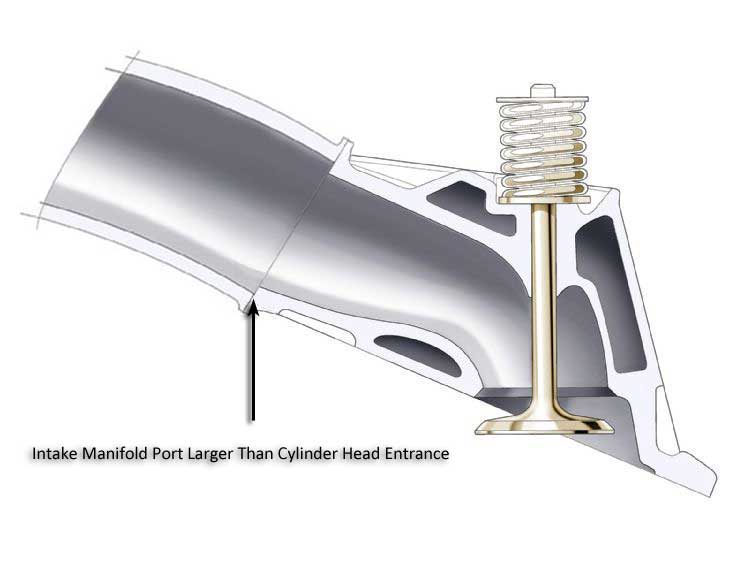

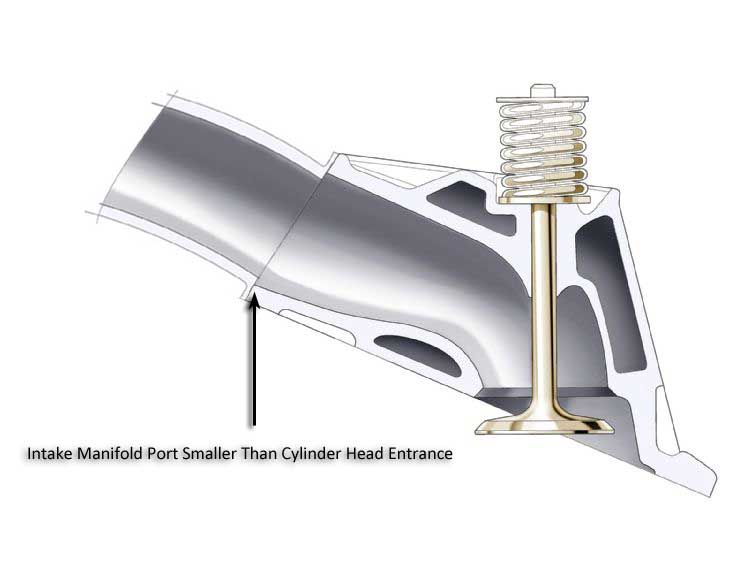

PORT MATCHING THE INTAKE RUNNER EXIT TO THE CYLINDER HEAD PORT ENTRANCE USUALLY HELPS REDUCE RESTRICTIONS TO FLOW RATES, AND REDUCES FUEL/AIR DISTRIBUTION ISSUES

http://www.thunderracing.com/catalog/?a ... 48&sid=281

http://www.gmhightechperformance.com/te ... index.html

http://www.firstfuelinjection.com/products.htm

http://www.eecis.udel.edu/~davis/z28/wi ... 21105.html

Satin FIRST® manifold without electronics. Prices starting at $999.95

All intake manifolds without electronics include all required gaskets, all stainless steel hardware, TPS bracket, throttle bracket, and fuel rails.

keep in mind you need to exactly match the compression ratio and head flow and exhaust scavaging rpm bands and the drive trains gearing too maximize the intakes flow charicteristics........something I doubt was done in those dyno runs

the first intake or the Holley stealth ram should be matched to a 3000rpm stall, 3.73"1 rear gear, a 383-427 displacement engine with about a 10.5:1 cpr, heads that flow a minimum of 250 cfm at .500 lift (270cfm at .500 lift would be better) and a cam with about a 230-235 duration to match the intakes flow range

I found this info and I figured you guys might like to look it over, now the first thing I want to point out is where the DATA came from. and KEEP IN MIND ITS REAR WHEEL HP AND The TPI INTAKE IN THE TEST consists of 58mm TB, fully ported plenum, AS&M large tube runners, and highly ported Edelbrock base WHICH MEANS ITS ALREADY MAKING AT LEAST 25HP-30HP MORE THAN A STOCK TPI INTAKE)

http://www.eecis.udel.edu/~davis/z28/winter01/dyno/

The engine was basically the same,in all the test except for the intake manifold, consisting of a ZZ4 crate motor, AFR190 heads, LT4 HOT cam, and SLP 1-3/4" SS headers. Trans is a 700r4 with a Vigilante 2800 stall converter. The Engine Control Module (ECM) was a '92 TPI stock ECM (MAP/speed-density) with a modified EPROM.

I HAVE GONE TRU AND WILL PICKED OUT THE IMPORTANT POINTS TO SAVE YOU TIME IN THE CHARTs AND GRAPHS ON THE SITE

TPI engine.....283 PEAK rwhp @4800rpm peak

AVG. TQ 291.5

AVG HP 269.5

miniram

303 PEAK rwhp @6200rpm peak

AVG. TQ 285.8

AVG HP 269.1

IT LOST 29 HP at 3800 rpm and MADE 48 MORE HP THAN THE stock TPI at 6300 RPM

stealth ram

342 PEAK rwhp @6400rpm

AVG. TQ 319

AVG HP 300 it lost 28 hp at 3600 rpm BUT GAINED 66 HP AT 6600 RPM

over the stock TPI

342 rear wheel hp is aproximately equal to 427 flywheel HP FROM A 350 SBC ENGINE, figuring a 20% driveline loss rate.

the use of a longer duration cam and only measureing PEAK HP would tend to benefit the miniram and STEALTH RAM intakes to a MUCH GREATER extent than the TPI, THATS HOW claims of gains of 100hp are made for some intake combos, while its TRUE that you can make in excess of a HUNDRED EXTRA hp at 6600rpms is due more to the TPI not being able to flow air (LOSSES) keep in mind that a LARGER ENGINE DISPLACEMENT WOULD BENEFIT EVEN MORE from the steathram

IF you look thru the combos linked below carefully youll see that it takes a decent combo of heads, displacement and cam timing and gearing to take full advantage of the increase in intake flow potential

heresa site with several combos

http://stealthram.com/hsrcars.html

http://www.ws6transam.org/ported.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.popularhotrodding.com/engine ... index.html

http://www.popularhotrodding.com/tech/0 ... index.html

http://www.hotrod.com/techarticles/engi ... index.html

http://www.circletrack.com/techarticles ... ching.html

btw the holley benefits from porting the runner entrances noticeably

keep in mind both the SUPER RAM and THE TPI, and clones can use several different bases from the stock intake designs and up to several different larger runner aftermarket bases and all runners won,t provide full flow potential, and the mix & match nature provides a great deal of variations, between designs, and the heads you match them too, the cam selected, and the headers also have a huge effect on your results

(weakest link in the chain, determines the max flow and power potential)

put a killer intake on crap heads,use the wrong cam, or gear the car for the wrong rpm band, or use a restrictive exhaust and you still get crap results,both the TPI and super ram can use the same base, so the runner length, diam. and plenum volume can change but if the base runners remain the same the flow is restricted to the lowest flow rate component used, and the components used with them,get the plenum and runners to flow 270cfm, and bolt them to a base that flows 210cfm, or heads that flow 210cfm, and the NET result is still 210CFM OR LESS

you should read this, but keep in mind that the cam timing and engine compression , and the drive train gearing MUST match the intakes designed rpm range and the head flow, and exhaust flow, scavenging rpm bands must, match the intakes designed rpm band and flow for the intake to work to its full potential,

example

a TPI is designed to operate in the 1600rpm-4500rpm band, so a cam that matches that power band will have significantly lower duration than a cam (something in about the 215-220 intake duration range, and a 9:1 cpr) matching a stealth ram that's ideally running in the 3500rpm-6500rpm band with a cam in about the 235-240 duration range with about a 10.5:1 compression ratio, obviously the power bands will make the stock TPI look pretty feeble, if compared but that's not really a fair comparison, as the stall speed and rear gearing, and engine compression ratio, head flow, and headers need to be changed to allow the stealthram to obtain its true power potential increase, while its easy to show a 150 hp increase or more with those changes its comparing apples to oranges

read this but keep that in mind

http://www.compcams.com/Community/Artic ... 1737510521

Ive tested a bunch of IMPROVE TPI REPLACEMENT style intakes on my cars, one of the best is the ported HOLLEY STEALTH RAM, but theres CLEARANCE ISSUES on some cars as its 10" tall and a corvette for example has only 9" of hood clearance so a CUSTOM PLENUM or a HOOD SCOOP is MANDATORY TO RUN ONE on a corvette for example !

both can be ported and BOTH can produce very good hp numbers. both work in approximately the same 3000rpm-6000rpm band with the FIRST coming in at about 2500rpm-5500rpm, and the Holley at about 3500rpm-6500rpm , due to runner length and other factors, but both require the correct matched components, to maximize thier potential, and that increased air flow will require a matching increase in fuel injector size if you want to reach decent hp levels, youll want a MINIMUM of a 30lb to take advantage of the increased flow rates and might need a 36#-42# injector size in each port depending on your combo

PORT MATCHING THE INTAKE RUNNER EXIT TO THE CYLINDER HEAD PORT ENTRANCE USUALLY HELPS REDUCE RESTRICTIONS TO FLOW RATES, AND REDUCES FUEL/AIR DISTRIBUTION ISSUES

http://www.thunderracing.com/catalog/?a ... 48&sid=281

http://www.gmhightechperformance.com/te ... index.html

http://www.firstfuelinjection.com/products.htm

http://www.eecis.udel.edu/~davis/z28/wi ... 21105.html

Satin FIRST® manifold without electronics. Prices starting at $999.95

All intake manifolds without electronics include all required gaskets, all stainless steel hardware, TPS bracket, throttle bracket, and fuel rails.

keep in mind you need to exactly match the compression ratio and head flow and exhaust scavaging rpm bands and the drive trains gearing too maximize the intakes flow charicteristics........something I doubt was done in those dyno runs

the first intake or the Holley stealth ram should be matched to a 3000rpm stall, 3.73"1 rear gear, a 383-427 displacement engine with about a 10.5:1 cpr, heads that flow a minimum of 250 cfm at .500 lift (270cfm at .500 lift would be better) and a cam with about a 230-235 duration to match the intakes flow range

I found this info and I figured you guys might like to look it over, now the first thing I want to point out is where the DATA came from. and KEEP IN MIND ITS REAR WHEEL HP AND The TPI INTAKE IN THE TEST consists of 58mm TB, fully ported plenum, AS&M large tube runners, and highly ported Edelbrock base WHICH MEANS ITS ALREADY MAKING AT LEAST 25HP-30HP MORE THAN A STOCK TPI INTAKE)

http://www.eecis.udel.edu/~davis/z28/winter01/dyno/

The engine was basically the same,in all the test except for the intake manifold, consisting of a ZZ4 crate motor, AFR190 heads, LT4 HOT cam, and SLP 1-3/4" SS headers. Trans is a 700r4 with a Vigilante 2800 stall converter. The Engine Control Module (ECM) was a '92 TPI stock ECM (MAP/speed-density) with a modified EPROM.

I HAVE GONE TRU AND WILL PICKED OUT THE IMPORTANT POINTS TO SAVE YOU TIME IN THE CHARTs AND GRAPHS ON THE SITE

TPI engine.....283 PEAK rwhp @4800rpm peak

AVG. TQ 291.5

AVG HP 269.5

miniram

303 PEAK rwhp @6200rpm peak

AVG. TQ 285.8

AVG HP 269.1

IT LOST 29 HP at 3800 rpm and MADE 48 MORE HP THAN THE stock TPI at 6300 RPM

stealth ram

342 PEAK rwhp @6400rpm

AVG. TQ 319

AVG HP 300 it lost 28 hp at 3600 rpm BUT GAINED 66 HP AT 6600 RPM

over the stock TPI

342 rear wheel hp is aproximately equal to 427 flywheel HP FROM A 350 SBC ENGINE, figuring a 20% driveline loss rate.

the use of a longer duration cam and only measureing PEAK HP would tend to benefit the miniram and STEALTH RAM intakes to a MUCH GREATER extent than the TPI, THATS HOW claims of gains of 100hp are made for some intake combos, while its TRUE that you can make in excess of a HUNDRED EXTRA hp at 6600rpms is due more to the TPI not being able to flow air (LOSSES) keep in mind that a LARGER ENGINE DISPLACEMENT WOULD BENEFIT EVEN MORE from the steathram

IF you look thru the combos linked below carefully youll see that it takes a decent combo of heads, displacement and cam timing and gearing to take full advantage of the increase in intake flow potential

heresa site with several combos

http://stealthram.com/hsrcars.html

http://www.ws6transam.org/ported.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.popularhotrodding.com/engine ... index.html

http://www.popularhotrodding.com/tech/0 ... index.html

http://www.hotrod.com/techarticles/engi ... index.html

http://www.circletrack.com/techarticles ... ching.html

btw the holley benefits from porting the runner entrances noticeably

keep in mind both the SUPER RAM and THE TPI, and clones can use several different bases from the stock intake designs and up to several different larger runner aftermarket bases and all runners won,t provide full flow potential, and the mix & match nature provides a great deal of variations, between designs, and the heads you match them too, the cam selected, and the headers also have a huge effect on your results

(weakest link in the chain, determines the max flow and power potential)

put a killer intake on crap heads,use the wrong cam, or gear the car for the wrong rpm band, or use a restrictive exhaust and you still get crap results,both the TPI and super ram can use the same base, so the runner length, diam. and plenum volume can change but if the base runners remain the same the flow is restricted to the lowest flow rate component used, and the components used with them,get the plenum and runners to flow 270cfm, and bolt them to a base that flows 210cfm, or heads that flow 210cfm, and the NET result is still 210CFM OR LESS