quikss said:So I'm looking to purchase my first welder. I plan to do the body on my 69, as well as fix the lower doors on my truck. Beyond that I foresee doing plenty of welding making carts and such for working on and moving around large generators in my shop.

After doing some research it appears the Miller 180 might suit my needs. I plan on taking some welding classes at the local tech school, but I guess I'm wondering if anyone has experience with this unit and will it suit my needs? I plan to stick with Miller, their world hq is 2 miles from my business and I have a lot of friends employed there and I'd like to support them.

Jeff

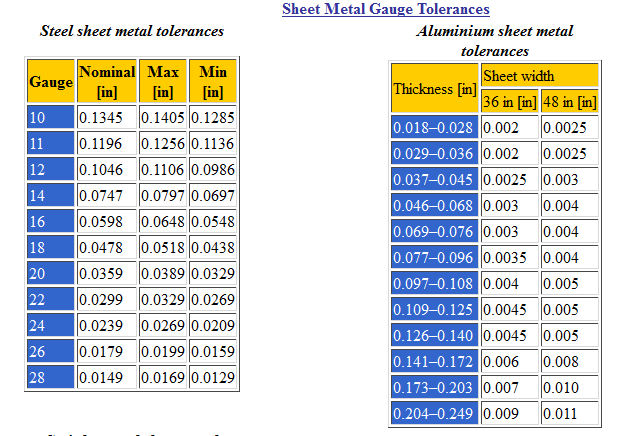

heres a few tips

If you have a hard time judging MIG wire diameter or sheet metal gauges, they make a tool for that little issue in lack of judgmental skills

even the $20 import version is accurate enough for that use!

this link might be useful

http://www.engineersedge.com/gauge.htm

http://www.harborfreight.com/6-inch-dial-caliper-66541.html

Just a bit of education here, Ive never claimed to be a great welder but Ive been welding on car repairs like accessory brackets spring perches and sheet metal body work etc.for over 4 decades so, heres a few things wou might want to know

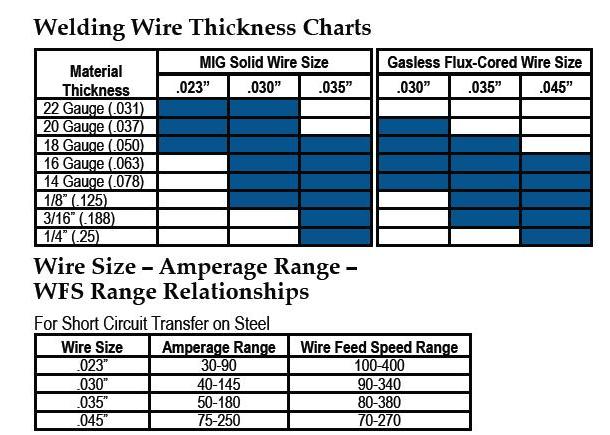

youll need to RENT or BUY a shield gas tank ,buy gauges,and several types of mig wire.

http://forum.grumpysperformance.com/viewtopic.php?f=60&t=1283

http://forum.grumpysperformance.com/viewtopic.php?f=60&t=1108

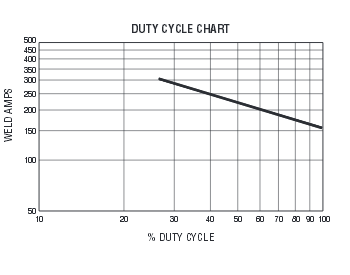

that miller 180 will most likely meet your needs but Id be remiss unless I brought up a point many guys new to welding seem to be clueless about and thats , checking out the welders DUTY CYCLE

this is one of the reasons cheap welders you see at discount pricing tend to not be worth much.

lets look at some facts

most of the better welders will be rated at some amp level, like your 180 miller, thats rated at 180 amps max and its rated at 230 volts BUT look carefully

THE MILLER 180 your looking at

Rated Output

135 A at 22.5 VDC, 30% Duty Cycle

Welding Amperage Range

30 - 180 Amps

http://www.welders-direct.com/mm5/m...e_Code=WD&Product_Code=907312&Category_Code=M

IF you spend $200 more you get a miller 211 RATED AT 210 AMPS

http://www.welders-direct.com/mm5/m...e_Code=WD&Product_Code=907422&Category_Code=M

Rated Output

* 150 A at 23.5 VDC, 30% duty cycle (230V)

* 90 A at 20 VDC, 20% duty cycle (120V)

Welding Amperage Range

* 30 - 210 Amps

if you really needed 180 amps most of the time (YOU DON,T)

YOU WOULD NEED A MILLER 252 MIG

Rated Output

200 Amps at 28 VDC, 60% duty cycle

250 Amps at 28 VDC, 40% duty cycle

Welding Amperage Range

30 - 300 Amps

http://www.welders-direct.com/mm5/m...e_Code=WD&Product_Code=907321&Category_Code=M

keeping mig wire rust free is the key,most quality mig wires lightly copper wash coated, if your not using the spool put it in a re-sealed 2 gallon zip lock plastic bag, laid on a couple sheets of paper towel with WD40 lightly sprayed on the towels, it will last for years sealed like that

http://www.use-enco.com/1/1/61271-mig-w ... -4695.html

http://www.use-enco.com/CGI/INPDFF?PMPA ... M=328-4695

http://www.gowelding.org/MIG_Welding.html

http://www.weldingtipsandtricks.com/mig ... ip-13.html

http://www.eastwood.com/blog/eastwood-c ... -mig-weld/

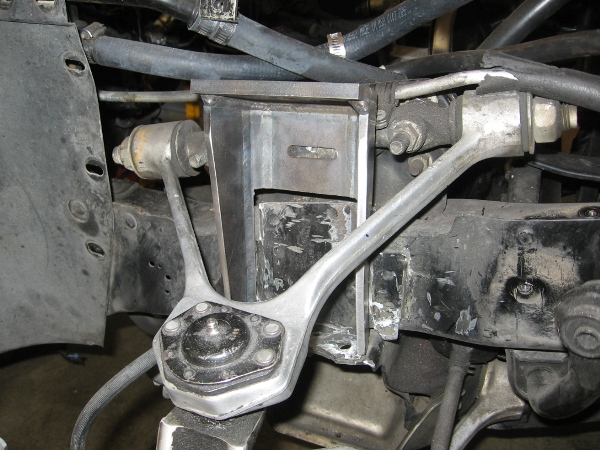

http://garage.grumpysperformance.co...me-repair-when-parts-are-not-available.11371/

Last edited: